Moreno Valley, California, resident Rex Thomas bought his 1977 Mustang II as a derelict back in 2000. Ever since, the original V8/C4 auto trans car has been a work in progress. The now-retired postal worker says he “was trying to fix things up so it would be a nice car to drive.” The engine has had one issue after another. According to Rex, “It was in and out of the car at least four or five times to replace major parts.” When a cylinder finally cracked five years ago, he scratch-built a whole new engine based around a 1989 5.0L cylinder block and 1985 heads. “I piece-worked the engine together incrementally.” Although the late-model block was factory roller-cam-compatible, Rex—on a retiree’s budget—put in a flat-tappet RV cam and initially reused the original two-barrel, variable-venturi carb. However, Rex says the “POS” carb had never worked right as long as he owned the car, so eventually he decided to take the EFI plunge, which potentially could make the car California smog-legal with referee approval as an “engine swap.” “I bought the parts for a late-1980’s 5.0L EFI system on eBay. It took a long time to do it. I had to learn about EFI—and I’m not a Ford expert.”

Rex Thomas purchased his 1977 Mustang II back in 2000 and has been incrementally fixing its myriad issues ever since.

Rex Thomas purchased his 1977 Mustang II back in 2000 and has been incrementally fixing its myriad issues ever since.

When he finally got the EFI up and running about a year ago, a frustrated Rex laments, “There were so many problems I can’t remember them all!” Idle quality was unstable and the car often stalled. Fuel mileage was horrible. Acceleration was lazy. Rex took the car to three different shops—none could fix it. Enter Mark Sanchez at Advanced Engineering, HOT ROD’s go-to SoCal Ford fuel-injection and retrofit expert. With the car now at Sanchez’s compound, we hoped the fourth time would be the charm.

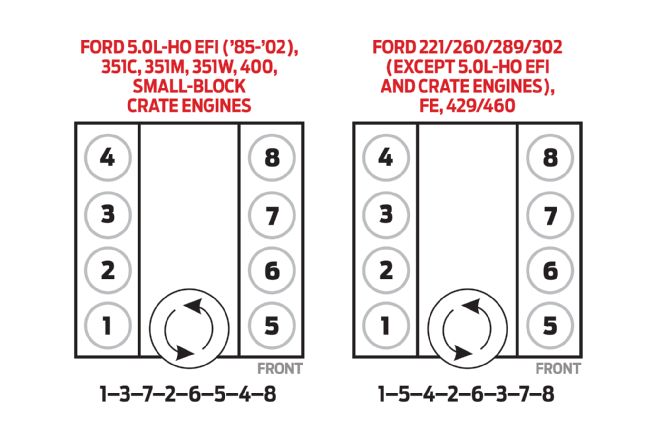

Fundamental error: The firing order of the distributor and flat-tappet cam didn’t match that of the late-model 5.0L-SFI computer.

Fundamental error: The firing order of the distributor and flat-tappet cam didn’t match that of the late-model 5.0L-SFI computer.

After noting the Mustang’s “extremely bad idle and acceleration,” Sanchez says he “found the basic problem within two minutes of popping the hood—the computer and firing order were mismatched.” He could see the distributor cap was wired to conform to the old Ford carbureted 302’s 1-5-4-2-6-3-7-8 firing order. That’s correct for the original 1977 engine and Rex’s flat-tappet cam, but totally wrong for a 5.0L Mustang with sequential fuel injection (SFI) that uses an engine control unit (ECU, aka “the computer”) set up for a 1-3-7-2-6-5-4-8 order.

Ford EFI expert and retrofit specialist Mark Sanchez at AEW diagnosed and fixed the car’s firing order and Sensor problems.

Ford EFI expert and retrofit specialist Mark Sanchez at AEW diagnosed and fixed the car’s firing order and Sensor problems.

The Mustang would never run right until the sequential injectors’ firing order was fixed. “The car had been to numerous shops, but no one had enough common sense to pick this basic problem up,” Mark says.

Sanchez rewired the late ECU’s injector driver output wires to match the car’s early firing order, then dealt with a bunch of Sensor issues.

Sanchez rewired the late ECU’s injector driver output wires to match the car’s early firing order, then dealt with a bunch of Sensor issues.

A scan-Tool plugged into the vehicle’s diagnostic port revealed a passel of Sensor trouble codes that required either proper adjustment or replacement of multiple Sensors and Relays. The Neutral/Drive Switch (NDS) at the trans was also MIA, there were problems with the mass-airflow Sensor (MAF) and air-filter layout, the O₂ Sensor location, the idle air control (IAC) motor, and even the fuel pump and fuel line routing and plumbing. But first things first: Fix the frakked-up firing order.

Mark confirmed the computer was indeed for a 1989 Mustang 5.0L EFI application with the “late” firing order. If Thomas had used a 5.0L EFI F-150/F-250 pickup truck ECU, everything would have worked out because the trucks had less timing-sensitive batch-fire injector sequencing. Still, Mark was able to make the Mustang’s sequential-fire ECU work by swapping the injector-firing wires in its 60-pin master connector to correspond to the different firing order. With the basic problem fixed, Sanchez went on to address the failed Sensors and fine-tune the retrofit installation.

The 5.0L-SFI retrofit had many mismatched parts. The second wire counterclockwise after the distributor cap’s No. 1 was routed to the No. 5 cylinder on the driver side, cueing Sanchez the engine’s firing order didn’t match the late-model ECU. Sensor problems generated additional codes. The EFI intake’s upper plenum had been flipped to the driver side to clear the battery, but that caused some interference between the throttle-body and fuel rails. (The “correct” fix is a Crown Vic throttle-body and fuel rails.) The numbered callouts refer to detail photos on these pages.

The 5.0L-SFI retrofit had many mismatched parts. The second wire counterclockwise after the distributor cap’s No. 1 was routed to the No. 5 cylinder on the driver side, cueing Sanchez the engine’s firing order didn’t match the late-model ECU. Sensor problems generated additional codes. The EFI intake’s upper plenum had been flipped to the driver side to clear the battery, but that caused some interference between the throttle-body and fuel rails. (The “correct” fix is a Crown Vic throttle-body and fuel rails.) The numbered callouts refer to detail photos on these pages.

The O₂ Sensors were located too close to the exhaust flange on the car’s log-type exhaust manifolds, where they couldn’t equally sample all the cylinders on their respective banks. The Sensors themselves were of unknown origin. Sanchez recommends the use of genuine Ford or Motorcraft Sensors engineered specifically for the application. “Even real Ford Sensors may appear identical, but there are different calibrations for different vehicles. If the calibration is off, the average range of value will be skewed, and the vehicle can run too rich or lean.” Sanchez replaced the Sensors with gennie 1989 Mustang 5.0L EFI Ford units, relocating them downstream after the exhaust manifolds where they’d have common sampling points.

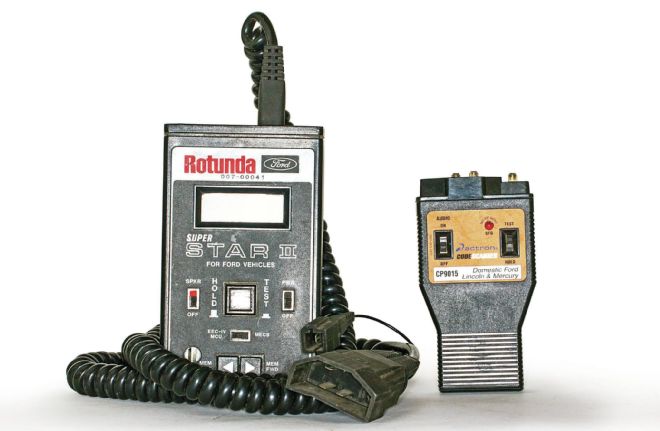

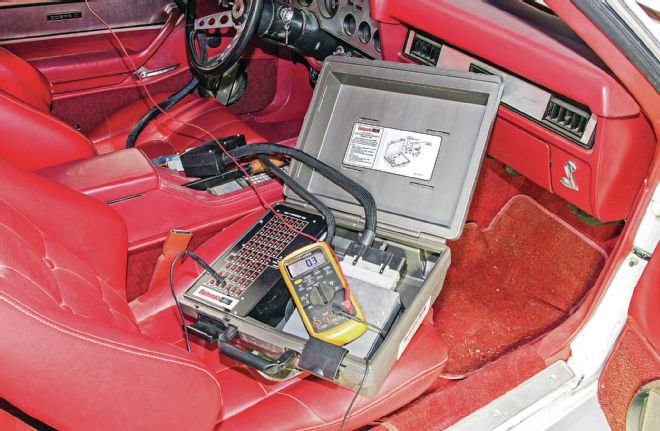

Anyone working on OE electronically managed engines needs a code scanner. One affordable Ford solution is Actron’s $20 CP9015 (right)—it can at least statically read the codes. High-end (pricey) solutions include the now-osbolete Rotunda Super Star II (PN 007-00041, left); it reads codes and runs diagnostic tests in real time on a running engine. Even more sophisticated units are now available from Rotunda.

Anyone working on OE electronically managed engines needs a code scanner. One affordable Ford solution is Actron’s $20 CP9015 (right)—it can at least statically read the codes. High-end (pricey) solutions include the now-osbolete Rotunda Super Star II (PN 007-00041, left); it reads codes and runs diagnostic tests in real time on a running engine. Even more sophisticated units are now available from Rotunda.

Ford numbers its V8 cylinders consecutively down each bank, starting with No. 1 on the passenger side. Rex’s cam and distributor were set up for the early 302 firing order, but the 5.0L-EFI Mustang ECU was wired for the late-model firing order. It was a wonder the car ran at all.

Ford numbers its V8 cylinders consecutively down each bank, starting with No. 1 on the passenger side. Rex’s cam and distributor were set up for the early 302 firing order, but the 5.0L-EFI Mustang ECU was wired for the late-model firing order. It was a wonder the car ran at all.

The exhaust gas recirculation (EGR) valve regulator’s coil was bad (had no resistance), and the EGR position Sensor couldn’t properly determine what position the EGR valve was in as it moves through its cycle. This caused the car to run full rich. Mark replaced both.

The Thermactor (smog pump) control circuitry had a failed Thermactor air bypass (TAB) and Thermactor air diverter (TAD). This causes catalytic converter light-off problems as well as the O₂ Sensors to read lean, resulting in an excessively rich mixture. All were replaced.

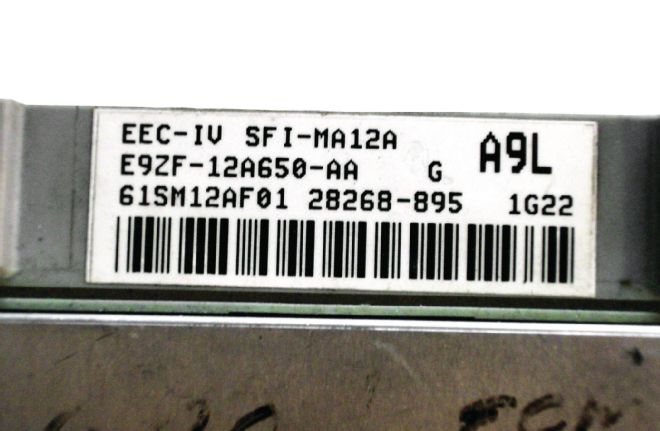

At least Rex’s car did have the “A9L” 1989 Ford 5.0L Mustang stick-shift California ECU. Sanchez says, “It’s the best 5.0L Mustang processor ever, with a huge air-correction window. You can get away with the stupidest s**t with it, and the car will still run. It even works fine with automatics.” Combined with MAF metering, this ECU is very tolerant of hot rod mods.

At least Rex’s car did have the “A9L” 1989 Ford 5.0L Mustang stick-shift California ECU. Sanchez says, “It’s the best 5.0L Mustang processor ever, with a huge air-correction window. You can get away with the stupidest s**t with it, and the car will still run. It even works fine with automatics.” Combined with MAF metering, this ECU is very tolerant of hot rod mods.

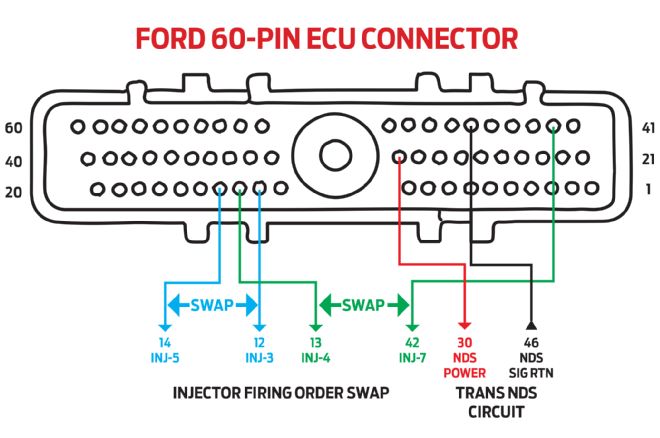

Sanchez fixed the firing order by swapping the injector-firing wires in the ECU’s 60-pin master connector to correspond to the different firing order. “Flip the wires normally connected to connector cavities 14 and 12. Then move wire 13 to 42, and 42 to 13. This changes a 1-3 firing-order ECU to the early 1-5 order.” Also note the NDS circuit add-on wiring.

Sanchez fixed the firing order by swapping the injector-firing wires in the ECU’s 60-pin master connector to correspond to the different firing order. “Flip the wires normally connected to connector cavities 14 and 12. Then move wire 13 to 42, and 42 to 13. This changes a 1-3 firing-order ECU to the early 1-5 order.” Also note the NDS circuit add-on wiring.

To check ECU wiring, hard-core Ford techs like Sanchez use breakout boxes that eliminate the need to back-probe the connector cavities or pierce the wire insulation. OTC PN 3235 works with up to 104-pin ECU connectors. With Rotunda adapter 014-00951 it still works on earlier 60-pin connectors as used on the 1989 5.0L ECU.

To check ECU wiring, hard-core Ford techs like Sanchez use breakout boxes that eliminate the need to back-probe the connector cavities or pierce the wire insulation. OTC PN 3235 works with up to 104-pin ECU connectors. With Rotunda adapter 014-00951 it still works on earlier 60-pin connectors as used on the 1989 5.0L ECU.

The throttle position Switch (TPS) was out of range: In order to keep the car running with its mismatched firing order, it had been deliberately misadjusted to raise idle speed. Once Sanchez fixed the firing-order problem and repaired or replaced the faulty Sensors, he was able to achieve a stable 750-rpm Park idle-speed, and adjust the TPS to read “exactly 1 volt at idle, the setting preferred by performance guys.”

Installing the breakout box between the connector and ECU allows checking before/after electrical integrity, voltage, and correct wire firing sequencing. This is the early version (OTC PN 3225) that only works with the 60-pin connectors. The old 60- and 104-pin boxes have been superseded by Ford Rotunda PN NUD105-R0108, which comes with adapters that handle any 1986–present Ford ECU. Check auction sites like eBay for reasonably priced used older boxes.

Installing the breakout box between the connector and ECU allows checking before/after electrical integrity, voltage, and correct wire firing sequencing. This is the early version (OTC PN 3225) that only works with the 60-pin connectors. The old 60- and 104-pin boxes have been superseded by Ford Rotunda PN NUD105-R0108, which comes with adapters that handle any 1986–present Ford ECU. Check auction sites like eBay for reasonably priced used older boxes.

After swapping the pins in the ECU connector, Mark used the breakout box at the ECU connector end along with a standard digital multimeter attached to the injector wires in the engine bay to see which injector is getting voltage and under what conditions.

After swapping the pins in the ECU connector, Mark used the breakout box at the ECU connector end along with a standard digital multimeter attached to the injector wires in the engine bay to see which injector is getting voltage and under what conditions.

Many OE 1983–1991 Fords experienced intermittent idle problems. Ford had a service fix (Google “TSB 91-25-07”) that references an IAC flow-control valve Kit with two manual adjustment screws (arrows). The valve itself is stamped “F2PE-9F942-AA” and is still available new from Ford dealers under PN F2PZ-9F939-A.

Many OE 1983–1991 Fords experienced intermittent idle problems. Ford had a service fix (Google “TSB 91-25-07”) that references an IAC flow-control valve Kit with two manual adjustment screws (arrows). The valve itself is stamped “F2PE-9F942-AA” and is still available new from Ford dealers under PN F2PZ-9F939-A.

That left the antistall NDS, which on stock 5.0L cars is built into the AOD (automatic overdrive) trans. The old C4 trans lacks internal provisions for this Sensor, so Sanchez installed a generic Switch on the shift linkage.

Originally issued to eliminate the need to clean sludge buildup off IAC sliders, the valve Kit installs between the IAC motor and the throttle-body (arrow). Just like an old-school carburetor’s idle-speed and idle-mixture screws, the valve can be manually adjusted to fine-tune the idle, so it’s also proven a real boon for hot rodders dealing with pesky idle issues on nonstock installations.

Originally issued to eliminate the need to clean sludge buildup off IAC sliders, the valve Kit installs between the IAC motor and the throttle-body (arrow). Just like an old-school carburetor’s idle-speed and idle-mixture screws, the valve can be manually adjusted to fine-tune the idle, so it’s also proven a real boon for hot rodders dealing with pesky idle issues on nonstock installations.

Collectively, these fixes vastly improved idle quality, but there was still an occasional, intermittent idle instability, especially under cold-start conditions. The IAC should be able to compensate for momentary idle-speed fluctuations, but even the original, stock 5.0L Mustangs sometimes had issues in this regard. Ford issued a service fix adjustable bypass flow-control valve to address them. It’s still available from Ford and Sanchez installed it as the final idle-quality enhancement.

Rex’s idle stability and stalling have been fully rectified, and the engine now runs smooth overall. However, with the basics cured, some chronic problems still remain: Sanchez identified an airflow turbulence issue with the existing air filter and air inlet duct. In this case, the flow was going around the edges of the filter and MAF, creating a vortex. Sanchez explains he “temporarily fixed the problem during tuning with a cardboard baffle. The owner will fabricate a permanent aluminum baffle for a final fix.”

Sanchez temporarily fixed a lean-reading MAF meter condition with this cardboard baffle. “When the MAF Sensor gets a bad signal from the air,” explains Sanchez, “it causes turbulence. The flow isn’t smooth, so it gets a bad reading.”

Sanchez temporarily fixed a lean-reading MAF meter condition with this cardboard baffle. “When the MAF Sensor gets a bad signal from the air,” explains Sanchez, “it causes turbulence. The flow isn’t smooth, so it gets a bad reading.”

The Mustang still retained its old-school 1977 C4 precomputer auto trans. This photo shows the new O2 Sensor location, plus the late-model Sensors added to the trans.

The Mustang still retained its old-school 1977 C4 precomputer auto trans. This photo shows the new O2 Sensor location, plus the late-model Sensors added to the trans.

Additionally, Thomas’s primary electric fuel pump and undersized filter are, in Sanchez’s opinion, “located too close to the front of the car—it’s a pusher pump being used here as a puller. This created [a vacuum] in the fuel line, so the owner installed another pump near the gas tank to feed the front pump, but it’s not big enough. The main pump was overheating because it was starving. After warm-up, during extended driving, this causes a fuel-pressure fluctuation. And that means the injectors aren’t delivering fuel correctly, and the O₂ Sensors are always chasing the fluctuation. This issue still needs correction.”

BEFORE The 5.0L V8 Mustangs use two O2 Sensors, one per cylinder bank. They had been installed too far upstream, relatively close to the heads (driver-side, shown). Besides running hot, they couldn’t accurately sample all cylinders on that bank."> <strong>BEFORE</strong> The 5.0L V8 Mustangs use two O2 Sensors, one per cylinder bank. They had been installed too far upstream, relatively close to the heads (driver-side, shown). Besides running hot, they couldn’t accurately sample all cylinders on that bank.

AFTER For more accurate sampling, Sanchez relocated the Sensor mounting locations downstream beyond the end of the exhaust manifolds. This also keeps them cooler (driver-side, shown). ">

<strong>BEFORE</strong> The 5.0L V8 Mustangs use two O2 Sensors, one per cylinder bank. They had been installed too far upstream, relatively close to the heads (driver-side, shown). Besides running hot, they couldn’t accurately sample all cylinders on that bank.

AFTER For more accurate sampling, Sanchez relocated the Sensor mounting locations downstream beyond the end of the exhaust manifolds. This also keeps them cooler (driver-side, shown). ">

<strong>AFTER</strong> For more accurate sampling, Sanchez relocated the Sensor mounting locations downstream beyond the end of the exhaust manifolds. This also keeps them cooler (driver-side, shown).

<strong>AFTER</strong> For more accurate sampling, Sanchez relocated the Sensor mounting locations downstream beyond the end of the exhaust manifolds. This also keeps them cooler (driver-side, shown).

Rex’s generic Sensors were replaced with genuine Ford Racing–sourced Sensors that are factory-calibrated to work properly with the Mustang ECU. In 1989, the heated, three-wire, Sensors were still narrow-band, so proper OE calibration is crucial. Sanchez mounted them in Accufab stainless steel O2 bungs installed at the new downstream mounting locations.

Rex’s generic Sensors were replaced with genuine Ford Racing–sourced Sensors that are factory-calibrated to work properly with the Mustang ECU. In 1989, the heated, three-wire, Sensors were still narrow-band, so proper OE calibration is crucial. Sanchez mounted them in Accufab stainless steel O2 bungs installed at the new downstream mounting locations.

The precomputer C4 trans has no provisions for the NDS that prevents stalling in gear. Sanchez installed a generic single-pole, single-throw (SPST), normally open (NO) Switch on the C4’s shift linkage. It closes in gear, signaling the ECU to raise engine speed by 150 rpm. Wire the nonpolarized Switch to ECU connector cavities 30 (power-out) and 46 (ground) (ill. 05).

The precomputer C4 trans has no provisions for the NDS that prevents stalling in gear. Sanchez installed a generic single-pole, single-throw (SPST), normally open (NO) Switch on the C4’s shift linkage. It closes in gear, signaling the ECU to raise engine speed by 150 rpm. Wire the nonpolarized Switch to ECU connector cavities 30 (power-out) and 46 (ground) (ill. 05).

A vehicle speed Sensor (VSS) is needed to keep a computer engine from stalling on deceleration. This piggyback VSS can run the old Mustang’s mechanical speedo while providing the needed electrical input to the ECU. Stock on 1988–1993 Mustangs with all engine and transmission options, it even fits the old C4, screwing right into its existing speedometer cable hole.

A vehicle speed Sensor (VSS) is needed to keep a computer engine from stalling on deceleration. This piggyback VSS can run the old Mustang’s mechanical speedo while providing the needed electrical input to the ECU. Stock on 1988–1993 Mustangs with all engine and transmission options, it even fits the old C4, screwing right into its existing speedometer cable hole.

Really designed as a “pusher,” the main fuel pump was installed about halfway between the fuel tank and the engine, too far from the fuel tank, forcing it to act as a “puller.” Plus, Sanchez says the filter feeding it is too small. The poor mounting location and restrictive filter causes the pump to pull a vacuum and run hot, reducing its output.

Really designed as a “pusher,” the main fuel pump was installed about halfway between the fuel tank and the engine, too far from the fuel tank, forcing it to act as a “puller.” Plus, Sanchez says the filter feeding it is too small. The poor mounting location and restrictive filter causes the pump to pull a vacuum and run hot, reducing its output.

To crutch the poor forward pump-mounting location, back by the fuel tank the owner built this Rube Goldberg–like rear fuel-supply system with an additional small pump incapable of delivering sufficient fuel to the big pump up front. The filters cause even more restriction; they’re not needed because the stock tank already has an in-tank sock. The pump is also mounted too high, above the tank. The one smart move was adding an external reservoir. Mark will be relocating the big pump to the rear, properly mounting it below the tank so it can gravity-feed.

To crutch the poor forward pump-mounting location, back by the fuel tank the owner built this Rube Goldberg–like rear fuel-supply system with an additional small pump incapable of delivering sufficient fuel to the big pump up front. The filters cause even more restriction; they’re not needed because the stock tank already has an in-tank sock. The pump is also mounted too high, above the tank. The one smart move was adding an external reservoir. Mark will be relocating the big pump to the rear, properly mounting it below the tank so it can gravity-feed.

The reservoir is needed because the 1977 fuel tank isn’t baffled to prevent starvation in hard turns with a high-pressure EFI system, which doesn’t have float bowls to act as reservoirs like an old carburetor. Flow path is: inlet from the small rear pump (A), outlet to the big forward pump and engine, engine bypass return, and (if the reservoir gets full) return to tank.

The reservoir is needed because the 1977 fuel tank isn’t baffled to prevent starvation in hard turns with a high-pressure EFI system, which doesn’t have float bowls to act as reservoirs like an old carburetor. Flow path is: inlet from the small rear pump (A), outlet to the big forward pump and engine, engine bypass return, and (if the reservoir gets full) return to tank.

Order parts that correspond to the model year of the engine you are retrofitting, not the car’s model year. Rex used model year 1977 to piece the motor together and order parts. That got him into trouble when converting to EFI. With individual parts sourced separately on eBay, the EFI set-up itself was not fully compatible, with several mismatched parts. Lack of knowledge kept Thomas from fully exploiting the technology of the roller-cammed 1987–1989 5.0L engine. Be sure to research engine changes and evolution before diving in, especially with tricky Ford engines. If you must incrementally piece things together, come up with a master plan and stick with it to avoid incompatibilities. “Don’t ‘Johnny Cash’ your car!” sums up a laconic Sanchez, referencing Cash’s iconic car-ballard “One Piece at a Time.”

The Mustang II now idles and runs smoothly. It will even be capable of passing California’s stringent smog check as an engine conversion.

The Mustang II now idles and runs smoothly. It will even be capable of passing California’s stringent smog check as an engine conversion.

Parts and Prices Includes the major parts required to fix the problem. Does not include miscellaneous small parts, labor, tuning, shipping, or sales taxes. Priced 12/12/14 and subject to change. Brand Part Description Part No. AMT. Price Source Cost Accufab Fitting, oxygen Sensor OXYFIT 2 Accufab $19.98 Actron Tool, diagnostic code reader, OBD-1, 1981–1995 Ford CP9015 1 AutoZone $19.99 Duralast¹ Sensor, barometric air pressure (BAP) SU216 1 AutoZone $72.99 Sensor, EGR position SU209 1 AutoZone $29.99 Sensor, VSS, electro/mechanical w/ speedometer cable-drive provisions² SU1022 1 AutoZone $19.99 Ford Racing Relay & Sensor PKG., includes dual O2 Sensors, EGR valve regulator solenoid, Thermactor TAD & TAB solenoids, and fuel, A/C, and EEC power Relays³ M-12071-K302 1 Don Wood Ford $104.34 Ford Service Kit, IAC bypass and flow-control valve, adjustable, w/ seals F2PZ-9F939-A 1 University Ford4 $59.54 Omron Switch, basic, miniature, SPST, NO, simulated roller lever, 0.250" quick-connect terminals5 D3V-16G4-3C5-K 1 Mouser Electronics $2.27 Notes: ¹Duralast is AutoZone’s private-label brand. ²Already installed by owner prior to Rescue. ³The Kit’s included Relays weren’t needed for this rescue, but buying the entire Kit is less expensive than buying the other parts individually. 4Via eBay store. 5Used as trans Neutral/Drive Switch; an equivalent Switch with the same functionality may be substituted. Total $329.09

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at [email protected] and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.