Remember when stand-alone EFI systems seemed beyond the reach of the average car guy? Oh sure, the computer geeks could get it to work, but for those of us without a computer degree, the risks just seemed to outweigh the benefits. Well, now that the EFI companies are well past their infancy, anyone who really wants to take a bit of time to learn about them can have a great performing EFI system in as little as a weekend.

But what if you don’t want to run a single or pair of four-barrel throttle bodies? What if you have (or want) a Six-Barrel car and want to keep it that way? And what about using a Shaker hood?

That’s the issue that Muscle Car Restorations came up against recently, when the owner of a ’70 Challenger wanted to upgrade from a 383 four-barrel to a 512-inch stroker and a Six Pack. Sure, repop carbs are available, but EFI on a six-barrel throttle body sounds cool.

It just so happens, that Bruce K. Bridges, founder of F&B Performance Engineered Products, has been working with Chrysler two-barrel throttle bodies for well over a decade, and has been building billet aluminum versions for some time now. He has come up with a complete six-barrel setup that will work with either FAST’s XFI or EZ-EFI systems. Just like the original Six-Pack cars, you can run around on a mild two-barrel and still have as much as 2,300 cfm at your disposal.

Because F&B builds their throttle bodies from billet aluminum instead of cast aluminum, they can offer bore sizes of 44-50 mm, and claim that they will flow more air than any other throttle body of the same size. The billet construction also allows them to build-in larger inlet areas than stock, use tapered flow paths for maximum ram effect, and most important in this case, they are compatible with factory air cleaners and shaker hoods.

F&B also supplies an Edelbrock Performer intake that has been fitted with the proper injector bungs and vacuum ports for the MAP sensor and etc., so you can get a complete bolt on kit that even comes with custom spacers so your shaker hood will end up at the correct factory height. You will need to upgrade your fuel system, but we’ll show you what you need to do to for that as well.

So no longer are you six-barrel guys left out of the EFI loop. Whatever your application, contact F&B and they’ll set you up with what you need to enjoy the full rush of six barrels with the precision of modern EFI.

Cost for Six Pack EFI: starting at $2,650

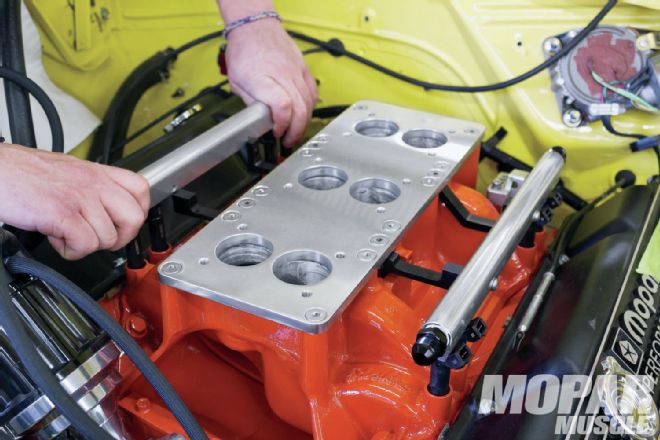

01 F&B modifies Edelbrock Performer intakes for use with their throttle bodies by opening the bores from 42 to 48mm, installing injector bungs, and adding vacuum ports for the MAP sensor. Runners are also gasket matched. They will also custom configure the manifold for specific applications.

01 F&B modifies Edelbrock Performer intakes for use with their throttle bodies by opening the bores from 42 to 48mm, installing injector bungs, and adding vacuum ports for the MAP sensor. Runners are also gasket matched. They will also custom configure the manifold for specific applications.

02 Because the throttle bodies’ bolt pattern is smaller than the original Holley carbs, a spacer (also polished billet aluminum) is needed to provide the proper mounting pattern. It also provides a place to attach the fuel rail mounts.

02 Because the throttle bodies’ bolt pattern is smaller than the original Holley carbs, a spacer (also polished billet aluminum) is needed to provide the proper mounting pattern. It also provides a place to attach the fuel rail mounts.

03 Fuel injectors (60 lb/hr in this case) are fitted using the supplied fuel rails, which easily bolt to their spacer-attached mounts. Very clean and simple.

03 Fuel injectors (60 lb/hr in this case) are fitted using the supplied fuel rails, which easily bolt to their spacer-attached mounts. Very clean and simple.

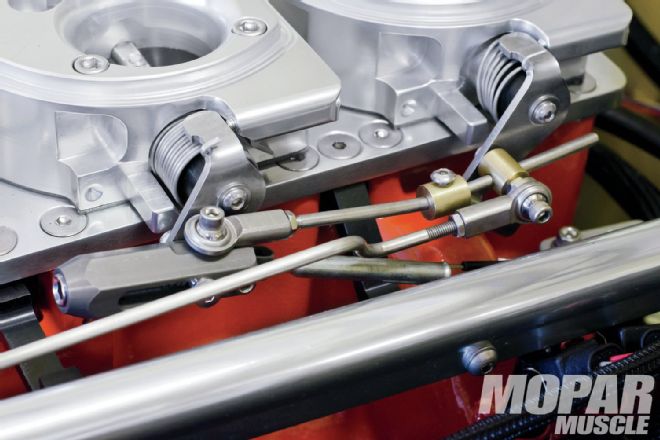

04 The complete set up with sensors and adjustable linkage in place.

04 The complete set up with sensors and adjustable linkage in place.

05 Throttle position sensor is used only on the center throttle body.

05 Throttle position sensor is used only on the center throttle body.

06 While throttle speed is ultimately controlled by the FAST software, base idle airflow is set by adjusting the throttle stops of the outboard throttle bodies. A single IAC motor is mounted on the front throttle body only.

06 While throttle speed is ultimately controlled by the FAST software, base idle airflow is set by adjusting the throttle stops of the outboard throttle bodies. A single IAC motor is mounted on the front throttle body only.

07 One of the really cool features of this system is the F&B designed fully adjustable progressive throttle linkage. The outboard throttles can stay closed until the center throttle has reached as much as 35-percent of its rotation.

07 One of the really cool features of this system is the F&B designed fully adjustable progressive throttle linkage. The outboard throttles can stay closed until the center throttle has reached as much as 35-percent of its rotation.

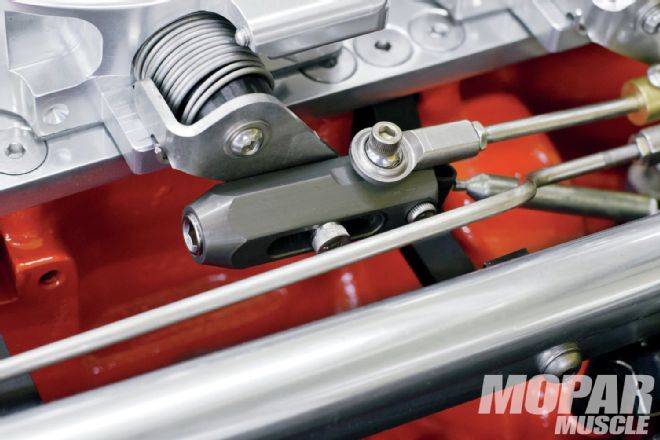

08 This really nifty piece of engineering is what allows you to set the point at which the outboard bodies begin to open. Bruce calls it a progressive spring slider. The linkage attachment-stud is held all the way to the right by an internal spring from idle to WOT for the center throttle body. The spring is stiff enough so that it doesn’t allow any movement until the center throttle body reaches WOT. Once WOT is achieved on the center throttle body, the spring will begin to compress, allowing enough additional cable travel to completely pull open the outer throttles. Note that the stud has moved to the left in the slot.

08 This really nifty piece of engineering is what allows you to set the point at which the outboard bodies begin to open. Bruce calls it a progressive spring slider. The linkage attachment-stud is held all the way to the right by an internal spring from idle to WOT for the center throttle body. The spring is stiff enough so that it doesn’t allow any movement until the center throttle body reaches WOT. Once WOT is achieved on the center throttle body, the spring will begin to compress, allowing enough additional cable travel to completely pull open the outer throttles. Note that the stud has moved to the left in the slot.

09 In this application, the MAP and air temp sensors are mounted under the air cleaner base.

09 In this application, the MAP and air temp sensors are mounted under the air cleaner base.

10 F&B custom spacers match the air cleaner base openings, and raise the Shaker scoop back to factory height.

10 F&B custom spacers match the air cleaner base openings, and raise the Shaker scoop back to factory height.

11 Not only is this air cleaner assembly at the correct height, it also does a pretty fair job of hiding what’s underneath. If you are not running a Shaker, and you’d like to show off instead, F&B offers a smaller billet oval air cleaner to finish off the system.

11 Not only is this air cleaner assembly at the correct height, it also does a pretty fair job of hiding what’s underneath. If you are not running a Shaker, and you’d like to show off instead, F&B offers a smaller billet oval air cleaner to finish off the system.

12 The stock fuel tank can be used but, that will require modifications. We used a Rock Valley Antique Auto Parts tank, as they are a direct bolt in, accept an in tank fuel pump, and make it easy to add the required fuel return line. You can get one for use with an inline pump if you’d prefer but the internal ones are much quieter.

12 The stock fuel tank can be used but, that will require modifications. We used a Rock Valley Antique Auto Parts tank, as they are a direct bolt in, accept an in tank fuel pump, and make it easy to add the required fuel return line. You can get one for use with an inline pump if you’d prefer but the internal ones are much quieter.

13 Stainless steel lines with AN fittings are the only way to go. At a nominal 43 psi of fuel pressure, you simply do not want any chance of a leak. We installed a 1⁄2-inch feed line and a 3⁄8-inch return.

13 Stainless steel lines with AN fittings are the only way to go. At a nominal 43 psi of fuel pressure, you simply do not want any chance of a leak. We installed a 1⁄2-inch feed line and a 3⁄8-inch return.

14 A fuel pressure regulator is required, but we took the extra step of using a vacuum referenced unit. This will sense when the engine needs more pressure, so the fuel pump doesn’t have to work any harder than it really needs to.

14 A fuel pressure regulator is required, but we took the extra step of using a vacuum referenced unit. This will sense when the engine needs more pressure, so the fuel pump doesn’t have to work any harder than it really needs to.

15 Using their in house Mustang dyno, the guys at MCR set up the FAST XFI system for maximum performance, reliability, and drivability. If you’re not sure that you want to tackle custom tuning, Bruce says that this setup is also compatible with FAST’s EZ-EFI system. When the dyno stopped, we measured 430 horsepower, and 488 lb-ft of torque at the wheels.

15 Using their in house Mustang dyno, the guys at MCR set up the FAST XFI system for maximum performance, reliability, and drivability. If you’re not sure that you want to tackle custom tuning, Bruce says that this setup is also compatible with FAST’s EZ-EFI system. When the dyno stopped, we measured 430 horsepower, and 488 lb-ft of torque at the wheels.

16 Alan Anderson of Prototype Solutions Group made a one off emblem for the scoop that should generate a lot of questions at the shows. mm

16 Alan Anderson of Prototype Solutions Group made a one off emblem for the scoop that should generate a lot of questions at the shows. mm