Growing up on Chicago’s South Side, Cecil Murray has, in his words, “owned many different makes and types of muscle cars, but I’ve always had a special spot for Mopars.” So back in 1994 when a friend of Murray’s who’d moved to Los Angeles latched on to what appeared to be a basically straight and original ’70 Plymouth Road Runner coupe equipped with a big-block 440 engine running the relatively rare 6-BBL induction system with three two-barrel Holley carbs, Murray couldn’t resist its $1,500 asking price. He and a buddy flew out to L.A. and drove it back to Chitown following the path of Route 66, stopping several times to repair a bunch of glitches.

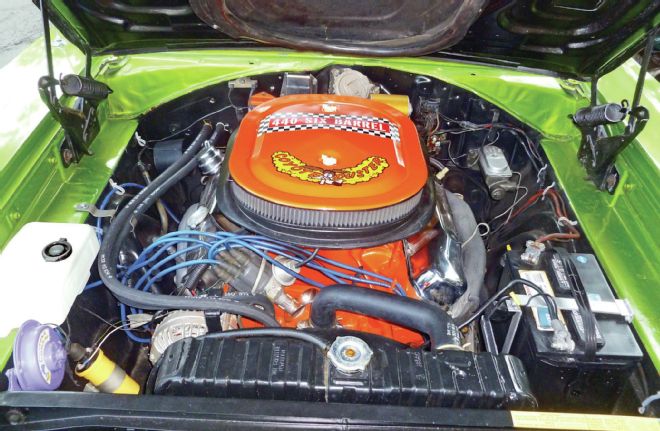

Now painted Dodge Viper Snakeskin Green, visually Murray has tried to match the classic ’70s muscle-car look with Cragars and a slight rake.

Now painted Dodge Viper Snakeskin Green, visually Murray has tried to match the classic ’70s muscle-car look with Cragars and a slight rake.

The years rolled by; the car was in and out of storage. The car, chassis, and driveline were treated to a bunch of cosmetic upgrades, repairs, and enhancements. The incremental driveline changes included a Mopar Performance electronic distributor with an Orange Box ignition controller, a valve job, and a healthy, but old-school, “lazy” Mopar Performance Purple Stripe hydraulic flat-tappet cam. The 727 TorqueFlite failed and was rebuilt with a shift-improver kit and 3,000-rpm-stall converter. The 8¾-inch Chrysler rearend stuffed with a Sure Grip diff and 3.91:1 gears remained intact.

Through it all, the car was never a reliable driver. It continued to have so many issues Murray says he nicknamed it “Christine” after the famous possessed Plymouth, explaining, “The carbs in particular were always a problem, but no one knew how to adjust them properly.” When the car was pulled out of its latest prolonged storage back in 2010, the problems worsened. Rebuilding the carbs didn’t help; installing all new carbs “actually made things worse. It would overheat constantly, backfire, and miss badly under load. It just had no get up and go.”

When the Road Runner came in here, it would have made a good meal for the Coyote.

Murray never could get the 3x2 Holley Six Pack running right.

Murray never could get the 3x2 Holley Six Pack running right.

Norm Brandes’ Westech Automotive in southern Wisconsin solves driveability problems like this all the time, so Murray drove the car up there under its own power for what everyone assumed was some relatively simple carb and ignition tuning.

As received, the car wasn’t happy idling under 1,200 rpm. “There was less than 5 inches of vacuum if you backed down the idle,” relates Brandes. “The car came in with 12 degrees initial timing at idle, but we had to jack it up to 24 degrees to get it to run at all. Total timing ended up in the low 40s!” Even with the timing tweaked, the car “wasn’t able to run up to 3,500 rpm under a no-load condition when we tried to clean it out. It was still running ragged no matter what we did.”

“At this point we decided to run a compression test. We removed the spark plugs. They were golden brown in color and showed signs of heat damage. Cranking compression was only 80–90 pounds on six out of eight cylinders. Even with a Purple Shaft cam, you should still see at least 140 psi, but as a general rule of thumb, on a performance car I like to see 150 pounds or greater. If it gets below 130 psi the car needs a band-aid, ’cause it won’t create enough cylinder pressure to run right.

“The assumption at this point was that the car was a genuine Six Pack, with the stock 10–10.5:1 static compression-ratio. Switching to our cylinder leakage tester, we applied air pressure and immediately heard hissing in the exhaust pipe.”

That’s not good! Convinced there was an engine problem, Brandes removed the heads. “We saw severe valve-seat erosion. At least six exhaust valves were sunk as much as 0.120 inch into the heads. On some of them, there literally was no seat left!” The car’s early No. 906 heads lacked induction-hardened valve seats needed to resist valve-seat erosion caused by unleaded gas. The 906 castings had big, lazy, 88–90cc combustion chambers. “The severe valve-seat recession probably added another 4–5 cc to that,” Brandes adds.

But that was just the tip of the iceberg. Brandes says at top dead center (TDC), “the pistons were 0.070 inch down in the hole. They’d be about 0.019 inch down on a real Six Pack—but we identified it as not a true Six Pack by checking the block ID numbers. It was really a ’75 block, with a stock ’75 rotating assembly. It even had the late externally balanced cast-iron crank and standard late-model factory forged rods, rather than a Six Pack’s forged crank and heavy-duty rods. The static compression was only about 8:1.”

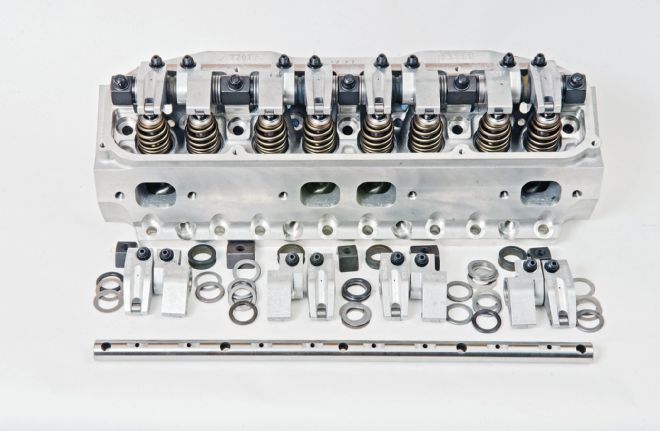

A major rebuild with modern parts was needed. Here, Westech’s Jim Daley preps Edelbrock Victor heads with Comp Cams’ beehive springs.

A major rebuild with modern parts was needed. Here, Westech’s Jim Daley preps Edelbrock Victor heads with Comp Cams’ beehive springs.

Yet another problem was unequal valve-stem heights. On a shaft-mount rocker system, uniform valve-stem heights are critical for achieving proper valvetrain geometry and preventing accelerated valvetrain and valve-seat wear. In this Chevy-centric world of independent, stud-mount rocker arms, maintaining proper and equal valve-seat depth may be overlooked by some shops.

Whoever had built (or serviced) the engine in the past had tried to correct the problem by installing an aftermarket adjustable valvetrain. Brandes explains, “As the exhaust valves were receding, the pushrod would get shoved further down into the hydraulic-lifter plunger. This would delay exhaust-valve closing. Backing off the adjusters on the shaft-mount rockers crutched things for awhile, but eventually the seats receded so far it was beyond the ability of the adjusters to compensate. In some cases, the exhaust valves weren’t fully closing. A late or nonclosing exhaust valve puts more heat out the exhaust, further accelerating seat recession. Backing off the adjusters also changed the pushrod angles, screwing up the valvetrain geometry.”

Did the nonuniform valve-stem heights make the recession worse, or did recession exacerbate the valve-stem geometry problems? Did the adjustable valvetrain crutch contribute to accelerated recession? Did the low piston deck height and lazy, old-school combustion chambers slow the burn rate so much that the exhaust valves got too hot from excess waste heat being dumped into the exhaust? It’s impossible to know for sure which of these factors initiated the problem, but regardless of its original origin, all these symptoms fed off each other, creating a feedback loop that brought the engine to its knees.

“When compression is that low, it’s just not livable with a performance cam,” maintains Brandes. “To have it run as a Six Pack with the big Purple Shaft cam, it needs at least 10:1. When the piston is that far down in the hole at TDC, you loose quench. There’s no mixture motion and it takes longer to burn the fuel. Slow burning plus no quench plus a soft cylinder head exacerbates the recession problem.”

Height of folly: What turned out to be a ’75 short-block had only 8:1 compression and no quench. Chrysler inflicted this on the poor 440 by lowering piston CH, placing it way down in the hole at TDC. Compare the CH on a typical ’75 stock-style replacement piston (Silv-O-Lite PN 1276, left) with the performance forged piston spec’d by Westech for the rebuild (Icon PN IC968, right).

Height of folly: What turned out to be a ’75 short-block had only 8:1 compression and no quench. Chrysler inflicted this on the poor 440 by lowering piston CH, placing it way down in the hole at TDC. Compare the CH on a typical ’75 stock-style replacement piston (Silv-O-Lite PN 1276, left) with the performance forged piston spec’d by Westech for the rebuild (Icon PN IC968, right).

With multiple issues, a multiprong approach is needed to really set things right. Obviously, something needed to be done about the cylinder heads. But the Mickey Mouse smog-era short-block was DOA in terms of being able to support the Six Pack’s performance potential, and these days there are lots of better cams out there as well. As Brandes put it, “The engine needed stitches, not a band-aid.”

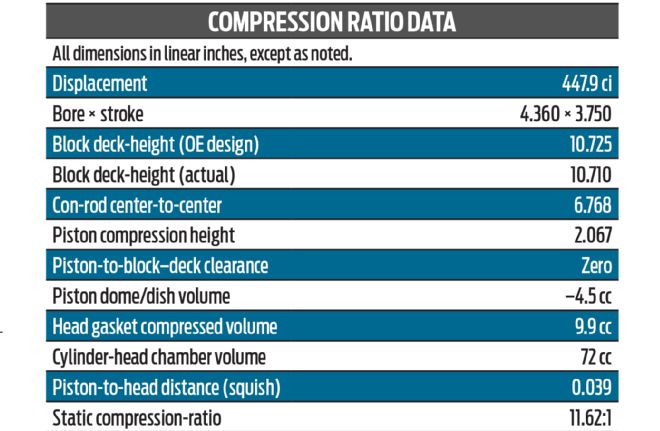

Brandes has a unique approach to street-engine combos. Taking a leaf from late-model tech, he is able to build even old carbureted, noncomputer engines in excess of 11:1 static compression ratios and successfully run them on unleaded pump premium gas. The keys are heads with quick-burn combustion chambers, optimal quench achieved with near-zero deck heights, an aggressive cam ground to Brandes’ specs, and careful carburetor and ignition tuning.

Cure for a sick Six Pack: Icon forged lightweight 0.040-over flattop pistons and Edelbrock 72cc small-chamber aluminum Victor heads raise compression over 11.5:1 with a zero-decked block and Fel-Pro heavy-duty head gasket. Fel-Pro supplied all the gaskets; Speed-Pro provided all the bearings. Total Seal premium ductile rings are included in Icon’s piston kit. High-port Victor heads require the use of Big E’s gold valley cover.

Cure for a sick Six Pack: Icon forged lightweight 0.040-over flattop pistons and Edelbrock 72cc small-chamber aluminum Victor heads raise compression over 11.5:1 with a zero-decked block and Fel-Pro heavy-duty head gasket. Fel-Pro supplied all the gaskets; Speed-Pro provided all the bearings. Total Seal premium ductile rings are included in Icon’s piston kit. High-port Victor heads require the use of Big E’s gold valley cover.

Brandes explains, “I try to achieve around 0.040-inch quench. That’s about what a modern LS-series motor has. Spark-plug positioning in the chamber, slightly biased toward the exhaust valve, is also critical. It’s one of the keys to making a high-compression motor live on the street. We are making a 21st-century engine here. Assuming parts are available that meet these parameters, there’s no reason why any engine can’t run high compression on today’s pump gas.”

When Detroit dropped compression ratios in the ’70s in its desperate attempt to meet the new emissions standards, for the most part it did so by increasing combustion-chamber volume and increasing piston dish volume. One big exception was Chrysler: Beginning in ’72 it lowered compression by drastically reducing piston compression height (CH)—the distance from the piston pin-bore centerline to the top flat on the piston. That’s why on Murray’s 440, for instance, the original pistons were so far down in the bore at TDC. If compression had to be dropped, this was about the worst way to go about it. The big quench decrease made the engines even more sluggish than what’s normally attributable to just the base compression drop alone, even promoting increased detonation tendencies in a high-performance application.

The solution is a higher-CH piston that restores quench and static compression ratio. With its 2.067-inch CH (compared to a typical late stocker’s 1.902 inch), Icon’s 440 lightweight forged flattop piston (PN IC968) is just what the doctor ordered. The fully machined piston weighs only 685 grams and accepts modern, lightweight 1⁄16-, 1⁄16-, and 3⁄16-inch rings for reduced friction plus even more weight savings.

With the bottom end apart and the engine requiring rebalancing anyway to support the new pistons, Murray stepped up and let Westech optionally replace the late short-block’s stock rods and externally balanced, cast-iron crank with one of its good, used early 440 forged cranks, a set of Magnum forged rods bushed for floating pins and upgraded with ARP bolts, and a stock harmonic damper designed for internally balanced engines. Externally balanced, auto-trans-equipped, Chryslers have their rear balance weights on the torque converter instead of the flexplate; Westech simply ground them off, then rebalanced the engine internally.

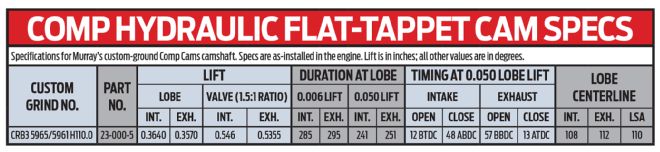

Getting a pump-gas-friendly, high-compression engine to be both driveable and responsive mandates careful camshaft selection. The exact profile depends on the overall engine combo. For example, with full-length tube headers, Brandes says “we like to open the exhaust valve sooner. That gives a better charge pressure and better blow-down into the pipe—which means more bottom-end torque. I like to open the exhaust valve about 60 degrees before bottom dead center (BBDC) at 0.050-inch tappet lift. Typical catalog cams in this performance range might not open until 50 degrees.

“To help intake manifold vacuum, you don’t want too much overlap, but on the other hand, you want to be careful not to induce tip-in ping. I like to open the intake around 14 degrees BTDC and close the exhaust at 11 degrees ATDC. Some of my engines have 112-degree lobe-separation angles (LSA), but for this big-block Chrysler I had the cam ground on a 110-degree LSA.”

Most motors need a hydraulic roller cam to meet Brandes’ demanding requirements, but Chrysler has a key advantage here: It uses a large 0.904-inch-diameter flat-tappet lifter, compared to 0.875 for Ford and just 0.842 for most GM apps. The larger foot reduces unit loading, permitting near roller cam lobe profiles without a roller’s expense. But that requires a cam specifically ground for the Chrysler lifter, which isn’t typical for generic off-the-shelf “catalog” grinds. Brandes went into Comp Cams lobe-profile catalog to spec a custom dual-pattern grind using its Xtreme Mopar lobe profiles (see “Cam Specs” table).

Repairing the existing heads would require machining them for new hardened insert seats for all 16 valves—the exhausts because of the severe seat recession, the intakes because the seats had sunk from the cheapie valve job (remember shaft valvetrains want all the seats at the same height). “The cost of rebuilding the heads—including new guides, seats, valves, and a valve job—is halfway toward a set of new aftermarket aluminum heads,” maintains Brandes. “For a performance engine, it’s just not cost effective.” Additionally, aluminum heads, with their superior heat-rejection properties compared to cast-iron stockers, permit going at least one full point higher in static compression ratio—and that assumes the same old-school, lazy combustion chamber as the stockers.

Victor heads need 0.600-inch offset intake rocker arms to clear the big intake ports and develop correct geometry; the exhausts are standard. Hughes Engine’s bulletproof yet reasonably affordable shaft-mount system for the Victors includes 16, 1.5:1 adjustable aluminum rockers, billet spacers, fine adjustment shims, and (for better oiling) “banana-groove” shafts.

Victor heads need 0.600-inch offset intake rocker arms to clear the big intake ports and develop correct geometry; the exhausts are standard. Hughes Engine’s bulletproof yet reasonably affordable shaft-mount system for the Victors includes 16, 1.5:1 adjustable aluminum rockers, billet spacers, fine adjustment shims, and (for better oiling) “banana-groove” shafts.

Comp beehive springs improve stability and harmonics while reducing valvetrain mass. With reasonable seat pressures, they’re still stiff over the nose for great valve control. Spring PN 26120-16 develops 185 pounds at a 1.800-inch seat height and 388 pounds open at 1.25 inch. Max coil-bind occurs at 1.160 inches. PN 611-16 10-degree Super Locks tie PN 795-16 steel retainers to the Victor’s 11⁄32-inch valve stems .

Comp beehive springs improve stability and harmonics while reducing valvetrain mass. With reasonable seat pressures, they’re still stiff over the nose for great valve control. Spring PN 26120-16 develops 185 pounds at a 1.800-inch seat height and 388 pounds open at 1.25 inch. Max coil-bind occurs at 1.160 inches. PN 611-16 10-degree Super Locks tie PN 795-16 steel retainers to the Victor’s 11⁄32-inch valve stems .

But head tech has come a long way in the last half-century. The best of today’s aftermarket aluminum heads eschew traditional old-school chambers in favor of modern, race-derived, heart-shaped, combustion chambers with relocated spark plugs. Edelbrock’s Victor big-block Chrysler heads fit the bill perfectly. Why a “race” head like the Victor instead of the “milder” Edelbrock Performer RPM 440 head? Because the Victor’s smaller 72cc chambers when used with the 0.040-over Icon flattop piston, a zero-decked block, and heavy-duty Fel-Pro PN 1009 head gaskets, yield 11.6:1 static compression without detonation on pump gas (assuming proper tuning). That meets Brandes’ 0.040-inch-quench and compression-ratio goals without a restrictive piston-dome impinging into the chamber. And as a “race” head, the Victor’s intake and exhaust ports are raised over the stock location, considerably improving head flow.

The heads were bolted to the block with Fel-Pro head gaskets and ARP bolts. ARP additionally supplied the intake, header, and engine dress-up accessory bolts.

Edelbrock Victor heads have unique valvetrain geometry and require offset intake rocker arms. As a “race” head, they’re sold bare or (as used on this motor) bare with valves, in either case leaving valvespring and upper valvetrain parts selection up to the end user. Comp Cams supplied flat-tappet-friendly beehive variable-rate springs; the hard-core Chrysler specialists at Hughes Racing sent its premium aluminum 1.5:1 rocker-arm kit for Victor Heads. Hughes custom-length, 4130 hard-tempered chrome-moly, 0.083-inch-wall pushrods tie the lifters to the rockers. A Hughes’ adjustable checking pushrod and checking lifter helped establish optimum geometry and length. The proper-length pushrod, a Hughes rocker-stand shim kit, and the Edelbrock heads’ consistent valve-stem lengths and hardened valve-seat depths make Murray’s seat-recession problems only a bad memory.

Quench was restored and static compression raised using Icon forged pistons with a taller compression height and zero-decking the block.

Quench was restored and static compression raised using Icon forged pistons with a taller compression height and zero-decking the block.

The last step was fine-tuning the car around the new combo. Major work was needed to get the three Holleys to work with the free-flowing heads and large cam. Finicky Six Pack carb-tuning was made much easier with trick parts supplied by Quick Fuel Technology (QFT). It also turns out the stock fuel pump couldn’t flow enough fuel to support the new engine’s higher output. Westech replaced it with a Carter high-performance mechanical fuel pump rated at 120 gph (free-flow). Finally, Brandes fine-tuned the ignition advance curve. “By virtue of the Victor heads’ modern, quick-burn chambers, the car likes 14 degrees initial, with 34 degrees total.” That’s on both unleaded pump premium and race gas. In fact, the engine made the same power numbers with either fuel.

Owner Murray loves the car’s “rumpity-rump” sound. The car’s cranking compression is now 155–165 psi even with the big cam, right in Westech’s preferred sweet-spot groove for a pump-gas street car. With the aggressive cam, idle vacuum is only 5 inches at 550 rpm, rising to 8 inches at 700–750 rpm. That seems kind of low, but remember, there are no power brakes on this car. Low as the idle vacuum is, once the carbs were properly tuned, the idle is now totally stable and no longer “hunts.” On Westech’s Mustang chassis-dyno, at the rear wheels the car now makes 376 hp at 6,048 rpm, with 355 lb-ft of torque at 5,194 rpm. That’s using the conservative SAE J1349 correction factor, the same method used to measure output on today’s new cars. Figure about a 20 percent drivetrain loss plus another 4 percent compared to the more liberal “hot rod” correction factor and we’re looking at about 470 hp and 444 lb-ft at the flywheel. We feel the old-school Six Pack intake is holding the engine back from realizing its true potential, but the owner elected to retain original underhood appearance over max output.

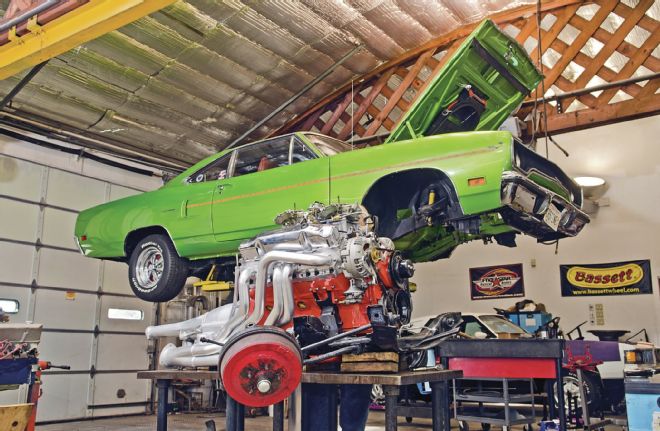

Edelbrock recommends Tube Technologies (TTi) headers for its high-port Victors. Westech chose a ceramic-coated, thermal-barrier TTi set with 2-inch primaries and 3.5-inch collectors that supports 500–750 hp. With the K-member already removed to add the spacers, the easiest engine-installation method was a body drop over the engine/trans/front-end combo.

Edelbrock recommends Tube Technologies (TTi) headers for its high-port Victors. Westech chose a ceramic-coated, thermal-barrier TTi set with 2-inch primaries and 3.5-inch collectors that supports 500–750 hp. With the K-member already removed to add the spacers, the easiest engine-installation method was a body drop over the engine/trans/front-end combo.

Not all apparent driveability issues are due to ignition and carburetion problems. When after careful tuning the engine doesn’t respond, you need to check the engine’s internal health. Home mechanics should always have a compression tester and a vacuum gauge as part of their standard kit. Shaft-mount valvetrains must have equal valve-seat depths and valve-stem heights. Don’t lower compression by using pistons that end up a mile down in the cylinder at TDC.

Completed and sitting in the car at last: Everything works, both internally and externally. Even the Air Grabber hood remains functional. “It’s the millennium upgrade for the old-school 440,” Brandes proclaims.

Completed and sitting in the car at last: Everything works, both internally and externally. Even the Air Grabber hood remains functional. “It’s the millennium upgrade for the old-school 440,” Brandes proclaims.

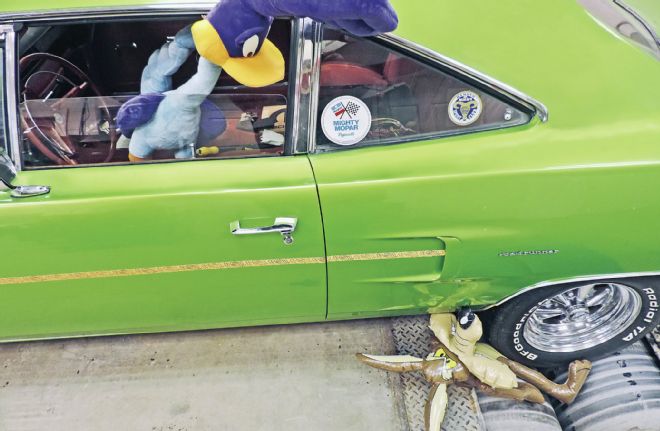

Beep! Beep! Watch out, Coyote, your days are numbered: Thanks, ACME Westech Automotive Repair Shop.

Beep! Beep! Watch out, Coyote, your days are numbered: Thanks, ACME Westech Automotive Repair Shop.

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at [email protected] and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.