We know that the LS engine family responds well to changes in cam timing and that, like every engine ever made, the LS also responds favorably to boost. The question isn’t whether you can get power from a cam swap or from boost, but whether your boosted LS will respond to a dedicated turbo cam. While it’s certainly possible to add boost to an otherwise stock LS engine — from the lowly 4.8L LR4 to the massive 7.0L LS7 — a stock cam is somewhat less than ideal for an engine equipped with forced induction, especially a turbocharger. As with any combination, the trick is to tailor the actual valve events to the cam timing needs of the engine. Boost will certainly wake up your stock LS, but the right camshaft will take things to the next level.

This test was designed to illustrate what happens when you apply a dedicated turbo cam to a turbocharged LS application.

Truth be told, it is easy to tailor any LS cam test to make us look like heroes. Simply install the mildest stock LS cam (the 5.3L LM7) and then replace it with almost any other cam on the market. Included in that upgrade list are all of the other factory LS cams, including the one we decided to use as the baseline for this test: the LS9.

I know what you are thinking, “Why run a cam designed for a supercharged application in a turbo engine?” The answer is simple: we chose the LS9 because of its position as the most powerful factory cam offered. This is a position it shares with the nearly identical LS7 cam, but since the LS9 was designed for forced induction, it got the nod over the equally powerful LS7. Having previously tested all of the factory LS cams on a 5.3L for our sister publication Car Craft, we know firsthand how all of the factory offerings stacked up. Choosing the most powerful of the factory grinds (already up 70 hp over the LM7) elevated not only the power output of the baseline, but put even more pressure on the dedicated turbo cam to deliver on their promise of power.

To properly test the turbo LS cam, we first needed a turbo LS engine. While an ordinary LS might suffice, we built anything but an ordinary LS test engine. Code-named Hybrid, the turbo test mule combined a big-bore LS3 (6.2L) block with a short-stroke LR4 (4.8L) crank. The resulting combination yielded 339 cubic inches thanks to 6.30-inch Lunati rods and custom JE forged pistons. Additional components included an ATI Super Damper working with a complete Moroso oiling system using an F-body oil pan, pickup, and windage tray. We employed Crane lifters and hardened pushrods activating the stock rockers. Since head flow is a critical element in power production, we topped the big-bore hybrid with a set of Trick Flow Specialties GenX 255 LS3 heads and a Holley Hi-Ram intake manifold. The Hi-Ram was configured with a FAST 102mm throttle body and 83lb Holley injectors controlled by a Dominator EFI management system. To establish our baseline, the hybrid was configured with a factory LS9 cam.

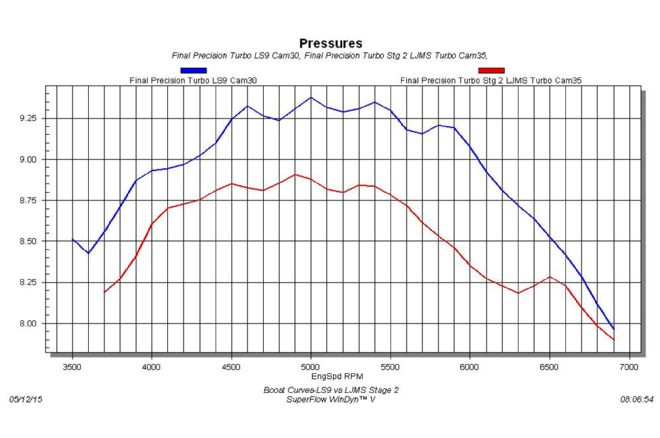

We had the engine portion of the turbo engine covered so now it was time for some boost. The positive pressure portion of the equation was provided by a custom single-turbo system that included a pair of DNA Motoring tubular turbo manifolds feeding a custom Y-pipe. The front-mounted Y-pipe included V-band attachment flanges, a T4 turbo flange, and a pair of flanges designed to accept 45mm Turbosmart HyperGate wastegates. The wastegates were set up to limit boost pressure supplied by the 76mm Precision turbo to just 7 psi. Given the fact that this turbo was capable of 25+ psi and 1,200 hp, it wasn’t even breathing hard during this cam test. Despite the relatively low boost level, the heated charge air was channeled through an air-to-water intercooler from Cxracing. The free-flowing core featured a 3.5-inch inlet and outlet, and dropped the charge temps by over 90 degrees. The discharge pipe connecting the intercooler to the throttle body featured a Turbosmart Race Port BOV (blow-off valve). Run with the LS9 cam, the turbo LS produced 701 hp at 6,500 rpm and 598 lb-ft of torque at 5,500 rpm. Despite the 7-psi wastegate setting, the boost pressure started at 8.5 psi, rose to 9.4 psi, then dropped back down to 8.0 psi.

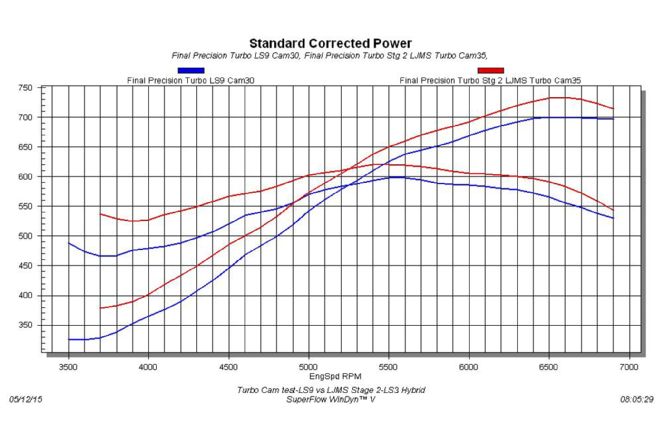

With a peak power output exceeding 700 hp, obviously the LS9 cam was no slouch, but we were anxious to install the turbo cam from Lil John’s Motorsport Solutions. Compared to the factory LS9 cam, the Stage 2 grind offered an additional 15 degrees of intake duration but just 1 degree more of exhaust duration. The Stage 2 cam also featured a much tighter LSA (by nearly 10 degrees). What effect did these changes have on the power curve? Equipped with the Stage 2 cam, the peak power numbers jumped to 733 hp and 621 lb-ft of torque. Remember, this came with no change to the wastegate setting. It is also important to note that the cam upgrade actually dropped the boost pressure by as much as 0.5 psi. The dedicated turbo cam not only made more power but did so with less boost pressure (see graph). Every bit as important was the fact that the turbo cam improved power across the entire powerband. With more power and less boost, it’s safe to say the Stage 2 cam easily up-staged the factory LS9 cam.

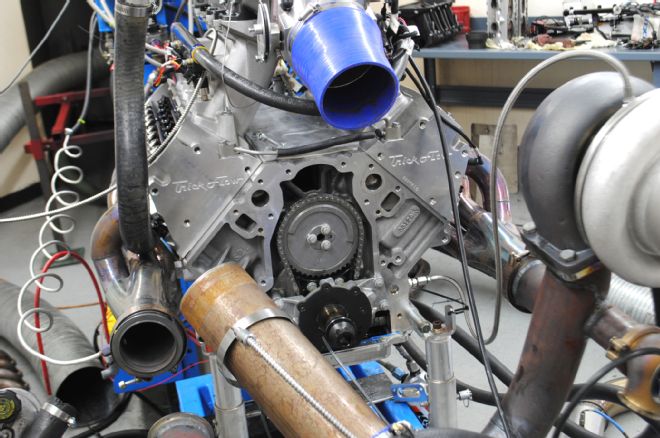

To properly test our boost cams, we built a dedicated test engine. The short-block featured an LS3 block stuffed with a 4.8L crank, Lunati rods, and custom JE pistons. Note also the ATI Super Damper, Moroso oil pan, and Fel-Pro head gaskets.

To properly test our boost cams, we built a dedicated test engine. The short-block featured an LS3 block stuffed with a 4.8L crank, Lunati rods, and custom JE pistons. Note also the ATI Super Damper, Moroso oil pan, and Fel-Pro head gaskets.

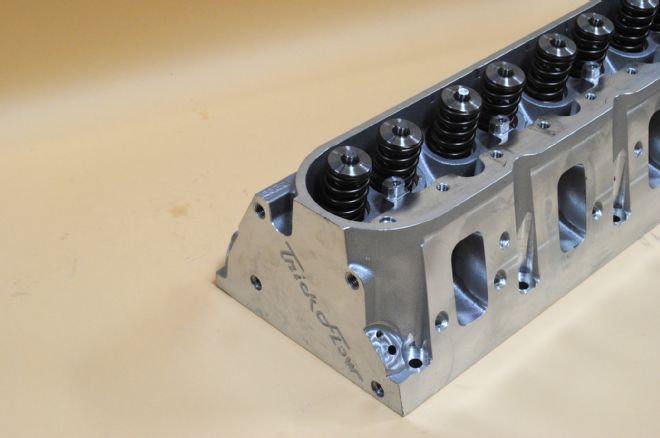

Topping the short-stroke LS3 hybrid was a set of TFS GenX 255 heads. The rectangle-port (LS3) heads flowed an amazing 385 cfm.

Topping the short-stroke LS3 hybrid was a set of TFS GenX 255 heads. The rectangle-port (LS3) heads flowed an amazing 385 cfm.

Just as important for our needs was the fact that the GenX 255 heads featured a spring package that allowed us to safely run cams sporting as much as 0.650-inch lift.

Just as important for our needs was the fact that the GenX 255 heads featured a spring package that allowed us to safely run cams sporting as much as 0.650-inch lift.

Finishing off the TFS-headed LS3 was a Holley Hi-Ram intake and FAST 102mm throttle body.

Finishing off the TFS-headed LS3 was a Holley Hi-Ram intake and FAST 102mm throttle body.

Ensuring adequate fuel for the turbo engine was a set of 83lb injectors fed by a set of billet fuel rails from Holley.

Ensuring adequate fuel for the turbo engine was a set of 83lb injectors fed by a set of billet fuel rails from Holley.

Holley also supplied the Dominator fuel management system for our testing.

Holley also supplied the Dominator fuel management system for our testing.

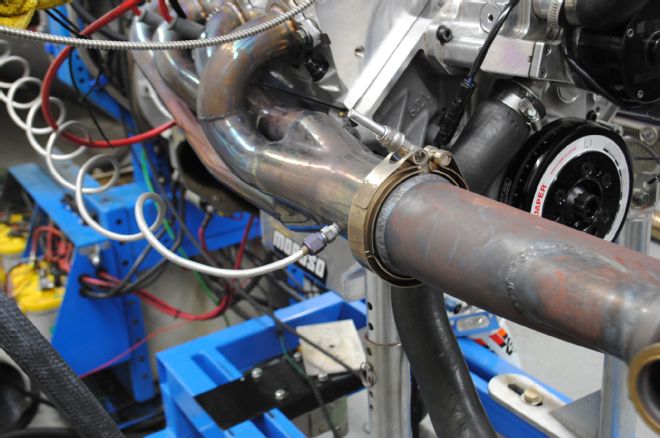

The custom, single-turbo system included a pair of tubular headers from DNA Motoring feeding a custom Y-pipe designed to accept a T4 turbo.

The custom, single-turbo system included a pair of tubular headers from DNA Motoring feeding a custom Y-pipe designed to accept a T4 turbo.

Keeping things cool was an air-to-water intercooler from Cxracing. Note the temperature probe used to monitor the air temps exiting the turbo.

Keeping things cool was an air-to-water intercooler from Cxracing. Note the temperature probe used to monitor the air temps exiting the turbo.

Boost was supplied by this Precision 76mm turbo. Capable of supporting 25+ psi and 1,200 hp, the Precision piece was just getting started at 8.0 psi.

Boost was supplied by this Precision 76mm turbo. Capable of supporting 25+ psi and 1,200 hp, the Precision piece was just getting started at 8.0 psi.

The baseline tests were run with a factory LS9 cam. The LS9 offered 0.562-inch lift, 211/230-degree duration split, and 122.5-degree LSA. Equipped with the LS9 cam, the turbo LS produced 701 hp and 598 lb-ft of torque.

The baseline tests were run with a factory LS9 cam. The LS9 offered 0.562-inch lift, 211/230-degree duration split, and 122.5-degree LSA. Equipped with the LS9 cam, the turbo LS produced 701 hp and 598 lb-ft of torque.

Cam swaps on the LS, even a turbo LS, were simple on the engine dyno. Off came the ATI damper and front cover to provide access to the timing gear.

Cam swaps on the LS, even a turbo LS, were simple on the engine dyno. Off came the ATI damper and front cover to provide access to the timing gear.

Out came the LS9 cam and in went the Stage 2 cam from Lil John’s Motorsport Solutions (LJMS).

Out came the LS9 cam and in went the Stage 2 cam from Lil John’s Motorsport Solutions (LJMS).

This sensor in the collector allowed us to monitor the changes in boost and backpressure from cam to cam.

This sensor in the collector allowed us to monitor the changes in boost and backpressure from cam to cam.

The Stage 2 cam offered a 0.605/0.598-inch lift split, a 226/231-degree duration split, and a 113-degree LSA. Replacing the LS9 cam with the Stage 2 cam from LJMS increased the power output from 701 hp and 598 lb-ft of torque to 733 hp and 621 lb-ft of torque.

The Stage 2 cam offered a 0.605/0.598-inch lift split, a 226/231-degree duration split, and a 113-degree LSA. Replacing the LS9 cam with the Stage 2 cam from LJMS increased the power output from 701 hp and 598 lb-ft of torque to 733 hp and 621 lb-ft of torque.

As expected, the dedicated turbo cam offered significantly more power than the LS9 blower cam. The Stage 2 cam offered an additional 32 hp, jumping from 701 hp to 733 hp.

As expected, the dedicated turbo cam offered significantly more power than the LS9 blower cam. The Stage 2 cam offered an additional 32 hp, jumping from 701 hp to 733 hp.

It is interesting to note that the turbo cam offered both power gains and a drop in boost (and back) pressure. This, despite no changes to the Turbosmart wastegate setting (we ran on the spring).

It is interesting to note that the turbo cam offered both power gains and a drop in boost (and back) pressure. This, despite no changes to the Turbosmart wastegate setting (we ran on the spring).

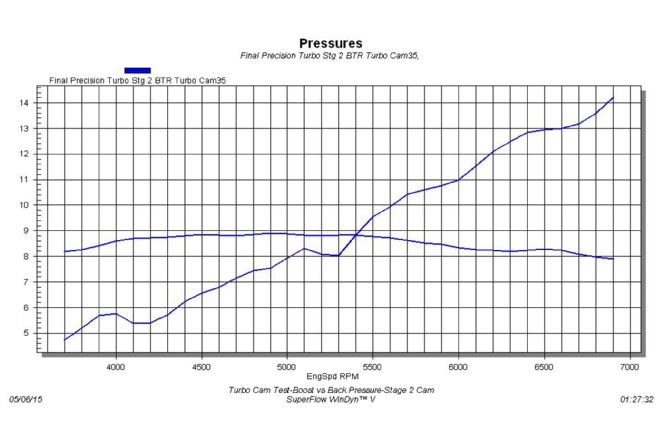

The graph illustrates a comparison between the boost pressure and the backpressure on our single-turbo system with the Precision 76mm turbo. Note that despite the consistent boost pressure, the backpressure in the exhaust continued to climb with engine speed. Below 5,400 rpm, the boost pressure actually exceeded the backpressure.

The graph illustrates a comparison between the boost pressure and the backpressure on our single-turbo system with the Precision 76mm turbo. Note that despite the consistent boost pressure, the backpressure in the exhaust continued to climb with engine speed. Below 5,400 rpm, the boost pressure actually exceeded the backpressure.