We've all read the claims that adding a certain part or widget will add X-amount of horsepower to your engine, but are the claims actually true. Well, yes—and no. It all comes down to application, and no matter how similar two engines might be, the outcome will never be exactly the same.

Let's take for instance, swapping camshafts. Relatively speaking, it's not actually a lot of work to perform to receive what could be the greatest gains in power that an engine can experience. The camshaft is one of the main determining factors in an engine's potential to make power—especially within a given rpm range. Since the affected power band is different depending on camshaft, one of the most important aspects to consider when selecting a camshaft, is to have a realistic, specific rpm goal in mind before you begin. If you are changing the camshaft to get more low-end grunt, choose accordingly. On the other hand, gaining maximum high-rpm horsepower takes an entirely different set of camshaft dimensions. Lying to yourself about what you actually need as opposed to what you actually think you want, has caused many car guys to park their rides and lose interest because the car is no longer enjoyable to drive. We want to help you avoid that particular scenario. To do that, you might need a little information about camshaft specifics, so check out the sidebar.

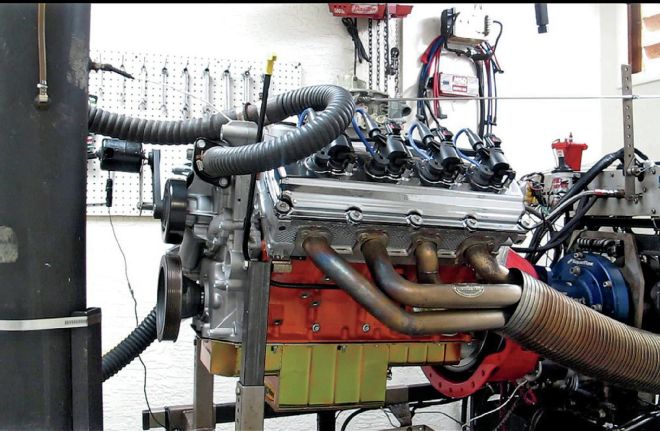

It's been proven that the 5.7 Hemi responds well to more aggressive cam timing than the factory installed, but just like an old school engine, we wanted to find out if it's possible to over cam an engine—especially when working on a daily driver. To make this swap ideal, we had to make sure that the cam upgrade improved horsepower throughout the entire rev range, not just at the upper limits. While big cams provide a ton of extra power at the top of the rpm range, large cams often sacrifice low and mid-rpm range torque. Since we're discussing street cars, the reality is that the engine spends most of its life between 2,000 and 3,500 rpm, not over 5,000. Occasionally, spirited driving will push that limit, but that only happens occasionally. You need to take that into account when considering a cam swap. Now, there are exceptions to this rule, and it all depends on the desired outcome of the engine, the parameters of the engine build, and other factors. If you're building a modified engine, then it would be best to call the manufacturer and get their recommendations. We're focusing on a completely stock 5.7 Hemi. Although our 5.7 is a crate engine from Mopar, other than a carbureted intake, this engine is the just about the same as thousands of other "as-installed" 5.7 Hemis that were delivered by Chrysler.

We know that a lot of you guys want to boost the power of your ride, but you're just not sure what will work for you. Well, when it comes to increasing the power of a stock 5.7, we figured that we could help you guys choose a camshaft that best suits your needs by testing three different cams from Crane Cams. The camshafts we tested all displayed near stock to what we'll call a mild, muscle car type idle. Our three test cams all raised valve lift of the 5.7's factory .472/.460-inch lift, to .550/.550-inch lift. This lift alone will definitely increase power, but we were curious about what affects, changes in duration would have. Our 5.7 Hemi came with a camshaft that has 196/196-degrees of duration, which definitely enhances a smooth idle quality and higher vacuum. Our Crane cams each came with duration numbers of 210/216, 216/222, and 222/228-degress of duration respectively.

On With the Testing

Stock

We first needed to establish a baseline, so we bolted the 5.7 to the Superflow Dyno. It immediately fired, and right away, we noticed its stock-like idle quality. We ran it through a couple of warm up cycles, and decided to turn up the rpm. Everything sounded good until we got to 5,800 rpm. As soon as the tach hit 5,800, the engine began to shake and miss. At the time, we weren't exactly sure whether the stock controller had a rev limiter, or if the stock valve train had reached its limit. Once we made sure that the engine was ok, we made one more pull to see if it happened again—it did. We figured that since we needed to change the valve springs anyway, we would change only the springs, and see if it eliminated our miss. All of the Crane cams used the same PN 99831-16 valvesprings that are good to 600-inch lift, so we only had to do one spring swap.

Once again, the engine missed at 5,800 rpm, and we confirmed the presence of a rev limiter in our engine controller. Unfortunately, we were unable to disable it, and since we were focusing on a true street engine, a 5,700 rpm limit is where we would end our tests. We ran all tests from 3,000 - 5,700 rpm. In stock form, the engine made a very respectable 352 horsepower at 5,300 rpm, and 359 lb-ft of torque at 4,600 rpm. At 3,200 rpm, our torque was 338 lb-ft, and went up from there. The averages in stock form were 293 horsepower and 346 lb-ft of torque at 4,450 rpm.

Crane Cam One (PN 1989501)

As soon as the baseline was out of the way, we installed our first Crane camshaft. We were confident that our increase in lift and duration would boost power, but we were hesitant to guess at how significantly. With .073/.080-inch more lift than the stock cam and 14/20 more degrees of duration, anything was possible. The engine fired immediately, and if going by sound, we weren't sure we even swapped the cam. It idled smoothly, and acted very docile. Our swap was confirmed when we ran our test, as the new camshaft raised our power numbers to 391 horsepower at 5,700 rpm, and torque was up to 375 at 4,500 rpm. The added lift and duration had definitely increased power, but it also moved our average to 306 horsepower and 360 lb-ft of torque.

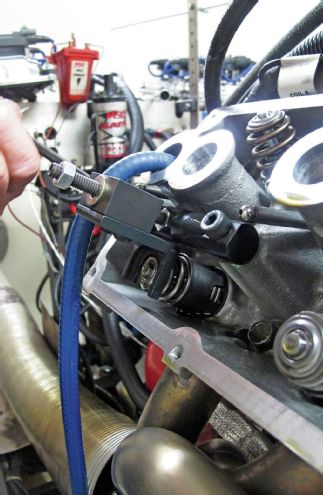

Now it's time to change the springs. You will need to pressurize the cylinder using an air compressor. The valvespring tool bolts to the shaft stands, and once you have compressed the spring, you can remove the valvespring keepers. Discard the old spring and place the retainer and new spring on the valve. Next, reinstall the keepers. Make sure that to verify that the keepers are flush against the valve, and that the retainer is sitting flat at the top of the valve.

The Crane springs are slightly larger in diameter than the factory pieces, so the damper surrounding the spring will not be used.

After our first pull, we thought we might have a valve train issue, as the engine would miss after 5,700 rpm. To verify whether it was valvetrain or a built-in rev limiter in our engine controller, we changed just the springs and ran it again. The controller has a rev limiter.

Once we had our stock baseline, it was time to try the first of our three Crane camshafts. Our first one was PN 1989501. With .550/.550-inch lift, and duration coming in at 210/216 degrees, we had big hopes.

Crane Cam Two (PN 1989511)

We were hopeful that our next swap would also give us an increase in horsepower. Our second camshaft had the same .550/.550-inch lift, but duration had increased to 216/222 degrees. Since a longer duration will move the power band, we wanted to see what happened at our rpm limit. We knew that we were limiting the cam's potential with a 5,700 rev limit, but with our Mopar engine controller, we are unable to change it. As soon as we started the engine with our second Crane cam, we immediately noticed a more aggressive idle. It wasn't drastic, but did have a mild lope to it. When we got the engine to operating temperature 160 degrees, and the oil to 135 degrees, we started our testing. When we were done, the second Crane camshaft gave us 389 horsepower at 5,700, and 375 lb-ft of torque at 4,600 rpm. With power only being down two horsepower, we called it even. With this camshaft, our peak power came in just at the end of our rpm range. As expected, the increase in duration did affect our power at the bottom of our rpm range. What's this mean? If you have a hard time leaving the line, taking some bottom end away might help you get the car moving. Our averages for this cam were 305 horsepower, and 358 lb-ft of torque. Again, the difference was so minute, that we call it an even trade—unless you count the more aggressive idle characteristics. That alone is a plus in our book.

Crane Cam Three (PN 1989521)

We knew going in that our test was not going to show this camshaft in the best light. This camshaft—with its .550/.550-inch lift, and 222/228-degrees of duration, would really want to stretch its legs just as our rev limiter would cut it off at the knees. Does this mean that this cam has no reason in a street car? Not at all, it means that this cam would best be suited for a street car that might carry a few more mods than most of its brethren. If you're willing to sacrifice a little power lower in the rpm range because your engine does spend time at higher rpm, than this might be the cam for you. Once started, the engine's idle was again "lopey," but it was hard to actually distinguish whether it was any "lopier" than our last camshaft. What we noticed was, at 5,700 rpm, we had 375 horsepower. Sure, this might be lower than the previous two cams we tested, but what the "limited" test doesn't show you, is that the engine was still gaining horsepower at our 5,700 rpm test limit. Since our controller limited the engine rpm, we can't say whether or not the third camshaft would have eventually made more power than our other two Crane camshafts, but even if it made the same power, having it at the upper end of the rpm range definitely makes it more of a racer-oriented camshaft. The averages for this camshaft were expectedly lower than our previous camshafts, as the power came in at a higher rpm, but even so, Crane camshaft number three had an average horsepower of 286, and an average toque of 336 lb-ft.

Price Tag

part PN COST Valvesprings 99831-16 $232.00 Cam 1 1989501 $468.00 Cam 2 1989511 $468.00 Cam 3 1989521 $468.00 Valvespring tool 99476-1 $168.00Choosing Wisely Means Know These Terms

Lift

The valves need to open, in order to allow the air and fuel mixture to enter the engine, and to let exhaust gas out of the engine. Generally speaking, opening the valves quicker and further will increase engine output. Increasing lift and not duration can have the effect of increasing power without much of a change to the power curve.

Duration

Duration has a tremendous effect on an engine's running personality. When using a lower duration camshaft, an engine will typically produce more torque in the lower rpm range. Conversely, camshafts that possess larger duration specifics will sacrifice some low-rpm torque, to gain upper rpm power. It is commonly believed that each 10-degree change in duration moves the engine's power band up or down in the rpm range by 500 rpm.

Lobe Separation

This is the actual angle as measured in camshaft degrees, between the maximum lift points of the intake and exhaust valves. It is the placement of the intake and exhaust lobes on the camshaft. Lobe separation has an effect on valve overlap, which affects the nature of the power curve, idle quality, and idle vacuum.

Overlap

Overlap is the measurement—in crankshaft degrees, of when both the intake and exhaust valves are open. This occurs at the end of the exhaust stroke, and the beginning of the intake stroke. Increasing lift duration and/or decreasing lobe separation increases overlap. At high rpm, camshaft overlap allows the rush of exhaust gasses exiting the cylinder to help pull fresh air and fuel into the cylinder. Increasing overlap does increase top-end power, but will also reduce low-speed power and idle quality.

Centerline

The intake centerline is the highest point of lift on the intake lobe. It is referred in crankshaft degrees after top dead center (ATDC). Exhaust centerline is the highest lift point on the exhaust lobe. It's expressed in crankshaft degrees before top dead center (BTDC). The cam centerline is the point halfway between the intake and exhaust centerlines.

Check out www.moparmuscle.com for video and complete dyno graphs and charts for each cam.

We weren't disappointed, as our first Crane camshaft improved horsepower by 39 horsepower, and 16 lb-ft of torque.

Our second Crane camshaft had the same lift as our first Crane cam, but the duration was a little larger at 216/222 degrees. We didn't know how much more power it would make. Especially knowing that more duration likes more rpm, and we were limited.

With everything buttoned up, and the engine ready for a couple of runs, we started our tests. Even with slightly more duration, the second Crane cam had very comparable results with our first Crane cam.

It was time for our final cam swap. Would the Crane cam with .550/.550-inch lift and even more duration (222/228) degrees do any better? We were really concerned about the rpm limit of our controller with this camshaft, as we were certain that it would like the higher rpm area.

With the final Crane cam installed, our fears were confirmed—the third cam liked higher rpm. Although horsepower was down below 5,000 rpm, it really came alive after 5,000. Unfortunately, our rev limiter wouldn't allow us to find its final happy spot, as power was still climbing after 5,700 rpm.