Jake Kyle

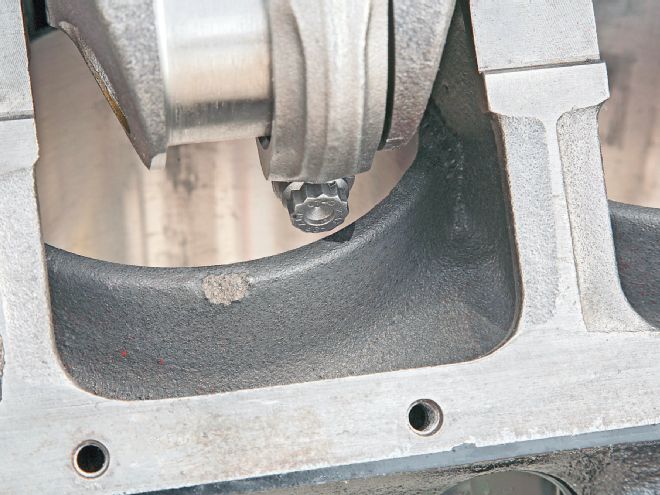

A definite clearance break-point is moving up to a custom-ground 3.5-inch stroker crank and bulky aluminum rods, as shown here on a Joe Sherman 816hp, 374ci Windsor motor. The 4.125-inch bore heavy-duty Ford Racing block required minor oil-pan rail clearancing, although the rods did clear the build’s reduced base-circle solid-roller cam with no problem. The complete buildup is online at HOTROD.com.

A definite clearance break-point is moving up to a custom-ground 3.5-inch stroker crank and bulky aluminum rods, as shown here on a Joe Sherman 816hp, 374ci Windsor motor. The 4.125-inch bore heavy-duty Ford Racing block required minor oil-pan rail clearancing, although the rods did clear the build’s reduced base-circle solid-roller cam with no problem. The complete buildup is online at HOTROD.com.

Len Cossey

St. Ann, MO

Bruce Maurice

Via email

On the Edelbrock carb, usually, but not always, ported vacuum is preferred. Sometimes a car runs better with no vacuum advance, especially if it “hunts” in and out of vacuum advance at cruise near the WOT tip-in point. Hopefully, Bruce’s Vette rear-axle ratio is at least 3.55–3.73:1 or even numerically higher.

On the Edelbrock carb, usually, but not always, ported vacuum is preferred. Sometimes a car runs better with no vacuum advance, especially if it “hunts” in and out of vacuum advance at cruise near the WOT tip-in point. Hopefully, Bruce’s Vette rear-axle ratio is at least 3.55–3.73:1 or even numerically higher.

I’ll assume that your basic carburetor adjustments, as explained in the instructions that came with your carbs as well as in widely available books and manuals, are correct. These include the float level, the idle mixture , the idle speed, the accelerator pump rod, and the dual-carb throttle linkage. The fact that you reported no idle-quality issues and say the car runs fine at wide-open throttle (WOT) from a standing start provides me with reasonable confidence that this assumption is correct. Of course, you can also get a clue by “reading” the spark plugs: black (rich) or white (lean). Ideally, the center porcelain should be reddish-tan in color.

If it was me, I’d take a close look at the ignition curve. Your 350’s extremely low compression ratio, Thumpr cam, and aluminum heads call for a fairly quick advance curve and lots of timing, even with pump gas. Start by determining the cruise rpm (or rpm range) where the Vette hesitates when you step into it. Then check the amount of ignition advance at that point—you’ll need either a dial-back timing light or a degreed balancer to do this. Initially, it’s OK to have the vacuum advance hooked up, because what you want to observe first is not only the total timing (in this case, the sum of base timing, centrifugal advance, and vacuum advance) at the onset of lay-down, but also if and how much the timing decreases during the tip-in process (because the engine vacuum decreases at tip-in to WOT).

With your combination, at around 2,500–2,800 rpm I’d like to see no less than 25–30 degrees of advance. If it’s under 20 degrees at or under 3,000 rpm, for sure you have a problem. If the observed total advance is less than this during or just after tip-in, temporarily disconnect and plug the vacuum advance. See if the car runs better. If the car does run better, and the vacuum advance was previously hooked up to a manifold (full-time) vacuum port, try connecting it to a ported vacuum-port. Timing fall-off will be less when the advance is connected to ported vacuum, but any such fall-off during tip-in still must not reduce total advance below the 25–30 degree threshold. If advance still is insufficient, add more base timing into the motor. Depending on your gearing, you may not be able to run vacuum advance if the “sour spot” occurs at your WOT tip-in point rpm at cruise.

My money’s on a timing issue on this one. Low-compression, heat-rejecting aluminum heads and a Thumpr cam call for lots of initial timing and a fast-opening centrifugal advance curve. Don’t be afraid to play with the distributor weights and springs.

My money’s on a timing issue on this one. Low-compression, heat-rejecting aluminum heads and a Thumpr cam call for lots of initial timing and a fast-opening centrifugal advance curve. Don’t be afraid to play with the distributor weights and springs.

Whether or not you ultimately run vacuum advance, the proper timing with your combination would be about 15-degrees initial, with a total of 36–38 degrees of centrifugal (mechanical) advance by 3,000 rpm (as read at the balancer). You may need to play with the distributor springs, weights, and (if used) internal distributor advance stop-bushing to achieve this.

If none of this helps, you will need to take a serious look at the internal carburetor transition circuit and calibration. At that point, I strongly recommend biting the bullet and consulting a tuning shop with a chassis dyno. Good luck.

There’s also the cop-out solution: Have you tried downshifting to a lower gear when you step into it?