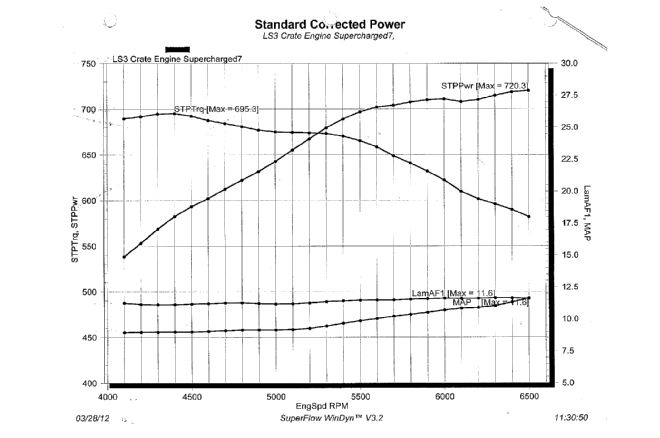

Higher pressure and more volume. Those two basic elements are what’s required to pull 720 hp and 695 lb-ft from Edelbrock’s hard-charging LS3 crate engine. The higher pressure results from the forced induction of an E-Force TVS blower. And more volume comes from a stroked crank and rods.

All easier said than done, of course. So we spent some time sweating the details with the engine guys at Edelbrock to find out what it takes to whip an LS3 into a lather. After all, getting a thoroughbred to run harder and faster requires way more than just ringing a bell.

Consider the performance parts that Shaver Racing Engines installed into the LS3 block. Increasing the swept volume of the cylinder from 376 to 416 cubes begins with a Manley crankshaft boasting a 4.0-inch stroke (increased from 3.62 inches stock). It in turn pumps elongated H-beam connecting rods and aluminum pistons through a 4.065-inch bore.

While this stroked setup is a well-proven path, some background info shows just how far we’ve come in the last 16 years or so. Recall that the old 5.7L LS1 was inherently constrained by its 3.90-inch bores, so that even when honed almost to the water jacket, a 4.00-inch-stroke crank achieved only 383 inches. A larger bore required sleeving the cylinders—an expensive and not always reliable option, since coolant leaks and poor cylinder sealing often resulted.

In 2005, the LS2 featured siamesed cylinder bores, making a 400ci displacement possible with a stroker crank. Then just two years later, the 6.2L block was released (basically the same one found in the LS3), featuring a 4.065-inch bore. Now, hone out the bores by 0.005 inches and fit in a 4.00-inch crank, and voila—the displacement goes from 376 to 416 cubic inches.

What sort of crank does Edelbrock use? Manley’s lightweight design consists of 4340 forgings, nitrided for added strength, along with other treatments such as stress relieving, shot-peening, and magnafluxing. The large, 0.125 radius journals are micropolished and lightened as well. For sufficient clearance from the piston skirts, the counterweights are fully profiled, and the main journals are gun-drilled for further weight reduction.

The aforementioned Manley H-beam rods measure 6.125 inches (versus 6.098 inches stock), with the block clearanced to prevent interference with the rod bolts. As for the forged 2618-aluminum pistons, they have an 18cc dish, for a comparatively lower 9.5:1 compression to offset the increased airflow from the blower and ensure a smooth, knock-free burn of 91-octane pump gas. (In a naturally aspirated LS3 stroker, a CR of 11.7:1 is not uncommon, delivering an output of 600 horses or more.)

The pistons feature low-friction, 0.150-inch floating pins instead of pressed-fit units. In addition, Manley employs a one-fixture manufacturing process to maintain an optimum ring-groove-to-skirt squareness. An offset wristpin design reduces piston slap, and a bridging ring spans the pin area. Total Seal’s package has 1.5, 1.5, and 3mm rings. Roundwire locks, tool steel wristpins, and pressure balance grooves are included with every set.

As already noted in passing, a naturally aspirated stroker engine leaves some ponies on the table, which leads us right into supercharging—the source of the higher pressure mentioned at the outset. Edelbrock’s E-Force LS3 blower spins Eaton TVS 2300cc/rev four-lobe rotors with 160 degrees of twist. They’re designed for maximum flow, minimum temperature rise, and quiet operation for better driveability. An integrated bypass valve helps eliminate parasitic loss under light throttle for improved mileage potential (as if fuel efficiency is even a consideration when running a blown stroker).

E-Force superchargers have an innovative inlet configuration with a shorter, less restrictive intake path for improved airflow, and no need for a jackshaft. Keeping the air cool is a high-capacity, air-to-water intercooler and low temp heat exchanger.

The supercharger features a driver-side throttle body orientation for ease of intake routing in a variety of project vehicles, and a Corvette belt offset for a compact installation. The top of the supercharger measures 21.54 inches from crank centerline in its standard configuration. A special order is available for a lower profile, Corvette C6 lid for an additional 2 inches of hood clearance, and Edelbrock is receptive to other custom requests.

With the supplied 2.75-inch supercharger pulley, boost is approximately 12 psi. Even more pressure is possible, up to about 14 psi, by adding an optional overdrive crank pulley. To keep pace with increased airflow of the blower, Edelbrock supplies 60 lb/hr injectors and custom fuel mapping with its pre-programmed ECU. But for the higher psi figure noted above, a custom tune and bigger fuel pump would be required.

Typically, positive-displacement, supercharged cam profiles have wide lobe separations and minimal (or negative) overlap, hence the 121 LSA of the bumpstick. The hydraulic roller camshaft offers up to 215 degrees intake/247 degrees exhaust duration at 0.050 inch and 0.629/0.656-inch lift using the included 1.7:1 ratio roller rocker arms. The heads are high-flow LSA units designed for supercharged applications with a swirl feature on the intake ports that allows for more spark advance.

The Edelbrock GM LS 416-cid E-Force supercharged long-block crate engine comes complete with essential supercharger kit components, such as the electric intercooler water pump, intercooler plumbing and recovery tank, as well as fuel rails, 60 lb/hr fuel injectors, a mass airflow sensor housing, and a reusable air filter. A turnkey package with all the front-drive accessories is also available to suit the particular needs of vehicle builders.

Either way, this racehorse is ready to run in a Corvette or other projects. Just spank the flanks and you’re off!

1. Rather than a press-fit pin, the Manley pistons have low-friction, floating pins with an offset design to reduce piston slap.

2. Here’s a close-up of the bridge ring in the wristpin area.

3. Close-up of Manley’s H-beam rod and dished piston with valve clearance.

4. The camshaft is specifically configured for a supercharged application with a 121-degree lobe-separation angle.

5. Manley’s 4.00-inch crank not only has a longer throw, but also profiled counterweights for clearance.

6. Edelbrock uses stock GM LSA cylinder heads and rocker arms with its own Beehive springs (PN 5768) to accommodate the camshaft. LSA heads are identical to LS3 except that they are “rotocast” from A356T6 alloy to eliminate porosity. This makes for a stronger cylinder head with better heat dissipation, designed specifically for a supercharged application.

7. The standard supercharger assembly and matching aluminum coil covers are black powderedcoated for durability.

8. A low-profile Corvette lid (shown here) is available for the blower case, to provide an extra 2 inches of clearance. Normally, the top of the supercharger measures 21.54 inches from crank centerline.

9. This closeup of the low-profile blower case shows the driver-side throttle body orientation for ease of intake routing.

10. The standard pulley size delivers 12 psi of boost.

11. The Bosch MAP sensor comes mounted on the blower case.

Specs Displacement: 416 cid Horsepower: 720 hp Torque: 695 lb-ft Compression: 9.5:1 Block: GM LS3 aluminum Crankshaft: Forged 4340 Pistons: Forged aluminum - 18cc Rods: Forged H-beam Camshaft: 215°/247°, 0.629/0.656, 121 LSA Rocker Arms: LS3, 1.7 ratio Induction: E-Force Supercharger System (PN 1540) Cylinder Heads: GM LSA with Edelbrock valvesprings (PN 5768) Finish: Black powdercoat Warranty: 2-year / Unlimited mileage

At a fairly high 6,500 rpm, Edelbrock’s 416ci stroked and supercharged LS3 hits its peak horsepower of 720 hp. Peak torque of 695 lb-ft is at 4,500 rpm and is nearly instantaneous. If the dyno read lower, we’d bet this flat line extended all the way to 3,000 rpm or below. That’s the kind of power you can really feel leaving a stoplight.

At a fairly high 6,500 rpm, Edelbrock’s 416ci stroked and supercharged LS3 hits its peak horsepower of 720 hp. Peak torque of 695 lb-ft is at 4,500 rpm and is nearly instantaneous. If the dyno read lower, we’d bet this flat line extended all the way to 3,000 rpm or below. That’s the kind of power you can really feel leaving a stoplight.