What kind of idiot takes out a perfectly good Mustang engine with less than 10,000 miles on it? The kind who's addicted to speed, of course, and the owner of this Mustang (who prefers to remain anonymous) needed more—more horsepower, more rpm, and more speed. He's a regular participant in local track events, and this car gets driven hard. He sent the car to Brian Schapiro, owner of B&D Racing in Van Nuys, California, who removed the engine and sent it to our friends at JMS Racing Engines in El Monte. While JMS enhanced the engine, Schapiro got the rest of the car ready for hard-core track duty, with bigger brakes and sway bars. With the engine back in the car, he tuned it on his chassis dyno, cranking out a thrilling 505 hp at the wheels. That means this little Coyote is making around 600 at the crank without a blower or nitrous. How is that possible? Read on to find out.

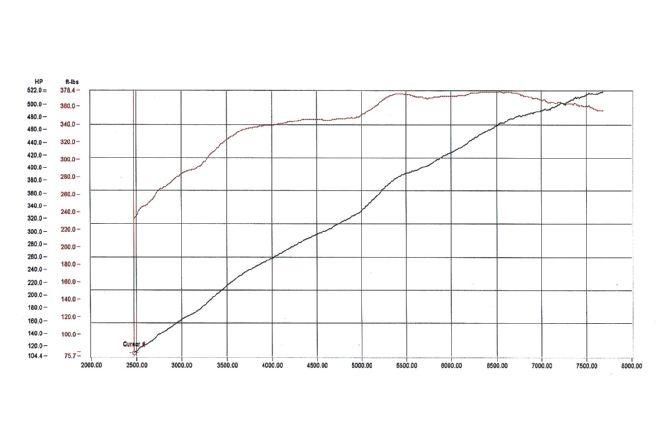

On the Dyno

Note how the torque curve (upper line) is relatively flat once the engine reaches 4,000 rpm and only begins to taper off at 6,500. Also, you may notice the horsepower curve is still climbing and hasn't peaked, even at 7,000.

PARTS Description PN Source Price CNC-machined cylinder heads LME50CNC Livernois Motorsports $2,559.98 Wiseco/K1 rotating assembly Custom Wiseco Call XFI-NSR cams CCA-191100 Comp 1,499.95 Cam phase limiter COMP 5493 Comp Cams 69.99 Head studs 256-4702 ARP 403.88 Boss 302 intake M-9424-M50BR Ford Racing Performance Parts 499.95 Long-tube headers 6027-2011 Kooks 952.29

1. It was cool to see the internals of such a newly developed engine. Ford's new Coyote is an evolution of the 4.6 Modular V8s—sharing the same deck height (8.937 inches) and bore spacing (3.937 inches)—but both the bore and stroke are larger: 3.629x3.649 inches versus the 3.552x3.543 on the 4.6. Interestingly, the firing order is different from the 4.6: The Coyote fires 1-5-4-8-6-3-7-2, same as the Flathead. These engines are assembled at Ford's Essex Engine Plant in Windsor, Ontario.

2. The main caps are similar to the earlier Teksid engine blocks (found in Mark VIII and Mustang Cobras until 1999), as they have four main bolts and two side bolts to anchor the crankshaft into the deep-skirted block.

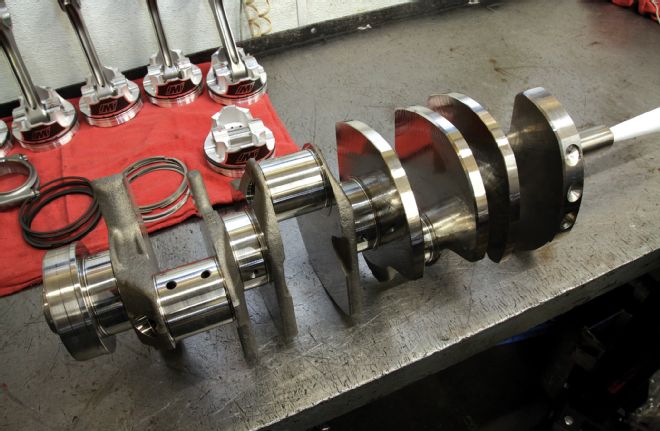

3. In stock form, the Coyote has hypereutectic pistons and powdered metal connecting rods, so it's understandable that one would seek upgraded parts when high-rpm durability becomes a factor. These Wiseco forged pistons will take plenty of abuse. Though the tops of the pistons are shaped differently, they retain the stock compression ratio of 11.0:1. They are a floating-pin style, and the pins are retained by wire locks (one of which is seen in the background). The K1 H-beam connecting rods are reminiscent of the Manley rods that came standard in the supercharged Terminator Cobras.

4. Instead of mixing and matching components, the customer opted for this newly developed reciprocating assembly from Wiseco. Sold as a package with K1 Technologies, it offers more strength, less friction, and higher rpm potential. The Coyote crankshaft is already a forged piece, but this K1 crank is stronger and features chamfered oil passages and rolled fillet edges in the bearing journals.

5. The stars of this build, however, are the CNC-ported cylinder heads from Livernois Motorsports. They're not cheap, but they are worth the money if high-rpm, naturally aspirated breathing is what you seek. They have been fully ported on Livernois' five-axis CNC machine and come with a CNC valve job and custom-ground valves. Though we haven't been able to verify the figures, Livernois claims a 344-cfm intake and 219-cfm exhaust flow, both at 0.600-inch valve lift. These are better numbers than the already impressive Boss 302 heads.

6. Here are close-up views of Livernois' port work.

7. Livernois' heads are sold assembled (valves, springs, and retainers) but without camshafts. Rather than installing the stock cams, the customer opted for a quartet of Comp cams with 228/231 duration at 0.050 tappet lift and 0.492/0.453-inch valve lift. Made from billet, the cams are also counter weighted to reduce engine vibrations.

8. One of the new features on the Coyote engine is variable cam timing on both the intake and exhaust cams, but with more compression and the new cam specs, piston-to-valve clearance can become an issue. Comp sells these cam-timing limiters that fit into the cam phaser and cut the amount of total timing adjustment from 50 degrees (of crankshaft rotation) to 20. JMS put them in the phasers before installing them on the new camshafts.

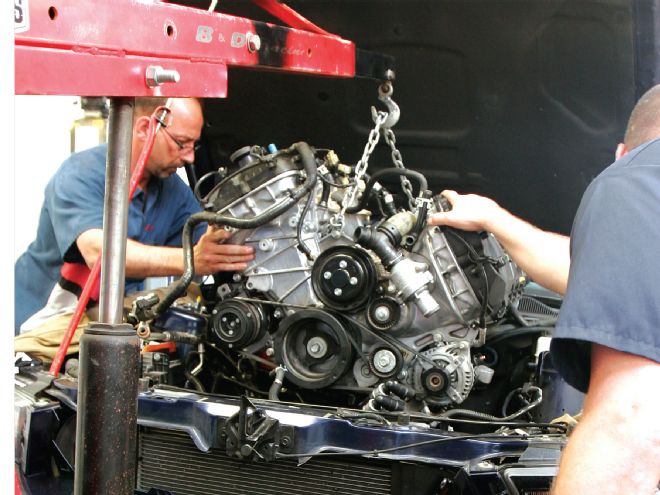

9. With the engine assembled and back at B&D Racing, it didn't take long for shop owner Brian Schapiro (left) and assistant Mason Rowland to drop the engine back in the car.

10. With the engine's newfound airflow, courtesy of the Livernois cylinder heads and Comp cams, it would have been a shame to choke it down with a stock intake manifold. Schapiro rightly recommended installing a Boss 302 intake manifold.

11. A pair of Kook's long-tube headers is on the other end to catch the exhaust. Schapiro installed them along with Kook's full exhaust kit, complete with catalytic converters and high-flow mufflers.

12. The suspension was also upgraded with Ford Racing springs and sway bars and Koni shocks. Shapiro also installed these lower-control-arm relocating brackets that alter the car's instant center.

13. New Mustangs have electric power steering. Here's a picture of the steering rack.

14. With everything back together, Brian re-flashed the computer so it would work with the new cams. "The PCM software is totally different from the 3V engines, and we ran into a couple booby traps along the way." One of the issues Brian dealt with was that the car needed to go to the Ford dealer for a complete software update. Still, all those keystrokes paid off. Brian was happy to report that he not only met but slightly exceeded his goal of 500 naturally aspirated horsepower at the wheels.