It's common knowledge that most modifications made to an engine involve a tradeoff somewhere in the overall equation. You might want a higher compression ratio, but the trade-off here is a need for higher octane fuels. A single-plane manifold might help make more high-rpm power, but you'll give up some at the bottom. The examples here could go on and on, but the most obvious case of this kind of compromise usually involves the camshaft. Most of the time, a bigger camshaft will mean more peak power, but the cost is generally clear, with an increase in idle chop, poor low-speed performance, and a drop in idle vacuum. Sure, for a lot of guys the uncivilized roughness of a big, nasty stick is actually a plus. This is especially true if the engine is to be used solely as a Saturday night street brawler, or a purpose-minded race car. For those looking for good road manners and drivability, camshaft selection is a tough balance to strike while looking for power.

Generally, the factors that have the greatest effect on a given cam's idle and low-rpm characteristics are related to the camshafts's duration, lobe separation, and overlap, though they are all interrelated specifications. What all these have in common, is that they relate to the cam's timing points. As you start piling on the duration and overlap, power up the rpm range will build, though low-speed operation and idle quality suffer. While the above mentioned specifications have a pronounced effect on an engine's operational characteristics, the one key-specification omitted until now is lift. Generally, a more aggressive lift-profile will increase power output by adding more area under the lift curve, but unlike added duration, the increased power will usually come with a minimal penalty at low engine speed.

Choice Results

We had a freshly built 383 on hand, that is destined for install in a true street driver. Here is an application where we certainly did not find it acceptable for the engine to idle like a Pro Stocker, but we did want to optimize the overall power curve in a reliable operating range of just off idle, to a maximum of 6,000 rpm. In fact, we really wanted to approach a dead-smooth idle quality. The initial camshaft choice was very conservative. It was a hydraulic flat-tappet with 214/224-degrees of duration at .050-inch lift, a lobe separation angle of 112-degrees, and .442/.465-inch lift with stock 1.5:1 rockers. This profile is one that should be familiar to old-timers in the hobby, having been a popular grind for decades under numerous private labels. In fact, it is still sold by large mail-order houses today. By any definition, this is a mild camshaft, though it is considerably hotter than most older factory flat-tappet passenger car cams, with specifications comparable to mid-range OEM performance cams of yesterday.

Our overall engine combination (See Sidebar: The Engine Combo) was that of a mild street performance engine. It's something definitely carrying more punch than stock, but tame enough to comfortably claim daily-driver status. We knew going in, that the camshaft would provide a very nice idle-quality, but we had to wonder if we might be leaving a little power on the table. The lobes on our baseline camshaft are designed for a minimum tappet diameter of .842-inch, which makes the profiles generic for most popular engine types. With flat-tappet camshaft lobes, the tappet diameter determines the maximum velocity achievable, and since Mopar engines have a much larger .904-inch tappet diameter, a cam designed for the larger lifter, could be designed with more lift for a given amount of duration.

To settle the question of how much potential was locked away in the engine, we decided a test including a modern, more aggressive .904-inch-tappet specific camshaft would be worth looking at. Taking the bigger picture into account, we could see that with a very mild 214/224-degree duration, our baseline camshaft choice was skewed more in favor of smooth low-speed operation, than what you might find in a typical street machine. With all of the above in mind, we decided that it would be worthwhile to run the engine with a camshaft that is much more representative of a hotter performance application, and use a fast-rate .904-tappet profile. We settled on Comp Cams' XE275HL, also a hydraulic flat-tappet, but substantially healthier in specs, with 231/237-degrees duration at .050-inch tappet rise (275/287 advertised duration), .525-inch lift, and a 110-degree lobe separation. With 17 degrees more intake duration and .080-inch more lift, this cam is right smack in range for a hot-street application.

1. We brought a freshly built 383 to the dyno, packing an extraordinarily mild hydraulic flat-tappet camshaft. We knew that this cam—with only 214/224-degrees duration and .442/465-inch lift—would be leaving some power behind, but it does offer the near-stock idle quality we wanted.

2. After the initial fire-up and run-in, we looped the timing to find just what the engine wanted. The engine responded best with 38-degrees total advance, a setting we retained for all further testing.

3. We equipped the engine with a vacuum-secondary Holley 770 Street Avenger carb with the goal of trouble-free performance on the street. The carb performed flawlessly on the dyno. We carefully monitored air/fuel ratio throughout the test session, though once jetted for the baseline combination, we found no further gains in revising the carb even with the cam changes.

4. While running the very small cam, we were rewarded with 18.5 In-Hg of manifold vacuum, 402 horsepower, and 441 lb-ft of torque. Actually, considering the smooth idle, strong low-end torque and an rpm range that isn’t dead until over 6,000 rpm, this combination was pretty good.

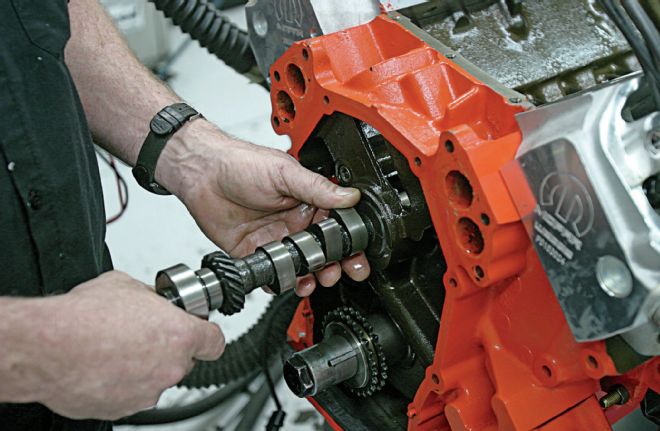

5. For the next configuration, the cam was stepped up to a Comp XE275HL, a very fast-rate .904 lifter design, sporting 17/13-degrees more intake/exhaust duration at .050-inch lift than the baseline cam, .083/.060-inch more lift, and 2-degrees tighter lobe separation. Make no mistake, this is a lot more cam. A new set of Comp’s 822-16 lifters went in with the new camshaft. These are their standard hydraulic lifters.

The Kicker

Okay, so this looks to be stacking up as just another small-cam, big-cam comparison, but there's a kicker. We could predict with a fair degree of certainty two things that would result when comparing these two cams: the more aggressive cam will make more power, but the mild cam will idle smoother. Now, what if we wanted to make as much power as the bigger hydraulic flat-tappet, but we wanted it to be just as smooth-idling as the baby cam? You can almost predict that any time the duration is increased or the lobe separation is narrowed, that idle quality will deteriorate. About the only way to try and achieve the best traits of both these cams, was to go to a camshaft that closely matches the timing points (duration and lobe separation specifications) of the small cam, while opening and closing the valves with even more speed than the big cam, with a very aggressive and fast lobe. Basically, it comes down to short duration for idle quality, and high lift to make up as much of the power difference as possible.

Clearly the XE275HL, being one of the latest .904-tappet designs, is about as fast of a lobe design as you are going to find in a flat-tappet profile. To beat it in lift with a camshaft with far less duration, takes a roller cam profile, and a very high-velocity design at that. We went back to Comp for their XFI hydraulic roller profiles, which are about the best street hydraulic-rollers we have tried to date. Sure, a solid roller can be found that is even more intense, but for street use in an application below 6,000 rpm, the hydraulic roller is far more practical and durable.

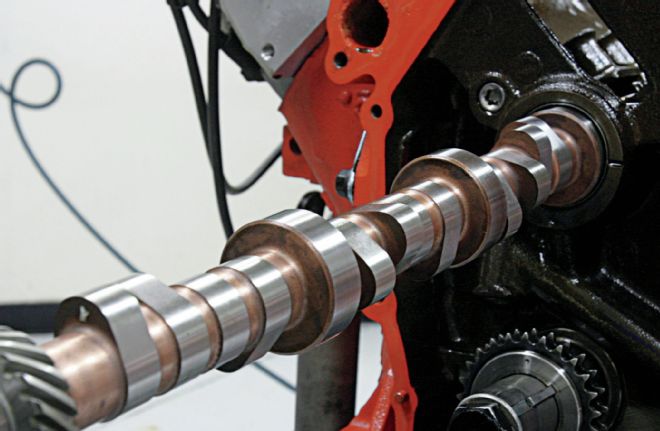

We ordered a custom hydraulic retrofit-roller camshaft using lobes 3013/3035, which provide exactly the same 214/224-degree duration at .050 as our baseline cam, and had it ground on the same 112-degree lobe separation. This matching short-duration and relatively wide lobe separation suggested that the cam should exhibit idle characteristics very similar to our mild baseline, which we sought to maintain, but the lift of .530/.530-inch is actually slightly higher than that of the aggressive, bigger flat-tappet cam we planned to try. Our objective was to see if the hydraulic roller could match the idle quality of the mild flat-tappet cam, while making the power of the beefy flat-tappet cam.

The Test

With these theories in mind, we headed to the Westech Performance Group's testing facility to see just where the numbers stack-up. Stabbed inside the little big-block was the baseline 214/224 hydraulic flat-tappet cam, working through a set of Comp pushrods, and stock 1.5:1-ratio stamped-steel rockers. The engine fired to life, and after a break-in period and some carb adjustments on the Holley 770 Street Avenger, we found a nearly dead-smooth idle, and 18.5 In-Hg of manifold vacuum. Still, it wasn't until the handle was pulled on the dyno that we knew just how much power the mild engine would deliver. The numbers told the tale, with a very respectable 402 horsepower at 5,300 rpm, and 441 lb-ft of torque recorded at 3,700 rpm.

With just a hair over 400 horsepower, and stump-pulling low-end torque, the baseline combination was impressive for its intended application. Knowing that our baseline cam choice is much milder than what most would select for a performance street application, we dug in and extracted the little cam, and replaced it with our 231/237-degree Xtreme Energy Hi-Lift. This cam immediately made its presence known with a noticeable performance-minded chop at idle. We also had an expected drop in manifold vacuum to11.3 In-Hg. The healthy Comp 'shaft wouldn't rattle your fillings out, but was just about perfect for producing a boulevard sound while still being streetable. Spinning the engine up against the pump showed a substantial power gain, with 434 horsepower at 5,600 rpm, and an increase in peak torque, recording a maximum of 448 lb-ft, from 3,900-4,200 rpm. Torque was down below 3,700 rpm, but that is typically an expected trade with a large increase in duration. Overall, this cam combination is a nice choice for a street performance application.

So far, the results could have been predicted a mile away—the bigger cam made considerably more horsepower, gave up a little torque lower in the rpm range, and the idle quality deteriorated from near-stock to a modest lope. The real question was, how would our short-duration, high-lift hydraulic roller compare to the other two choices? Getting the cam installed required a swap to Comp's retrofit hydraulic roller lifters. Due to the change in lifter-plunger position, a shorter set of pushrods was also required. Our cam was ground on a billet core, so a bronze distributor gear was needed as well. Comp can also provide the same cam on a core that is compatible with the stock distributor gear. To accept the required thrust-control button, our roller was also configured with a three-bolt camshaft rather than the stock single-bolt. This required a matching timing set. Despite the changes, the hydraulic roller cam was no more difficult to install than the flat-tappets, and before long it was show-time.

6. Up top, we retained the stock stamped-steel, non-adjustable valvetrain. The factory rockers may not be adjustable, but they work well in hydraulic applications, are lightweight, and when they came with the engine, they’re free.

7. Back up and running with the stout Comp hydraulic flat-tappet, the 383 definitely gained power, now posting 434 hp at 5,600 rpm, and hanging in nicely to 6,200 rpm. The tradeoff for the newfound power was a loss of 7.2 In-Hg of vacuum, and a rougher idle.

8. We loved the power of the big hydraulic flat-tappet, but wanted the stock-type idle of the baseline cam. We figured a short duration/high-lift hydraulic roller might provide the best of both worlds, so we had a custom XFI hydraulic roller ground accordingly, matching the .050-inch duration and lobe separation angle of our baseline cam.

9. Getting a hydraulic roller to work where a flat tappet once lived, takes a few additional parts. Of course we needed a set of Comp’s retrofit hydraulic-roller lifters, as well as a three bolt timing set and a thrust button to control the cam’s fore and aft movement.

10. With some quick wrenching, we had the 383 reassembled and ready for its final run on the dyno. The hydraulic-roller cam did exactly what we had hoped, matching the idle quality of the small flat tappet, and making nearly the top-end power of the big cam. What we didn’t quite expect was the powerful surge in torque right from the bottom through the mid-rpm range.

Upon firing up the engine with our final cam configuration, it was astounding just how closely the idle matched the small flat-tappet. The numbers were identical to the baseline, with a dead-smooth idle and 18.5 In-Hg of vacuum. You couldn't tell it was a different cam by the sound or gauge readings at idle. It seemed to prove that by matching the 214/224-degrees duration at .050-inch lift, and the 112-degree lobe separation, angle we had nailed the match at idle. The questions remained whether the faster lobes and higher lift offered by the hydraulic roller would produce more power than our baseline cam, and would this cam make anywhere near the power of the more radical XE275HL, which packed sizably more duration than either of the other two cams.

As the test pull began at 2,800 rpm, we could see that the small hydraulic roller was delivering torque like we hadn't seen with either of the flat-tappets, coming in with 425 lb-ft. We watched the dial run up to a peak 454 lb-ft at 4,300, and held our breath to see if it would hang on to post a strong power number. As the rpm rolled up, the cam kept pulling, showing a peak of 431 horsepower at 5,600-5,700 rpm.

The tiny hydraulic roller idled like a stocker, pulled torque like a beast down low, and came through within a couple of horsepower of the much longer duration flat tappet at the very top of the curve. Overall, the average power and torque with the hydraulic roller was substantially improved as compared to either flat tappet. Our test showed that we could have the power of the larger cam while enjoying the smooth running quality of the small cam. All of that extra torque through the low and midrange was an unexpected bonus, but one that will not go unnoticed once the engine is installed.

The Engine Combo

Our test engine began as a well-used 1971 high-performance 383, factory rated at 300 hp gross. The engine received a very basic rebuild, with the block bored .060-over for a set of KB No. 162 hypereutectic pistons, and was zero-decked. The factory crankshaft and rods were reconditioned, along with the stock oil pan and windage tray, while a new Melling oil pump provides the lube. Up top, the factory heads were replaced with a set of Mopar Performance No. 5153524 cylinder heads as an economical upgrade for the stock iron castings. The resultant compression ratio is 9.2:1.

As with the short-block, the valvetrain consisted of re-used OEM parts, including the pushrods, rockers and shafts. An Edelbrock Performer RPM intake and Holley 770 vacuum secondary Street Avenger carb take care of the induction needs. A rebuilt OEM electronic distributor provides the spark. On the dyno we used a set of Hooker 17⁄8-inch Competition headers. All of the parts were used “out-of-the-box” with no custom porting or modifications, and the engine was assembled with Fel-Pro gaskets throughout. In summation it is a simple, budget-minded engine combination that is easy to build and delivers good results.

Cam Specifications

CamPAWCOMPCOMP Part Number1032321-227-4Custom XFI* TypeHyd. FTHyd. FTHyd. Roller Adver. Duration280/290275/287264/276 Duration @ .050214/224231/237214/224 Lobe Seperation112110112 Lift (inch).442/.465.525/.525.530/.530*Lobes 3013 intake/3035 exhaust on a 112-degree separation with 4-degrees advance. Call Comp's cam line for custom cam orders.

Dyno Results

383 Cam Test SuperFlow 902 Engine Dyno

Torque

RPM 214/ 224FT 231/ 237FT 214/ 224HR 2,800 413 381 425 3,000 417 405 430 3,200 427 422 438 3,400 436 432 446 3,600 441 437 451 3,800 441 445 453 4,000 440 448 452 4,200 439 448 453 4,400 438 447 453 4,600 435 446 452 4,800 429 443 447 5,000 420 434 439 5,200 406 425 426 5,400 390 417 416 5,600 375 407 404 5,800 360 391 389 6,000 344 375 372 6,200 316 361 NRHorsepower

RPM 214/ 224FT 231/ 237FT 214/ 224HR 2,800 220 203 227 3,000 238 232 245 3,200 260 257 267 3,400 282 279 289 3,600 302 300 309 3,800 319 322 328 4,000 335 341 344 4,200 351 358 362 4,400 367 374 380 4,600 381 391 396 4,800 392 405 409 5,000 399 413 418 5,200 402 421 423 5,400 401 429 428 5,600 400 434 431 5,800 398 432 430 6,000 392 428 424 6,200 373 426 NRPower Averages 2,800-6,000 rpm

214/ 224FT 231/ 237FT 214/ 224HR Avg. TQ 415.9 425.2 433.4 Avg. HP 344.8 355.3 360.8Legend:

214/224FT: 214/224-Duration; Hydraulic Flat Tappet.

231/237FT: COMP XE275HL; 231/237-Duration; Hydraulic Flat Tappet

214/224HR: COMP Custom XFI; 214/224-Duration; Hydraulic Roller