Q: Hi James. I have been a subscriber since the mid-1990s. I own a survivor ’62 Corvette with a 300-horsepower engine with a Carter AFB carburetor. It has started leaking out of every orifice where there is a gasket or seal. I have been running pump gas in the car and I think the alcohol in the fuel has gotten the best of it. I was thinking of rebuilding the carburetor but a friend suggested that I do not attempt the job. I usually try and do all the repairs to my Corvette myself. I just don’t trust many folks with my car. So the question is, do you think this is a job I can perform myself at home? If not, just who can I trust with rebuilding my vintage carburetors? Also, is the Carter AFB a performance carburetor or would I do better changing to a Holley or Edelbrock? I do like to keep my Corvette as original as possible and would like to continue to use the Carter AFB if you think it can handle today’s fuels. Also, is there a way to tell if the Carter AFB that is on the car is the original one? When I bought the car it also came with some extra parts that included an additional Carter AFB in a box. I am not sure which one may have been installed originally. Thanks.

Richard

A: Richard, let’s take your questions one at a time. The Carter AFB (Aluminum Four Barrel) carburetor is one of the best options for your ’62 Corvette and once it is rebuilt with parts compatible with today’s fuels the carburetor should give you years of worry-free service.

In fact, Richard, when the Carter AFB carburetors were introduced to the automotive industry in 1957 they were perhaps the first performance carburetor, ringing in the dawn of the muscle car era. The ’53 Corvettes even used a version of the Carter carburetor the: YH model.

Chevrolet initially used the AFB carburetors on the 348 engine packages. The AFB carburetor was the logical choice for the Corvette’s new 327 engines. From 1962-1965, a single, high-flow Carter AFB four-barrel carburetor fueled the 300- and 340hp Corvette powerplants, During this era, only Rochester’s mechanical fuel injection could surpass the AFB’s performance.

In 1964, the introduction of the Holley 4150 carburetor on the 365-horsepower L76 would inevitably change the carburetor Corvette would use in its future. Even though the AFB carburetor is less vulnerable to altitude and atmospheric effects and requires fewer adjustments than its Holley counterpart, the Carter AFB would be phased out beginning with the production of the ’66 Corvette.

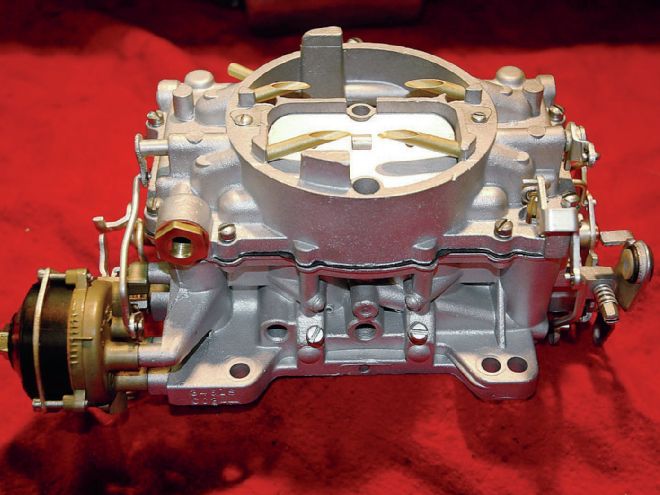

The AFB carburetor is easy to distinguish by the round air horn at the top of the carburetor body. The first design AFB carburetors have a 4.5-inch diameter air cleaner base; a design used until 1961. The cfm (cubic feet per minute) of this carburetor is 500.

The second design of the AFB carburetor was larger overall than the first. The air horn is more pronounced and extends down the side of the carburetor itself. The second design AFB carburetors have a 5.5-inch diameter air cleaner base. The cfm of this carburetor is approximately 600.

The earlier Corvettes used a Carter WCFB (Wrought Cast Four Barrel) and were used exclusively on the Corvette until 1962. From 1962 through 1965, only lower-horsepower Corvettes would use the WCFB. The cfm of the Carter WCFB four-barrel carburetor is approximately 400.

The Carter WCFB carburetors have a square-ish body with a rectangular air horn that protrudes above the air cleaner flange. In Corvettes equipped with a dual four-barrel application, the WCFB carburetors use a mechanical linkage.

The next evolution for the Carter AFB was the Carter AVS, which was a significant enhancement of the AFB design. The improvement was done by increasing airflow without increasing the carburetor’s bore size. This was accomplished by removing the secondary venturis.

To the casual observer, the AVS looks very similar to the AFB. It was so similar that the AVS never achieved the same widespread recognition in the performance world as the AFB. During the height of the muscle car years, the AVS was never used on Corvettes but had success on many competition factory production muscle cars with outstanding results. The AVS was used on Chevy IIs and Chevelles equipped with the 327/275-horsepower engines.

The simplicity of the Carter AFB carburetor design is remarkable. The AFB carburetor has only two major castings, as the throttle body and bowl assembly are incorporated into one casting. The second casting is the bowl cover, or air horn.

Carter Carburetor Application Chart Year Application Model Carter Number Chev Number 1953 150hp All YH 2066S 1st Design, 2066SA 2nd Design 3706151 1st Design, 3706989 2nd Design 1954 150hp All YH 2066SA 3706989 1955 155hp All YH 2066SA 3706989 195hp All WCFB 2218S 1st Design, 2351S 2nd Design 3717687 1st Design, 3724158 2nd Design 1956 210hp All WCFB 2366SA 3733246 225hp Front Carb WCFB 2419S 3730599 225hp Rear Carb WCFB 2362S 3720953 1957 220hp All WCFB 2366SA 1st Design, 2655S 2nd Design 3733246 1st Design, 3744925 2nd Design 245hp Front Carb WCFB 2419S 1st Design, 2626S 2nd Design 3730599 1st Design, 3744002 2nd Design 245hp Rear Carb WCFB 2362S 1st Design, 2627S 2nd Design 3720953 1st Design, 3744004 2nd Design 270hp Front Carb WCFB 2613S 3741089 270hp Rear Carb WCFB 2614S 3741090 1958 230hp All WCFB 2669S 3746384 245hp Front Carb WCFB 2626S 3744002 245hp Rear Carb WCFB 2627S 3744004 270hp Front Carb WCFB 2613S 3741089 270hp Rear Carb WCFB 2614S 3741090 1959 230hp All WCFB 2818S 3756676 245hp Front Carb WCFB 2626S 3744002 245hp Rear Carb WCFB 2627S 3744004 270hp Front Carb WCFB 2613S 3741089 270hp Rear Carb WCFB 2614S 3741090 1960 230hp All WCFB 2818S 1st Design, 3059S 2nd Design 3756676 1st Design, 3779178 2nd Design 245hp Front Carb WCFB 2626S 3744002 245hp Rear Carb WCFB 2627S 3744004 270hp Front Carb WCFB 2613S 3741089 270hp Rear Carb WCFB 2614S 3741090 1961 230hp All WCFB 3059S 3779178 245hp Front Carb WCFB 2626S 1st Design, 3181S 2nd Design 3744002 1st Design, 3785554 2nd Design 245hp Rear Carb WCFB 2627S 3744004 270hp Front Carb WCFB 2613S 1st Design, 3182S 2nd Design 3741089 1st Design, 3785552 2nd Design 270hp Rear Carb WCFB 2614S 3741090 1962 250hp Auto Trans WCFB 3190S Early Production 3788245 250hp All WCFB 3191S 3788246 300hp Auto Trans AFB 3310S 3819207 300hp Man Trans AFB 3269S 3797699 340hp All AFB 3269S 3797699 1963 250p Auto Trans WCFB 3500S 3826005 250hp Man Trans WCFB 3501S 3826003 300hp Auto Trans AFB 3460S 3826006 300hp Man Trans AFB 3461S 3826004 340hp All AFB 3461S 3826004 1964 250hp Auto Trans WCFB 3696S 3846246 250hp Man Trans WCFB 3697S 3846247 300hp Auto Trans AFB 3720S, SA & SB 3851762 300hp Man Trans AFB 3721S, SA & SB 3851761 1965 250hp Auto Trans WCFB 3696S 3846246 250hp Man Trans WCFB 3697S 3846247 300hp Auto Trans AFB 3720SA 3851762 300hp Man Trans AFB 3721SA 3851761

One of the most desirable features of the AFB carburetor is the “dual two-barrel design.” What that means is that the primary barrels functioned as a true two-barrel carburetor, including a low-speed and high-speed circuit as well as its own acceleration and power systems. The secondary circuit throttle plates are opened mechanically as the throttle linkage reaches a predetermined stage and the vacuum-actuated auxiliary valves smooth the transition into the secondary stage.

Another feature of the Carter AFB carburetor is when it comes to performance or track tuning, the AFB is uncomplicated. The carburetor is equipped with vacuum-operated step-up pistons that have calibrated counterbalance springs. The metering rods are attached to these pistons and can be easily accessed for regulating performance by simply removing the air cleaner, one Phillips head screw, and changing the metering rod. All of the performance changes and adjustments can be performed without disassembling the carburetor.

Richard, when it comes to simple carburetor rebuilding I think this is something that a mechanically inclined person can attempt at home if they take their time. However; there are several tricks and settings that could give a novice rebuilder problems.

My personal opinion is that you are better off if you do not attempt to rebuild the unit yourself or even have the local garage tackle the project. In today’s era, the local garage will typically not have the proper equipment and the day-to-day skill level to perform a proper, inclusive restoration or rebuild. Typically, you will find this is better left to the professionals who are skilled in the art, and only restore or rebuild carburetors. Fortunately, there are people at several companies that can perform this service, such as Al at Chicago Corvette, who specializes in carburetor restoration.

Some Corvette enthusiasts just want to enjoy driving their vehicles and don’t care about every part having the correct date code, finish, or markings. However, if you are a collector who wants to keep the vehicle as close to original as possible the process is a little different. It starts with an inspection of the carburetor’s overall condition to determine what is original and what is not. You will need to check all the part numbers found on the carburetor, as well as the date codes. You will also need to inspect items that were changed through the production run, such as throttle shaft or choke pull off to ensure the most correct parts are put back onto your carburetor.

An inspection for any part numbers that may have been restamped is also a crucial step that will need to be performed. Al at Chicago Corvette finds several restamped carburetors every year in his inspections, especially on Carter AFBs. This is one reason why having a carburetor restored is best left to the professionals.

Remember, some of these carburetors are over 50 years old. If your carburetor was ever used as a core and sent to a production rebuilder it’s very possible the parts could have become mismatched during the overhaul. A production rebuilder will normally tear down 10 to 15 like units at a time and run all of the components through a cleaner before the reassembly process begins. This can easily cause a mismatch of parts.

Carburetors are precision parts so an inspection of overall condition is important. You are looking for metal fatigue, slightly stripped threads, hairline cracks, worn throttle lever bushings, and pitting from oxidation, which can be a problem with older carburetors.

Alloy-type carburetors such as the Carter AFB are vulnerable to throttle shaft wear and main body throttle bore wear. If the throttle lever bushings are worn or the body throttle bore has worn away it may require oversizing the base plate and using oversized bushings, which may be a challenge to perform at home.

If pitting from oxidation has occurred, a replacement part may be required. In the replating process it is very rare to be able to repair the pitting and there is typically not enough material to grind out the pitting. Fortunately, most carburetor restorers have an abundance of extra parts they can draw from if a problem is found with your unit.

If you are looking for the correct carburetor or parts for your car at a swap meet, remember to try and find a core unit that fits well with no oxidation or pitting. Also, be aware of restamped carburetors. Do your homework and become familiar with what the characters in the stamping should look like and for a carburetor that has been resurfaced in the stamping pad area.

The Carter AFB carburetors are roll stamped with an identification marking at the right front base of the carburetor’s mounting ear. The roll stamp identification first will display the carburetor identification number. The lowercase numbers will reflect the date code, which will be displayed with two or three characters. If three characters are displayed, the first is the week code. If only two characters are displayed there is no week code, only a month and year code.

The example shown is number 3269S, which designates the carburetor as a 300-horsepower manual transmission or a 340-horsepower application. The date code CB2 breakdown is: C, third week of the month; B, February; 2, 1962.

Don’t worry, next month we will decode the Carter AFB carburetor’s triangular metal identification tag, identifying a few unique suffix codes and carburetor identification numbers. We will also go through the rebuilding process for the Carter AFB carburetor.

Questions?

Got a question for our Tech Corner expert? Just jot it down on a paper towel or a lightly soiled shop rag and send it to us at VETTE Magazine, Attn: Technically Speaking, 1733 Alton Parkway, Suite 100, Irvine, CA 92606. Alternatively, you can submit your question via the Web, by emailing it to us at [email protected]. Be sure to put “Technically Speaking” in the subject line.