The fastest way to a faster car is boost. Yep, engines are just big air pumps, so stuffing in more air allows for more fuel, and that equates to more horsepower. There are different types of superchargers on the market, but one popular type is the Roots style. These are also referred to as positive displacement blowers because they deliver a fixed amount of air per revolution. For a peek into this segment of the supercharger world we dropped in at Magnuson to take a look at their new HeartBeat kit.

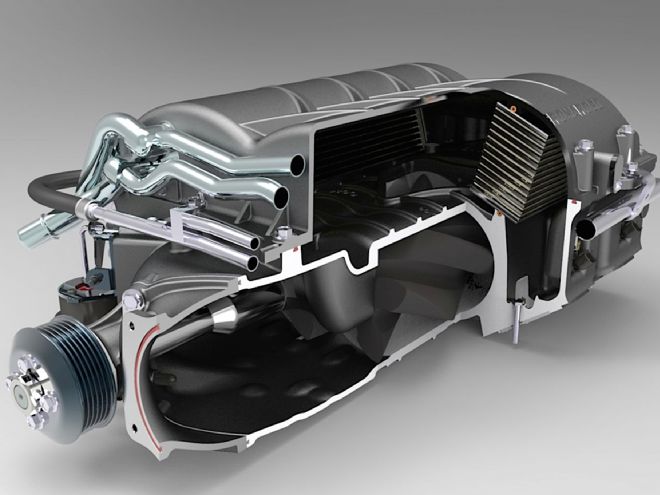

Their units differ quite a bit from the blowers of decades past. Instead of air being drawn in through the top, like a typical Roots unit, it’s drawn in through the inlet port and pushed into the engine along the axis of the rotors. According to Matt Hately at Magnuson, “The TVS rotors are different from a screw-type found in some superchargers. They don’t compress the air, they simply move the same volume of air (in the case of the HeartBeat 2.3L, or 2300 cc). The rotors touch, and create a nearly perfect seal, which is why they have the dark grey abradable powdercoat. The boost happens when the air backs up in the manifold. The key advantage is that they create less heat and are very efficient. In fact, a 2.3L TVS pushes more cfm than a 2.9L screw-type blower. Whereas the screw-type compresses air in the screws, and hence, inside the housing, the TVS is simply pumping, or pushing, the air, with the advantage being that the housing doesn’t heat up, so the bearings last longer. That’s one of the main reasons you see more Eaton TVS superchargers in OE cars than any other type. Thanks to a vacuum-referenced bypass valve, the inlet pressure is equalized with the manifold pressure. This pretty much negates any parasitic loss while cruising and makes for a very efficient design.

For quite some time now, the Magnuson units have featured the improved Eaton TVS four-lobe rotor arrangement. This very popular four-lobe design (also found inside GM’s LS9 and LT4 blower) is a big improvement over the previous three-lobe design. Where the twist of the rotors on the older GenV units was 60 degrees, the new TVS rotors are twisted to an aggressive 160-degrees. Also, the intermeshing design of the lobes helps quiet the supercharger even at high rpm. Like other Roots systems, the TVS Magnacharger is especially good at delivering boost at low engine rpm, which, for a street car, is where you really want the power to be.

The first-generation 2300 TVS units have been affixing smiles to gearhead’s faces for some time now, but Magnuson knew they could do better. Part of this was driven by the ever decreasing hood lines found on modern cars, especially the Corvette. The old design required a new, roomier hood, and owners were reluctant to go through the hassle of trying to color-match paint. Magnuson also knew there were areas where they could improve performance in addition to packaging. The result of 18 months of research and development is their new sixth-generation MP2300 TVS HeartBeat supercharger system.

About the only thing the new HeartBeat has in common with the older TVS design is the use of Eaton four-lobe rotors. The rest was a “clean slate” design. By starting from scratch, the engineers at Magnuson were able to come up with a much more efficient design that ended up smaller, lighter, and more efficient than what was previously available. And while their previous design is still a great option for those that want to bolt on well over 100 rwhp, the new kit is perfect for those with tighter engine bay confines or those that want every last possible horsepower.

To check out the new system we headed over to Magnuson Products in Ventura, California, to cover an install. Rick Andrade has had a TVS2300 Magnuson blower system on his 2010 Camaro SS since it was new. In fact, it was the third production unit Magnuson sold for the fifth-gen Camaro. He, along with lead technician/fabricator Kyle Donohue, run J&R Performance Center in Phoenix. They are one of the leading Magnuson dealers in the area, so they were just as excited as us to check out this new blower. It would also be a great experiment to compare the new and old units back to back on the chassis dyno.

01. Our test mule was a 2010 Camaro SS owned by Rick Andrade from J&R Performance Center in Phoenix. He installed his TVS2300 Magnuson kit when the car had only 246 miles on the odometer. Well, it now has over 115,000 miles on the clock and the stock LS3 is still running strong. Back when he added a cam and long-tubes (6,000 miles), the SS put down 609 rwhp. Well, we baselined the Camaro before pulling off the old parts and it made a best pull of 633 rwhp. So much for the myth of superchargers causing engines to prematurely wear out.

02. Before we could install the new sixth-generation MP2300 TVS HeartBeat system we had to vacate the tried-and-true 2300 TVS blower. To save time we decided to not pull the nose off the car and swap out the heat exchanger since they were nearly identical. Modifications the SS has are ADM camshaft, ADM twin fuel pump system, Dynatech long tube headers, aftermarket exhaust, Roto-Fab cold-air kit, and Centerforce DYAD clutch. (photo by Erin Helm)

03. At first glance, one might notice a similarity to factory GM blowers (as found on the LSA and new LT4 mills). Well, they do have much in common, but not as much as you think. Saving space is one reason why the LT4 blower displaces 1.7L (compared to the 2.3L Eaton blower on the LT9). By doing this they saved 0.4 inches in length and 0.5 inches in rotor diameter. That may not sound like much, but it was enough. To make up for lost displacement, the blower on the LT4 is driven at 3.10 times crank speed (compared to 2.32:1 for the LS9). After a lot of design work, Magnuson was able to build a blower built around 2.3L Eaton TVS rotors that still fit under the stock hood of the Corvette. Their HeartBeat Vette blower is just 1 7/8 inches taller than a stock LS3 intake manifold! On a fifth-gen Camaro there’s more hood clearance so those blowers get a taller lid and a slight increase in intercooler area. And yes, it will clear the later Camaro’s strut brace and hood vent insert.

04. The new HeartBeat blower isn’t just smaller; it also comes in 17 pounds lighter than their previous TVS 2300 kit. Magnuson also claims that the new kit, due to better airflow and heat exchanger design, makes a full 25 more ponies to the rear wheels. In terms of design, the new HeartBeat is vastly different from their previous designs. The previous blower was driven from the back via a side-mounted jackshaft. Also, the blower sat directly atop the intercooler block. This worked well, but made for a tall blower.

05. Superchargers love air, so opening up the intake was one of Magnuson’s top priorities. On the new HeartBeat the air no longer has to go up and over the bypass port. Instead it has a straight shot into the 2300 Eaton TVS rotors. All the kits carry a 3-year warranty on the hard parts and 1-year on the electronics. For a few bucks more, they even offer extended coverage. Blower maintenance is minimal, consisting of an oil change every 80,000-120,000 miles.

06. For the new C7 Z06, GM’s main constraint was that the blower needed to fit under the Corvette’s hood. This meant the intercoolers had to be wedged in the area near the valve covers. Magnuson decided to instead angle the twin intercooler blocks part way between the cylinder heads and blower outlet. The tradeoff of a bit more height for bigger rotors and increased plenum volume was more than worth it.

07. While the TVS 2300 rotor pack is super-efficient, it still compresses air and that process makes heat. For drag cars, an ice water tank is often used to chill the air charge, but that option isn’t practical for the street, not to mention running hard on a road course. According to Magnuson, the recovery times and intake air temperatures (IATs) are very impressive on the HeartBeat. The passages of the new intercoolers are dimpled to create turbulence in the water so that it cools better. Magnuson told us that you can run a road course, flat out, in 100-degree heat and see a rise of just 25-30 degrees above ambient in the IATs. The HeartBeat kit is also packaged with an improved front-mounted heat exchanger.

08. Back to our install, the LS3 has been cleaned and prepped for the new blower. To clean things up Rick added a set of Holley valve covers that he had painted to match his car. Unlike their previous kit, the new HeartBeat blower will work with the GM valley cover. We didn’t have one on hand so we kept the billet plate in place from the previous blower.

09. The blower intake utilizes reusable GM LSA-style intake gaskets. In fact, we found all of the gaskets, O-rings, brackets, and hoses to be of OEM quality. We would also like to mention that their 71-page, full-color install manual is one of the best ones we’ve seen.

10. It was then time for Rick Andrade and Kyle Donohue to set the main intake section in place on the LS3. Oh, make sure that you remove any tape you put over the intake ports on the heads. Believe it or not, it’s happened.

11. Here you can see how Magnuson optimized the airflow through the unit. The HeartBeat is, like the GM units, driven from the front and exhaust upwards through twin intercooler blocks pushed to the sides. These design changes results in a more efficient and space saving design compared to the older style TVS unit.

12. The reason that the intake is installed without the lid is that the intake bolts reside inside. Needless to say, care has to be taken to make sure none are dropped into the engine. Blue thread locker was used on these fasteners and they were torqued to 106 in-lb. Keep in mind there’s a specific torque sequence called for in the instruction manual.

13. With the intake bolted down, we could then install the lid. It came with fasteners, but Rick decided to jazz it up (in addition to the custom paint and pinstriping) with some stainless ARP fasteners. Due to the O-ring design they only needed to be torqued to 106 in-lb.

14. The intercooler coolant pump was also an upgrade to what we were running on the older TVS 2300 unit. The new one moves more coolant and we couldn’t help but notice the heat sink attached to the bottom. We ended up mounting it in the same location as the previous one. If this was a “from scratch” install it would have been located behind the front fascia near the heat exchanger.

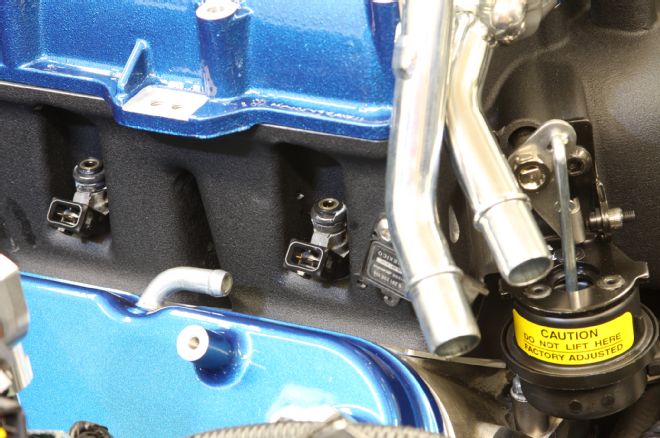

15. The HeartBeat kit included eight new high-flow fuel injectors, but to keep our before and after dyno numbers fair we transferred the 65-pound units that were used on the previous blower.

16. We could then install the polished fuel rail. Rick sent the stainless lines out to be polished to match the intercooler hardlines, which also received the same treatment.

17. Next up was installing all of the included, and for the most part pre-cut, coolant lines. On the blower side they used factory-style push-lock connectors. The new coolant tank had a small overflow barb which, if we had installed the new heat exchanger, would be plumbed down to it. In our case we simply capped it off for now.

18. Included in the kit was this OE-looking, cast-aluminum tensioner mount. It’s items like this that give the Magnuson unit a nice OE look. The tensioner used is just the stock Camaro part.

19. We then went about plumbing in all of the other items like the EVAP line, PCV line, and such. We also plugged in all the fuel injectors, coils, and the inlet air temperature sender. When relocated senders are moved too far, Magnuson included pre-cut and ready to go extension harnesses.

20. The front of the intake was opened up as well and can accommodate anything from stock up to 108mm throttle bodies (with the correct adapter). The larger throttle body’s increased efficiency let them make the same power on 2-3 fewer pounds of boost. We kept it simple and just bolted on the stock 90mm Camaro throttle body. To plug it into the harness we used one of the supplied extension harnesses.

21. The kit came with parts to mate it to the stock airbox, but our car had a Roto-Fab cold-air intake. We were in luck since Roto-Fab prototyped the correct elbow for this kit and sent one over beforehand.

22. And just like that, we were done and ready for some tuning. Of course, since we were just swapping blowers our install was easy. Expect a full install from stock to done to take around 10 hours.

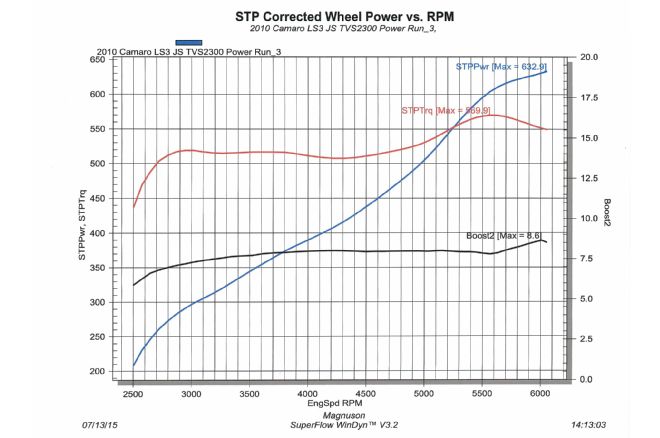

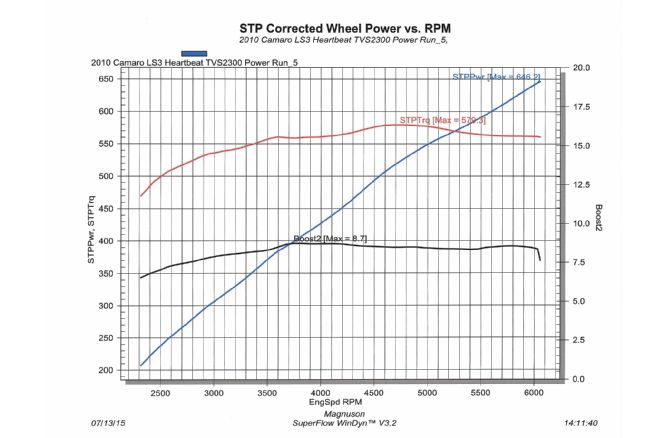

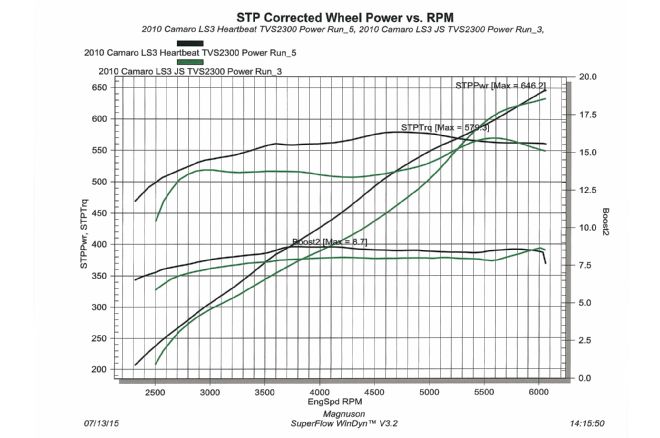

23. As for the dyno Rick relayed, “We did this comparison to compare power differences and IAT differences, and between the two Maggie blowers. Both were run with a 3.3-inch pulley, the HeartBeat was run with the available Maggie 3.3-inch and our J&R Performance 3.3-inch GripTec pulley. GripTec (sold through J&R) is a patented technology that prevents belt slip without tearing up the belt. Our base pulls with the TVS netted us 633 rwhp. Our HeartBeat base netted us 646 rwhp, and with the GripTec Pulley it bumped us up to 651 rwhp. All these were done on 91-octane pump gas with the same tune, the only change made was to the MAF readings for the new air intake tube. The TVS supercharger put out 8 psi of boost, the HeartBeat 8.8 psi of boost, 8.9 psi of boost with the GripTec pulley. The car is equipped with a Snow Performance Meth kit, but it wasn’t used for this comparison. The only difference in the supercharger kits is the 3.3-inch pulley instead of the stock 3.8-inch pulley. Otherwise this is an off-the-shelf kit. The tuning was done by J&R Performance.”

24. But there’s more to the performance gain than just peak numbers. As you can see, the new HeartBeat made more power just about everywhere. Boost was also up along the entire pull.

25. Dyno air is always pretty good, so the real test came when Rick got the SS back onto the hot summer roads of Arizona. As he told us, “At Magnuson we saw about a 10 degree decrease in IATs and quicker recovery with the HeartBeat in 72-degree temps. Now that we are back in Phoenix in 110-degree temps I am seeing 20-25 degree IAT reduction and substantially quicker recovery times after a full boost pull.” As expected, the improved intercooler design in the HeartBeat really shines in real-world driving conditions more so than on static chassis dynos.