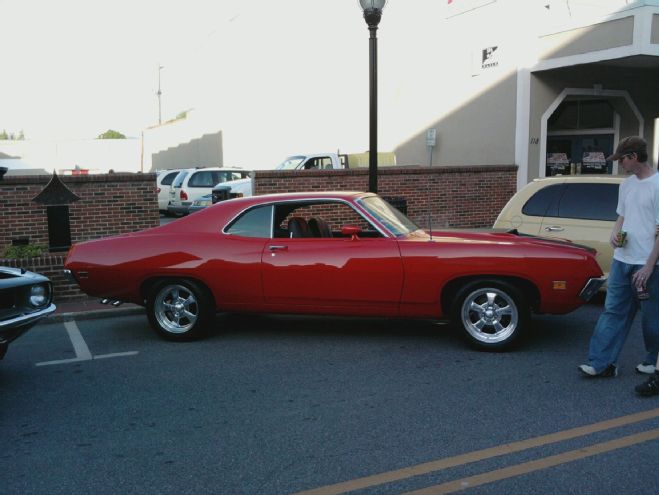

Here's our subject, a '70 Torino that has received a rack-and-pinion swap. Now the driver-side header doesn't fit.

After locating all the necessary parts (flange, 1-3/4-inch primary J bends and collector) it was decided to try using the old header as a starting point.

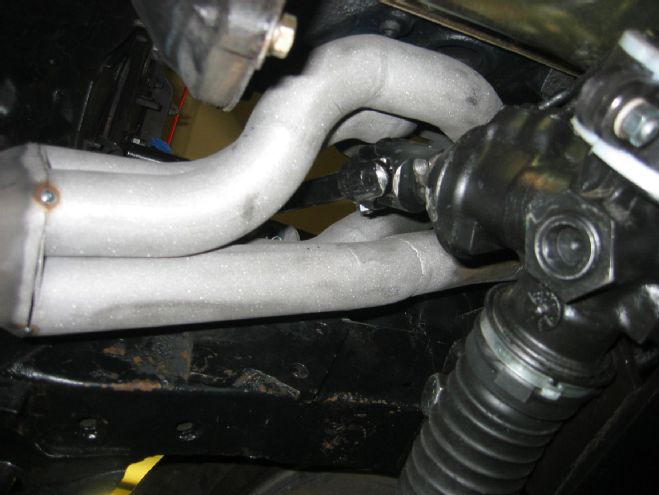

Some judicious cutting saw two primary tubes passing on one side of the steering shaft, and two on the other, with much of the old header reused.

The new J bends were cut and fit to build the custom lower section of the header, tack welding along the way.

The steering rack U-joint and Double-D shaft were removed to enable the header to come out, once it was tack-welded together down to the point where the collector would be welded in place.

With all four primaries cut to the same length, a “star” was cut from 16swg steel and welded in the center, followed by four sections to fit between the tubes, so the collector could be tacked in place.

After sand blasting all welded area, the header was installed to ensure fit. The double-D shaft and U-joint were also re-installed.

Viewed from below, you can see how the header wraps around the steering shaft.

Finish welding all of the primary tubes on the header and grind welds smooth. Sandblast all areas that were welded. Cut the end off of the collector to achieve a nice square opening for around the four primary tubes. Cut a star and four sides out of 16GA steel and weld to the four primary tubes to make them square for welding to the collector. Fit and tack-weld collector to header after cutting collector off of the remaining main header tube.

Reinstall header, U-joint, and DD shaft. Fits good!

Cut off the exhaust pipe with ball flange. Cut header ball flange to length and keep trimming and shaping until both of them fit together, mating to the collector and the exhaust pipe. Tack-weld both pieces and remove header. Final weld exhaust ball-flange piece to exhaust and paint. Remove header and weld up the collector and the other cut. Sandblast and reinstall header to check fit. Fits great!