If size is the only thing that matters, then big-block Fords would dominate the street/strip world. They don't. At least not yet, but big changes are on the horizon thanks to Air Flow Research. Most commonly unleashed to the public in 429- and 460ci configurations, Ford's 385-series big-block has all the right stuff for maximizing displacement. With a 10.320-inch deck height and an extra-wide crankcase, it can easily swallow up a 4.500-inch crank. Likewise, the big Ford's 4.900-inch bore spacing yields cylinder walls thick enough for at least a 4.440-inch bore. Consequently, 557 ci can be yours using an OEM block that sells for peanuts at the local junkyard. On the flip side, easy access to cheap stroker kits and mega cubic inches means you need some serious cylinder heads to keep pace. While the big-block Ford crowd has been seething with jealousy over the endless cylinder-head options their big-block Chevy competition has to choose from, all of that's about to change if Air Flow Research has any say in the matter. The company's brand-new Cobra Jet–style heads are poised to revolutionize the Ford market.

Thanks to our incessant finagling, we were able to bribe AFR's security with some Q16 and VHT to check out these new cylinder heads in person. Although they're still a work in progress, the initial flow figures from AFR's prototype castings are very promising. The intake ports on AFR's entry-level 270cc heads check in at close to 400 cfm at just 0.650-inch lift. Considering that the factory Cobra Jet architecture is stricken with notoriously weak exhaust ports, the 280-plus-cfm AFR is even more impressive. AFR also plans on releasing heads with larger 285cc and 300cc intake-port configurations. Tony Mamo, AFR's R&D manager and chief designer behind the project, speculates the 300cc version could approach or clear 420 cfm on the intake side and more than 300 cfm on the exhaust.

Granted that AFR has earned an outstanding reputation within the small-block Chevy, big-block Chevy, GM Gen III/IV, and small-block Ford markets, the big-block Ford arena represents an entirely new frontier for the company. Nevertheless, AFR felt that the time to pounce is now.

"Over the years, lots of people have asked us to develop a big-block Ford cylinder head," Mamo explained. "We have many happy customers running our small-block Ford heads, so it made sense to round out our Ford lineup. There are certainly some good big-block Ford heads on the market, but we wanted to raise the bar considerably and felt that by ditching the large-and-inefficient, factory, egg-shaped intake-port design and coupling that with a vastly improved exhaust port, we could really give the BBF fans something to rejoice over. In fact, our new big-block Ford product is the most clean-sheet cylinder-head design we've ever undertaken. Despite the fact that it shares very little with most of the other heads in the marketplace, it's still a bolt-on upgrade that readily accepts OEM and aftermarket accessories."

Cobra Jet Shortcomings

Fully understanding where the new AFR castings stand on the big-block Ford evolutionary ladder requires examining the history of the 385-series cylinder heads. In the realm of high-end drag racing, options abound for big-block Ford heads capable of flowing well over 500 cfm. Much like a spread-port big-block Chevy casting, these 429/460 race heads trace their roots to NHRA Pro Stock. Likewise, they typically require extensive prep work, exotic valvetrain components, and intake valves too big to fit inside a bored-to-the-max factory block. Consequently, once factoring in the labor and supporting top-end hardware to make it all work, they can set you back more than $10,000. In other words, flow numbers aside, these aren't exactly street-friendly or budget-friendly options.

On the opposite end of the spectrum are aftermarket castings based on Ford's OEM Cobra Jet cylinder head architecture. Often referred to by the Ford faithful as "A429" castings, the factory Cobra Jet heads were plagued by a fundamental design flaw that positioned the valves too close to the exhaust-header side of the block. As such, airflow never quite lived up to potential offered by the big-block Ford's canted-valve layout and flat 15-degree valve angle. "With the stock Cobra Jet heads, the valves are crowded too close to the outer cylinder wall. You're not utilizing the entire circumference of the valve," Mamo said. "Air likes a continuous flow path, and you're essentially chopping off the curtain area if the valve is up against the cylinder wall. When that happens, you can end up with a 2.300-inch intake valve that performs like a smaller valve because it's so shrouded."

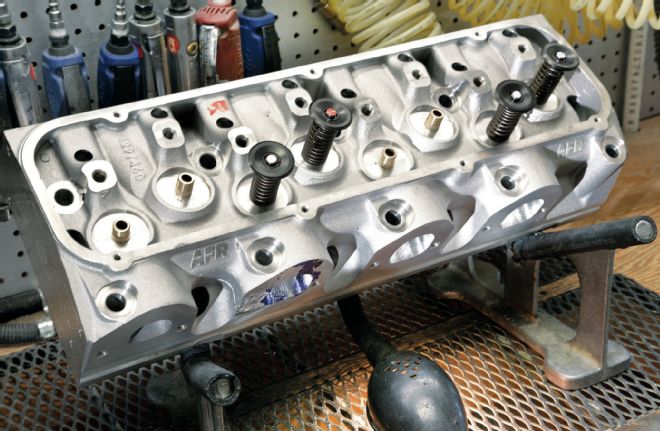

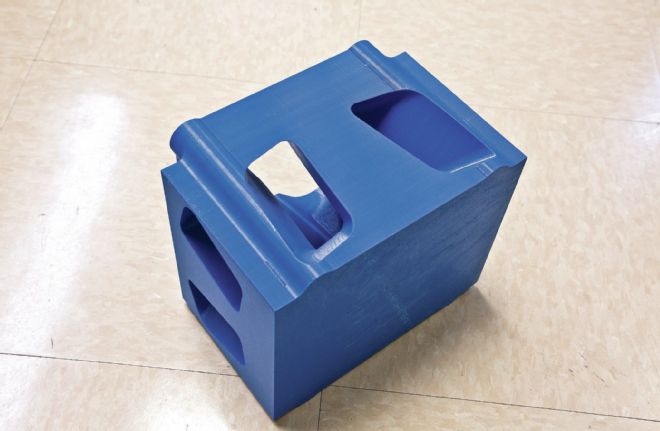

With a 3⁄4-inch-thick deck and beefy reinforcements throughout, AFR's big-block Ford cylinder head can handle power-adders with ease. It's drilled for 7⁄16-inch rocker studs and is fully compatible with the standard 429/460 valvetrain components.

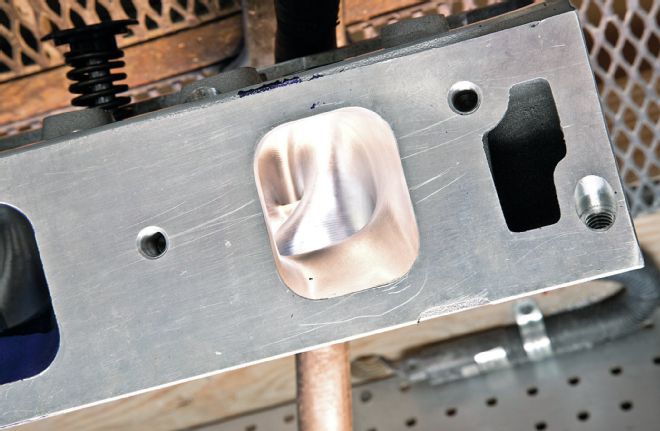

Overlaying a stock intake manifold gasket on the AFR heads clearly illustrates how dramatically the intake-port geometry has been revised. AFR's flow testing revealed that there is little to no air movement around the edges of the inefficient OEM-style, egg-shaped port.

Since AFR will offer standard-height exhaust ports, as well as ports raised 0.250 and 0.600 inch, the head casting boasts plenty of material around the exhaust ports. Many aftermarket 429/460 cylinder heads utilize a big-block Chevy header flange pattern, but AFR stuck with the big-block Ford layout to maintain compatibility with existing headers.

AFR determined early on that designing the intake ports around existing off-the-shelf intake manifolds would severely limit its ability to optimize port architecture. Instead, AFR designed a new intake manifold around the cylinder heads, which allowed completely abandoning the inefficient egg-shaped factory port design. To eliminate sharp edges that restrict airflow, the new ports feature smooth, rounded corners. While they can technically be considered oval-port heads, they are much more rectangular than the stock egg-shaped ports (aka Mamo's "roval" designation).

Revised Valve Positioning

Considering the problematic valve positioning of the factory Cobra Jet cylinder heads, one of AFR's top design priorities was relocating the valves closer to the cylinder-bore centerline. "Relocating the valves closer the bore centerline gives you a lot more real estate for unshrouding both the intake and the exhaust valve. This allows the ports to become more efficient, especially in the lower lift regions of the flow curve," Mamo said. "It also opens up opportunities to install a larger valve without the typical shrouding associated with less-than-ideal valve positioning. This change really helped our exhaust-port flow, which, as most big-block Ford engine builders know, is the Achilles' heel of the OEM 385-series cylinder heads. Even the newer Cobra Jet heads—which are an upgrade over stock—are hampered by exhaust flow numbers that wouldn't even get a small-block Ford enthusiast excited. It's the major bottleneck of this cylinder-head architecture and the reason why most big-block Fords don't make the power that their intake-port cfm might lead you to believe is possible. They just can't properly evacuate the cylinder to make room for the next fresh charge of air during the intake stroke."

Filling the Floors

In addition to repositioning the valves closer to the center of the bore, AFR substantially filled the floor of the exhaust port to remove the dog-leg shape that's inherent to the stock head's design. "The airflow is trying to negotiate a 120-degree turn, and it simply can't do that once you start moving a reasonable amount of high-speed air through the port. By filling the exhaust floor, we removed an area of dead space that causes back swirl and turbulence," Mamo said. "Not only do you pick up cfm from doing so, you greatly enhance the port's efficiency because the smaller, higher-flowing port has a lot more air speed. That creates a better siphoning effect for the next intake charge, which helps get it moving into the cylinder on the overlap cycle of the valve events. With the improved valve locations, the filled floor, and a ton of time invested in the overall port design, our standard-height exhaust port will flow over 275 cfm, a very stout number for a bolt-on-style 385-series cylinder head." AFR will also have two raised exhaust-port versions of this design with flow numbers exceeding 300 cfm.

Valve Angle

Of course, great exhaust flow doesn't mean squat without intake ports capable of filling up the cylinders in the first place. Although a super-flat valve angle would have definitely been worth some wow factor, AFR took a more practical approach to designing its intake ports instead. "We could have gone with a very flat valve angle to make our heads look more impressive on paper. However, if you don't have the right port geometry to go along with it, it's not going to work," Mamo explained. "Unless you can substantially raise the height of the port entrance, a flatter valve angle forces the air to make a much sharper turn at the short-turn radius. As air speed and density increase at the higher lifts, forcing the air to negotiate a sharper turn will ultimately limit how much you can get through the port, and the airflow is likely to stall and go turbulent. To avoid this, we opted for a 14-degree valve angle, which is certainly flat in the grand scheme of things, but not as flat as some other heads on the market. Similar to improving the shape of the exhaust port by filling the floor, we also improved the ‘angle of attack' of our intake port by taking advantage of the tall, egg-shaped OEM ports. By filling and raising the floor considerably with our rectangular-oval-port design—which we call ‘rovals'—it helps reduce the angle the airflow must turn to get into the cylinders, creating a slightly straighter shot from the port entrance to the backside of the intake valve. We took the available real estate we had in the excessively large factory port design and used it to our advantage by positioning our smaller, more-efficient roval design at the roof—not on the floor like the OEM port architecture"

The combustion chambers should be an extension of the valve job, and AFR has accomplished exactly that. The entry-level 270cc head will come with a rougher level of CNC port work to keep machining time and costs down, while the 285- and 300cc variants will receive a finer level of full CNC porting. Reducing the speed of the CNC machine helps achieve a smoother, more accurate copy of the highly developed prototype cylinder-head design. Regardless of runner volume, all heads will come with a competition, five-angle valve job.

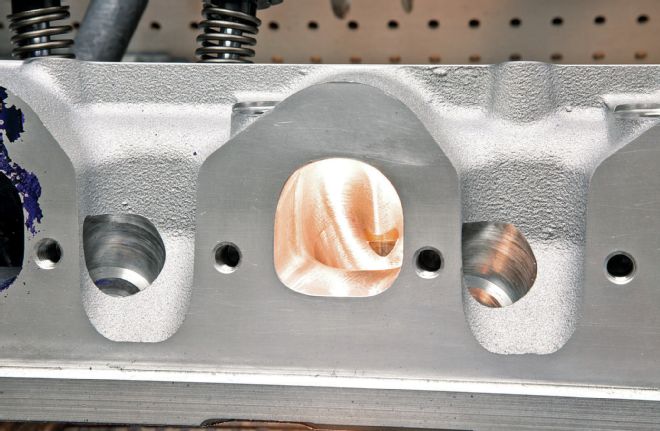

AFR spent hours profiling the area directly beneath the valve seats to ensure that air could flow freely around the valve's entire circumference. With a standard 2.250-inch intake valve in place, there's plenty of room for air to flow around the valve face.

In addition to unshrouding both the intake and exhaust valves, relocating the valves closer to the bore centerline also creates two similarly sized quench pads and both sides of the combustion chamber. For increased fuel homogenization and detonation resistance, quench is a very good thing.

In a factory Cobra Jet cylinder head, the intake-port floor is positioned so close to the deck that the incoming air charge is forced to move "uphill," which reduces air speed and wastes energy. By raising the port floor, AFR was able to increase air velocity while creating a smoother transition at the short-turn radius. This also helps stabilize airflow at high lift.

Customers opting for AFR's standard-height exhaust port will still benefit from a huge increase in flow. By filling in the port floors, AFR was able to dramatically improve high-lift exhaust flow. Once development work is complete, the company is hoping that its 0.600-inch raised port head will flow more than 300 cfm. As any big-block Ford fan will attest, that's a very big deal.

Port Geometry

From the outside, the most dramatic difference between AFR's new cylinder head and the factory Cobra Jet casting are its rectangular intake ports. Technically speaking, their rounded corners could qualify them as oval ports, but, compared to the factory ports, they're very squared-off indeed. Nevertheless, according to AFR, the stock egg-shaped ports are very inefficient by nature and don't move enough air to warrant their cross-sectional area. "The factory-style Cobra Jet ports are a huge waste of space. Due to their inefficient shape and improper sizing, there simply isn't much air speed and inertia in the ports, and that kills any potential responsiveness in the engine," Mamo said. "A lazy port design with low air speed creates a pretty lazy power curve. Dramatically increasing port velocity will increase power and torque through the entire curve, in addition to improving throttle response, air speed inertia, cylinder filling, and fuel efficiency. The result is high-rpm horsepower with no compromises in part-throttle snappiness and low- and mid-range torque."

While AFR's revised port shape represents a dramatic departure from the factory Cobra Jet port geometry, rectangle ports are nothing new in the big-block Ford camp. Make that the super-high-end, big-block Ford camp. The cold, hard truth is that Ford's best Pro Stock heads since the 500ci era began—whether they're A460, B460, C460, D460, or E460 castings—all utilize rectangular intake ports, which validates the merit of the design. AFR is now incorporating this race-inspired technology in a true bolt-on street package that's 100 percent compatible with standard big-block Ford bore diameters, rocker arms, and headers. Of course, AFR's revised intake ports will require a new intake manifold, but the company is also developing an all-new cast intake manifold designed specifically for its cylinder heads.

Rat-Stomping Airflow

Getting 400-plus cfm of airflow out of a 270cc intake port is plenty impressive, but to put things in perspective, let's compare them to AFR's big-block Chevy castings.

Since the popular hot rodder method of comparing different types of cylinder heads (i.e. BBF versus BBC) based on intake runner volume is pointless, we focused on cross-sectional area instead. According to Mamo, the new 270cc big-block Ford heads have a cross-sectional area that's most comparable to the company's 300- and 315cc big-block Chevy castings. As the flow-comparison chart reveals (page 36), the Ford head has the Chevy competition handily covered on the intake side by 16 cfm. Furthermore, it's not until stepping up to AFR's 335cc big-block Chevy heads that the Bow Tie brigade catches up to AFR's new big-block Ford casting. Making the feat even more impressive is the fact that the Ford heads were flow-bench tested using a 4.390-inch bore fixture, which is rather small considering the 429/460's standard bore diameter of 4.360 inches.

These are some seriously mean cylinder heads, and with roughly 400 cfm of airflow on tap from AFR's entry-level offering, they can easily support 750–775 hp in a pump-gas application. If AFR is able to hit its goal of 420-plus cfm from its 300cc casting, then 800–850 hp is well within reach for aggressive pump-gas combos and 950-plus isn't out the realm of possibility for a 15.5:1 race-gas motor. That's not too shabby for out-of-the-box, bolt-in-and-go, street/strip heads. It's worth noting that these are preliminary airflow figures gathered from pre-production cylinder heads, but we know from experience that AFR tends to be conservative with its airflow figures.

AFR's new big-block Ford cylinder heads are tentatively scheduled to be on sale by the time your read this. Once the first batch of production heads have been cast, stay tuned to Car Craft for an exclusive first flow-bench and dyno test.

Flow Comparison (cfm at 28 inches)

AFR BBF 270 cc AFR BBC 315 cc AFR BBC 335 cc Valve Lift Intake Exhaust Intake Exhaust Intake Exhaust 0.200 171 139 169 148 164 142 0.300 245 156 249 187 240 193 0.400 311 225 312 238 304 244 0.500 356 253 353 271 352 278 0.600 392 272 380 296 385 310 0.700 402 279 386 310 404 321

By The Numbers

AFR BBF Head Specs 270 cc 280 cc 305 cc Intake valve diameter 2.250 in 2.250 in 2.300 in Exhaust valve diameter 1.760 in 1.760 in 1.760 in Valvespring diameter 1.550 in 1.550 in 1.550 in Combustion chambers 75/88 cc 75/88 cc 75/88 cc Intake valve angle 14 degrees 14 degrees 14 degrees MSRP (pair) $2,099 $2,599 $2,799

One of the oldest tricks in the book for inflating airflow numbers is using an unusually large bore fixture on the flow bench. To keep its figures honest and realistic, AFR flow tested these heads on a 4.390-inch fixture. Considering that the standard bore on a 429/460 block is 4.360-inch, AFR's test procedure is about as realistic as you can get. Likewise, a test pipe bolted to the exhaust ports keeps the exhaust flow figures as accurate as possible.

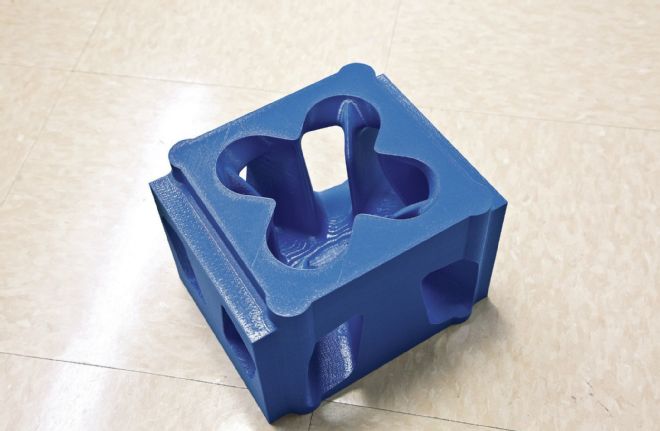

To streamline the R&D process, AFR mocked up 3-D prototypes of its new 429/460 intake manifold. The single-plane design isn't much taller than current aftermarket offerings in order to preserve hood clearance, but it still has plenty of plenum volume to feed big-cube motors at high rpm.

In an effort to reduce the disparity in airflow between the inner and outer cylinders, the new manifold features an elongated plenum design. This increases the length of the center runners, while decreasing the length of the outer runners.

With prices starting at $2,099, AFR's big-block Ford cylinder heads will be one of the most affordable 429/460 options on the market. AFR hopes to have them available to the public by the time you read this.