Our Blue Collar 454 first appeared in the July '12 issue and consisted of a stock-bore block and rotating assembly from a late-'70s Suburban and a pair of 049-casting oval-port cylinder heads (rebuildable cores can be found on eBay for about $100–$150 apiece). Though the parts were incredibly grimy, the block cleaned up well and showed very little wear in the cylinders. JMS Racing Engines in El Monte, California, rebuilt the heads for us while we reconditioned the block and stock rotating assembly at home. With a tiny RV cam, this combination made 408 hp and 511 lb-ft of torque for the paltry sum of $1,900 carb-to-oil pan (including the machine shop cost!). We were so cheap, we ran out of engine paint and didn't finish painting the heads. All the details can be found in the July '12 issue.

We did a couple more builds with it, adding forged pistons and a tunnel ram, and making 594 hp (naturally aspirated) and 800 hp on nitrous before destroying one of the main bearings. We've brought the Blue Collar 454 back this month to try to duplicate that feat, but without the pricey tunnel-ram/dual-quad setup. We achieved that goal—exceeding it by a few ponies, in fact—and in the process, we laid a good foundation from which to proceed. Our plans are to fully maximize the potential of these lowly cast-iron cylinder heads before seeking an aftermarket solution.

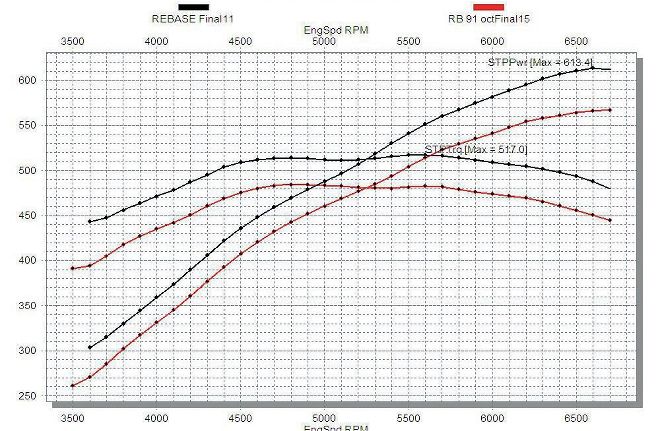

On the Dyno

114-octane Rockett Brand gasoline, 36 degrees total timing

91-octane Rockett Brand gasoline, 28 degrees total timing

RPM TQ HP 3,500 391.3 260.8 3,600 394.3 270.2 3,700 404.9 285.2 3,800 417.8 302.3 3,900 427 317.1 4,000 435.2 331.5 4,100 442.1 345.1 4,200 450.8 360.5 4,300 460.5 377 4,400 469 392.9 4,500 475.3 407.2 4,600 480.2 420.5 4,700 483.1 432.3 4,800 484.5 442.8 4,900 484.3 451.9 5,000 483.7 460.5 5,100 482.6 468.6 5,200 481.3 476.5 5,300 480.4 484.8 5,400 480.2 493.7 5,500 481.5 504.3 5,600 482.4 514.4 5,700 481.7 522.8 5,800 479.2 529.2 5,900 476.4 535.1 6,000 474 541.5 6,100 471.9 548.1 6,200 469.5 554.2 6,300 465.5 558.4 6,400 460.6 561.2 6,500 455.9 564.3 6,600 450.7 566.4 6,700 444.6 567.2

Watching Star Trek and assembling big blocks.

Stepping into the Wayback machine, here's what the engine looked like when we first took possession. It's difficult to believe something this gross could make decent power.

Based on previous building experience, we decided to try a bigger cam and slightly bigger intake valves—going from 2.18-inch to 2.250-inch, the same size that performance rectangle-port heads use. The exhaust valves remain 1.88-inch, as used in the last test. We installed Comp Cams' Sportsman stainless steel valves this time, with an 11⁄32 diameter, which is slightly thinner than stock.

We also knew the cam we wanted to use would make peak power somewhere above 6,500 rpm, so we opted for Comp's tool steel valvespring retainers, shown in the foreground. They weigh about 33 percent less than chromoly retainers and are within 4 grams of titanium, yet cost about $100 less. Shedding some weight from the retainers allowed us to rev the engine a little higher and offers better valve control at high rpm.

Fred De La Cruz at HPS Automotive Machining did some basic clean up in the exhaust ports, where big-block heads can use more airflow.

Upon disassembly of the last iteration of Blue Collar, we discovered the spark plugs had been hitting the piston domes in all the cylinders. We were lucky that no damage was done, but this shows the importance of not only selecting the correct heat range spark plug but also the correct reach into the combustion chamber.

We used a carbide cutter to grind the spark-plug gouge out of the pistons. We also took the time to grind all the sharp edges off the piston domes. We didn't remove much material, just rounded off the sharp edges.

We chose a solid flat-tappet cam from Comp with 270/280 degrees duration at 0.050-inch tappet lift and 0.650-inch valve lift with stock ratio rocker arms. Because of the increased lift and duration from the previous build, we needed to check piston to valve clearance again, so we temporarily reinstalled the cam.

Test Day

At Westech, we installed an Edelbrock Victor Jr. intake manifold and MSD distributor, filled the crankcase with 6 quarts of Comp's engine break-in oil, fired the engine, and ran it through a break-in cycle. Even with relatively high valvespring pressure (150 lb-in installed height/350 lb-in open), our flat-tappet cam broke in fine. With the right assembly lube, break-in oil, and a proper break-in procedure, there's no need to fear using a flat-tappet cam.

Westech's Steve Brulé used 114-octane Rockett Brand gasoline for break-in and the first several dyno pulls, and our engine surprised us with a peak horsepower number of 613 at 6,600 rpm. Brulé eased off the throttle at what appeared to be the onset of valve float. With lighter valvetrain components and/or more spring pressure, we think this engine will continue to make power up to 7,000 rpm—something we will experiment with soon.

Brulé then surprised us even more by reducing the total timing to 28 degrees and running the engine on Rockett 91-octane gasoline. Blue Collar cranked out 567 hp with absolutely no indication of detonation.

*This engine actually costs a bit more than it needs to because we are using parts left over from some roller cam R&D tests. The good news is that you can build it for less and make the same amount of power. According to Comp's web page for our cam grind, the company recommends less-expensive rocker arms, pushrods, and timing set than the ones we used. You can also save some money using Fel-Pro's composite head gaskets, which cost about half the cost of MLS gaskets. We still recommend the tool steel retainers, however. Recalculating our total with Comp's recommendation and composite gaskets comes to a grand total of $3,766.05—an awesome price for a ready-to-run, 600hp, big-block Chevy, especially one you could drive to the track. If you can spend more, the added insurance of our Ultra Gold rocker arms and boost-ready MLS gaskets mean you will have room to grow if you want to squeeze more power out of this combination, which we plan to do soon.

Parts List

Description P/N Source Price Used 454 NA Hot Rod Magazine $300.00 Sealed Power engine rebuild kit CSMHP771-300 Summit Racing 789.97 MLS head gaskets Fel-1071 Fel-Pro 151.94 Cylinder head bolts ARP-135-3601 ARP 82.66 Main cap bolt kit ARP-135-5002 ARP 41.72 Connecting rod bolts ARP-135-6401 ARP 68.96 7/16-inch rocker studs ARP-135-7102 ARP 47.98 Comp solid flat-tappet cam CCA-11-406-5 Summit Racing 191.99 Performance Series solid lifters CCA-2900-16 COMP 99.97 Intake valves: 2.250-inch CCA-6022-8 Comp 99.97 Exhaust valves: 1.880-inch CCA-6023-8 Comp 89.97 Valvespring locators CCA-4759-16 Comp 34.97 Valvesprings CCA-954-16 Comp 129.97 Valvespring retainers CCA-1732-16 Comp 149.97 Viton valve seals CCA-517-16 Comp 17.97 Roller rocker arms CCA-17021-16 Comp 299.97 Valve locks CCA-611-16 Comp 21.97 Pushrod kit CCA-7154-16 Comp 195.97 Timing set CCA-7110 Comp 103.97 Water pump, aluminum SUM-310125 Summit Racing 139.97 Intake manifold EDL-2904 Edelbrock 279.97 950 HP carburetor HLY-0-82951 Holley 699.99 Engine paint NA O'Reilly Auto Parts 8.99 RTV sealer VER-99839 O'Reilly Auto Parts 5.49 Sealed Power Assembly lube SLP-55-400 Summit Racing 4.25 Comp Cams Engine Break-In Oil, case CCA-1590 Comp Cams 59.95 Oil filter PH-30 Fram 4.59 Spark plugs NGK R5673-9 NAPA 27.92 Total as Tested 4,061.01By the Numbers

Blue Collar 454:

We dropped a cylinder head on the driver side without a gasket and cycled the engine through a couple rotations of the crankshaft with the valves set at zero lash and a pair of checking springs. The exhaust valve left no impression on the CC-approved Silly Putty we smooshed on top of the piston. The intake valve showed 0.070-inch clearance, which, combined with our 0.041-inch compressed-thickness head gasket, is plenty of clearance.

With the knowledge that our clearances were in spec, we cleaned the deck of the block and the tops of the pistons with a Scotch-Brite pad and wiped everything with brake cleaner, then automatic transmission fluid in preparation for final assembly.

While we had the Silly Putty out, we also checked the oil pan–to–pickup clearance, which was acceptable at about 3⁄4 inch.

We are planning to hit this engine with about a 200 shot of nitrous in a later test, so we opted for Fel-Pro's MLS head gaskets. Naturally aspirated builds can save a few bucks by using standard gaskets. We are using Comp's two-piece timing cover for this build because this engine has recently been used to test several of its new cam designs. We left it out of the parts list because the stock cover would work just fine here. We actually would have put the stock one back on, but we couldn't find the fasteners.

We installed the cam "straight up" (with no advance or retard) and verified the intake lobe centerline, which was spot on with Comp's spec of 114 degrees after TDC. The intake and exhaust opening and closing events were also perfect. Note that we haven't installed the poly locks on the rocker arms yet. It's easier to rotate the crankshaft without the load of the valvesprings.

We assembled the rest of the valvetrain using plenty of assembly lube on the lifters, rocker arms, and pushrods and set the valve lash to 0.028-inch intake and 0.030-inch exhaust, per Comp's specs.