It seems a certainty that Chevy guys would rather eat dirt than drive a Ford, but not all Chevy guys agree about their choice of powerplant. The original small-block has a lot going for it, including power potential, minimal weight and even affordability. By comparison, the big-block takes a few giant steps up the performance ladder, but does so saddled with both additional weight and cost. There is no denying the power potential of a nasty Rat motor, but it is considerably larger, heavier and more expensive to build than a comparable mouse.

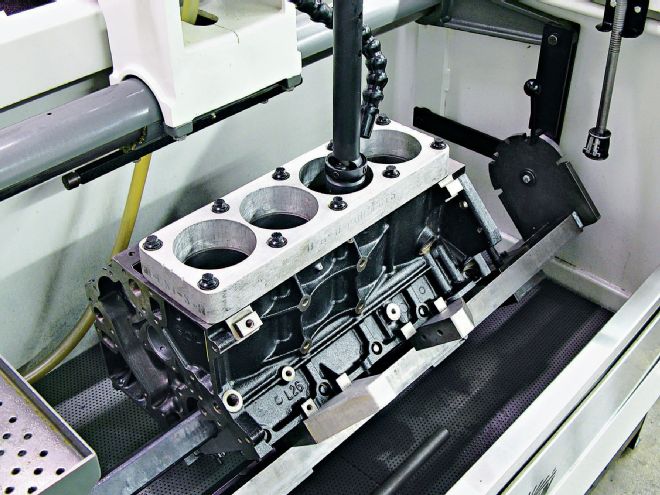

The 454 short-block chosen for this build up was purchased from a local Pick-a-Part wrecking yard for just $85.

The 454 short-block chosen for this build up was purchased from a local Pick-a-Part wrecking yard for just $85.

In the past, big-block guys had to be serious about their need for power in order to overlook the mass and cost issues associated with building the Rat. The old adage that "speed costs money, how fast do you want to go" certainly applies here. Or does it? What if we told you there was a magical land where big-blocks and small-blocks were available for the exact same price? What if we further sweetened the deal with a serious weight reduction for the big-block with the addition of some aluminum cylinder heads? In one fell swoop we have all but eliminated the cost and weight penalties associated with building a fat-block Chevy. Interested? Read on!

Where is the magical land where big-blocks roam free, ripe for the picking? The answer is your nearest wrecking yard. It seems that the wrecking yards label every method of motivation as simply "complete engine" and let it go at that. This means the complete big-block can be had for the same price as a small-block, V-6 or (God forbid) four-cylinder, econo-box motor. Lest you think that the boneyards are devoid of big-block Chevys, we snagged not one but two different big-blocks from our local Pick-a-Part (and found three more), so obviously they are still available (hint-stop looking for that LS6 Chevelle and check out the engine bays of full-size trucks).

The 454 truck block was sporting the very desirable four-bolt mains, though the weak link was definitely the cast pistons and not the block. A two-bolt block would actually work just as well at this power level.

The 454 truck block was sporting the very desirable four-bolt mains, though the weak link was definitely the cast pistons and not the block. A two-bolt block would actually work just as well at this power level.

Most impressive was the fact that a complete BBC (meaning carb to oil pan and fan to flywheel) could be had for the bargain basement price of just $200, plus $40 core. This price can be reduced on special sale days where everything in the lot (including a complete BBC engine) is 50 percent off. Additional discounts can be had by purchasing a long-block (for $170) or a short-block (for $129). Since we planned on replacing the heads, cam and intake in our build up, we started with the basic short-block for a meager $85 ($45 plus core purchased on half-off sale weekend).

With big-blocks available for such a minimal cash outlay, we decided a low-buck build was in order that simultaneously maximized power and minimized expenditure. Naturally we had to set official goals for each. In the power department, we decided that any decent big-block (even one starting out life in the wrecking yard) should produce a minimum of 500 hp. To this power output we decided to add a small shot of nitrous and reach for no less than 700 hp. While a 700hp big-block build is not ground breaking, reaching 700 hp for our self-imposed ceiling of $2,500 (including the engine) is considerably more impressive.

Though we did replace the wimpy stock truck cam, to save money the stock timing chain was reused. We’d strongly recommend stepping up to a new double roller chain, but when money is tight, you do what you have to.

Though we did replace the wimpy stock truck cam, to save money the stock timing chain was reused. We’d strongly recommend stepping up to a new double roller chain, but when money is tight, you do what you have to.

To put this into proper perspective, check out the pricing on some of the big-block (or even small-block) crate motors online. You'd be hard pressed to find a BBC short-block for that price, let alone a long-block equipped with aluminum heads, a performance cam and high-rise intake (with nitrous no less). Heck, there are a lot of BBC cylinder heads that cost more than $2,500, but our plan was to secure a suitable (running) 454 truck engine, add the necessary (cost-conscious) performance components and test the whole mess on the engine dyno. Think of this build up as your own personal stimulus package.

Our Gen-IV 454 pulled from a one-ton work truck was equipped with the desirable four-bolt block, but the reciprocating assembly was a combination of a cast crank, forged rods and cast pistons. Naturally, the lack of forged components worried us, especially the pistons, but we had full confidence in the stock crank at our intended power level. Given the lack of forged internals, every precaution had to be taken with regard to the tune, lest we blow our low bucker to smithereens.

The Pro Comp as-cast head came complete with a 2.25/1.88 stainless steel valve combination valves, valve springs and retainers. The flow rate of our Pro Comp as-cast heads was further enhanced with a custom valve job.

The Pro Comp as-cast head came complete with a 2.25/1.88 stainless steel valve combination valves, valve springs and retainers. The flow rate of our Pro Comp as-cast heads was further enhanced with a custom valve job.

The factory pistons presented another problem in the form of piston-to-valve clearance. The low-compression, dish-top pistons featured valve reliefs designed for the 2.06/1.72 valve combination used on the factory (iron) peanut-port heads, not the larger 2.25/1.88 valve package in our Pro Comp heads. Knowing we needed a healthy cam to reach our goal of 500 hp with the low-compression 454, we mocked-up a pair of cams using the Pro Comp heads and factory pistons prior to assembling the motor. Since we did not have access to the Summit cam we planned to order for this build up, we did the next best thing. We tested P-to-V with a pair of Comp cams, one larger and one smaller than the cam we planned on purchasing from Summit. The smaller XE274H (flat-tappet) cam fit with a minimum P-to-V clearance of 0.115, while the larger XE284H cam snuck by with 0.065. This meant the Summit grind (0.540 lift, 238/248 duration) would easily fit. Running wilder cam timing (like the Comp XE284H or larger) would require use of the Isky valve-notching tool to add the necessary clearance.

The next obstacle was ring seal. A visual inspection and leak down of the motor indicated that it had been run hot sometime in its long life. While we hoped to simply install the new cam, heads and intake on the used short-block, it looks like this particular motor required a bit more attention before final assembly. Due to our budget, new pistons were definitely out of the question, but we elected to install a cheap set of rings after a quick hone to break the glaze. To keep costs down, we honed the cylinders ourselves using a flexible ball hone. The only costs associated with this adventure were the new rings and a couple of cans of brake clean, engine degreaser and Chevy Orange spray paint.

The small valve reliefs in the factory pistons and larger valves in the Pro Comp heads required us to measure the piston-to-valve clearance. The Summit Racing cam snuck by with roughly 0.090 (measured with a pair of larger and smaller Comp Cams).

The small valve reliefs in the factory pistons and larger valves in the Pro Comp heads required us to measure the piston-to-valve clearance. The Summit Racing cam snuck by with roughly 0.090 (measured with a pair of larger and smaller Comp Cams).

While we had the pistons out, we decided to scrape off the years of grease and paint the block. We also hit the tops of the factory pistons with a wire wheel to clean off the oil and carbon deposits (though this reduced our static compression). We wanted a nice, clean surface to minimize the chance of detonation once we hit the nitrous. When we had the block painted, the pistons cleaned and the new rings installed, we reassembled the short-block using the original bearings. Naturally, we'd strongly recommend a complete rebuild (using the stock crank), but this story is for those who accuse us of not speaking low-buck here at Super Chevy.

The awaiting short-block received the hydraulic flat-tappet cam from Summit Racing (K-1303) using the stock timing chain. Again, we'd recommend replacing a high-mileage chain with a new double roller version, but sacrifices had to be made to appease the low-buck gods. The engine was assembled using the low-buck gasket set from Pro Comp with the exception of the head gaskets. We stepped up to a set of Fel Pro 1027 gaskets designed for the Gen-IV block. The complete gasket set from Pro Comp included head gaskets, but the gasket set was designed more for a stock rebuild than performance usage. With nitrous use, we felt better stepping up to the Fel Pro head gaskets (which offered improved cooling passages compared to the Pro Comp set).

Though offered with full CNC porting, we selected a set of as-cast heads from Pro Comp for this low-budget build. The aluminum Pro Comp heads featured 320cc intake ports, a 2.25/1.88 stainless valve combination and flow numbers that easily eclipsed anything offered by the factory, especially our cast-iron, peanut-port heads. Wanting to maximize the power of our head selection, we set aside some of our budget for additional head work.

All dyno testing was run through a set of 2.25-inch Hooker Super Comp headers. This combination would work equally well with a smaller set of primary tubes.

All dyno testing was run through a set of 2.25-inch Hooker Super Comp headers. This combination would work equally well with a smaller set of primary tubes.

In addition to surfacing the heads to bring the chambers down to 116cc to help improve the static compression ratio, we also enlisted the aide of Bryce Mulvey of Dr. J's Performance to fine-tune the as-cast heads with a performance valve job and minor bowl blending. Our relatively mild cam timing could not take full advantage of the high-lift airflow offered by a set of fully-ported CNC heads, but the mild head work offered by Dr. J's would yield big low-lift dividends on the as-cast heads. Check out the before and after airflow numbers, taking note of the low and mid-lift flow gains. Given the max lift of 0.540 offered by our Summit Racing cam, we wanted to concentrate all our flow effort below 0.550 lift. That is exactly what the valve job and minor porting performed by Mulvey accomplished. The Pro Comp heads were torqued in place using a set of Pro Comp BBC head studs.

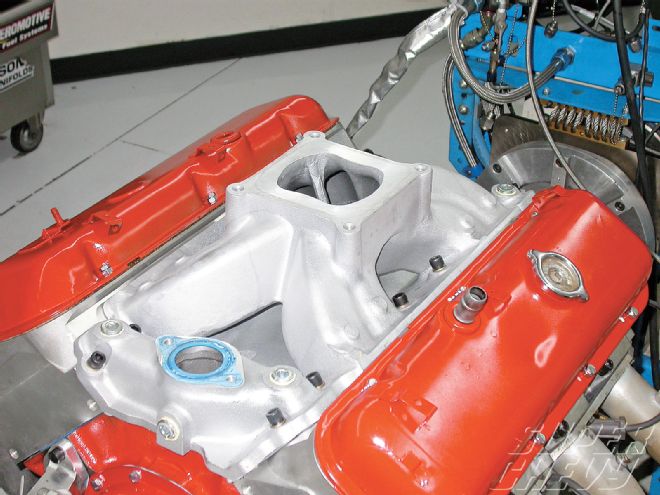

The finishing touches on our BBC build included a set of 1.7 ratio aluminum roller rockers and single-plane Screamer intake manifold from Pro Comp, though we also tested a Weiand Team G (which added roughly $105 to the total bill). The intake was fed by what we thought was a Holley 750 double-pumper carb purchased off eBay. To our surprise, the part number revealed a larger 850 Holley (PN 4781S). With so many carburetors listed for sale on eBay, readers could easily duplicate the cost.

Pro Comp supplied a single-plane intake for our test which performed admirably. We chose the single-plane intake in an effort to help bolster peak power but it was the dual-plane tested after running the nitrous that really impressed us.

Pro Comp supplied a single-plane intake for our test which performed admirably. We chose the single-plane intake in an effort to help bolster peak power but it was the dual-plane tested after running the nitrous that really impressed us.

For a distributor, we ran a stock HEI pirated from the wrecking yard with the motor. For a total cost of $19 (with wires), we made sure we got a distributor with both cap and rotor in good condition and ready to run. It took a little mixing and matching on our part, but there were plenty of HEIs in the wrecking yard available for us to piece together a usable combination. We also snagged a set of stamped steel valve covers for the paltry sum of $5.

All that was left was to install a set of spark plugs, Lucas oil and break-in additive and Hooker 2.25-inch dyno headers (not included in the total). The motor was run on the dyno with a Meziere electric water pump.

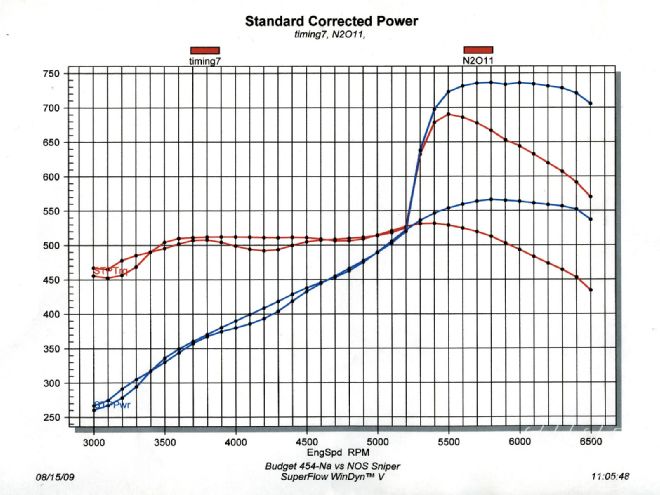

Before letting the hammer fly, we subjected the 454 to a pair of computer-controlled break-in procedures to seat the new rings and ensure the cam and lifters were properly acquainted. After this, the rat was run in anger to the tune of 565hp and 532 lb-ft of torque. Not only had we reached our goal of exceeding 500 hp, but managed to do so by a healthy margin. It appeared the new rings were money well spent. Despite its humble beginnings, the wrecking yard 454 offered a respectable torque curve, bettering 500 lb-ft from 3,500 rpm to 5,900 rpm.

Since we had the 454 on the dyno, we decided to compare the Pro Comp single plane to the Weiand Team G. As it turns out, both intakes produced nearly identical power curves.

Since we had the 454 on the dyno, we decided to compare the Pro Comp single plane to the Weiand Team G. As it turns out, both intakes produced nearly identical power curves.

Now it was time for the juice. To help us reach our secondary goal of 700 hp, we installed a low-buck NOS Sniper nitrous system on the 454. The NOS Sniper kit included everything we needed to add as much as 150 hp to the 454.

To ensure our cast pistons survived the test, we replaced the 91-octane pump gas with 114-octane race fuel and retarded the ignition timing six degrees before hitting the button. Some minor tuning with the bottle and fuel pressure allowed us to dial in the air/fuel mixture to a safe 11.8:1. After the minor tuning session, we were rewarded with peak power numbers of 736 hp and 691 lb-ft of torque.

We had officially reached our goal of producing 700 hp and did so with a total expenditure of just $2,403. The total cost could be reduced further had we secured a running short-block that did not require new rings, but all in all, we'd say a 700hp BBC for less that $2,500 makes good financial cents.

Cost list for BBC article Heads $875 (ebay On-Line Store)

Intake $95 (EBay On-Line Store)

Rockers $85 (EBay On-Line Store)

Gaskets $37 (EBay On-Line Store)

Head gaskets $43 (Auto Zone)

Pushrods $53 (Elgin)

Head bolts $37 (Pro Comp)

Cam & Lifters $89 (Summit Racing)

Carb $129 (EBay-Private Seller)

454 Short-Block $85 (Pick a Part)

Rings $75 (Hastings)

Head Work $325 (Surface, Valve Job & Port-Dr. Js)

HEI Distributor & Wires $19 (Pick a Part)

Stock Valve Covers $5 (Pick a Part)

Misc $24 (Carb bolts & gasket, paint, degreaser, Brake Clean) (Auto Zone)

NOS Sniper $387 (Summit Racing)

Bottle Fill $40

Total $2,403

Airflow Data Pro Comp As-Cast BBC Heads-Effect of Dr. Js Valve Job In/Ex In/Ex Flow Gains-cfm Lift Pro Dr. Js In/Ex .100 67/61 75/68 +13/+7 .200 137/105 151/115 +14/+10 .300 208/142 223/148 +15/+6 .400 263/176 281/179 +18/+3 .500 300/205 325/209 +25/+4 .600 324/225 346/239 +22/+14 .700 343/241 357/260 +14/+19 .800 351/255 366/275 +15/+20The budget 454 not only managed to exceed 500 hp, but did so in spectacular fashion with peak numbers of 565 hp at 5,900 rpm and 532 lb-ft of torque at 5,400 rpm. Credit the flow rate of the excellent Pro Comp aluminum cylinder heads and extra work performed by Dr. Js for some of the power. The Pro Comp single-plane intake worked well to optimize peak power and our used Holley carb and HEI distributor both performed flawlessly. We took extra precautions to properly break in the hydraulic flat-tappet cam from Summit Racing, but this was even more power than we expected from something just snatched from the local wrecking yard. I guess the new rings and head milling were money well spent. Adding the 150hp shot of nitrous from the NOS Sniper kit actually improved the power output by as much as 170 hp (not uncommon when properly tuned). We made sure to optimize the bottle pressure by heating it prior to hitting the button in anger. After adding race fuel and dropping the ignition timing back 6 degrees, we were rewarded with a whopping 736 hp and 691 lb-ft of torque.

The valve job performed to our as-cast Pro Comp BBC heads by Dr. Js yielded big dividends. More importantly, the flow gains came in the lift ranges (sub .600 lift) employed by our hydraulic flat-tappet cam from Summit Racing. No doubt these played an important role in the final power output of our low-buck 454.