One of the many facets of building a hot rod at home is the creation of an exhaust system. Though header design and fab'ing might be best left to professionals (the meticulous work and time required to make a great set of headers may be cost-prohibitive to the home builder), the rest of the system can be assembled and finished by someone with decent welding skills, a basic selection of tools, and the right parts.

Gathering the right parts becomes easier with an introduction to Patriot Exhaust Products. One of the brands under the PerTronix Performance Products banner (the folks who make Ignitor electronic ignition parts and Flame-Thrower distributors), Patriot was brought into the PerTronix family in 2000, which expanded further with the acquisitions of Doug's Headers in 2005, JBA Performance Exhaust in 2008, as well as the vintage Smithy's Mufflers line.

Besides selling three types of mandrel-bent J- and U-bend tubing (1010 mild steel, aluminized, and stainless steel) to the homebuilder, Patriot also has gaskets, flanges, tips, mufflers, and more. For this project, a Patriot VaraFlow muffler was used, which features a small DC servo motor mounted to the side of the muffler that operates a butterfly inside. This not only changes the exhaust note (to the driver's liking), but also gets rid of the droning exhaust noise that sometimes occurs at certain rpms.

Another way to help rid the exhaust system of an irritating drone is the addition of an X-pipe, which directs the exhaust in two different routes. The benefit of having the exhaust pulses interrupted by crossing over into another pipe before the muffler is an increase in low-rpm power. A custom X-pipe was fab'd for this ride using parts from Patriot, and it is something that a homebuilder could do himself, along with the rest of the exhaust system, so follow along and see how it was done.

01 The headers used on this project are the H8482-1 Patriot metallic ceramic-coated Tight Tuck headers for the 260-351W Ford motor.

02 This is the space we have to work with: a '32 chassis from Speedway Motors, with an X-member made from rectangular tubing.

03 Patriot offers several shapes of pre-bent exhaust tubing, including these curved sections that can be cut apart and used accordingly.

04 Those cut sections of tubing are made into this: a crossover section that allows the pulses of exhaust coming from the engine to flow into the other exhaust route.

05 The custom-fab'd X-pipe is the first part to be placed under the vehicle.

06 Patriot's Don Lindfors checks the fitment of the exhaust tubing, done with a heavy amount of eye-balling in order to line up the bends so smaller sections can be pieced together and made into longer ones.

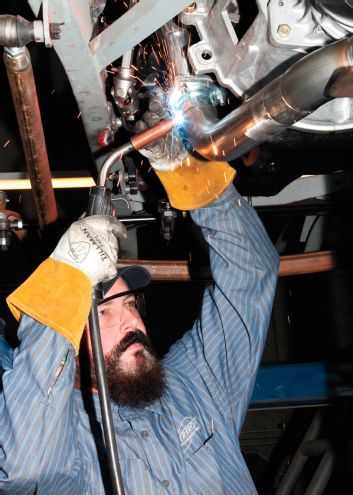

07 Once the pieces are where Lindfors wants them, Kurt Hilsen (Patriot's exhaust technician) does the no-look-tack with his Miller MIG welder.

08 Each small piece begins like this: The parts are marked with a Sharpie pen to help align them, and then they are pulled out and put on the workbench for welding.

09 After the parts have been tacked and rechecked for fitment, the section goes back on the workbench for final TIG welding.

10 With the exhaust beginning to take shape, Lindfors measures the outlets along the way to ensure they are level to one another.

11 The process of fit-and-tack is again followed by more TIG welding.

12 To hide the servomotor that is part of the Patriot H3200 VaraFlow muffler, each muffler is mounted so the motors face the driveshaft.

13-14 There is a small DC motor that regulates the flow of exhaust according to how much the driver desires by controlling a butterfly inside.

15-16 The exit side of the muffler has a slip fit for the rest of the tubing and is secured with stainless steel clamps that are supplied by Patriot.

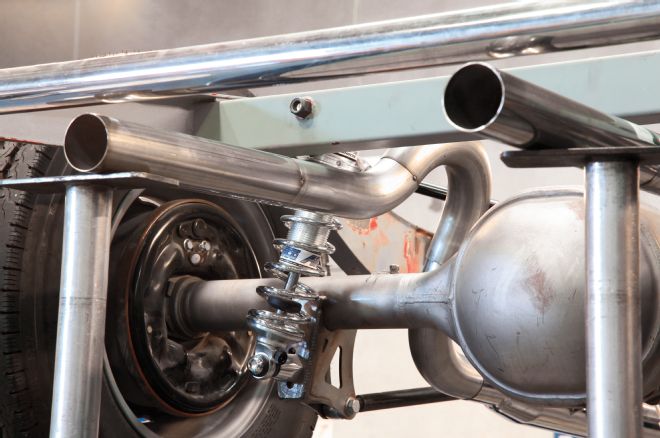

17 Progress is made up to the point of getting the exhaust over the rearend. You don't want to mount it underneath for two reasons: One, if you would ever need to pull the rearend, you'd have to pull the exhaust first, and two, it just looks ugly with exhaust running beneath the rearend.

18 A 90-degree and U-bend are fitted together to make the over-axle section of pipe.

19 Lindfors figures where the exhaust pipe will run and marks the over axle piece where it needs to be cut.

20 In order to keep the tailpipe tucked up close to the underside of the truck bed, custom angles needed to be made in both pieces to correctly route the pipe.

21 It's too hard to figure where to cut the tailpipes off at the end without the bed in place, so Lindfors left them a little long until their final length can be determined.

22 The complete system is tacked together, so now everything can be fully welded.

23-24 To hang the exhaust tubing from two spots on the chassis (behind the trans and near the rear crossmember), these hangers from Hot Rods by Dean (PN HR-1005) use high-temp Teflon bushings and allow the exhaust to move back and forth (with heat expansion) but not side-to-side.

25 If need be, the entire exhaust system can be pulled from the car in three pieces.