Jason Teixeira was one happy dude in the summer of 2012. On July 27, the Shelton, Connecticut, proprietor of the popular mustangjunkies.net website walked into Stevens Ford in Milford, Connecticut, and, after some negotiating, drove away in a brand-new Grabber Blue Mustang Shelby GT500. Being a performance junkie, Jason was sure to specify the SVT Performance Package for its steeper 3.73 axle ratio. The rest of the goodies (staggered 19/20-inch rim diameters, grippier tires, rear spoiler with Gurney flap, and tighter suspension settings) take a back seat to the enhanced acceleration the lower cogs deliver.

One other thing: The price Jason paid did not include the federally mandated Gas Guzzler Tax he would have paid if he’d bought a 2010 Shelby GT500. Why not? That’s because Ford managed to shave a whopping 102 pounds from the super ’Stang’s curb weight, which improved EPA fuel economy ratings to 15/23 mpg, exempt from Gas Guzzler territory. So how did Ford do it?

Taking a well-worn page from its Mod motor recipe book, the drastic weight reduction was simply the result of switching the engine block material from cast iron (2010) to aluminum for 2011 and beyond. The switch wasn’t revolutionary; Ford had been toggling Mustang engine block material between aluminum and iron since 1996 when basic 2-valve 4.6 Mustang GT’s got the iron lump and exotic 4-valve 4.6 Mustang Cobra buyers got the sexier aluminum block.

What made the 2011 Shelby GT500 Mustang’s 5.4 aluminum block unique in Mod motor history was its lack of the integrally cast iron cylinder liners found in preceding DOHC 4.6 aluminum blocks, as well as the special 5.4 aluminum block used in the exotic mid-engine Ford GT supercar. To shave every last ounce, Ford teamed with Flame-Spray Industries, Inc. to further develop Flame-Spray’s PTWA (Plasma Transferred Wire Arc) technology and application process.

In a nutshell, a single conductive wire stock consisting of the necessary properties for cylinder-wall survival is exposed to a plasma jet, which accelerates the atomized molten droplets against the aluminum at supersonic velocity. When contact is made, the droplets flatten, overlap, and cover the aluminum block surface with a microscopically thin surface barrier that’s capable of duplicating the characteristics of traditional iron at a fraction of the weight. Repeated application builds enough thickness to suit the needs of the job at hand. The PTWA plasma coating used in Shelby 5.4 engine blocks is about 0.005 inch thick.

You can bet Ford hasn’t adopted this technology without a world-class validation process to ensure it is ready for the harshest users. Though some Shelby GT500 buyers have tucked their prizes away for future generations to appreciate, just as many guys see the 540hp factory rating as a mere jumping-off point. And so it is with Jason’s Shelby, which he has nicknamed the Smurfinator, thanks to its Smurf-esque blue hue.

Over the course of the last 20 months, he’s racked up more than 6,000 street miles and more than 60 quarter-mile passes. Modifications include a 2.3L TVS supercharger with 20 pounds of boost, Kooks 1-7/8 headers, a Whipple 123-mm MAF housing, a L&M twin 72mm throttle-body, an Innovators West 15 percent overdrive pulley, and a Ford Racing Cobra Jet cold-air intake. Rolled together, the massaged Shelby pegs the Mustang chassis dyno (notoriously realistic) at 712 hp, while running a best of 10.31 at 136 on M&H 315-50-15 drag radials. Through it all, Jason says the stock rear suspension, clutch, and 6-speed manual transmission have endured hundreds of 6,200-rpm power shifts just fine.

And about that cutting-edge plasma cylinder wall coating—despite plenty of cries from naysayers, the PTWA plasma cylinder walls seemed to be doing just fine. But Jason had his doubts. No, the engine wasn’t burning oil, kicking “check engine” lights, or doing anything unusual. He just had a hunch he’d eventually run into the limit soon, since more go-faster modifications are planned. It kept him up at night.

To restore peace of mind, Jason yanked the otherwise healthy 5.4 Cobra mill in the winter of 2014 and delivered it to R.A.D. Auto Machine of Ludlow, Massachusetts, for installation of Darton steel cylinder sleeves. The process is pretty straightforward and takes about a day. Let’s watch as Steve Chmura and the crew at R.A.D. Auto Machine install a full set of sleeves and give this Shelby room to grow.

The stock 91.4-pound block gains 21 pounds after sleeving. But the added potential for future displacement growth, repairs, and extra boost easily offset the added nose weight. Listed as a non-service item by Ford, replacement blocks cost $5,000, while the sleeve upgrade is about half that amount.

Before digging in, R.A.D. Auto Machine lightly honed the cylinders to show how delicate the factory PTWA coating is. The dark region is the engine block’s unprotected parent aluminum. Note the uneven pattern, an indication the bores are no longer round. Since "mere mortals" lack the ability to restore the exotic PWTA thermally applied plasma surface, steel sleeve inserts are the way to go.

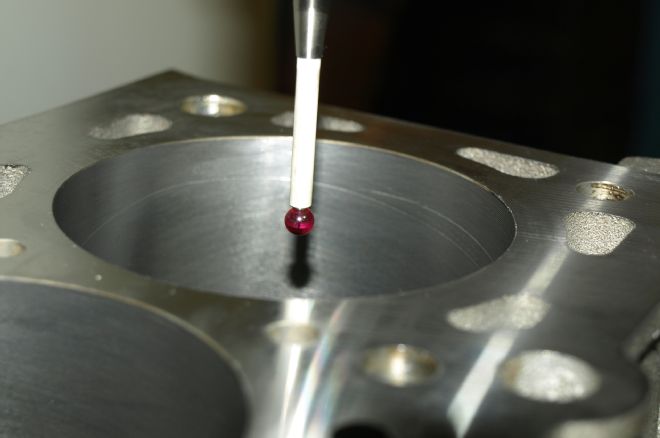

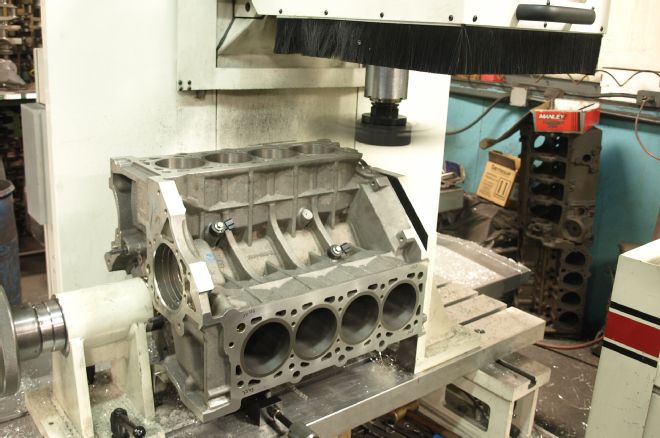

With the block mounted in R.A.D.’s Rottler F79A three-axis CNC milling station, machinist Steve Chmura uses an $8,000 Renishaw RMP probe (PN M-4071-0058) to map the block’s X, Y, and Z coordinates in relation to the movable bed so automated metal removal is done accurately.

The probe’s spherical ruby tip is placed against various positions in the bores and block to define the work zone. Subsequent table and cutter head movements will be dictated entirely by these coordinates. The probe can also compare the block’s actual dimensions to an ideal Ford blueprint spec. This particular block was found to have its cylinder bores positioned 0.0009 rearward and 0.0052 toward the driver-side spring tower (versus ideal). The error will be corrected with the new sleeves.

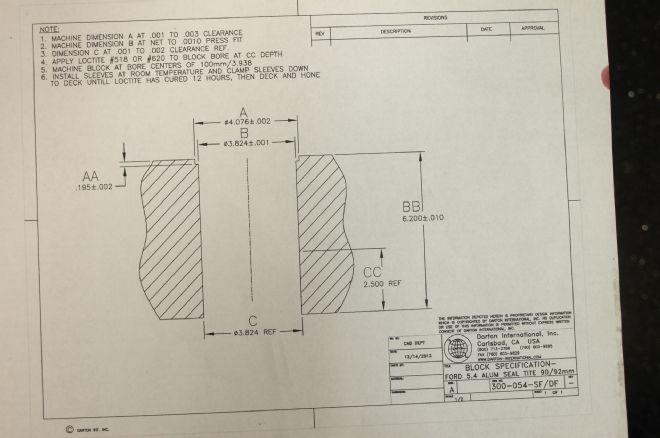

Darton provides this nifty blueprint/instruction sheet with directions to describe where block material must be removed to make way for each 6.200-inch-tall sleeve. The cutter depth data is fed into the Rottler’s computer via a keyboard.

The Rottler’s boring bar is fitted with a cutting tip that will temporarily enlarge each bore from 3.52-inch (stock) to 3.793-inch (0.273-inch larger than stock). Steve takes three 0.080-inch cuts, then sneaks up on the final dimension with series of lighter cuts.

The cobra sheds its skin. Photographed through a safety shield, the cutter makes quick work of the aluminum. Chmura says it’s important to repeatedly clear the chips during cutting so they don’t accumulate in the cutter and make scratches.

The process is performed on each bore, one at a time. Compare the shiny surfaces of the two machined bores on right with the dull finish of the stock PWTA-coated bore on left (finger points).

Here, all bores are enlarged to 3.793-inch, as highlighted by the reduced 0.115-inch space between bores. Before surgery, this section was 0.387-inch thick. We’re halfway home.

Next, the top of each bore is machined 0.195-inch deep to create a 4.076-diameter, counter-bored shelf. This is where the top flanges of the steel sleeve inserts will rest. The sleeves require a 0.002-inch press fit to ensure stability and zero movement once installed in the block.

Bits of loose material and sharp edges can break off and prevent free passage of the sleeve inserts during installation. To prevent this, a light pass is made with the ball hone.

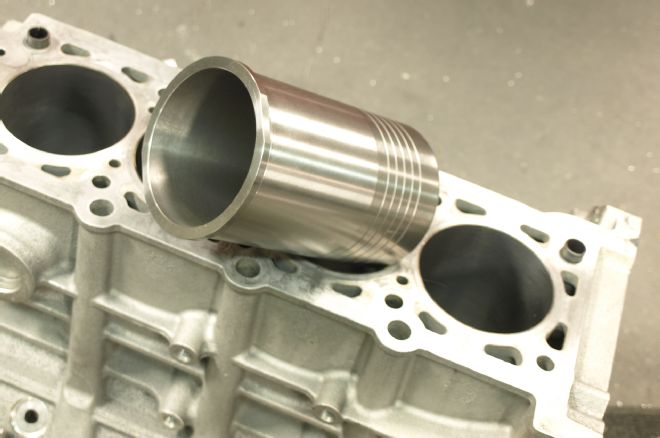

Darton’s Ford 5.4 aluminum block sleeve master kit uses straight wall (aka tubular) sleeves with 0.323-inch thick walls. The 6.200-inch overall height, 4.250-inch outside diameter and 4.702-inch flange diameter is the same for each of the eight sleeves. The shapes of the 0.400-inch-thick flanges are tailored to interlock via machined flats when installed. Cylinders 1 and 8 use sleeve PN 300-052-SF1; cylinders 4 and 5 use sleeve PN 300-054-SF2; and cylinders 2, 3, 6, and 7 take sleeve PN 300-054-DF. All necessary sleeves are included in the master kit (PN 700-125) that is sold through Darton’s distributors for about $1,300.

A few hours before they’re needed, the sleeves are put into a freezer to shrink them a bit for easier installation.

Likewise, an acetylene torch is used to warm the aluminum block. Plenty of time is spent ensuring the heat is applied evenly, and the whole block is quite warm to the touch (but never hot enough to burn skin). Localized overheating must be avoided.

Darton provides a tube of Loc-Tite 518 (red), which is applied to the warmed bores prior to sleeve installation. Though sleeve preparation machine work on the Ford modular V8 block does not intrude into coolant passages, the Loc-Tite helps bond the sleeves in place.

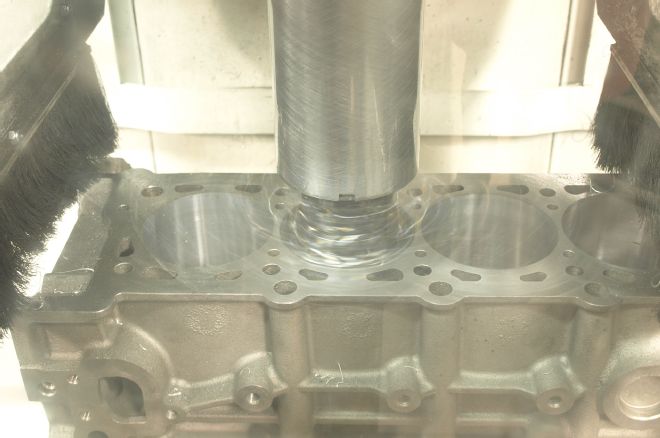

This series of pictures shows how easily the sleeves drop into their bores. A soft mallet is used to seat each sleeve onto the machined ledge deep in the block. Once cooled to room temperature, a safe 0.002-inch press-fit results.

With the opposite bank in process, note how the flanges of the installed sleeves stand about 0.007 taller than the surrounding deck. Also note how each sleeve has a specific flange intersection contour. Pay close attention and grab the right sleeve during installation to ensure they intersect as intended. If the block begins to cool while you fiddle, greater force will be needed to drive the sleeves home. You don’t want that. Generally speaking, sleeves that are supported by the deck (like this) are more stable than sleeves supported at their bases (deep in the block). Block architecture generally dictates which support method must be employed.

Once all of the sleeves are in place, Darton suggests clamping them for several hours to properly set the Loc-Tite. Here, a BHJ Products torque plate (PN FO-4.6/5.4-R-AL-T) and 1.850-tall spacers (to duplicate the thickness of a DOHC cylinder head) are installed and torqued to 80 lb-ft.

Once the Loc-Tite has cured, the tops of the sleeves are machined to remove excess height. A very light pass levels the tops of the sleeves so each stands exactly 0.002 inch taller than the surrounding aluminum deck surface. This will help compress the fire rings and seal the head gasket when the engine is assembled.

The final process involves boring the sleeves 0.025-inch oversize, then mounting the block (still fitted with torque plate) into R.A.D.’s Rottler HP6A hone for the final 0.005-inch cut. Here a diamond hone is used to apply a plateau finish to the bores for quick ring sealing. Final bore size is 3.552-inch (0.030-inch oversize). Darton’s sleeves are capable of a 0.180-inch overbore, which would yield 365 cubes with stock stroke. There’s plenty of room here for future growth—or repairs.

R.A.D. Auto Machine’s Steve Chmura and Donnie Wood (right) pose with the revived Shelby block. In addition to the sleeves, car owner Jason Teixeira is upgrading to Weisco coated pistons and Manley billet steel rods so he can really crank up the boost and put the Smurfinator into the 9s.