Q: For the LS1 aluminum block, how much overbore is safe for a turbo? What is the largest bore for this block? I would have to go 0.020-inch over to clean up my cylinders; is this block still usable?

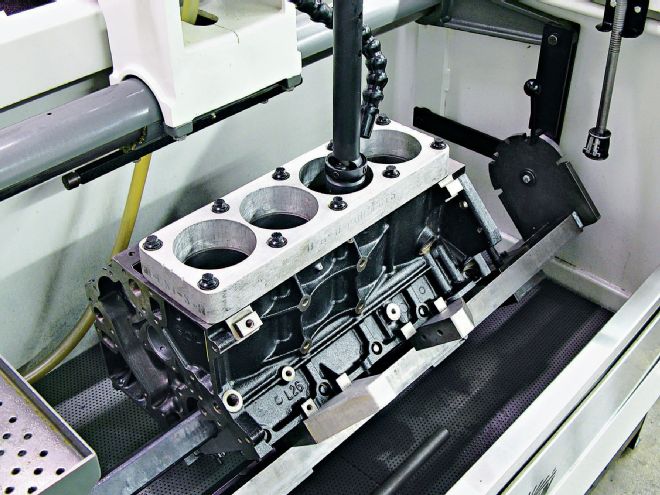

Plentiful and affordable iron truck blocks serve as cost-effective alternatives for a used-up LS1 aluminum casting. Here, the School of Automotive Machinists enlarges a 4.0-inch-bore 6.0L truck block to 4.030 using a diamond hone. A torque plate is mandatory to simulate the bore distortion of a fully assembled engine.

Plentiful and affordable iron truck blocks serve as cost-effective alternatives for a used-up LS1 aluminum casting. Here, the School of Automotive Machinists enlarges a 4.0-inch-bore 6.0L truck block to 4.030 using a diamond hone. A torque plate is mandatory to simulate the bore distortion of a fully assembled engine.

A: Compared to beltdriven superchargers or nitrous oxide, today’s electronic controls make it fairly easy to manage big power gains on a turbocharger. Although officially GM says an LS1 block “has been tested at over 400 hp,” real-world field experience indicates short-duration competition LS1 blocks have withstood at least double that with the standard bore size—for a while, anyway.

Note we said “with the standard bore size.” Bluntly, in terms of accepting traditional standard overbores, LS1 blocks should be considered “throwaway” castings: They accept virtually no overbore at all, even if running normally aspirated. Before the advent of aftermarket aluminum blocks, trick (and high-buck) cylinder sleeving methodology was needed to achieve big bore sizes on production LS1 block castings (see Pit Stop, Mar. 2014).

The reason: Aluminum LS1 blocks have very thin, centrifugally cast iron liners. The blocks are actually cast in place around these liners (rather than the normal practice of pressing the liners into the block after it has been cast). On the very earliest LS1 blocks produced in 1997 and 1998, the sleeves may not always be positioned 100 percent perpendicular within the block casting, meaning that the final-bore sizing and honing process left one side of the walls thinner than the official engine design specs called for. Therefore, 1997–1998 LS1 5.7L aluminum blocks can only be safely honed (not even bored!) just 0.004-inch over the stock bore diameter. Improved liner positioning in 1999-and later 5.7L LS1 blocks and all LS6 blocks permit boring up to 0.010-inch oversize. Either way, you are SOL at wanting to go 0.020-over for a reliable LS1 aluminum block rebuild.

There are several ways to distinguish early from late LS1 block castings. One is by checking the oil-passage configuration located on the rear block face. Visible with the rear cover removed, 1997–1998 blocks that can’t be overbored also have a shallow oil-transfer passage that limits equal oil flow to the main lifter oil galleys (photo). Complete original early assemblies also have perimeter-bolt valve covers, versus the center-bolt covers used on 1999-and later engines. Of course, there are always the block casting numbers located at the back of the block on top of the driver side of the bellhousing flange. Although there may be others, verified casting No. 12550592 definitely designates an early, first-design, “undesirable” block.

So if your LS1 block is used up, what are the realistic alternatives? If on a budget, the best approach is grabbing a sleeveless iron truck block out of the wrecking yard. Plentiful, inexpensive 4.8L and 5.3L iron truck blocks are common as dirt and usually have sufficient wall thickness to accept at least a 0.118-inch overbore (with about a 0.020 “safety margin” left over for future cleanup rebuilds). A 0.118-inch overbore brings them out to 3.898 inches, the same as the LS1 aluminum block.

Although relatively rare (and hence more expensive than their iron sibling), there are also some 5.3L aluminum blocks; several sources report that the outer diameter of the sleeves used in those blocks is the same as the sleeves used in 5.7L LS1 blocks—which would allow boring 5.3L aluminum blocks to the LS1 5.7L block size without incurring the 70–80-pound weight penalty incurred when using the iron block.

The 1997–1998 LS1 block’s rear face (bottom, versus 1999-and later, top) has a shallow, restrictive, oil-transfer passage. Note the early blocks have just two holes above the cam bore; later ones have a large cavity cast into the block above the cam bore. The later blocks’ enhanced oiling and marginally improved overbore capability make them more desirable for performance use.

The 1997–1998 LS1 block’s rear face (bottom, versus 1999-and later, top) has a shallow, restrictive, oil-transfer passage. Note the early blocks have just two holes above the cam bore; later ones have a large cavity cast into the block above the cam bore. The later blocks’ enhanced oiling and marginally improved overbore capability make them more desirable for performance use.

Then there’s the larger-displacement iron 6.0L truck blocks that have 4.0-inch bores; they can be punched 0.060-over to 4.060 inches (although for serious power-adder use I’d back that down to 4.030). Production iron blocks with moderate overbores have survived through 1,100 hp in turbo apps without filling the block with concrete.

Incidentally, some rare 4.8L/5.3L iron block castings can be bored all the way out to the 6.0L engine’s 4.0-inch bore size. As reported by Lingenfelter Racing’s Jason Haines, that’s because (you guessed it), this is a rare universal casting used interchangeably at the foundry to make 4.8-, 5.3- or 6.0L engines. Look for “4.3L-5.3L-6.0L” (all three displacement designators) cast into the block’s front passenger side.

For the Daddy Warbucks crowd, heavy-duty nonproduction GM (Chevrolet Performance Parts/CPP) and aftermarket blocks are available—some of them can accept up to 4.200-inch bores and have lived at the 2,500hp level. They also have more clearance for big stroker cranks, six-bolt head-bolt patterns, optionally available taller deck heights, and plenty of hardcore, professional-engine-builder-friendly features.

Production GM Gen III/IV“LS-Series” Overbore Guide Compiled using information from a variety of sources, this table is correct to the best of our knowledge—but corrections or comments are welcome. Always sonic-check the block first before going for the max listed overbore. Gen III and IV architectures do not directly interchange as a complete assembly. All dimensions in inches unless otherwise noted. Gen Liters Typical RPO Codes Blockmaterial Stock CI Bore Stroke Max Overbore Max Bore-Size Max Overbore CI III 4.8L LR4 Iron 293.6 3.78 3.27 0.130 3.910¹ 314.1 III 5.3L L59, LM7 Iron 325.2 3.78 3.622 0.130 3.910¹ 347.9 III 5.3L L33, LM4 Aluminum 325.2 3.78 3.622 0.128 3.908 347.6 III 5.7L LS1 (1997–1998) Aluminum 345.8 3.898 3.622 0.004 3.902 346.5 III 5.7L LS1 (1999–up), LS6 Aluminum 345.8 3.898 3.622 0.010 3.908 347.6 III 6.0L LQ4, LQ9 Iron 364.1 4.0 3.622 0.060 4.060 375.1 IV 4.8L L20, LY2 Iron 293.6 3.78 3.27 0.130 3.910¹ 314.1 IV 5.3L LY5, LMG Iron 325.2 3.78 3.27 0.130 3.910¹ 347.9 IV 5.3L LC9, LH6, LH8, LS4² Aluminum 325.2 3.78 3.622 0.128 3.908 347.6 IV 6.0L LY6 Iron 364.1 4.0 3.622 0.060 4.060 375.1 IV 6.0L L76, L98, LS2, LFA, LZ1 Aluminum 364.1 4.0 3.622 0.030 4.030 369.6 IV 6.2L L92, L94, L99, L9H, LS3, LS9, LSA Aluminum 376.1 4.065 3.622 0.020 4.085 379.8 IV 7.0L LS7 Aluminum 427.6 4.125 4.000 0.005 4.130 428.7 Notes: ¹Some rare 4.8L/5.3L iron truck blocks can be bored out to 4.00-inch (see text for details). ²LS4: Modified block for transverse engine installations only.

Aftermarket and Nonproduction LS Block Overbore Guide Brand Series Material As-Delivered Bore Options Max Bore Max Stroke Max CI CPP (GM) C5R Aluminum 4.117 4.160 4.10 445.8 CPP (GM) LSX Iron 3.880, 4.065, 4.185 4.200 4.50¹ 498.8 Dart LS Next Block Aluminum 4.00, 4.125 4.165² Not listed Dart LS Next Block Iron 4.00, 4.125 4.220 Not listed RHS GM LS Aluminum Race Block Aluminum 4.100, 4.120, 4.125, 4.160, 4.165 4.165 4.600¹ 501.4 World Warhawk LS1/LS7 Chevy Aluminum 3.990, 4.120 4.155 4.500 488.1 World Motown LS Iron Block Iron 3.995, 4.120 4.200 Not listed Notes: ¹Achieving listed maximum stroke may require optionally-available “tall-deck” version plus small base circle camshaft. ²Darton MID sleeve option permits up to 4.220-inch bores.