The Combo

Back in 1985, Rob Van Vleet bought his 1966 Olds Cutlass 4-4-2 for $350 from its original owner, his father-in-law. It still had the factory drivetrain—an early short-stroke 400ci Olds big-block, Muncie M21 close-ratio four-speed trans, and the spindly 8.25-inch Olds 10-bolt rearend—but overall Rob says, “It was in serious need of work.” Rob fixed what was broken, restored what needed restoring, added Weld wheels, and (as befitting a Valspar Paints employee) repainted the car in its original Ocean Mist color.

Car owner Rob Van Vleet as “Dr. Oldsmobile,” eager to personally assist in solving his 400ci big-block’s bearing and crankshaft woes.

Car owner Rob Van Vleet as “Dr. Oldsmobile,” eager to personally assist in solving his 400ci big-block’s bearing and crankshaft woes.

Through it all, the car’s powerplants were seemingly cursed. “I’ve been through seven Olds engine variations: a 350, three 455s, and three short-stroke 400s. At first, I did my own engines, and they held up fair. I just kind of slapped them together, but seven years ago, I wanted to step it up. I went to what was said to be a ‘reputable’ Olds engine builder and had them rebuild the original 400 to make it a little hotter than stock but also so it would last.”

Rob’s Olds big-block was plagued by spun rod bearings. Before putting the 400 back together yet again, he asked HOT ROD for help.

Rob’s Olds big-block was plagued by spun rod bearings. Before putting the 400 back together yet again, he asked HOT ROD for help.

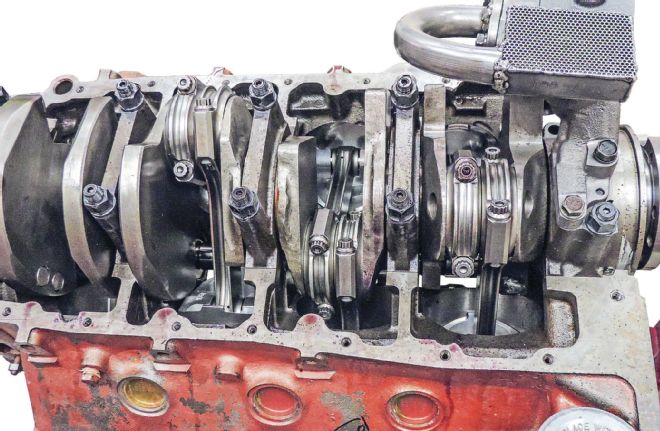

Right down into the copper: Three rod bearings had spun. Numbers 7 and 8 (shown) were the worst. Self-proclaimed “experts” had told Rob detonation had caused the piston wristpins to seize, in turn resulting in bearing failure. Wrong! Wear all the way around the bearing surface and journals is, as Norm puts it, “A clear indication of an oil-system problem.”

Right down into the copper: Three rod bearings had spun. Numbers 7 and 8 (shown) were the worst. Self-proclaimed “experts” had told Rob detonation had caused the piston wristpins to seize, in turn resulting in bearing failure. Wrong! Wear all the way around the bearing surface and journals is, as Norm puts it, “A clear indication of an oil-system problem.”

The Problem

But the engine didn’t last. “I got about 1,400 miles on it before rod bearings 4 and 5 spun. The engine builder said it was ‘detonation’. I had everything remachined, added a Milodon deep-sump oil pan and pickup, main-saddle oil restrictors, and a high-volume oil pump. I got 1,400 miles on it before I spun the 6, 7, and 8 rod bearings. I was told three piston wristpins seized and that supposedly took the bearings out. Put it back together again and got about 600 miles out of it—same problem. This last time I got 450 miles on the motor. The compression ratio was 9.5:1, but the ‘experts’ still said it was a detonation problem. I never heard any pinging or detonation, the piston tops looked OK, and the spark plugs read fine.” At this point, Rob asked HOT ROD for help. Initially, it was just to request a good dyno tune to cure his supposed detonation problem after he put the motor back together for what would be the fourth time.

Westech Automotive rescuer Norm Brandes (left) schools Rob and Rob’s brother, Tim, on proper big-block Olds bearing clearances.

Westech Automotive rescuer Norm Brandes (left) schools Rob and Rob’s brother, Tim, on proper big-block Olds bearing clearances.

The Diagnosis

When we got back to Rob, the engine was still apart. The Machesney Park, Illinois, resident lives only about an hour away from our favorite northern Illinois/southern Wisconsin rescue facility, Westech Automotive in Silver Lake, Wisconsin. One of a vanishing breed of full-service automotive repair facilities, owner Norm Brandes and his crew can fix just about anything. Before Rob assembled the motor, Norm asked him to bring the rotating assembly and engine block by for an engine autopsy.

Adjusting the bearing clearances and installing a new Eagle stroker crank and rods plus Diamond pistons was the primary fix.

Adjusting the bearing clearances and installing a new Eagle stroker crank and rods plus Diamond pistons was the primary fix.

“We examined Rob’s rotating assembly,” Brandes reports. “He had several spun bearings and scoured rod journals. If detonation was the cause, I’d have seen damage concentrated on the side of the rod bearing that’s closest to the piston. But in Rob’s case, the entire bearing surface and rod journals were scoured all the way around. He had lost the hydrodynamic oil wedge between the bearing and journal, resulting in direct metal-to-metal contact.”

Production Big-Block Olds Engines CI Years Bore Stroke Journals Rod Length Piston Height (CD) Rod/Stroke (R/S) Ratio Mains Rods 400 1965-1967 4.00 3.975 3.0 2.5 6.998 1.615 1.76 400 1968-1969 3.870 4.250 3.0 2.5 6.735 1.740 1.58 425 1965-1967 4.125 3.975 3.0 2.5 6.998 1.615 1.76 455 1968-1976 4.125 4.250 3.0 2.5 6.735 1.740 1.58

Miking the rotating assembly, Norm discovered excessive bearing clearances. “Both rod and main bearings had more than 0.0035-inch clearance, when they should have been in the 0.002–0.003-inch range on a regularly street-driven motor. The main bearings were also fully grooved—that’s an old-time ‘trick’ to improve marginal oiling systems on full-race builds, but they also have less load-bearing area, plus more oil can escape instead of forming the proper insulating wedge. This concept may work on a short-duration, race-only motor that doesn’t see even 200 degrees of oil temp, but on the street you can easily get up to 230–250 degrees, or even higher. Conventional multiviscosity oils may start breaking down at these temperatures, once again weakening the wedge.” Lending credence to this, Rob says the failures never happened when short-tripping in town, or even when getting it on wide open; instead, they all occurred during mild-rpm sustained cruising over 50 miles in length.

The Plan

The usual fix for a problem like Rob’s is turning the crank journals undersize and rebuilding the connecting rods, which also allows the machinist to tighten up the bearing clearances. But Rob’s elderly short-stroke 400 crank was toast, already ground 0.040-inch undersize. The cylinder walls weren’t looking good, either: The already 0.030-over engine needed yet another overbore. Norm also felt the motor could do better in the cam department, a rationalization made easy because, Norm relates, “Debris from the failed bearings and damaged crank journals had scratched several cam journals.” The good news was that the main journals had previously been align-bored, and its main saddles at this point were still checking straight.

However, Rob’s 1966 short-stroke 400 had several factors that, like a row of falling dominoes, can complicate repairs:

The short-stroke Olds 400 was made for only three years, 1965–1967. Its 6.998-inch center-to-center connecting rods and forged-steel 3.870-inch-stroke crank are shared only by the equally rare 1965–1967 425. Later, commonly available, long-stroke Olds 400s and the Olds 455 have different cranks and rods (see table), as well as a slightly different flywheel bolt pattern.

The short-stroke 400’s 4.0-inch standard bore size is not shared with any other big-block Olds.

Rob’s engine, like some (but not all) 1968-and-earlier Olds engines, was machined for huge 0.921-inch-od lifters, instead of GM’s mainstream 0.842-inch lifter diameter.

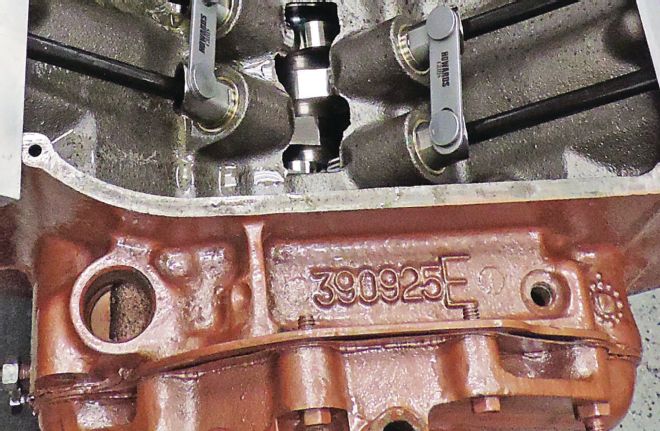

Which displacement block? 0.842- or 0.921-inch lifters? 39- or 45-degree lifter bank angles? Block casting No. 390925, ID “E,” indicates Rob’s block is a 1966–1967 400 with 39-degree bank angles and 0.921-inch lifter bores. Mondello’s “Oldsmobile V8 Technical Reference Manual, Vol. 3” ($26) is full of hard-core data and engine-building tips like this.

Which displacement block? 0.842- or 0.921-inch lifters? 39- or 45-degree lifter bank angles? Block casting No. 390925, ID “E,” indicates Rob’s block is a 1966–1967 400 with 39-degree bank angles and 0.921-inch lifter bores. Mondello’s “Oldsmobile V8 Technical Reference Manual, Vol. 3” ($26) is full of hard-core data and engine-building tips like this.

Some mid-1960s Olds V8s had nonstandard 45-degree lifter-bank angles. Most later Olds big- and small-block engines use 39-degree bank angles. Bank-angle affects cam availability as well as valvetrain geometry. Fortunately, Norm determined Rob’s original 4-4-2 400 block had a 39-degree bank angle.

With Rob’s engine needing both a new crank and an overbore, Norm decided to go for broke: “Too much is just enough! I sonic-checked Rob’s block and determined that I could take the bores all the way out to 4.125-inch—the same bore size as a stock Olds 455—while still retaining 0.191-inch or greater wall thickness, even at the thinnest point. I can’t say that every early Olds 400 will go this far, but it was perfectly safe on this particular casting. There’s even enough remaining wall thickness to bore it again in the future.”

Scratch the journals, scratch the crank: Already 0.040-inch undersize, Rob’s crank was maxed out beyond economical repair.

Scratch the journals, scratch the crank: Already 0.040-inch undersize, Rob’s crank was maxed out beyond economical repair.

At this point, Norm could have installed a remanufactured production 455 Olds crank or new 4.25-inch-stroke Eagle crank, along with a 455’s different-length rods and readily available 455 Olds pistons. But, hey, this is HOT ROD: We don’t build stockers. Instead, we upped the game and designed a new combo centered around a modern, brand-new, aftermarket stroker crank, rods, and pistons. And when you throw in a whole new rotating assembly to move up from 400 to 481 ci, it only makes sense (at least to hot rodders) to get an optimized cam and improved cylinder heads capable of keeping up with all the added cubes.

When looking at an entire engine combination, every choice affects every other choice. You need to consider the total package—bore, stroke, cam, valvetrain, and cylinder heads—as an integrated whole. For hot rodded street motors, Norm has a unique approach. He routinely builds even old-school carbureted, noncomputer, engines to 11:1 or more static compression ratios that successfully run on unleaded pump-premium gas. The keys are aluminum heads with their quicker heat-rejection characteristics and (hopefully) more modern quick-burn combustion chambers, optimal quench achieved with near-zero deck heights, an aggressive cam ground to Norm’s specs, and careful carburetor and ignition tuning.

“I try to achieve around 0.040-inch quench,” Norm explains. “That’s about what a modern LS-series motor has. Spark-plug positioning in the chamber, slightly biased toward the exhaust valve, is also critical. It’s one of the keys to making a high-compression motor live on the street. We are making a 21st-century engine here. Assuming parts are available that meet these parameters, there’s no reason why any engine can’t run high compression on today’s pump gas.”

The Fix: Rotating Assembly

Eagle offers a reasonably affordable big-block Olds “cast-steel” 4.5-inch stroker crank that comes machined with big-block Olds 3.0-inch main journals and 2.20-inch big-block Chevy rod journals. Going to big-block Chevy rod journals allows the use of big-block Chevy rods, which are readily available from aftermarket sources in a wide choice of lengths.

Stock. The rare forged-steel big-block Olds 3.975-inch stroke crank was used only on 1965–1967 400 and 425ci engines. Good luck trying to find another usable crank.

Stock. The rare forged-steel big-block Olds 3.975-inch stroke crank was used only on 1965–1967 400 and 425ci engines. Good luck trying to find another usable crank.

Stroker. New and rebuildable Olds 455 cranks are available, but this Eagle 4.5-inch cast-steel stroker crank is only about $20 more expensive at Summit Racing than Eagle’s new 4.25-inch stroke 455 Olds replacement crank.

Stroker. New and rebuildable Olds 455 cranks are available, but this Eagle 4.5-inch cast-steel stroker crank is only about $20 more expensive at Summit Racing than Eagle’s new 4.25-inch stroke 455 Olds replacement crank.

Buildsheet All dimensions in linear inches, except as noted. Engine family Oldsmobile OHV big-block V8 Engine builder Westech Automotive Firing order 1-8-7-3-6-5-4-2 (4/7 swap) Lifter bank angle 39 degrees Fuel 93-octane unleaded pump gas Max timing 34 degrees @ 3,500 rpm Spark plugs Champion RC12YC, 0.035 gap Max torque @ rpm 590.9 lb-ft @ 4,000 Max power @ rpm 525.3 hp @ 5,200 Displacement and Compression Ratio Data Displacement 481.1 ci Bore × stroke 4.125 × 4.5 Block deck-height (OE blueprint) 10.625 Block deck-height (as-built) 10.610 Con-rod center-to-center 6.800 Rod/stroke ratio 1.51:1 Piston compression height 1.560 Piston-to-block–deck clearance Zero Piston dome/dish volume –4.8 cc (flattop w/ valve reliefs) Head gasket compressed volume 9.2 cc Cylinder-head chamber volume 84 cc Static compression ratio 11.06:1 Critical Clearances Crankshaft main bearing 0.00265 Connecting rod bearing 0.0025 Connecting rod side clearance 0.018 Crankshaft thrust 0.005 Piston-to-wall 0.0035 Piston ring end gap 0.018 1st, 0.015 2nd, as-received oil Camshaft thrust 0.003 Piston-to-head distance (squish) 0.039 Piston-to-valve 0.375 intake/0.296 exhaust Valvespring Data (PAC 1219X) For camshaft profile data, see the separate “Camshaft Specifications” table. Pressure @ installed height 145 psi @ 1.800 Pressure @ valve open 358 psi @ 1.175 Spring rate 340 lb/in Max coil-bind 1.100 Max lift 0.625 Nonproduction Critical Torque Values ARP 2000 head stud nut (7⁄16-20) 80 lb-ft w/ ARP assembly lube ARP main stud nut (½-20) 105 lb-ft w/ ARP assembly lube ARP Eagle rod bolts (7⁄16-20) 63 lb-ft w/ ARP assembly lube

You can buy the Eagle crank individually or as part of a complete kit including rods, pistons, rings, and bearings. Norm prefers a slightly shorter-length rod than the 7.100-inch center-to-center ones normally included in the complete kit. With a rod that long, the piston skirt ends up too short for Norm’s taste. “I prefer a longer skirt on a street car, which means you need a shorter rod so everything stacks up right. I don’t want noisy pistons in the morning, which is what they tend to do when the skirt is too short. A shorter skirt also means more piston rock; with more rock, you need more piston-to-wall clearance.” In addition, the added clearance may adversely affect sealing (increasing detonation tendencies). The Olds also wants to retain as much oil as possible downstairs, as Rob had unfortunately discovered in his real-world escapades. Taking this into consideration, Norm spec’d a set of shorter 6.800-inch Eagle big-block Chevy H-beam rods.

Eagle’s big-block Olds cast-steel cranks weigh in at 70–75 pounds and feature generous (and strength-enhancing) 0.092-inch journal radii. Chamfered oil holes come standard. These cranks are normally used with standard externally balanced Olds dampers and flywheels.

Eagle’s big-block Olds cast-steel cranks weigh in at 70–75 pounds and feature generous (and strength-enhancing) 0.092-inch journal radii. Chamfered oil holes come standard. These cranks are normally used with standard externally balanced Olds dampers and flywheels.

Norm prefers to internally balance high-performance motors. There’s less crank flex when the counterbalance weight is as close as possible to the pistons, rods, rings, and bearings. This extends bearing life and crank longevity, while reducing stress on the crank snout. Picture how an Olympic weightlifter’s barbell flexes during the clean and jerk when there’s lots of weight on each end.

Norm prefers to internally balance high-performance motors. There’s less crank flex when the counterbalance weight is as close as possible to the pistons, rods, rings, and bearings. This extends bearing life and crank longevity, while reducing stress on the crank snout. Picture how an Olympic weightlifter’s barbell flexes during the clean and jerk when there’s lots of weight on each end.

The 6.800-inch-long rods in turn required custom pistons. At least a 4.125-inch bore is the same as more mainstream engines like Chevy’s 400ci small-block, so premium ring sets are readily available. In fact, small-block Chevy piston forging blanks aren’t too far off; an Olds typically uses pure flattops with (as needed) valve notches. Even more fortuitously, the 1.560-inch piston compression height needed with Norm’s chosen rod length, the Eagle stroker crank, and Norm’s zero-decked block was in the ballpark for many small-block Chevy off-the-shelf pistons. After getting in touch with the good folks at Diamond Pistons, Norm ordered a set of forged 4032 aluminum alloy flattop pistons with correctly located valve reliefs for the Mondello Performance Olds aluminum heads this build would be using.

To resolve the spun-bearing issues, Westech installed the rotating assembly using Speed-Pro main and rod bearings with about 0.001-inch less clearance than on Rob’s previous build. The assembly was also neutral-balanced with several slugs of Mallory heavy metal.

The downside to internally balancing a lightweight big-stroker crank is that it often takes relatively pricey tungsten (aka “Mallory”) heavy metal to get the job done—in this case, five 1x1-inch slugs. Final retention will be by failsafe welding after they’re hammered in place.

The downside to internally balancing a lightweight big-stroker crank is that it often takes relatively pricey tungsten (aka “Mallory”) heavy metal to get the job done—in this case, five 1x1-inch slugs. Final retention will be by failsafe welding after they’re hammered in place.

With an internally balanced crank, you need a corresponding neutral-balanced harmonic damper. BHJ’s degreed, billet-steel, SFI 18.1-certified, damper measures 6.6-inch-od x 3.19-inches-ol and accepted Rob’s stock drive pulley with no problem.

With an internally balanced crank, you need a corresponding neutral-balanced harmonic damper. BHJ’s degreed, billet-steel, SFI 18.1-certified, damper measures 6.6-inch-od x 3.19-inches-ol and accepted Rob’s stock drive pulley with no problem.

The relatively weak Olds two-bolt cast main bearing caps are held in place by an ARP main stud kit. Olds caps need all the help you can give them. Clevite assembly lube was applied to all bearing and other wear surfaces.

The relatively weak Olds two-bolt cast main bearing caps are held in place by an ARP main stud kit. Olds caps need all the help you can give them. Clevite assembly lube was applied to all bearing and other wear surfaces.

The oil gallery holes leading up to the main bearing holes on the Number 2, 3, and 4 main bearings are too large and should be restricted to keep the crank from getting starved for oil. Norm reused these restrictors from Rob’s previous build.

The oil gallery holes leading up to the main bearing holes on the Number 2, 3, and 4 main bearings are too large and should be restricted to keep the crank from getting starved for oil. Norm reused these restrictors from Rob’s previous build.

Install the oil restrictors in the main bearing saddles’ offset holes using thread-locking compound.

Install the oil restrictors in the main bearing saddles’ offset holes using thread-locking compound.

Speed-Pro has upgraded its trimetal, Super Duty Alloy, PN 108M main bearing set to a ¾-groove design: The cap-side shell is partially grooved, while the saddle-side shell has a full groove. This strikes a balance between more oil flow without unduly sacrificing load-bearing ability.

Speed-Pro has upgraded its trimetal, Super Duty Alloy, PN 108M main bearing set to a ¾-groove design: The cap-side shell is partially grooved, while the saddle-side shell has a full groove. This strikes a balance between more oil flow without unduly sacrificing load-bearing ability.

During initial trial assembly, Norm determined the crank keyway location was 5½ degrees retarded. This was corrected with a custom-machined offset crank key, which allowed the degree marks on BHJ’s SFI-legal harmonic damper to correctly indicate true TDC. At the opposite end is a McLeod neutral-balanced flywheel.

The Fix: Heads

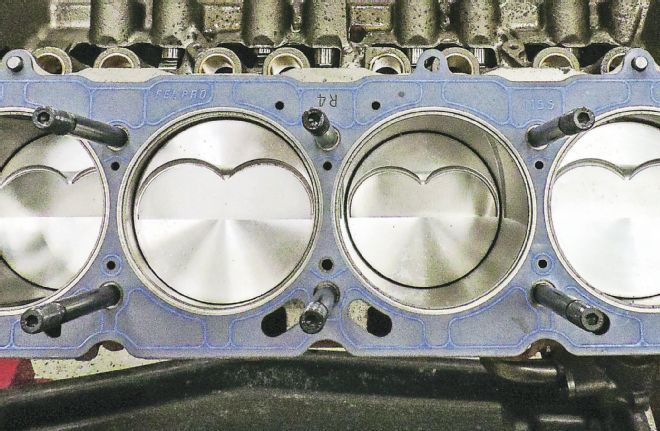

Current aftermarket Olds cylinder-head choices are somewhat limited. Van Vleet chose to go with a set of fully ported Mondello Performance Posiflow aluminum heads. Founded by the late, legendary Joe Mondello, the company is still around today and remains dedicated to hard-core Olds V8 performance. The heads usually come with valves, springs, retainers, locks, valve seals, and (unlike a stock Olds head with paired-pedestal rockers), a fully adjustable valvetrain set up for 7/16-inch rocker-arm studs and ⅜-inch pushrod guideplates, but Westech ordered them less springs and retainers so Norm could select valvesprings best matching his chosen cam profile. With the Diamond Pistons, a zero-block-deck height, Fel-Pro Performance head gaskets, and 84cc combustion chambers, compression came in at 11.06:1. If anything would put Norm’s high-compression engine theories to the test, this sure will.

Excessive bearing clearances were the root cause of Rob’s spun bearings. His previous 0.0035-inch bearing clearances were tightened up to 0.00265 inch and 0.0025 inch on the mains and rods, respectively.

Excessive bearing clearances were the root cause of Rob’s spun bearings. His previous 0.0035-inch bearing clearances were tightened up to 0.00265 inch and 0.0025 inch on the mains and rods, respectively.

The Fix: Camshaft

The engine’s “weird” 0.921-inch-od lifters were an obstacle for achieving this engine’s performance goals. First, because it’s hard to find performance-oriented 0.921 lifters, whether flat-tappet or roller (they’re larger than even a Mopar’s). Second, because an aggressive hydraulic-roller grind is the best complement to Norm’s mixture-motion/high-compression-ratio theories.

Production Olds V8s retained the annoying rope-style rear main seal right to the bitter end. Norm has a better idea: A Ford 429/460 two-piece rubber rear seal drops right into a big-block Olds. As further no-leak insurance, Norm offsets the Ford seal halves a tad from the cap-saddle parting line, then adds a drop of RTV silicone at the join-point before bolting the cap in place.

Production Olds V8s retained the annoying rope-style rear main seal right to the bitter end. Norm has a better idea: A Ford 429/460 two-piece rubber rear seal drops right into a big-block Olds. As further no-leak insurance, Norm offsets the Ford seal halves a tad from the cap-saddle parting line, then adds a drop of RTV silicone at the join-point before bolting the cap in place.

When Olds went to hydraulic-roller cams in its 350 diesels and 1985–1990 307 small-block gasoline engines, it reverted to a 0.921 lifter diameter, retained—like most OE roller-lifter setups—by a spider bolted to the block’s lifter-valley bosses. Olds big-blocks have the same bosses; on the old muscle-car motors, they were used to mount a one-piece metal lifter-valley tray/intake gasket. In theory, this makes it possible to retrofit a complete late-model Olds factory roller-lifter setup, but there are several drawbacks for serious high-performance use: The spider and other key hardware are no longer available new, the factory roller lifters (designed as they were for the diesels) lack durability for use with a modern aggressive camshaft, and they also pump way too much oil upstairs at high rpm.

Norm was able to take Rob’s already 0.030-over (4.030-inch bore) 400 all the way out to 4.125 inches, the same as a 455ci Olds. That’s 1⁄8-inch (0.125) more than a stock 1965–1967 Olds 400. If you’re low-bucking it, an early short-stroke Olds 400 could become a 455 by using the larger Olds engine’s pistons, rods, and crank. We’d sonic-check the block first, though!

Norm was able to take Rob’s already 0.030-over (4.030-inch bore) 400 all the way out to 4.125 inches, the same as a 455ci Olds. That’s 1⁄8-inch (0.125) more than a stock 1965–1967 Olds 400. If you’re low-bucking it, an early short-stroke Olds 400 could become a 455 by using the larger Olds engine’s pistons, rods, and crank. We’d sonic-check the block first, though!

Retrofit performance paired-guidebar lifters are the obvious solution. But there are no 0.921-inch guidebar lifters. Norm had to use BHJ’s Lifter-Tru tooling to bush the lifter bores to accept 0.842-inch Olds lifters. Retrofit Olds paired-guidebar hydraulic-roller lifters in that size are available from many sources, including Howards Cams, suppliers of the cam and most of the valvetrain for this build.

The custom Diamond Racing Olds flattop pistons have a 4.125-inch bore and 1.560-inch compression height. They feature a friction-reducing moly skirt coating and accept 0.990-inch big-block Chevy pins for compatibility with Eagle’s rods. Diamond also supplied the file-fit rings: a 1⁄16-inch plasma-moly top, a 1⁄16 RBT plain iron second, and a 3⁄16 standard-tension oil.

The custom Diamond Racing Olds flattop pistons have a 4.125-inch bore and 1.560-inch compression height. They feature a friction-reducing moly skirt coating and accept 0.990-inch big-block Chevy pins for compatibility with Eagle’s rods. Diamond also supplied the file-fit rings: a 1⁄16-inch plasma-moly top, a 1⁄16 RBT plain iron second, and a 3⁄16 standard-tension oil.

Diamond’s H13 tool-steel pins mate the pistons to Eagle 6.800-inch-long, big-block-Chevy-style SAE 4340 steel H-beam rods. The two-piece rod forgings have alignment sleeves for more precise cap alignment and bolt together using beefy ARP 8740 steel 12-point capscrews. The piston undersides have Diamond’s “Maxi-Lite” CNC internal mill to shave excess piston weight.

Diamond’s H13 tool-steel pins mate the pistons to Eagle 6.800-inch-long, big-block-Chevy-style SAE 4340 steel H-beam rods. The two-piece rod forgings have alignment sleeves for more precise cap alignment and bolt together using beefy ARP 8740 steel 12-point capscrews. The piston undersides have Diamond’s “Maxi-Lite” CNC internal mill to shave excess piston weight.

Spirolock retainers keep the floating pins in place on the bushed Eagle rods. Some say Spirolocks are a pain to install, but they’re even harder to remove—and that’s a good thing, right?

Spirolock retainers keep the floating pins in place on the bushed Eagle rods. Some say Spirolocks are a pain to install, but they’re even harder to remove—and that’s a good thing, right?

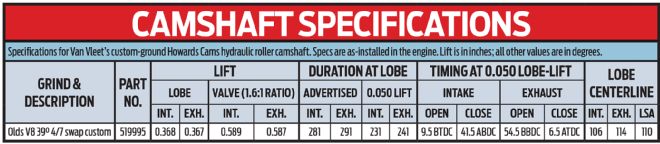

The hydraulic-roller cam itself was spec’d to work with the motor’s large displacement and high compression ratio. Howards’ custom profile is based on several of Norm’s previous Olds builds, one of which, “Is currently running 11.50 in the quarter at 118 mph in a heavy 1970 4-4-2,” Norm says. The grind has 240/253 degrees duration at 0.050-inch tappet lift, with high-580s valve lift (see cam table). “The engine has enough compression ratio to support a cam this big. It has good scavenging on the bottom-end, still makes huge amounts of bottom-end torque, yet bleeds off a little on the extreme bottom end to blow off some potential low-speed engine knock.”

The Fix: Valvetrain

The aggressive cam’s early opening exhaust valve mandates a stiff valvetrain. “When you open the exhaust valve early, more cylinder pressure needs to be overcome. Otherwise, this is where lift loss would show up. You don’t want the lifter to bleed down prematurely,” Norm says. The closest “off-the-shelf-fit” roller rockers for the Mondello heads’ nonstock stud-mount valvetrain geometry are 1.6:1 small-block Ford items. Several different brands were evaluated, with Comp Cams’ Pro Magnum rockers offering the best combination of geometry, fitment, durability, and pricing. Olds (and small-block Fords, for that matter) generally use 5/16-inch-diameter pushrods, but Westech stepped it up to a stiffer ⅜-inch size, with a 5/16-inch tip to still fit in the rocker’s pushrod cup. PAC 1219X beehive springs return the valves to their seats. Norm had to machine the heads’ as-delivered spring pockets deeper to develop the proper 1.800-inch installed valvespring height.

Diamond’s file-fit rings were carefully checked about 1-inch down in each bore. Top and second compression ring gaps were set to 0.018 and 0.015 inch, respectively.

Diamond’s file-fit rings were carefully checked about 1-inch down in each bore. Top and second compression ring gaps were set to 0.018 and 0.015 inch, respectively.

Actual ring-filing was accomplished using this quick, precise, and repeatable electric ring-filing machine.

Actual ring-filing was accomplished using this quick, precise, and repeatable electric ring-filing machine.

It’s still necessary to carefully hand-file the sharp edges left after achieving the final gap setting, though. With a plateau-hone, this engine leaked down less than 1½ percent, even after several thousand miles of street driving and some hard dyno pulls.

It’s still necessary to carefully hand-file the sharp edges left after achieving the final gap setting, though. With a plateau-hone, this engine leaked down less than 1½ percent, even after several thousand miles of street driving and some hard dyno pulls.

The complete rotating stroker assembly bolted-in the early 400 block with no need for any clearancing. A new Speed-Pro high-volume oil pump and heavy-duty driveshaft gives aid and comfort to the marginal Olds oil system. The pickup screen is for Rob’s deep Milodon oil pan.

The complete rotating stroker assembly bolted-in the early 400 block with no need for any clearancing. A new Speed-Pro high-volume oil pump and heavy-duty driveshaft gives aid and comfort to the marginal Olds oil system. The pickup screen is for Rob’s deep Milodon oil pan.

Mondello aluminum heads were ordered fully ported to support 481 cubes. The 2.072/1.685-inch valves reside in measured 84cc chambers. Even with the heads’ traditional Olds chamber layout, there were no detonation issues running 11.06:1 compression on 93-octane unleaded. The Olds’ nearly vertical valve-to-deck angle makes for gobs of piston-to-valve clearance.

Mondello aluminum heads were ordered fully ported to support 481 cubes. The 2.072/1.685-inch valves reside in measured 84cc chambers. Even with the heads’ traditional Olds chamber layout, there were no detonation issues running 11.06:1 compression on 93-octane unleaded. The Olds’ nearly vertical valve-to-deck angle makes for gobs of piston-to-valve clearance.

The exhaust ports exit in the stock location. Unlike many Olds factory heads, the Mondello heads’ center siamesed ports have a full divider extending all the way out to the exhaust header flange. Mondello says its ports work best with headers that have 1¾-inch primary tubes and 3-inch collectors.

The exhaust ports exit in the stock location. Unlike many Olds factory heads, the Mondello heads’ center siamesed ports have a full divider extending all the way out to the exhaust header flange. Mondello says its ports work best with headers that have 1¾-inch primary tubes and 3-inch collectors.

With only four head bolts per cylinder, Olds V8s really need premium head fasteners and gaskets. ARP 2000 7⁄16-inch studs were screwed into the block hand-tight, the heads dropped on top of Fel-Pro performance-series head gaskets, and the stud nuts incrementally torqued in three passes to 80 lb-ft using ARP assembly lube. Fel-Pro provided all the motor’s gaskets.

With only four head bolts per cylinder, Olds V8s really need premium head fasteners and gaskets. ARP 2000 7⁄16-inch studs were screwed into the block hand-tight, the heads dropped on top of Fel-Pro performance-series head gaskets, and the stud nuts incrementally torqued in three passes to 80 lb-ft using ARP assembly lube. Fel-Pro provided all the motor’s gaskets.

Westech bushed Rob’s 0.921-inch lifter bores to allow using common 0.842-inch-od lifters. This requires machining the bores oversize in the Bridgeport using BHJ’s Lifter-Tru blueprinting fixture to accept the new bronze bushings. BHJ’s tooling can also correct lifter bore location and angle, or even machine complete new lifter bores into unfinished racing blocks.

Westech bushed Rob’s 0.921-inch lifter bores to allow using common 0.842-inch-od lifters. This requires machining the bores oversize in the Bridgeport using BHJ’s Lifter-Tru blueprinting fixture to accept the new bronze bushings. BHJ’s tooling can also correct lifter bore location and angle, or even machine complete new lifter bores into unfinished racing blocks.

To match the Olds block’s lifter oil-supply galley, Westech had to machine an oil-relief groove and an 0.080-inch oil-pass-through hole into the new blank bushings.

To match the Olds block’s lifter oil-supply galley, Westech had to machine an oil-relief groove and an 0.080-inch oil-pass-through hole into the new blank bushings.

The bushings are installed with a 0.002–0.003-inch press-fit, oriented so the new oil-relief slots and oil hole align with the block’s oil galleys.

The bushings are installed with a 0.002–0.003-inch press-fit, oriented so the new oil-relief slots and oil hole align with the block’s oil galleys.

The last step is to final-hone the newly pressed-in bushings to size.

The last step is to final-hone the newly pressed-in bushings to size.

Howards Cams 0.842-inch guidebar hydraulic roller lifters work with its custom hydraulic-roller cam, ground with a 4/7 firing-order swap that’s said to reduce bottom-end stress by spreading the firing impulses. The ported Mondello heads’ intake-port entrances match the dimensions of Fel-Pro’s PN 1356 high-performance intake gasket. The runners remain taller and wider than stock Olds heads all the way down to the valve-neck area.

Howards Cams 0.842-inch guidebar hydraulic roller lifters work with its custom hydraulic-roller cam, ground with a 4/7 firing-order swap that’s said to reduce bottom-end stress by spreading the firing impulses. The ported Mondello heads’ intake-port entrances match the dimensions of Fel-Pro’s PN 1356 high-performance intake gasket. The runners remain taller and wider than stock Olds heads all the way down to the valve-neck area.

When installed, the cam degreed-in at 5½ degrees retarded. Was it the cam, the timing set, the crank, or the block? After measuring and checking everything, Westech determined the issue lay with the crank: Its journals were properly indexed, but the crank keyway location was off. Olds uses one long keyway for both the balancer and the timing chain’s crank sprocket.

When installed, the cam degreed-in at 5½ degrees retarded. Was it the cam, the timing set, the crank, or the block? After measuring and checking everything, Westech determined the issue lay with the crank: Its journals were properly indexed, but the crank keyway location was off. Olds uses one long keyway for both the balancer and the timing chain’s crank sprocket.

With its induction-hardened sprockets and cold-rolled 0.250-inch-od chain rollers, Cloyes’ Race Billet True-Roller 9-keyway timing set drives the cam. One of its extra keyways could have been used to properly phase the cam, but the “zero” mark on the degreed BHJ balancer would still not have pointed to true TDC. Instead, the problem was solved at its source by machining a custom offset crank key.

With its induction-hardened sprockets and cold-rolled 0.250-inch-od chain rollers, Cloyes’ Race Billet True-Roller 9-keyway timing set drives the cam. One of its extra keyways could have been used to properly phase the cam, but the “zero” mark on the degreed BHJ balancer would still not have pointed to true TDC. Instead, the problem was solved at its source by machining a custom offset crank key.

The Results

After final assembly, in mid-2014, Norm dropped the engine back in the car. Using the shop’s Mustang chassis dyno, he dialed-in the new Quick Fuel SS830 double-pumper carb, then threw a curve in Rob’s large-cap HEI distributor that’s boosted by an MSD 6 ignition box. The car made so much torque the wheels kept slipping on the rollers, precluding getting accurate torque and power readings at the time.

Custom Competition Products chrome-moly 9.400-inch-ol x 3⁄8-inch-od x 0.080-inch-thick wall pushrods have 5⁄16-inch tips to fit the 5⁄16-inch cups in Comp Cams’ 1.6:1 small-block Ford Pro Magnum rockers. PAC 10-degree titanium retainers top PAC 1219X beehive springs rated at 340 lb/in. The “X” indicates extra fatigue treatment for high rpm and increased loads.

Custom Competition Products chrome-moly 9.400-inch-ol x 3⁄8-inch-od x 0.080-inch-thick wall pushrods have 5⁄16-inch tips to fit the 5⁄16-inch cups in Comp Cams’ 1.6:1 small-block Ford Pro Magnum rockers. PAC 10-degree titanium retainers top PAC 1219X beehive springs rated at 340 lb/in. The “X” indicates extra fatigue treatment for high rpm and increased loads.

The high-rise, single-plane, Mondello Posiflow intake is the best match for the ported Mondello heads. The weird “unibit”-shaped bolt-in Mondello Stuffer is said to improve fuel distribution and broaden the powerband.

The high-rise, single-plane, Mondello Posiflow intake is the best match for the ported Mondello heads. The weird “unibit”-shaped bolt-in Mondello Stuffer is said to improve fuel distribution and broaden the powerband.

Rob’s brother, Tim, test-drove the car on the street, inadvertently starting out in Third gear—and didn’t even notice. With the summer 2014 cruising season well underway, Rob put 1,700 trouble-free street miles on the engine, reporting, “It ran great. I ran two legs of the Power Tour® and drove it back and forth daily to work. There were no detonation problems on pump premium.”

The intake is fed by a Quick Fuel SS830 double-pumper carburetor. The carb has an electric choke, 1.450x1.560-inch venturis, 1¾-inch throttle bores, four-corner idle, and—for ultimate tunability—changeable idle-feed and power-valve channel restrictors, and idle and high-speed air-bleeds.

The intake is fed by a Quick Fuel SS830 double-pumper carburetor. The carb has an electric choke, 1.450x1.560-inch venturis, 1¾-inch throttle bores, four-corner idle, and—for ultimate tunability—changeable idle-feed and power-valve channel restrictors, and idle and high-speed air-bleeds.

Sometimes big overbore/long-stroke engines tend to run hot, but Rob says the new motor “usually runs around 180 degrees, never more than 205. The old engine would run 200–225 degrees regularly. With the same Summit aluminum radiator as before, I had to put in a 180-degree thermostat in place of the previous 165-degree one because it was now running too cool!

“My Olds 8.25-inch 10-bolt didn’t hold up for long, though. I was giving my nephew a ride. Halfway through First gear, it ripped seven teeth off the ring gear. I’m running a 9-inch Ford and a Traction-Lok now.”

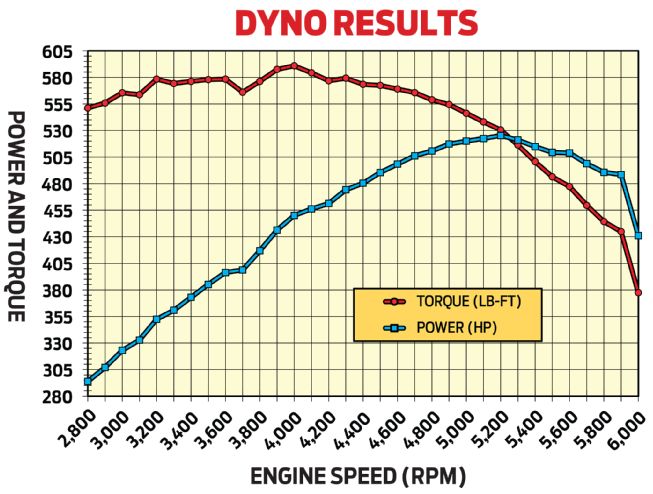

To obtain some real numbers and see how the engine’s guts were holding up, Rob yanked the engine last winter. The engine was brought over to Dan Timm’s Advanced Engine Concepts, a leading Wisconsin oval-track engine builder, to make a few runs on the shop’s Stuska engine dyno that’s capable of making wide-rpm-range pulls, even on torquey engines like the Olds. After minimal tuning and running on 93-octane unleaded pump gas with 34 degrees total advance, the engine pounded out 591 lb-ft of torque at 4,000 rpm, with 525 hp on tap at 5,200. It made more than 500 lb-ft as low as 2,800 rpm. Talk about usable street power!

In preliminary tests on Advanced Engine Concepts engine dyno, Rob’s 481ci Olds peaked at 525.3 hp and 590.9 lb-ft of torque. Average output from 2,800–6,000 was 447 hp and 542 lb-ft. It made over 500 lb-ft from 2,800 rpm (the lowest point tested) through 5,400 rpm, and more than 500 hp from 4,800 through 5,600.

In preliminary tests on Advanced Engine Concepts engine dyno, Rob’s 481ci Olds peaked at 525.3 hp and 590.9 lb-ft of torque. Average output from 2,800–6,000 was 447 hp and 542 lb-ft. It made over 500 lb-ft from 2,800 rpm (the lowest point tested) through 5,400 rpm, and more than 500 hp from 4,800 through 5,600.

But we ultimately became victims of our own success. Before dropping the engine back in the 4-4-2, Norm disassembled the engine for inspection. There were a few minor, easily rectified, issues, but then Norm discovered a main-bearing bore problem: Those fragile Olds two-bolt-main bearing caps, they’d been moving around. The main-bearing clearances had started to progressively increase front to rear from the engine’s as-machined condition. Apparently, this is a known problem with high-output Olds engines; we just didn’t think we’d be making as much power and torque as we did. Several solutions are currently under evaluation, including a beefy main-cap girdle. We’ll be back in a few months with an update and retest on the ultimate fix.

On AEC’s dyno with ported Mondello aluminum heads and a custom Howards cam, so far the now-481ci build is up to 525 hp and 591 lb-ft.

On AEC’s dyno with ported Mondello aluminum heads and a custom Howards cam, so far the now-481ci build is up to 525 hp and 591 lb-ft.

Lessons Learned

With a big-block Olds’ 3-inch mains, pay attention to the bottom-end clearances and overall oil-control scheme. Be prepared for mission creep when evaluating an engine combination: The top-end (heads and cam) must be capable of feeding all those added cubes generated by a stroker crank and overbore. Properly configured, you can’t not make torque on an undersquare big-block Olds. In fact, there will be so much torque the two-bolt cast main caps become questionable.

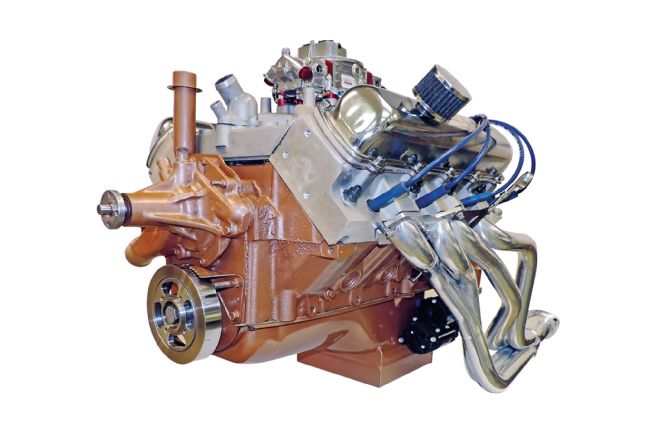

Not your father’s Oldsmobile: The complete 481 in all its glory, complete with Mondello heads and intake. Rob already owned the Hooker headers. The Milodon oil pan and pickup were transferred over from the engine’s previous incarnation.

Not your father’s Oldsmobile: The complete 481 in all its glory, complete with Mondello heads and intake. Rob already owned the Hooker headers. The Milodon oil pan and pickup were transferred over from the engine’s previous incarnation.

Parts And Prices Includes the major parts required to fix the problem. Shop labor and machining are listed only if they cannot typically be performed by the average home mechanic. Does not include parts reused from Van Vleet’s previous engine, shipping charges, sales taxes, or miscellaneous small bolts, hardware, and plumbing. Priced 02/12/14 and subject to change. All dimensions are in linear inches, except as noted. Brand Part Description Part No. AMT. Price Source¹ Cost ARP Stud Kit, cylinder head, ARP 2000, 7⁄16-od stud, 6-point nut 185-4001 1 CP $120.22 Stud Kit, main bearing cap, 8740 steel, 2-bolt main caps, ½-od stud, 6-point nut 185-5401 1 CP $74.53 BHJ Damper, harmonic, billet steel, 6.6-od x 3.19-ol, degreed, SFI 18.1, neutral-balance OL-IB-7 1 BHJ $537.50 Sleeve, lifter bore, extreme durability, bronze, standard length, 0.841-id x 1-od x 1.5 long LBS-ED-843 16 BHJ $11.60 Champion Plug, spark, Copper Plus, 14mm, 0.750 reach, 5⁄8 hex, gasketed, projected tip, resistor (RC12YC) 711 8 RA $11.76 Cloyes Timing Set, premium True HP double-roller, billet steel, 9-keyway 9-3613X9 1 CP $137.95 Comp Cams Arm Set, valve rocker, Pro Magnum, small-block Ford, 7⁄16 stud-mount, 1.6:1 ratio 1632-16 1 SR $327.97 Competition Products Pushrod Set, valve rocker-arm, chrome-moly, 3⁄8 body, 5⁄16 rocker-end tip, 9.400 ol, 0.080 wall T940803CL 16 CP $132.64 Diamond Pistons Piston Set, custom, flattop, w/ 0.990 big-block Chevy H13-steel pins and Spirolock retainers 104347 1 CP $1,429.95 Ring Set, piston, 1⁄16 plasma-moly top, 1⁄16 RBT plain-iron second, 3⁄16 std.-tension oil ring 09024125 1 CP $127.95 Eagle Rod Set, engine connecting, forged 4340 steel, 7⁄16 ARP 8740 steel bolts, 6.800 center-to-center CRS68003D² 1 SR $429.97 Crankshaft, cast steel, 4.500 stroke, 3.0 Olds main and 2.200 big-block Chevy rod journals 104554500 1 SR $509.97 Fel-Pro Gasket Set, conversion (short-block), 1966-1967 Olds 400 3x2 code “VG” CS 8171-2 1 RA $8.78 Gasket Set, exhaust header, perforated steel core w/ antistick coating, 1.56 x 1.95 port size 1439 1 RA $19.43 Gasket Set, intake manifold, composite w/ coating, 1.40 x 2.40 port size, 0.060 thk 1356 1 RA $22.79 Gasket Set, valve cover, molded rubber, 3⁄32 thick VS 50259 R 1 RA $7.41 Gasket, carburetor mounting, paper, Holley 4150 flange, open plenum 1900 1 RA $3.91 Gasket, cylinder head, stainless steel core laminate, preflattened steel wire combustion seal, 4.250 bore x 0.039 thick, 9.2cc compressed volume 1155 2 RA $135.58 Gasket, water outlet, composite, 1966-1967 Olds 400 3x2 code “VG” 35130 1 RA $0.80 Seal, crankshaft rear main, two-piece rubber, Ford 429/460 (replaces Olds rope seal) BS 40032 1 SR $8.97 Howards Cams Camshaft, hydraulic roller, custom, 4/7 swap, Olds V8, 39° bank angle, 0.589/0.587 valve-lift, 281°/291° advertised duration 519995 1 HC $302.92 Lifter Set, valve, hydraulic roller, Olds V8, 0.842-od, retrofit guidebar-style 91464 1 CP $429.95 Lock Set, valve, machined steel, 10°, 11⁄32 valve stem, 1 groove, w/ lash cap recess 93075 1 CP $29.95 KBS Coatings Paint, Motor Coater engine enamel, high-temp, Olds Bronze, brush-on, 1pt can 60318 1 SR $22.97 Paint, Motor Coater engine enamel, high-temp, Olds Bronze, spray-on, 12oz aerosol 60118 1 KBS $22.95 Mahle-Clevite Lubricant, engine assembly, 8 fluid oz bottle 2800B2 1 SR $9.97 McLeod Flywheel, neutral-balance (delivered w/ extra bolt-on weight, not used) 461505 1 SR $304.18 Mi-Tech Weight (Plug), crankshaft balancing, “Mallory” tungsten heavy metal, 1-od x 1-ol (parts only) F17B1C1010 5 WA $190.00 Mondello Performance Button, camshaft thrust, w/ retention bolt TB-745 1 MP $24.00 Heads, cylinder, aluminum, 84cc chamber, 2.072/1.685 valves, fully ported, 7⁄16 rocker studs, 3⁄8 pushrod guideplates, less springs or retainers (sold as a pair) Custom (call)³ 1 MP $2,325.00 Manifold, intake, Posiflow single-plane, 4150 Holley flange, second-design, ported w/ Stuffer 4150 (0.4) 1 MP $699.00 PAC Racing Springs Locator, Valvespring, 0.060 thk S112-1 16 CP $63.68 Retainer Set, valvespring, 10°, titanium RS11-16 1 CP or SR $248.88 Valvespring Set, beehive configuration, 340 lb/in rate PAC-1219X-16 1 CP or SR $243.82 Quick Fuel Carburetor, gasoline, Super Street, 4-bbl, 830 cfm, mechanical secondaries, 4-corner idle SS-830 1 CP $538.14 Sealed Power Plug Kit, freeze and expansion, brass 381-8020 1 SR $9.99 Speed-Pro Bearing Set, camshaft, babbitt material, full-round design 1234M 1 SR $26.99 Bearing Set, connecting rod, CH-series, trimetal, 2.200 big-block Chevy rod journal, std. 8-7200CH 1 SR $74.99 Bearing Set, crankshaft main, Competition Series, trimetal Super Duty alloy, 3⁄4 groove, std. 108M 1 SR $114.99 Pump, engine oil, high volume 224-41203V 1 SR $78.99 Shaft, oil pump drive intermediate, for high-volume pump 224-61203 1 SR $6.99 Valvoline OIL, engine, Premium Conventional, 10W-40, 1qt bottle4 VV141 16 AA $63.84 Westech Automotive Key, crankshaft harmonic damper locating, steel, offset (materials only) Custom 1 WA $10.00 Machining & Measuring Operation, crankshaft, correct crank keyway location (labor only) Labor 1 WA $95.00 Machining Operation, bush lifter bores (labor only) Labor 1 WA $675.00 Machining Operation, crankshaft, balance w/ Mallory heavy metal (labor only) Labor 1 WA $190.00 Machining Operation, cylinder block, bore-hone-deck Labor 1 WA $435.00 WIX Filters Filter, engine oil, 5.178 height, 13⁄16-16 thread, Olds V84 51049 2 RA $15.14 Notes: ¹Source key: AA = Advance Auto Parts, BHJ = BHJ Products & Dynamics, CP = Competition Products, HC = Howards Cams, KBS = KBS Coatings, MP = Mondello Performance, RA = RockAuto, SR = Summit Racing Equipment, WA = Westech Automotive ²Stocked by Summit under PN ESP-68003D. ³PN MON-605 with custom options. 4For two oil changes: break-in and post-break-in. Total $11,686.01

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at [email protected] and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.