There are a lot of ways to have fun with your Mopar, including driving on the street, attending car shows, or racing at the dragstrip, but to some enthusiasts, trucks are the Mopars of choice. And while many Mopar trucks are the workhorses of the family, trucks can also be a fun way to play in the mud, drive off road, climb hills, race, and they are even used in other motorsports events such as truck pulls. We decided to follow along as MRL Performance builds a stout big-block for a pulling truck, and see what it takes to make more than 700 horsepower and 625 lb-ft of torque from a cast-iron headed 470-inch Chrysler 400.

If there was ever a true test of a vehicle’s performance and durability, it’s truck pulling. These vehicles are designed to pull a weighted sled along a dirt course, with an ever increasing load being applied to the engine and drivetrain. The engine in a pulling truck doesn’t just need power and torque, but it also needs to be able to withstand high rpm and heavy loading for a sustained period of time. When engine builder Mike Liston of MRL Performance agreed to build a pulling engine for Minnesota native Eric Wright’s Dodge, he knew he’d have to pick the parts properly for this engine to survive.

01 To stiffen the bottom end, BCR billet-aluminum main caps were added, along with a main girdle and studs from Chenoweth Speed and Machine. These upgrades will prevent the main caps from “walking,” and ensure the bearings stay fresh for a long time. "> <strong>01</strong> To stiffen the bottom end, BCR billet-aluminum main caps were added, along with a main girdle and studs from Chenoweth Speed and Machine. These upgrades will prevent the main caps from “walking,” and ensure the bearings stay fresh for a long time.

02 A custom solid-roller camshaft from Comp Cams was used in this engine, along with Comp’s Elite solid roller lifters. MRL chose a Jesel belt drive system to eliminate harmonics, and also because it makes cam timing adjustments easy. ">

<strong>01</strong> To stiffen the bottom end, BCR billet-aluminum main caps were added, along with a main girdle and studs from Chenoweth Speed and Machine. These upgrades will prevent the main caps from “walking,” and ensure the bearings stay fresh for a long time.

02 A custom solid-roller camshaft from Comp Cams was used in this engine, along with Comp’s Elite solid roller lifters. MRL chose a Jesel belt drive system to eliminate harmonics, and also because it makes cam timing adjustments easy. ">

<strong>02</strong> A custom solid-roller camshaft from Comp Cams was used in this engine, along with Comp’s Elite solid roller lifters. MRL chose a Jesel belt drive system to eliminate harmonics, and also because it makes cam timing adjustments easy.

<strong>02</strong> A custom solid-roller camshaft from Comp Cams was used in this engine, along with Comp’s Elite solid roller lifters. MRL chose a Jesel belt drive system to eliminate harmonics, and also because it makes cam timing adjustments easy.

The truck pulling class this engine will run in requires a cast-iron block and cylinder heads, which limits the choices available. MRL decided to use a factory Chrysler 400 block for this build, stating that the 400’s shorter cylinders and beefy bottom end are ideal for durability and power, and that these blocks work great in moderately powered applications without spending the cash for an aftermarket block. The cylinders of this 400 were bored and honed with a torque plate, which ensures consistent, round bores once the cylinder heads are bolted in place. To beef up the bottom end, Mike chose a set of BCR aluminum main caps, and a main girdle from Chenoweth Speed and Machine. Mopar B, RB, and second-generation Hemi cam journals are known for misalignment and size problems, so MRL corrected these issues and installed Durabond coated cam bearings. The block was machined to strict tolerances, and the inside of the block was painted to aid oil return.

03 The Indy heads are oiled externally, so MRL designed an oiling system that restricted oil to the rockers, while still providing enough oil for lubrication and valvespring cooling. These heads were milled to get the desired compression ratio of 12.7:1, and installed with Mr. Gasket Ultra Seal MLS head gaskets and ARP head studs. "> <strong>03</strong> The Indy heads are oiled externally, so MRL designed an oiling system that restricted oil to the rockers, while still providing enough oil for lubrication and valvespring cooling. These heads were milled to get the desired compression ratio of 12.7:1, and installed with Mr. Gasket Ultra Seal MLS head gaskets and ARP head studs.

<strong>03</strong> The Indy heads are oiled externally, so MRL designed an oiling system that restricted oil to the rockers, while still providing enough oil for lubrication and valvespring cooling. These heads were milled to get the desired compression ratio of 12.7:1, and installed with Mr. Gasket Ultra Seal MLS head gaskets and ARP head studs.

For the rotating assembly, MRL picked a 4340 forged crankshaft from RPM, with a stroke of 3.91 inches. Compstar connecting rods come standard with ARP 2000 7⁄16-inch rod bolts, making them ideal for applications requiring durability, and lightweight Mahle forged, flat-top pistons were installed. MRL states that Mahle pistons are excellent in terms of weight and strength, come with a metric ring pack, and are fully coated. Of course the entire assembly was balanced and the cylinders were treated to Total Seal dry film lube to aid in ring seating during engine break-in.

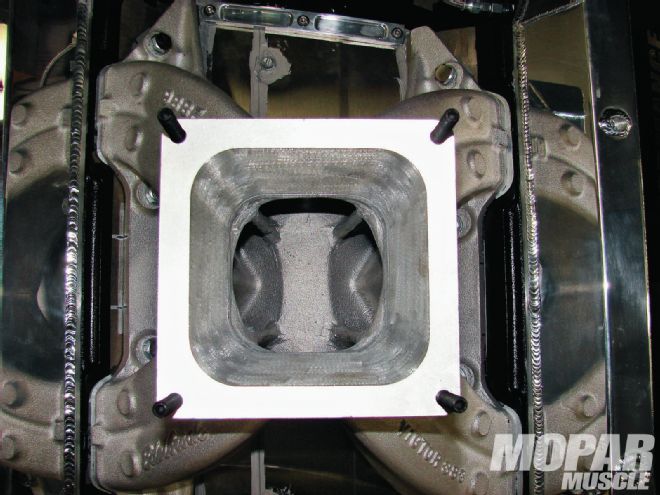

04 The Indy heads have a ton of quench area as shown by arrows 1 and 4. The combustion chambers are also notched slightly (arrows 2 and 3) to un-shroud the back-cut 2.20 intake and 1.81 exhaust valves. The tops of the cylinder bores were also notched slightly for valve clearance. "> <strong>04</strong> The Indy heads have a ton of quench area as shown by arrows 1 and 4. The combustion chambers are also notched slightly (arrows 2 and 3) to un-shroud the back-cut 2.20 intake and 1.81 exhaust valves. The tops of the cylinder bores were also notched slightly for valve clearance.

<strong>04</strong> The Indy heads have a ton of quench area as shown by arrows 1 and 4. The combustion chambers are also notched slightly (arrows 2 and 3) to un-shroud the back-cut 2.20 intake and 1.81 exhaust valves. The tops of the cylinder bores were also notched slightly for valve clearance.

Since the class requirements dictated a cast-iron cylinder head, Mike had to decide whether to use factory castings, or go with an aftermarket head. Fully porting a set of factory cylinder heads can produce respectable power, but durability can be compromised. Instead, Mike chose a pair of 440-C cylinder heads from Indy Cylinder Head, which are a cast-iron head with similar characteristics to Indy’s 440-1 aluminum cylinder head. The 440-C heads are currently out of production, but MRL found a set of pre-owned heads and did a little cleanup work on the castings before performing a performance valve job and installing a set of 2.20 intake and 1.81 exhaust valves.

05 To reduce windage and keep weight off the crankshaft and rods, MRL designed a custom crank scraper for this engine. Details like this really make a difference when power and durability matter the most. "> <strong>05</strong> To reduce windage and keep weight off the crankshaft and rods, MRL designed a custom crank scraper for this engine. Details like this really make a difference when power and durability matter the most.

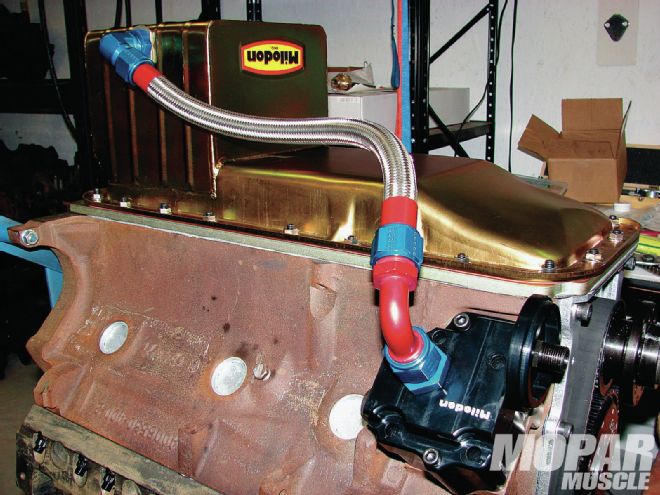

06 A Milodon deep-sump truck pan was used on this big-block, and modified for a pickup with an external line. The deep pan combined with a Milodon high-volume pump, Milodon pump cover, and internal oiling modifications, will allow this engine to survive nicely at sustained high rpm. ">

<strong>05</strong> To reduce windage and keep weight off the crankshaft and rods, MRL designed a custom crank scraper for this engine. Details like this really make a difference when power and durability matter the most.

06 A Milodon deep-sump truck pan was used on this big-block, and modified for a pickup with an external line. The deep pan combined with a Milodon high-volume pump, Milodon pump cover, and internal oiling modifications, will allow this engine to survive nicely at sustained high rpm. ">

<strong>06</strong> A Milodon deep-sump truck pan was used on this big-block, and modified for a pickup with an external line. The deep pan combined with a Milodon high-volume pump, Milodon pump cover, and internal oiling modifications, will allow this engine to survive nicely at sustained high rpm.

<strong>06</strong> A Milodon deep-sump truck pan was used on this big-block, and modified for a pickup with an external line. The deep pan combined with a Milodon high-volume pump, Milodon pump cover, and internal oiling modifications, will allow this engine to survive nicely at sustained high rpm.

Since this engine is relatively small in terms of displacement and will only be spun to 7,500 rpm, Mike chose not to port the heads but rather to run them as-cast, by Indy. The port volumes and flow numbers of the 440-C heads match up nicely to the 470 inch big-block, and since the truck this engine is going in isn’t set up to handle the added power that ported heads would produce, using the heads as-is will allow room to grow as the truck’s owner upgrades the transmission and suspension components.

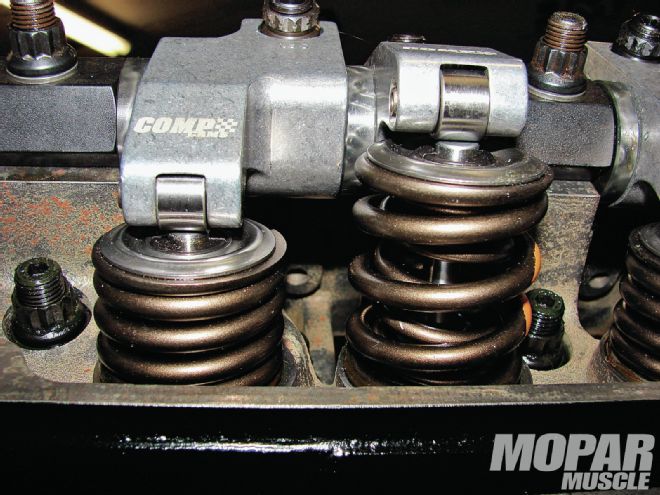

07 The Indy heads have much wider intake ports, requiring special offset rocker arms. MRL used T&D rockers with an offset of .800 inch, along with Comp springs, retainers, and locks. "> <strong>07</strong> The Indy heads have much wider intake ports, requiring special offset rocker arms. MRL used T&D rockers with an offset of .800 inch, along with Comp springs, retainers, and locks.

<strong>07</strong> The Indy heads have much wider intake ports, requiring special offset rocker arms. MRL used T&D rockers with an offset of .800 inch, along with Comp springs, retainers, and locks.

A solid roller camshaft from Comp Cams was utilized along with Comp pushrods and T & D offset rocker arms. The cam specs for a pulling engine are important, as the engine needs to make solid midrange torque numbers with a smooth transition to the horsepower curve. MRL chose to spec their custom Comp cam with 280 degrees intake and 288 degrees exhaust duration at .050-inch lift. Lift for this cam was .725 inch on both the intake and exhaust, and Comp Cams Elite solid roller lifters were utilized.

There are many options available from timing chain and gear sets, to gear drives, and even belt drives. MRL chose a Jesel belt drive for this engine, stating that the belt drive will reduce harmonics transferred from the crankshaft to the cam, and allow easy cam timing adjustments without having to go inside the engine. The Jesel drive requires a little bit of machining on the block to install, but in our opinion the benefits are well worth the trouble.

Since the Indy cylinder heads are fed by external oil lines, MRL designed smaller oil feed lines to restrict oil to the rocker gear. Using a Milodon deep-sump truck oil pan, MRL blocked off the internal oil pickup, and utilized an external pickup in the pan along with a Milodon high-volume oil pump and cover. The main bearing oil feeds from the main oil galley were enlarged to ensure plenty of oil gets to the crankshaft and rods, and a custom crankshaft scraper was installed to reduce windage.

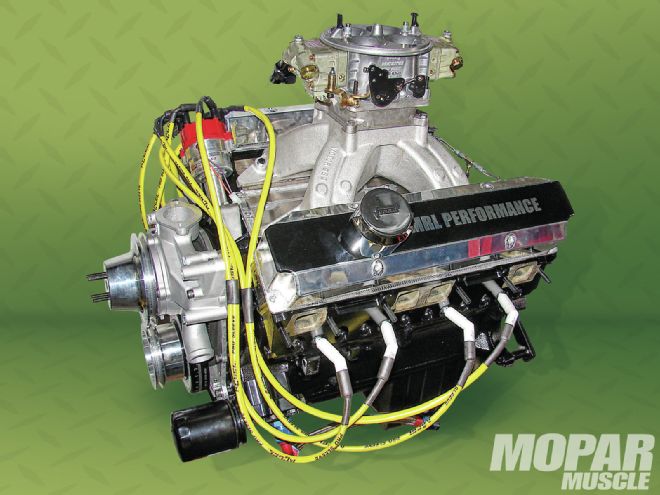

08 An Edelbrock Victor 383 intake manifold was utilized on this engine, along with a BIGS prepped Holley 1050 Dominator carb. The 4500 series carb was adapted to the intake with a two-inch spacer, and MRL blended the spacer to the intake and ported the intake runners. "> <strong>08</strong> An Edelbrock Victor 383 intake manifold was utilized on this engine, along with a BIGS prepped Holley 1050 Dominator carb. The 4500 series carb was adapted to the intake with a two-inch spacer, and MRL blended the spacer to the intake and ported the intake runners.

<strong>08</strong> An Edelbrock Victor 383 intake manifold was utilized on this engine, along with a BIGS prepped Holley 1050 Dominator carb. The 4500 series carb was adapted to the intake with a two-inch spacer, and MRL blended the spacer to the intake and ported the intake runners.

An Edelbrock Victor single-plane aluminum intake manifold is used -- which MRL states will give the intake charge a lot of velocity for a broad power curve. The intake runners were ported to increase the runner width from the port, all the way to the plenum area of the intake. Mike says that since the Victor intake runners are actually smaller than the ports in the heads, the engine will run more efficiently since this port mismatch will help keep reversion pulses away from the carburetor and plenum area of the intake. Since the heads were milled extensively to get compression to the desired level, the top of the intake runners match the ports in the heads, while the bottom of the intake runner provides a slight lip.

To feed this big-block, a BIGS-prepped Holley 1050-cfm Dominator was installed using a two-inch tapered spacer to adapt the 4500 series carb to the 4150 series intake flange. This carb and intake combination will give smooth acceleration, with improved intake charge velocity to aid in top end power. For an ignition system, MRL chose a Mallory 32 series distributor combined with a Mallory Hyfire6 ignition box, an E-Core coil, Accel 9000 plug wires, and Accel silver tip spark plugs.

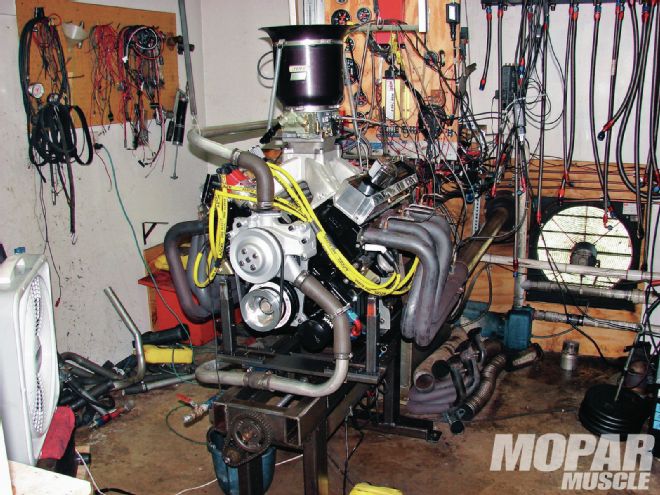

09 On the engine dyno, this 470-inch engine was fitted with a Mallory distributor and ignition box, Accel plugs and wires, and then tested to find out what kind of power and torque it would make. "> <strong>09 </strong> On the engine dyno, this 470-inch engine was fitted with a Mallory distributor and ignition box, Accel plugs and wires, and then tested to find out what kind of power and torque it would make.

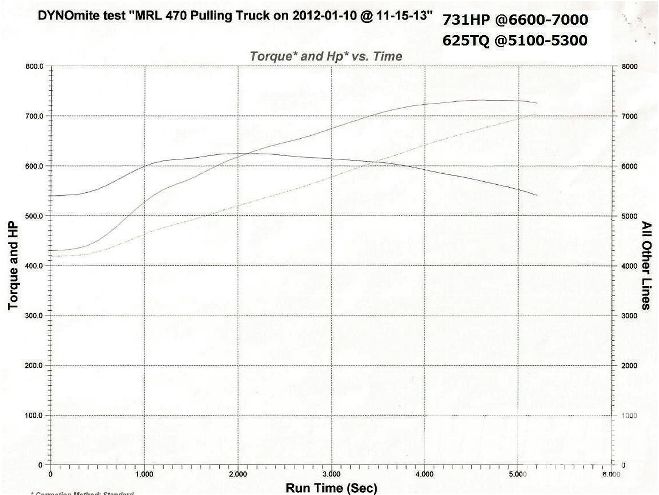

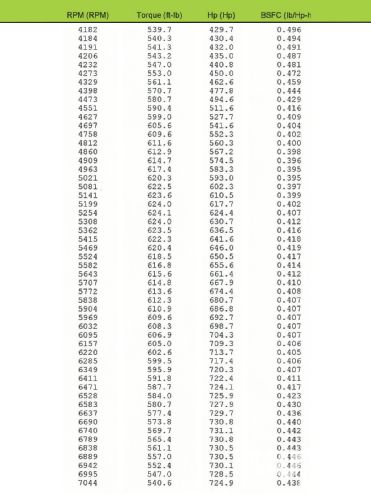

10 As you can see, this engine has very broad torque and smooth power and torque curves. At 625 lb-ft of peak torque and 731 peak horsepower, this big-block should be able to pull a heavy load. ">

<strong>09 </strong> On the engine dyno, this 470-inch engine was fitted with a Mallory distributor and ignition box, Accel plugs and wires, and then tested to find out what kind of power and torque it would make.

10 As you can see, this engine has very broad torque and smooth power and torque curves. At 625 lb-ft of peak torque and 731 peak horsepower, this big-block should be able to pull a heavy load. ">

<strong>10</strong> As you can see, this engine has very broad torque and smooth power and torque curves. At 625 lb-ft of peak torque and 731 peak horsepower, this big-block should be able to pull a heavy load.

<strong>10</strong> As you can see, this engine has very broad torque and smooth power and torque curves. At 625 lb-ft of peak torque and 731 peak horsepower, this big-block should be able to pull a heavy load.

On the dyno, this 470-inch big-block fired right up with no issues, sounding crisp and responsive. After a little break in time, Mike made a short pull on the engine to load the engine and help seat the rings. On the first full pull, it was apparent that this engine had broad torque and power curves, making over 600 lb-ft of torque and well over 700 horsepower. Subsequent tuning netted a peak horsepower number of 731 and peak torque of 625 lb-ft. Torque was over 600 lb-ft from 4,700 rpm all the way past 6,200 rpm, and horsepower was over 700 from 6,000 rpm well past 7,000 rpm. There’s no doubt this is a stout big-block for its size, and will certainly power Eric’s Dodge truck to some impressive pulls.

After dyno tuning the engine, it has been installed in the pulling truck and initial testing has shown positive results. This is a powerful combination, and will certainly be a fun ride at truck pulling events. Eric is looking forward to a productive season, and we’ll keep you posted about how his combination performs. Remember that when it comes to Mopars, cars aren’t the only way to have fun. Actually, with 731 horsepower and 625 lb-ft of torque, we think this MRL Performance prepped 470 would be fun no matter what type of Mopar it was installed in!

11 The MRL Performance big-block is already installed in Eric Wright’s Dodge pulling truck, and preliminary testing has been successful. We’ll be sure to let you know how this truck performs at the events it enters in a future issue of Mopar Muscle. "> <strong>11</strong> The MRL Performance big-block is already installed in Eric Wright’s Dodge pulling truck, and preliminary testing has been successful. We’ll be sure to let you know how this truck performs at the events it enters in a future issue of Mopar Muscle.

<strong>11</strong> The MRL Performance big-block is already installed in Eric Wright’s Dodge pulling truck, and preliminary testing has been successful. We’ll be sure to let you know how this truck performs at the events it enters in a future issue of Mopar Muscle.

NOTE: MRL Performance doesn't build crate engines: call them for a quote on a custom engine for your Mopar's specific application.