In case you missed the previous installments of the Slick-Built Small-Block (SBSB), we've built this 340/416 combo to be a fun street driver that is competitive with classic and modern muscle cars. In Parts 1 and 2, our friends at IDM Speed and Machine performed all the necessary machine work needed for the SBSB to be a reliable, strong runner. After dyno testing, we will implant it into the Slick Challenger, a 1973 Dodge Challenger Rallye 340 with a factory Pistol-Grip four-speed that we've been rebuilding.

As a refresher, this 93-octane pump gas street stroker ('72-casting, 340 block) consists of nothing but durable, high-quality components. For a dependable rotating/reciprocating assembly we chose Scat Crankshafts. The valvetrain came from COMP Cams with the exception of Smith Brothers pushrods. Our oiling system features a Milodon road-race pan with stock ground clearance. Holding it all together are fasteners from both Milodon and ARP. Gaskets from Cometic will keep it sealed up.

On the top end are the popular and reliable made-in-USA Edelbrock Performer RPM heads. Also from Edelbrock is an RPM Air-Gap dual-plane intake manifold that is proven to provide more street-style torque than any single-plane intake. In Part 2, the Edelbrock heads received a street-oriented home porting job by your author, followed by flow-bench testing and cc'ing. The Air-Gap's carburetor base/plenum area was massaged and the port exits were deep gasket matched by blending 2 to 3 inches into the port. This little stroker needed to inhale as well as it could through the smallish 178cc intake runners (stock is 171 cc) to make power.

We chose to use an HP-series Holley-type carburetor after previous testing and usage proved them reliable and easy to tune. This led us to call Holley in determining the right size HP carburetor for our combination. They suggested we try their new 850 Ultra HP that will flow more air than the old 950 HP. Their new 950 Ultra HP will flow over 950 cfm—but that's more flow than our combo needed for crisp throttle response. For strong firepower to the spark plugs, we looked no further than Performance Distributors for their great DUI distributor with their Livewires ignition wires. When contemplating our engine combination, we aimed for a street-oriented powerband (2,500 to 6,000 rpm) to make grabbing gears with the Pistol-Grip four-speed a pure pleasure; the dyno will show us where it's at.

After a conversation with Sam Davis of TTI Exhaust about our engine combination, Sam suggested we test both his 15⁄8 to 1¾-inch stepped, and 17⁄8-inch headers. This would allow us to find out what size headers would work best on a small-block with similar power production (the low to mid 500hp range). Check out our satisfying results dyno testing the Slick 340 along with three sets of headers at Ray Barton Racing Engines.

Fast Facts

416CI LA-Series Stroker

Bore x stroke: 4.070 x 4.000 inches

Block: stock '72-casting 340

Compression ratio: 11.3:1

Rotating assembly: Scat 4340 forged crank, Icon forged pistons, Scat I-beam rods

Camshaft: COMP solid roller, .616-/.622-inch lift, 248/254 degrees at .050, 110 LSA

Valvetrain: COMP solid roller lifters, COMP aluminum 1.6 roller rockers

Cylinder heads: ported Edelbrock RPM, 178cc intake port, 2.02-/1.60-inch valves

Intake: ported Edelbrock RPM Air-Gap, deep gasket matching

Carburetor: Holley 850-cfm Ultra HP

Ignition: Performance Distributors DUI with LiveWires

Headers: TTI 17⁄8-inch long-tube headers

Damper: TCI Rattler

Oil Pan: Milodon road race

Dyno peaks: 557 lb-ft at 4,600 rpm, 577 hp at 6,100 rpm

We knew the DTS engine dyno at Ray Barton Racing Engines (RBRE) could find the whereabouts of the powerband for our stroked 340 effort. Would our 416 produce the torque and power at the rpm we desired for our 3.55-geared, street-driver E-Body? Ray slipped us in for dyno testing between his busy Hemi builds. Here, Carl Fiedler of RBRE helps us connect the Slick-Built Small-Block to the pump.

The dependable DUI distributor (PN ITK708212) and LiveWires (PN C9064BK) from Performance Distributors will send a strong jolt of spark to the spark plugs. Notice the instant timing knob, which will make timing adjustments rather easy—it's better than messing with the distributor lock down bolt. The HEI power from the DUI produces excellent power while dramatically simplifying installation.

Holley suggested that our engine combination would like their new 850 Ultra HP (PN 80804). This carburetor proved to be a perfect match for the SBSB. We came armed with jets, air bleeds, and power valves, but didn't use any while testing the three sets of headers. Only the four-corner fuel mixture screws needed to be adjusted for a stable idle.

This Wilson Manifolds 1-inch, four-hole tapered spacer (PN 4110) has proven to add incremental throttle response, torque, and horsepower in past testing. The Wilson spacer will stay in place under the Holley 850 Ultra HP once the SBSB is resting in the engine bay of our street driver–type project car.

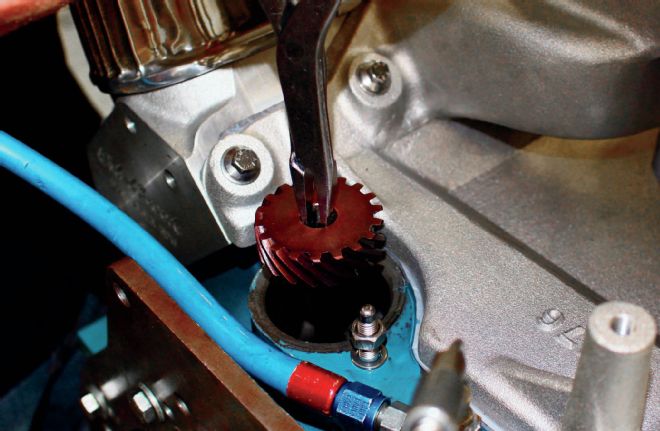

For any LA engine using COMP's latest Extreme Energy Solid Street Roller camshaft, there's no need to use a bronze gear/oil pump driveshaft. Here we're installing Milodon's steel gear/oil pump driveshaft (PN 21530). No worries about periodic replacement of a bronze gear! We primed the oil pump and engine before the steel gear/driveshaft and distributor were installed prior to dyno testing.

Our small-block stroker was fed with Joe Gibbs Driven BR30 break-in 5W-30 oil. Joe Gibbs Racing developed the Driven line of lubricants for high-performance race and street engines. The Driven BR30 break-in oil we're using features an additive package that provides excellent ring sealing. It's also formulated for full-power pulls on the dyno. RBRE uses the Driven break-in oil for dyno testing their Hemi builds.

Here we're connecting the dyno exhaust to a set of Schumacher tri-Y headers (15⁄8 to 2-inch into a 21⁄2-inch collector). Designed for applications where space and ease of installation are issues when other larger diameter headers won't clear, we decided to add them to our test.

After a quick 2,000-rpm break-in run, it's a good idea on solid roller motors like ours to have their valves re-lashed. Here Jay Zolko rechecks and resets the hot lash (.016/.018) on our COMP aluminum 1.6 roller rockers. We initially set the cold lash at .014/.016 on our aluminum heads to allow for expansion once warmed up.

Schumacher 1¾-inch Tri-Ys: Making The Install Easy!

For the first set of baseline pulls we tried the 1¾-inch (2-inch secondary) tri-Y headers from Schumacher Creative Services. These pieces are designed for easy top-down installation in cars where the engine is already in place, making them an awesome choice for guys with limited time and space. Moreover, their tri-Y design often makes them the superior power choice based on their unique tuning dynamics, their ease of installation notwithstanding. But would that pay off with our particular camshaft/induction choice? We had to try. We started at 34 degrees total timing and made progressive pulls from 4,500, 5,000, 5,500, and 6,000 rpm. When our first pull to 6,000 rpm showed us 570 hp while still climbing, we were ecstatic to beat our expectation of 550 hp. The following pulls for the rest of the day would go to 6,300 rpm. Our best pull with the tri-Y headers showed 574 hp at 6,100 and 554 lb-ft at 4,700 rpm. For the average (3,400 to 6,200 rpm), the Schumacher's pulled 472 hp and 517 lb-ft of torque. While not our leader, the tri-Ys are certainly good enough to consider them seriously on the basis of fitment and simplicity.

TTI Long-Tubes: 1¾-Inch Stepped vs. 17⁄8-inch Race

Our final test was a face-off of sorts using two similar but different sets of long-tube headers: TTI's 1¾ to 15⁄8-inch stepped street-oriented headers with a 3-inch collector, and TTI's slightly larger 17⁄8-inch race headers with a 3½-inch collector. Calculations told us our engine and cam size needed something in between the two, so we decided to test both to find out the one best suited for our application.

TTI full-length headers have been a long-time favorite of the Mopar enthusiast—plus they fit perfectly with all of TTI's Mopar exhaust systems. The smaller of the two TTI long-tubes strutted to the tune of 574 hp at 6,000 and 561 lb-ft at 4,600 rpm. Averages were up to 480 hp and 524 lb-ft, barely edging out the tri-Ys by 8 hp and 7 lb-ft.

Last up would be TTI's 17⁄8-inch long-tube race headers featuring a larger 3½-inch collector, which are recommended for small-blocks making over 550 hp. Pulling the handle proved our combo liked the biggest tubes, with peak power now at 577 hp. The torque was only 3 lb-ft behind the smaller stepped headers at 557 lb-ft. With the big guns putting out the most average hp and lb-ft (481 hp and 525 lb-ft), the 17⁄8-inch headers looked like the best ones for our particular engine.