"More power, Scotty!"

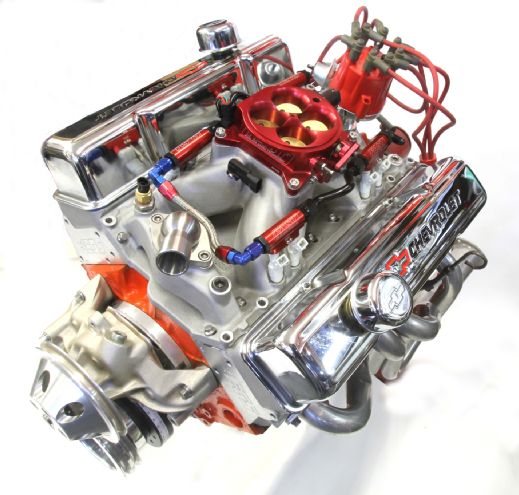

Captain Kirk beseeching his chief engineer to once again pull his buns out of an intergalactic tight spot has become nearly cliché. That line has also been the battle cry of hot rodders when the first cars quickly became race cars over 100 years ago. We haven’t progressed to dilithium crystals yet so we’ll settle for messing with small-block Chevys. A few months back we started with a basic Chevrolet Performance 290hp version small-block Chevy crate engine. Along the way we added Edelbrock Performer rpm heads and a COMP roller cam, but we still only made 431 hp—and in today’s world that just isn’t enough.

There are many well-documented ways to increase power. The easiest way is to just bolt on a supercharger, a pinwheel masquerading as a turbocharger, or even a load of nitrous. These are all really good ideas—and way too easy. We will try it the old fashioned way; we’ll earn it normally aspirated.

Along the N.A. path, the approaches are again straightforward; our crate engine needs more compression, good breathing, and a bigger cam with some attention paid to basic physics. The formula for horsepower is horsepower = torque x rpm ÷ 5,252. If you study that for a second or two, you quickly discover that if we can make the same torque at a higher engine speed, we can make more horsepower because the rpm number in the equation will become larger while the divisor (5,252) remains the same.

Let’s take an example. In our previous Great Crate III test, the engine made 424 lb-ft (339 hp) at 4,200 rpm. If all we did was make the same torque but extend the peak torque rpm point 1,000 rpm higher; all of a sudden we’re making more horsepower (420 hp) and we’re just talking about the power at peak torque. If we predict that our engine will have a power band of 1,500 rpm then extending the power band from 5,200 to 6,700 rpm, we now have the opportunity to make a bunch more horsepower. A longer duration cam will optimize breathing at a higher engine speed, which will push the peak horsepower rpm point higher, assuming the heads can supply enough air. This demands matching supporting component, like better breathing, a higher flow induction system, and more compression, which will squeeze harder what is captured in the cylinders.

Starting with the short block, it was time for better pistons. We disassembled our Great Crate and added a set of SRP flattop forged pistons and attached them to a set of 6.0-inch SCAT I-beam rods while retaining our cast-iron crankshaft. We also dumped the OE aluminum main and rod bearings and replaced them with higher load capacity Speed-Pro tri-layer bearings. This is a good idea anytime you expect to exceed 450 hp on a stock short-block because the aluminum bearings are not up to the task. The flattop pistons produce not only a much stronger 10.2:1 compression ratio, but they are much stronger than the stock castings and feature thinner, 1/16-inch rings that reduce some friction.

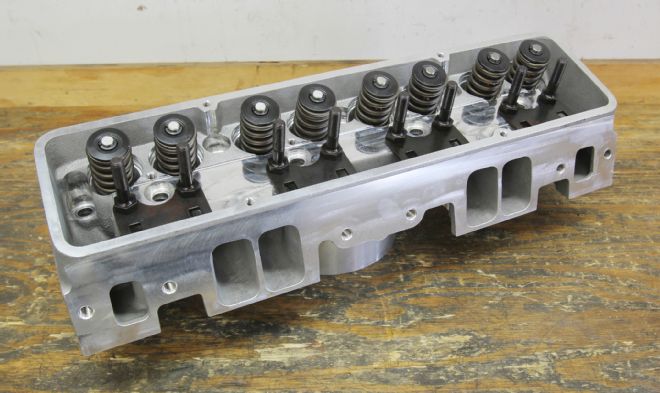

We also decided to try a set of affordable JEGS 195cc intake port heads with this combination. While these intake ports are on the conservative side, we liked the idea of a high port velocity for a street engine as opposed to a 210cc port where the velocity would be slower. All of this is intended to combine with the bump in cam timing. The previous cam sported 236/242 degrees of duration at 0.050, so we just bumped it one size up to 242/248 with a commensurate lift increase.

With the engine assembled and the cam degreed, the last question was induction. With a camshaft this size, we knew that idle quality and street driveability would be compromised because this was only a 355ci engine. We expected the idle vacuum to be around 10 inches (it turned out to be 9.5 inches at 950 rpm). From previous experience with big cams on the street, we knew going in the engine would demand a rich air/fuel mixture at idle and part-throttle from the carburetor in order to maintain any kind of decent driveability.

One way to allow the engine to run leaner would be to convert to electronic fuel injection. While we could have used any one of the many throttle-body fuel injection systems, we decided instead to try a multi-point system. Fuel Air Spark Technology (FAST) offers a complete manifold and electronics package that looked promising. Among the most attractive aspects was that we could use the RHS single-plane intake with its eight injectors and control all the electronic goodies with a multi-point version of the EZ-EFI 2.0 system. The EZ-EFI 2.0 is best known for its eight-injector throttle body that looks like a carburetor. What is less well known is that FAST makes this same self-learning technology available to control a multi-point fuel injection system.

What makes this system worth the investment is that with the manifold installed and the harness connected, it takes barely two or three minutes to enter the specific data into the handheld tuner. This includes specifying the idle, cruise, and wide-open throttle (WOT) air/fuel ratios, the cruise and WOT ignition timing you desire, and the ECU does the rest. There’s no complex tuning knowledge required. The hardest part is setting up the FAST Dual-Sync distributor for the proper rotor phasing, but that’s easy if you follow the instructions.

After bolting the engine to Westech’s SuperFlow dyno, the engine fired immediately and after the engine was fully warmed up our Great Crate immediately produced 482 hp with a commanded 12.7:1 air/fuel ratio. We changed the air/fuel ratio leaner to 12.9:1 with a simple couple of clicks on the handheld unit and the power jumped to 488 hp at 6,200 rpm. After a few tries at various total timing settings, we came back to the magic 36-degree number and our best peak power remained at 488 hp with 440 lb-ft of torque at 5,200 rpm. If it sounds like the system was near-best right out of the gate—you’d be correct.

Next, we plotted the difference in power curves between our Part V parts combination and Great Crate Part III with the single four-barrel dual plane intake, the Edelbrock Performer RPM heads, and the slightly smaller hydraulic roller cam. Peak power is always fun to look at and with that we succeeded adding 57 hp peak-to-peak while still only spinning the engine to 6,200 rpm. What is also interesting is investigating the rest of the curve. As expected, at the lower engine speeds the bigger cam wasn’t as powerful—losing as much as 16 lb-ft of torque at 3,800 rpm. In essence, the bigger cam moved the torque curve up in the rpm range. Looking at the band between 4,400 and 6,600, the bigger cam helped here too.

The smaller cam and head package produced peak torque at 4,200 rpm while the big cam version had to spin 1,000 rpm higher to 5,200 rpm to achieve peak torque. Yet the peak horsepower occurred roughly on both engines at the same rpm—6,100 to 6,200 rpm. This produced a much narrower overall power band (the rpm spread between peak torque and peak horsepower) on the big cam version. This is important to understand because while the big cam engine makes more power, you will want to make sure that the shift recovery point doesn’t drop below peak torque or that will cost e.t. on the dragstrip. The main reason the powerband narrowed could be because the smaller heads were not able to supply sufficient airflow to achieve more power. Had we opted for a set of 210cc intake port heads, power would almost certainly improve, carrying peak power perhaps to 6,500 rpm. That might have pushed the power past the 500hp mark.

Our goal here was to produce more horsepower, but not sacrifice too much in terms of street manners. But let’s be honest, this combination is pretty radical. Idle vacuum is a great indicator of how the engine’s radical nature and at barely 9.5 inches of vacuum at 950 rpm idle, it’s certainly on the lumpy side of street friendly. This is another point in EFI’s favor since it can be more finely tuned comparted to a carburetor at low vacuum settings, which allows it to run at slightly leaner air/fuel ratios at part throttle. This is in part due to multi-point’s ability to deliver better air/fuel mixture distribution at part throttle compared to a carburetor. All these points will generate much better fuel mileage and throttle response compared to an 850- or 950-cfm carburetor.

Finally, this combination would be best served in a lighter weight street rod with a manual transmission and some gear to really take advantage of that powerband. But even in a heavy car with an automatic, its nasty idle bump will certainly make you a hero at the weekly Saturday morning doughnut rendezvous. There’s nothing that sounds better than an engine with a little compression and a big cam.

We added a cam, forged pistons for compression, and a slightly bigger roller cam and pushed our Great Crate to nearly 490 street horsepower. Who says the small-block Chevy is dead?

We disassembled our 290hp Chevrolet Performance crate engine and bolted in a set of JE forged flattop pistons and stronger Scat connecting rods both to improve durability and to pump the compression to 10.2:1.

The biggest effect on power came from the next step COMP hydraulic roller. This cam only added 6 degrees of intake and exhaust duration but it was worth a bunch of power by pushing the torque peak higher. We also added better springs and tool steel retainers to make sure the valvetrain could handle the rpm.

After bolting in the new pistons and rods, we added the cam and degreed it with the intake centerline method.

We also wanted to try the new 195cc intake port JEGS heads, although the previous Edelbrock Performer RPM heads would certainly work nearly as well.

Our biggest move was to go with the FAST multi-point EFI system that uses the RHS single-plane intake. This intake is unique in that it has bolt holes for both standard and Vortec-style heads. The manifold is available configured either for a carburetor or multi-point EFI. The throttle body flows 1,375 cfm.

This is the entire EZ-EFI 2.0 multi-point kit. The wiring harness can look intimidating, but all the connectors are clearly marked.

We chose 36 lb/hr injectors that will deliver enough fuel to feed 550 hp at 45 psi of fuel pressure. Small injectors generally respond better at part throttle because they are easier to control under part-throttle but a larger injector offers room for additional power later on. For example, a set of 42 lb/hr injectors would push the normally aspirated fuel flow to nearly 650 hp.

Making all the connections isn’t difficult. Each separate sensor connector is marked and if you work carefully it won’t take long because each connector will only go to its intended sensor or position. The biggest hassle might be figuring out how to hide all this insulated spaghetti.

The EZ-EFI color touch-screen controller reinforces the EZ part of the EFI for configuring the system. All you do is answer a few simple questions about displacement and fuel pressure and then choose the idle, cruise, and WOT air/fuel ratios, ignition timing values, and the engine will run just as instructed. Here, we’re setting the air/fuel ratios.

Dyno day at Westech was uneventful since the engine fired up on the engine’s second revolution and the first test cranked out over 480 hp!

Power Curve RPMTQ1HP1TQ2HP2TQ+HP+ 3,200353215365222127 3,400376243372241-4-2 3,600397272385264-12-8 3,800412298396287-16-11 4,000421320410312-11-8 4,200424339420336-4-3 4,40042135342535643 4,6004183664303771211 4,8004133784353982220 5,0004083884384173029 5,2004044004404363636 5,4004014124404523940 5,6003954214374664245 5,8003884284324774449 6,0003774314194874256 6,2003644304134884958 6,400------399486------ 6,600------385483------

This graph illustrates the classic big cam tradeoff. The shorter duration cam makes more torque below 4,000 rpm but then the longer duration cam asserts its tuning range adding nearly 60 hp at the peak.

Cam Specs CamshaftAdv. DurationDuration at 0.050Valve LiftLobe Separation XR-288HR-10 Intake:2882360.52110 Exhaust:2942420.54 XR294HR-10 Intake:2942420.54110 Exhaust:3002480.562