This month we're out for torque, and nothing serves it up like huge cubes and a big arm. Stroking delivers both. Common Chevy 383 and Ford 347 combos have brought strokers to the masses, but there can be more creativity to stroking than just buying a kit and bolting it together. Increase your crankshaft stroke and you're gonna hafta deal with things like piston compression height, at which point you might as well consider longer rods, and while you're at it, why not go all-out with a tall-deck block? With this story, we'll share the whys and hows of all these aspects of your rotating assembly so you can understand the guts of your new big-inch crate engine, or so you can build your own custom short-block at home. With today's assortment of aftermarket cranks, rods, pistons, and blocks, the homebrewed stroker has finally become practical.

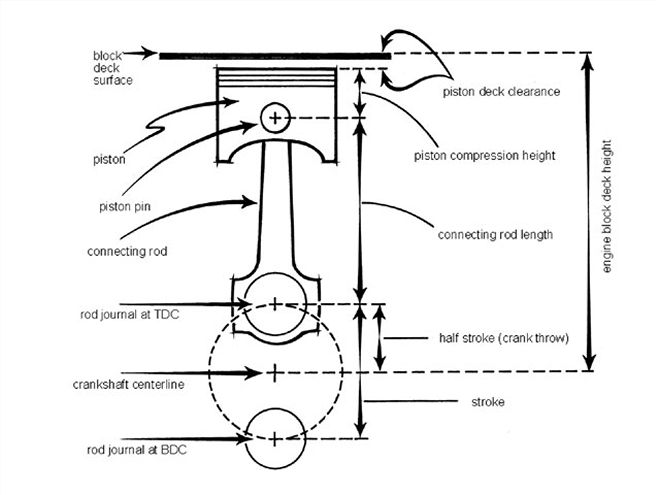

First, The DefinitionsBlock Deck Height: This is the distance from the centerline of the crankshaft to the top of the deck surface (the machined flat part that the cylinder heads bolt to). To accommodate stroked cranks and longer connecting rods, some aftermarket engine blocks are available with taller-than-stock deck heights; for example, a stock Chevy 454 deck height is 9.800 inches, though blocks with a 10.200-inch deck height are routinely available from the likes of World Products. Block deck height can be reduced by milling (or "decking") the block.

Stroke: The total distance traveled by the piston as it moves from bottom dead center to top dead center. It is determined by the diameter of the circle traveled by the connecting-rod journals of the crankshaft as the crank is rotated. Total stroke can be calculated as twice the distance from the centerline of the crankshaft to the centerline of one rod journal. Increasing the stroke increases the swept volume of each cylinder and enlarges an engine's displacement; decreasing the stroke reduces the swept volume and lessens the engine's displacement. In calculating stroker combos, you'll often deal with the crank "throw," which is half the stroke.

Bore: While not entirely relevant to the topic of stroking, overboring (enlarging the cylinders) is always a consideration when building an engine. Bore is defined as the diameter of the cylinder; the larger the bore, the larger the cylinder's volume. Bore and stroke are the only two aspects of an engine that affect cubic-inch displacement.

Rod Length: The distance between the center of the piston-pin hole (small end) and the rod-journal hole (big end) of a connecting rod. Aftermarket connecting rods are available in a number of nonstock lengths. For example, 6-inch rods are a common replacement for a 350 Chevy's original 5.7-inch rods.

Piston Compression Height: The distance from the center of the piston pin to the top of the piston head, not including any dishes or domes present on the piston. Longer stroke and longer connecting rods require less piston compression height to keep the piston within the limits of the engine block's deck height; less stroke and short rod length tends to allow greater piston compression height.

Piston Deck Clearance: The distance from the head of the piston (not including any dishes or domes) to the deck surface of the engine block. Production engines often have piston deck clearance in the range of 0.050- to 0.010-inch below the deck, or "in the hole." Performance engines are often machined to have 0 deck clearance, and in some cases, the deck clearance is positive, or "out of the hole," by as much as 0.010.

What To Do With That InfoWhen considering stroking your engine, the first thing to grasp is that the total combination of crank throw (half the stroke), plus rod length, plus piston compression height, plus piston deck clearance must equal the engine block's deck height. The exception is if the engine has positive piston deck clearance, in which case the piston deck clearance is the amount in excess of the block deck height. Each of the elements listed can be varied to accommodate the engine performance you're looking for. Here's how.

Pick Your Stroke

The first step is usually deciding what the crank stroke will be, and since the priority of this story is maximum torque, we'll focus on gaining the longest possible stroke. This will be determined by the crankcase room available in the engine block, as a long stroke can cause interference from the crank counterweights to the bottom of the cylinders or the oil-pan rails. Aftermarket engine blocks with wider pan rails and extra crank-clearance scallops can be a solution, though in some cases, careful grinding can supply the room you need. As an example, a 350 Chevy block with a stock stroke of 3.480 inches can usually fit a stroke as big as 3.800 with just a little grinding. An aftermarket small-block casting such as the Dart Iron Eagle has spread pan rails (requiring a unique oil pan) to fit strokes up to 4.125.

Another issue with longer strokes in many V-configuration engines is interference from the connecting rods to the camshaft, especially with connecting rods with a bulky big end, such as aluminum rods. Many aftermarket steel rods have low profiles or ground-down rod bolts for clearance, or a small-base-circle cam (available from most manufacturers for engines where it's required) can be a solution. For extreme strokers, some aftermarket engine blocks are available with raised camshaft locations for crank clearance. A stock small-Chevy cam height of 4.521 inches may be raised to 4.912 inches; longer timing chains and shorter pushrods are available for these blocks.

Adjusting Compression Height

Once the crank stroke has been chosen, the combination of rod length and piston compression height must be determined. If you intend to use stock-length connecting rods, the piston pin must be raised (i.e., the compression height reduced) by the same amount as half the increase in stroke. Using a common example, consider a 383 Chevy with a 3.750 stroke, original 5.7-inch rods, a block deck height of 9.025, and a target piston compression height of 0.025-inch below the deck. Here's how you'd determine the required piston compression height.

Deck Height - (Stroke/2 + Rod Length + Piston

Deck Clearance) = Compression Height

9.025 - (3.75/2 + 5.7 + 0.025) = 1.425

Therefore, a piston compression height of 1.425 (very common) is required for this 383 combo. Note that a 350's commonly used stock compression height is 1.560; the new height of 1.425 raised the piston pin 0.135-inch, which is exactly half the gain by going from 3.48- to 3.75-inch stroke. As a result, piston position at TDC is identical to what it was prior to the increase in stroke.

The same formula can be used if you decide to use connecting rods that are longer than stock. In that case, the piston pin must be raised by the same amount as the increase in rod length. For example, if you used the 383 described above but swapped to 6.000-inch rods, the piston compression height would need to be 0.300-inch less because 6.000-inch rods are 0.300-inch longer than 5.700-inch rods. That means the compression height would be reduced from 1.425 (for 5.700-inch rods) to 1.125 (for 6.000-inch rods). You can get the same answer by using the formula above. Either way, you can see that either a longer stroke or longer rods, or both, requires reduced piston compression height.

Finding The Longest Rods

Another scenario is that you know the stroke you want, the deck height, and the compression height of the off-the-shelf pistons you want to use. In this case, you want to find the longest available rods that will fit. Here's how.

Assume you've got a World Products Motown block with a 9.025-inch deck height. You'll use a big 4.000-inch stroke, and even though the block can be bored as big as 4.200, you're going to go 4.165 so you don't need custom pistons. (The 4.165x4.000 gives you 436 ci.) The JE catalog says the common 4.165-inch pistons are available in compression heights of 1.000, 1.062, 1.100, 1.125, and 1.425 inches. The common connecting rods from Eagle or Scat are 5.700, 6.000, 6.125, or 6.200 inches.

First, determine how much room you have within the limits of the block's deck height for the rod-and-piston combo; to do that, subtract half the stroke from the block deck height. In this case, that's 9.025 inches minus 2 inches, which equals 7.025 inches. Therefore, adding the piston compression height and the rod length will tell you the piston deck clearance you'll achieve. Here's the formula:

(Deck Height - Stroke/2) - (Piston Compression Height + Rod Length) = Deck Clearance

(9.025 - 4/2) - (1 + 6) = 0.025

In this case, the only choice would be 6.000-inch rods and pistons with a compression height of 1 inch. Any other combo creates a piston deck clearance that's either too low (too far down the hole) or way too high (too far out of the hole). In other cases, don't forget that the block can be milled to reduce the piston deck clearance to an acceptable amount-the amount that can be milled depends entirely on the block being used.

Using Deck Height To Your AdvantageIn the scenario above, maximum rod length and piston compression height was limited by the deck height of the block. This is exactly why tall-deck blocks are available from the aftermarket for Chevy and Mopar applications. GM has an aluminum small-block with a 9.525 deck (half an inch taller than stock), and Dart makes 9.325 heights. With the 9.325 deck height, our example of the 4.165x4.00 bore/stroke combo could use longer 6.200 connecting rods and pistons with a beefier 1.125 compression height for a piston deck clearance of 0.000. Do the math. It's fun.

Other Things To ConsiderMix and Match: So far we've used very common examples for the sake of simplicity, but the real fun is seeking out stroker combos for uncommon engines. By offset-grinding the crankshaft (described in an illustration elsewhere in this story), you can increase the stroke of any engine. You can also machine the rod journals to the size of those in a more common engine so you can get aftermarket rods, and perhaps the more common rod can also be narrowed to fit your crank if needed. Custom pistons can be made for virtually anything.

Compression height versus ring package: In the descriptions above, we did not address the practicality of very small piston compression heights. When this spec gets as small as 1 inch, it often requires narrow piston rings or ring buttons over the piston pin. It may also require the rings to be closer to the top of the piston than you may want for nitrous or endurance use. Short piston height means lighter weight, which is good, but it may also give up reliability you need. Sometimes a compromise for less stroke or shorter rods is prudent.

Piston-to-crank clearance: In a few cases with long strokes, short rods, and large piston compression heights, the piston skirts may interfere with the crank counterweights. The skirt can be cut to fit, but you may also want to rethink the combo.

Piston-to-head clearance: In determining piston deck clearance, don't forget the distance from the piston dome to the cylinder head as specified by the connecting rod manufacturer.

Rod ratios: Rod ratio is the connecting rod length divided by the stroke, and it's an indicator of the rod angularity seen in the engine. Longer rods have higher ratios (1.6:1 and higher) and less angularity than the low ratios (1.4:1) seen in ultra-long-stroke applications. The effect of rod ratio on performance is a topic far deeper than can be covered even if we spent the entire magazine trying. Suffice it to say that many engine-builders think the longest rods possible are the best rods, but modern thinking is that shorter rods may be torquier in a low-rpm application. If you opt for ratios less than 1.6:1, start thinking about beefier aftermarket connecting rods.

Compression ratio: Finally, any increase in displacement without a corresponding increase in combustion area is going to increase the compression ratio, and this must be addressed by tuning the piston dome or dish and the cylinder-head combustion chamber to the ratio you want. So there's an entire story about just that in this issue. How convenient.

Five Ways That Stroking Builds Torque

1.Cubes: Stroking delivers more displacement, and displacement means grunt.

2.Lever Action: A longer stroke is a longer lever acting on the crankshaft, thereby providing more torque. It's like using a long breaker bar on a lug nut instead of a short ratchet handle.

3.Compression: More displacement makes it easier to produce high compression without big ol' flamefront-killing domes on the pistons.

4.Sucking Power: Longer stroke creates faster piston speeds, and that means that the piston can create a more accurate pressure drop to fill the cylinder more thoroughly at low rpm for torque.

5.Rod Angularity: Some say that increasing stroke without increasing rod length increases torque because the piston-speed dynamics and rod ratio conspire to create more cylinder pressure at maximum rod angularity, at which point the rod has the greatest mechanical advantage over the crank. We're not sure if we buy that one or not.

How To Build A 454ci Small-Block

In researching this story, we came up with this combo that we may just have to try: a 454ci Mouse! We see it as a low-end torque killer. Check our daydream specs.

Block: Tall-deck Dart Iron Eagle

Deck height: 9.325

Bore: 4.185

Stroke: 4.125

Rod length: 6.125

Piston compression height: 1.125

Piston deck clearance: 0.0125 (actually, we'd probably mill the block to zero deck)

Rod ratio: 1.48:1

Displacement: 453.9

Destroking

Keep in mind that the stroking basics shown in this story can also be used to decrease the crank stroke. Why would you want to? Perhaps you run a weight-per-cubic-inch class or a displacement-limited class. Let's say the limit is 305ci. You sure don't want to run a pathetic 305 Chevy, because the cylinder bore is too tiny for decent size valves, and the bore is so close to the valves that airflow is compromised. Instead, use your newfound knowledge to build a small-block with a 4.010 bore and 3.000-inch stroke for 303 ci. Be extra trick and do it in a GM low-deck block (PN 12480050) with an 8.700 deck height to save weight, have a compact size, and keep the pistons short. You could still have 6-inch rods with custom pistons with a 1.200 compression height. With a 2:1 rod ratio, it'd be a 10,000-rpm screamer. Why not?

Cons Of Stroking

Many believe that cubes equal horsepower, and that's true, though long strokes are not as effective at pure horsepower production as large bores are. Why? Horsepower is a function of torque [hp = (lb-ft x rpm)/5,252], and stroke alone is rpm-limiting. Stroking increases piston speed (a 3.48 stroke engine at 6,500 rpm moves the piston at 3,770 feet per second; a 3.75 stroke does it at 4,063 fps), and the fast piston speed reduces the time available for cylinder filling at high rpm. Therefore, the torque production drops off at a greater rate than rpm increases, and horsepower production is cut short. Strokers can be made into high-rpm race engines, but there's a greater cost in heads (to flow with less pressure drop at high rpm), valvetrain (to survive the more aggressive profiles required), and lightweight internal components. On a street engine, lengthening the stroke (beyond a certain point) and changing nothing else tends to favor low-end torque over high-end horsepower. That's less true in the case of very small engines such as Ford 289s, Mopar 273s, and Chevy 283s, in which case the sheer increase in displacement is worth power everywhere.