When it comes to bolting a blower on your Chevy’s LS engine, it will hold up just fine with the low-boost configuration and tune that comes with most basic kits. The comparatively high compression ratio and the non-forged internals on the majority of factory LS engines generally means boost must stay down in the 5-8 psi range to keep everything safe and detonation free.

While the extra 100-125 horsepower that a bolt-on supercharger delivers is plenty of additional kick for many owners, there’s always the enthusiast who wants more. Lots more—and that means the engine’s foundation requires fortification to contain its guts when the boost level heads for double digits.

Detroit-area Livernois Motorsports (livernoismotorsports.com) has been in the business of building such foundations for more than 15 years now, and when it comes to forced-induction LS engines, they’ve got a lot of boost under their belt. That made Livernois the perfect source for a purposeful long-block assembly that would suit the needs of a street/strip supercharged engine that would see more than 10 psi of boost—and more than 700 horsepower.

More specifically, the engine would see more street duty than anything else. In fact, compromise-free street manners were second only to the desire for a big payday on the dyno. And yes, we have to admit cost would be a factor. There was budget for good parts, but as we said, this would be primarily a street engine, so there was no need for a Pro Mod-level of unobtanium in the rotating assembly.

With those loose parameters, Livernois Motorsports’ Andy Ricketts suggested one of their 419-cubic inch, LS3-based boost-ready Pro Series short-blocks and matching it with a set of CNC-ported LSA cylinder heads. Achieving the 419-inch (6.8L) displacement comes from replacing the original 3.62-inch crankshaft with a 4.00-inch-stroke crank and honing out the stock cylinder liners ever so slightly.

“Of course, the stroker short-block has all forged internals, which gives you the strength you’re looking for, but our CNC-ported LSA heads optimize the setup with exceptional airflow characteristics that really make the most of what a supercharger can cram into the engine, while providing a superior casting to an LS3 head,” says Ricketts. “If you’re looking for 700-800 horses or more with higher boost levels, this a great way to go.”

And what about the bottom line? Value is always subjective, but the cost for our boost-ready 419 stroker clocked in around $11,750. Keep in mind, that’s for a long-block assembly, not a complete engine. There’s still the matter of rifling through the sofa cushions and checking the coffee room snack machine for spare change to pay for the supercharger. So, no it’s not exactly chump change, but the cost-to-benefit analysis suggests it’s a strong value for the peace of mind and assurance that it will stand up to the cylinder pressures incurred with 10-plus psi of boost. For extra assurance, Livernois’ Pro Series line of engines are rated to withstand up to 1,100 horsepower.

We hope to put that assurance to the test soon. In the meantime, check out the accompanying photos to see what went into our blower-capable, stroked LS3.

What Makes a Good Blower Camshaft?

The right camshaft is crucial for optimizing the performance gains delivered by a supercharger. And while different engines of different displacements and rpm ranges will deliver unique performance characteristics, there are a few guidelines and tips to keep in mind when spec’ing a bumpstick for your blower motor:

Generally speaking, you need more duration in a naturally aspirated application than a supercharged engine operating at the same rpm.

However, the blower camshaft should deliver more exhaust duration than the stock camshaft’s intake/exhaust ratio to help evacuate the greater exhaust gas content of the boost air charge.

A blower camshaft does not need overlap to provide a signal from the exhaust to the intake, so it typically has less overlap.

Because charge is lost through the exhaust when both valves are open (overlap)—and scavenging isn’t required—optimized blower cams typically have a wider lobe separation angle. The side benefit is a smoother-running, easier-driving engine on the street.

With centrifugal superchargers, a smaller intake profile helps maximize low-speed torque, but it is matched with a larger exhaust profile to reduce exhaust pumping loss at higher rpm.

With positive-displacement superchargers such as Roots- or Lysholm-style, low-speed torque is generally not a problem, so a “larger” camshaft can be used because it doesn’t have to “cheat” the exhaust side as much.

In other words, with centrifugal blowers, you can make torque with the camshaft and power with the blower; and with the positive-displacement blowers, the blower delivers the torque, so make sure to give it enough camshaft to run at higher engine speeds.

Here’s the other tip to keep in mind: Let a professional help choose your blower cam. The tech hotlines at all the major camshaft companies dole out such advice like coffee at Dunkin’ Donuts. That’s what they’re there for, so there’s no reason to guess. And don’t be shy about asking about the grind specs you spotted on a parts retailer’s website.

01. The LS3 core engine was stripped down before the block goes through several machining operations to prepare it for the stroker rotating assembly, including align-honing of the main bearings and main caps. It’s a common procedure that improves the strength, durability, and high-rpm performance of the engine by ensuring the crankshaft bores are as straight as possible and within the proper specs for diameter and shape. It also allows Livernois to precisely set the main bearing clearance—a critical component for a long and happy engine life.

02. Achieving the 419-cubic-inch displacement couldn’t be done by stroke alone, which would take the engine to 415 cubic inches. The extra four cubes comes from a pretty standard honing of the iron cylinder liners—a job that ensures proper clearance for each piston as well as a great surface for ring seating.

03. The factory main bearing caps would be reused, but rather than installing them with the standard main bolts, ARP main studs were installed. The studs enable more accurate torque values because, unlike bolts, they don’t twist during tightening. Because they remain stationary during tightening, the studs stretch in one axis alone, providing more even, accurate clamping forces.

04. Manley forged H-beam rods and Livernois proprietary ceramic thermal-coated pistons are at the heart of the rotating assembly. The coating reflects heat and reduces heat soak on the pistons. The compression ratio for this forced-induction combination comes down nearly half a point, from 10.7:1 to about 10.3:1. That will work toward keeping detonation at bay under high boost while keeping the engine responsive under boost-free operation, such as cruising and light throttle.

05. The piston rings are optimized for a supercharged engine, too, with a stainless steel top ring that’s strong and helps seat quickly in the cylinders. The second ring is a cast iron torsional taper face and the oil ring is a three-piece flex vent design.

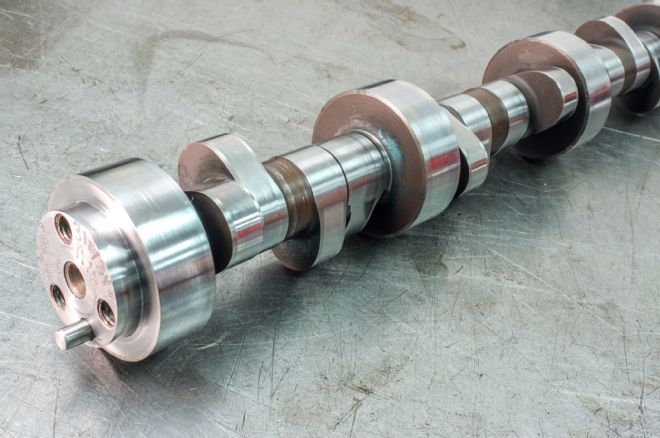

06. A Livernois-specific 4340 non-twist forged crankshaft provides strength at a moderate price. It’s heat-treated, stress-relieved, shot-peened, and nitrided for durability under boost. It’s also Magnafluxed from the factory to ensure its strength.

07. ARP connecting rod bolts provide great strength for the intense cylinder pressure and heat generated under boost. They’re made of upgraded ARP2000 chromoly steel and are heat-treated before the threads are rolled into them. By some measures, they’re up to five times stronger than stock fasteners.

08. Livernois Motorsports notches the bottom corner of each cylinder to provide adequate clearance for the bulkier rods on the longer-swinging stroker crankshaft.

09. Livernois uses a Melling Select High Volume oil pump for the build to ensure proper oiling under all conditions, especially under boost at high rpm.

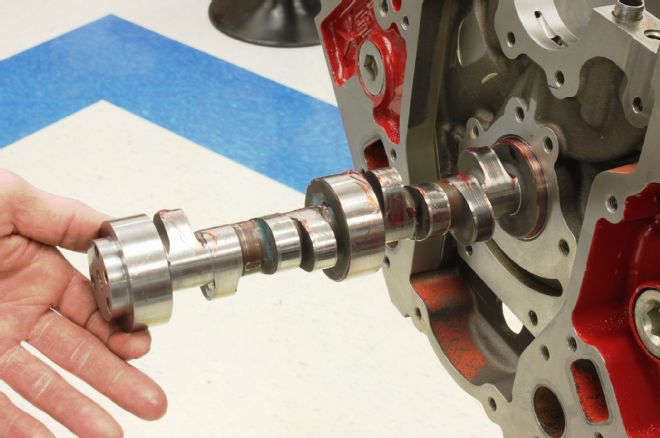

10. Livernois’ custom-grind 2C-HL (high-lift) camshaft got the nod for valve actuation. The specs include 0.646/0.646-inch lift, 224/236-degree duration, and a comparatively wide 117-degree lobe separation angle (LSA), which is ideal for a supercharged combination that doesn’t need the scavenging that comes with the valve overlap of a tighter LSA (see sidebar).

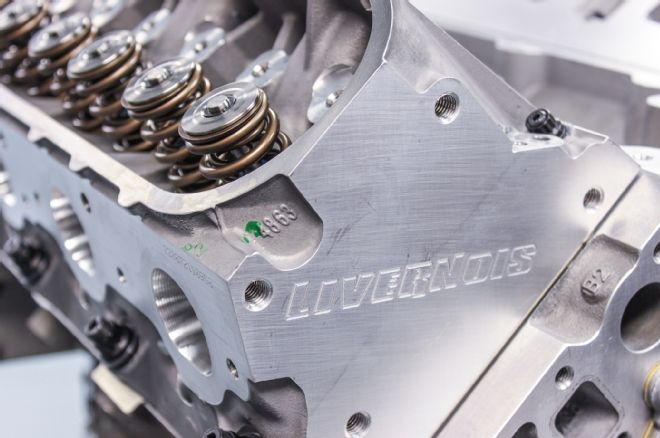

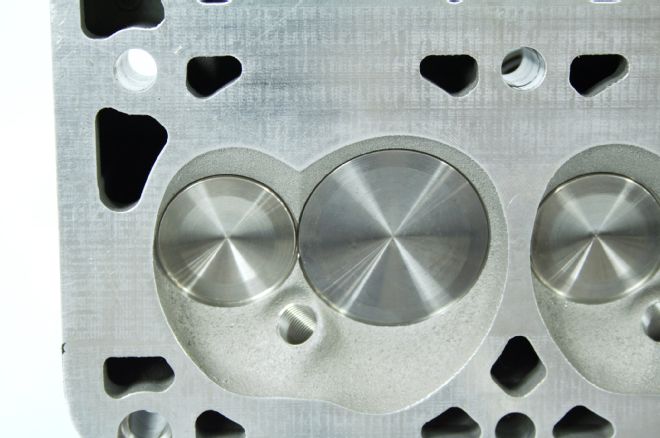

11. The heads are also Livernois’ in-house creation. They are Stage 3 CNC-ported versions of the GM LSA head. Importantly, Livernois starts with a set of brand-new heads, so there’s no concern about “seasoned” parts, and there’s no core charge.

12. The heads are five-axis CNC machined to enhance airflow. The L92-type intake ports are carved out to enable a 360-cfm flow rating, which allows the engine to process as much airflow as a supercharger can cram into it.

13. Large, 2.16-inch stainless intake valves and 1.59-inch exhaust valve usher the air charge in and out of the heads. The combustion chambers are left at their original 68cc volume.

14. While many LS combinations these days run lighter beehive-style valvesprings, Livernois uses super-strong USA-made dual-coil springs that are good to about 0.690-inch lift. Valvetrain mass is kept to a minimum with chromoly locks and titanium retainers.

15. Maximum cylinder sealing is a must with a high-boost supercharged engine, and to that end OEM LS9 multi-layer steel head gaskets are used. These gaskets provide two additional layers compared to their LS3 counterparts, ensuring the best possible seal available for a high-boost application.

16. As with the main bolts, the standard head bolts are swapped in favor of ARP head studs for more accurate torque specs.

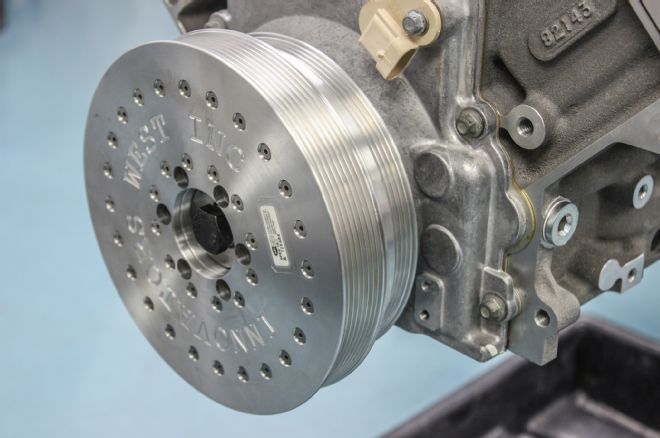

17. A custom, 10-percent oversized damper from Innovators West incorporates an eight-rib pulley for the blower belt. A steel hub resides inside of the lightweight aluminum case, along with a free-floating wet friction clutch pack that uses spring-loaded inertia rings to dampen crankshaft harmonics.

18. Here’s the assembled long-block, ready and waiting for the force-feeding of a supercharger. It’s a comparatively straightforward combination that should deliver exceptional strength under the mid-level boost planned for it. The bottom line for that strength was $11,750.

19. A similar combination for a Livernois Motorsports customer matched the 419 stroker and ported LSA heads with one of Magnuson’s Heartbeat superchargers. With methanol injection and a stout fuel system, the setup delivered 733 rwhp and 663 rwtq. That bodes well for our project engine.