Correct valvetrain geometry is critical to ensure trouble-free operation of an engine, especially during high-rpm operation. When building a new engine, many people simply reuse the original pushrods or buy a new set of stock-length pushrods. However, multiple factors (see sidebar on page 28) can cause a change in the distance between the top of the lifter and the end of the rocker arm.

Most engines that use pushrods make use of a rocker-arm assembly that pivots on a fulcrum. As the rocker arm pivots forward, the rocker-arm tip pushes down on the valve stem. At first glance, it may appear as if the rocker-arm tip remains in the same location on the top of the valve stem. However, as the rocker arm pivots, it moves in an arc across a portion of the valve stem. If the pushrod is too long or too short, the tip of the rocker arm will not be centrally located on the top of the valve, which can result in premature valve and/or valve-guide wear, parts failure, or binding during operation.

Thanks to easy-to-use measurement tools—such as items from Comp Cams—determining the proper-length pushrod for your engine is simple. Follow along as we show you the basics on how to determine the proper-length pushrod on a small-block V8 engine fitted with a solid-lifter camshaft.

Items That Affect Pushrod Length

Aftermarket "tall deck" cylinder block

Decked cylinder block

Decked cylinder heads

Thicker/thinner-than-stock head gaskets

Sunken/recessed valve seats

Longer/shorter-than-stock length valves

Non-stock ratio rocker arms

Non-stock rocker-arm assembly

Non-stock length/style aftermarket rocker-arm studs

Non-stock-style camshaft (flat tappet versus roller tappet)

Small base-circle camshaft

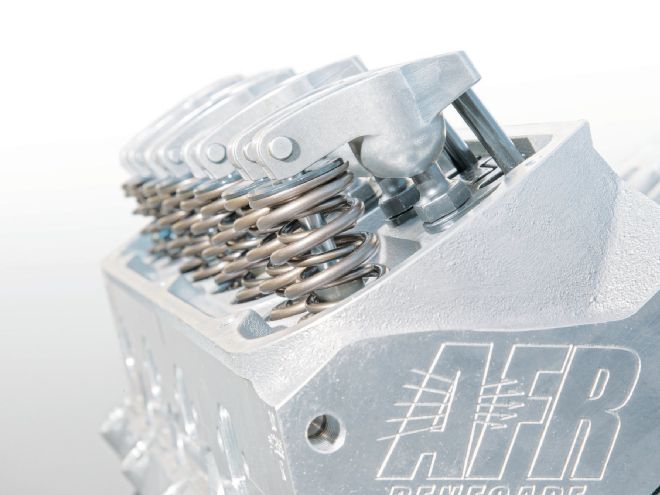

1 Comp Cams offers a Hi-Tech Master Pushrod Checking Kit (PN 7705) that includes four different adjustable pushrod-length checking tools. The tools cover pushrod lengths ranging between 5.800–9.800 inches.

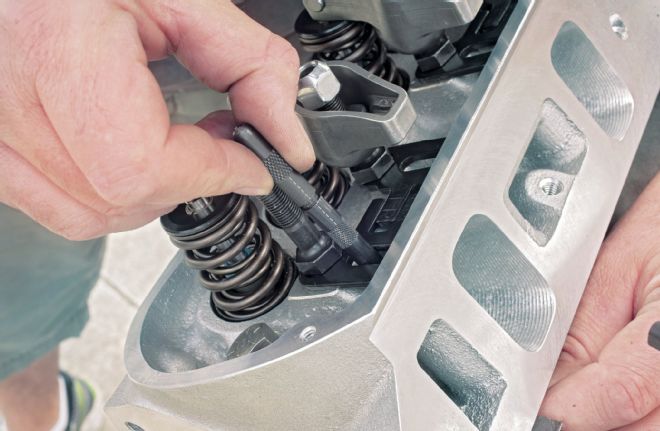

2 Each of the pushrod-length checking tools incorporates a threaded adjustment feature that allows you to lengthen the tool to adapt for different factors that affect pushrod length. To adjust the checking tool, simply unscrew the end.

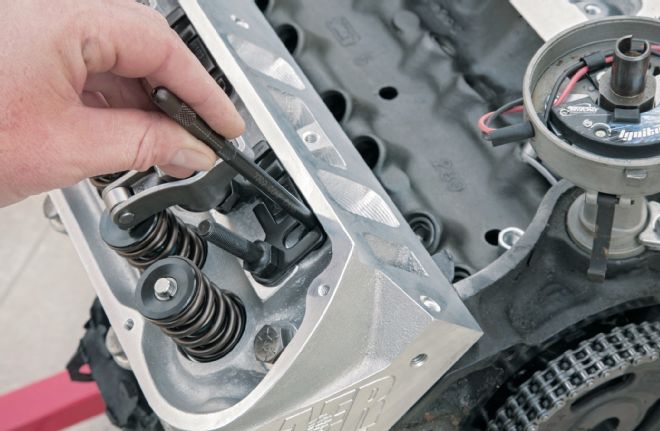

3 Start by identifying which of the pushrod-length checking tools from the kit is most similar in length to your stock pushrod. Then, adjust the checking tool so that its length is approximately the same as the stock pushrod. Install the checking tool so that one end fits into the cup portion on the top of the lifter.

4 Use a dry-erase marking pen to cover the valve tip with a black coloring.

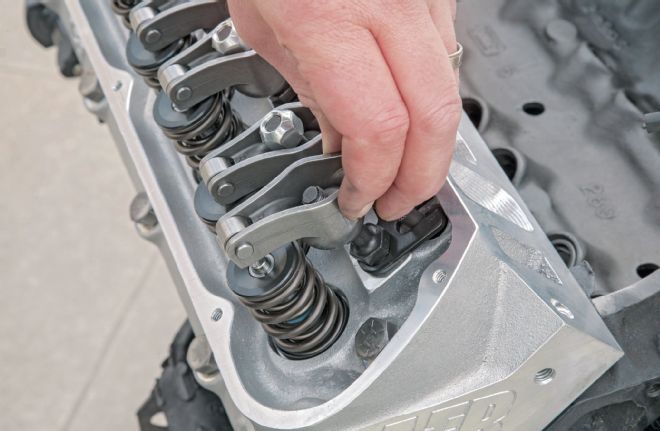

5 Install the rocker arm onto the mounting stud. In our case, we're using a set of Comp Cams Magnum roller-tipped rocker arms. However, determining proper pushrod length involves the same procedure if you're using stock-type, stamped-steel rocker arms.

6 With the lifter on the base circle of the camshaft, tighten the rocker-arm nut to obtain "zero lash," meaning that there's no clearance between the valve tip and the rocker arm. This can be done via visual inspection at the rocker-arm tip, but the easiest way is to spin the pushrod-checking tool with your finger tips while tightening the rocker-arm nut. When you feel resistance on the checking tool, you have reached zero lash, and tightening of the nut should stop. In applications with high-rate valvesprings, we recommend using a set of checking springs to avoid damaging the checking tool's threads.

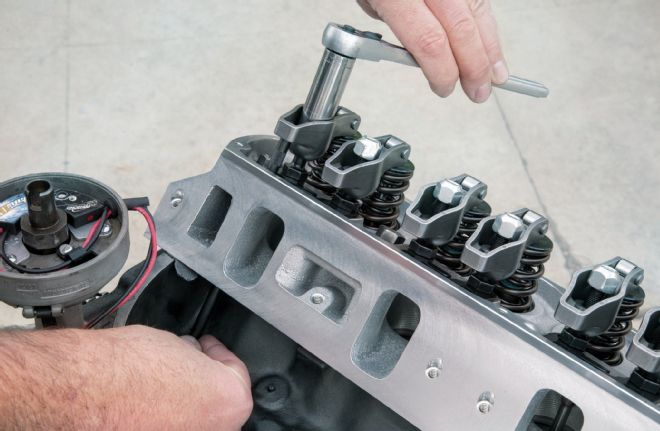

7 Rotate the engine through at least two complete cycles, making the rocker arm open and close the valve multiple times.

8 Keep rotating the engine until the lifter is on the base circle of the camshaft to remove tension from the valvespring, and remove the rocker arm.

9 Inspect the end of the valve tip. The area where the rocker arm has exerted force on the valve will cause the dry-erase pen to be rubbed off. In our case, the rocker arm was only pushing on the bottom half of the valve tip.

10 The location of the witness mark indicates the pushrod length was too long, so we shortened the length of the checking tool and performed the test again.

11 By making the pushrod shorter, the tip of the rocker arm is now centered in the middle portion of the valve tip, as indicated by the wear mark. The wear pattern in this picture indicates proper pushrod length.

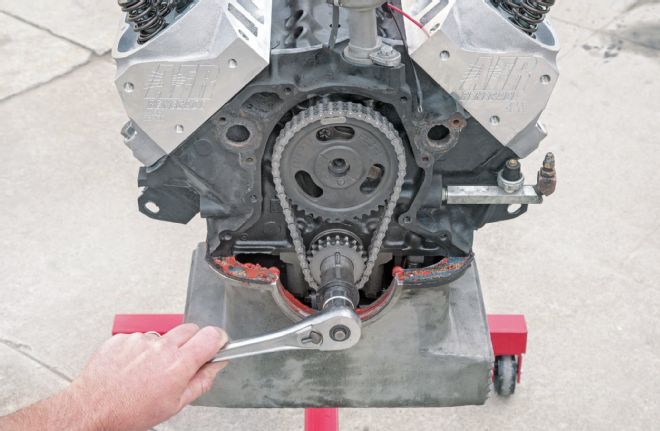

12 Remove the pushrod-checking tool and count how many turns out the tip is. For each full turn out, 0.050-inch length should be added to baseline measurement of the checking tool. In our case, two turns out generated the proper clearance, meaning the pushrod length needed for our engine is about 6.800 inches. With this measurement, a set of custom-length pushrods can be ordered—or you may be able to purchase a premade set of pushrods that are +/- 0.050 inch to your measured length. We ordered a set of Comp's 6.850-inch pushrods (PN 8312), which should be close enough to generate proper valvetrain geometry.

This illustration shows how the rocker arm should properly move across the valve tip when the correct-length pushrod is used.