There are times when a junkyard 350 or even a 6.2L aluminum LS engine just isn't enough. There's an ever-growing portion of the Car Craft population that embraces wretched excess, grabs ahold of ludicrous-sized engines, and puts the power down with tire-wrinkling acceleration. The players in this vignette are not stars of the quarter-mile—they are street-burners like us. But they know that massive displacement is what shakes the ground, and there's only one real way to get there. Spend the money on a good aftermarket block, a long-arm crank, and rods, add a great set of heads, and you have the recipe for an axle-twister. Sure, you can add a centrifugal supercharger like an F2R Procharger or an 8-71, or even a pair of hair dryers for ludicrous power, but frankly an 11:1 compression 572ci Rat with rectangle port heads and a big roller cam doesn't need a turbo to flatten your eyeballs to the back of your head when you hook all that torque to a stretch of 1,320 feet of asphalt.

We've been doing some part-number archaeology and discovered that building a big-inch Rat motor has never been easier and less expensive to build than right here, right now. Sure, you'll spend $10,000 for a carburetor-to-oil-pan big-inch Rat, but these durable parts will deliver righteous power for as long as you want, and the most you might have to do is change the oil. Then when you become cozy to all that power, add a 150 shot of nitrous and that good old feeling will come right back. While 1,000+ hp looks attractive, unless you have an NHRA 25.5 chassis certification to run 7.50 at 180 mph in the quarter, along with all the other safety gear that turns your cruiser into a race car with a rollcage, it seems counterintuitive to pay for 2,500 hp you can't really use. But you can run 10 flat at 138 mph with little more than a few safety pieces and a five-point rollbar. So roll back the ridiculousness a little and let's look at what it takes to build an affordable, normally aspirated big-inch Rat motor. It's easier than you think.

Forget that 427ci LS small-block. You can build 750 hp today for not much more than the cost of a strong Mouse motor. Buy a crate short-block for $4,000, add a cam and heads, and the power will change your life forever.

Forget that 427ci LS small-block. You can build 750 hp today for not much more than the cost of a strong Mouse motor. Buy a crate short-block for $4,000, add a cam and heads, and the power will change your life forever.

Cylinder Blocks

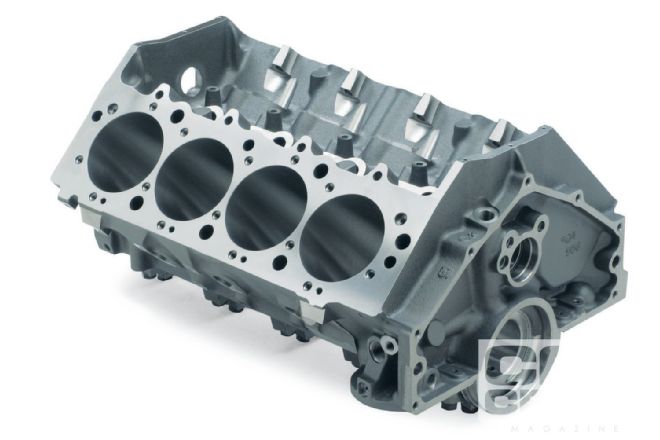

Any big-inch Rat worth its head studs begins with a good foundation. We've just finished assembling a 496ci Rat based on a stock 454 block, and frankly, we should have spent the extra money for an aftermarket block—one with a 4.50-inch bore. Factory 454 blocks are fine at 700 hp, but if you are serious about building an axle-twisting Rat, then invest in a good block. Chevrolet Performance, Dart, World, and now Blueprint Engines all offer new castings that can get the job done. A critical point is choosing the bore size. This is where bigger is always better. The minimum you should consider is 4.50 inches. Besides better breathing from the larger bore, the advantage is to create a big-inch engine without having to add the longer stroke, which increases piston and ring wall friction and windage. You can build a 555ci Rat with a 4.56-inch bore, while keeping the stroke to 4.25 inches.

Besides deck heights and bore sizes, you will need to decide whether to go with a one-piece or two-piece rear main seal block. The original MKIV block was two-piece, while the newer Gen V and VI blocks from GM are all one-piece rear main seal castings that do a better job of reducing oil leaks. This is the made-in-the-USA, one-piece hydraulic roller cam casting available from Blueprint engines.

Besides deck heights and bore sizes, you will need to decide whether to go with a one-piece or two-piece rear main seal block. The original MKIV block was two-piece, while the newer Gen V and VI blocks from GM are all one-piece rear main seal castings that do a better job of reducing oil leaks. This is the made-in-the-USA, one-piece hydraulic roller cam casting available from Blueprint engines.

Block Party Numbers

*Aluminum block

Larger-bore diameters automatically improve airflow from a set of cylinder heads, especially heads with larger 2.30-inch intake valves. The greater bore diameter improves airflow because the cylinder wall is moved farther away from the edge of the valve. The original GM 502 block is a great starting point with its 4.50-inch bore, and these can go as big as 4.60-inch bore.

Larger-bore diameters automatically improve airflow from a set of cylinder heads, especially heads with larger 2.30-inch intake valves. The greater bore diameter improves airflow because the cylinder wall is moved farther away from the edge of the valve. The original GM 502 block is a great starting point with its 4.50-inch bore, and these can go as big as 4.60-inch bore.

Displacement Disco

The following are examples of the most common big-block Chevy bore and stroke combinations. If you have an idea for a combination that's not on our list, the formula for displacement is as follows:

Displacement = Bore x bore x stroke x 0.7854 x number of cylinders

Displacement = 4.5 x 4.5 x 4.5 x 0.7854 x 8

Displacement = 572 ci

Standard Deck Height: 9.80

The best way to buy a crank/rod/piston package is with a complete rotating assembly that’s been balanced from the factory. This way you don’t need to worry about ensuring that the counterweights are matched to the piston and rod bob weight. If you are mixing and matching parts to build your rotator, be mindful of the bob weight. What you want to avoid is having to add weight to the crank because tungsten is very expensive.

The best way to buy a crank/rod/piston package is with a complete rotating assembly that’s been balanced from the factory. This way you don’t need to worry about ensuring that the counterweights are matched to the piston and rod bob weight. If you are mixing and matching parts to build your rotator, be mindful of the bob weight. What you want to avoid is having to add weight to the crank because tungsten is very expensive.

Rotating Assemblies

Did you know it costs no more to buy a 540ci Rat rotating assembly than it does for a 496? It's true. The explosion of Super Pro bracket drag racers building big-inch motors has jacked the volume so much that what used to be considered exotic drag race engine parts are now available at bargain-bin street prices. Ohio Crankshaft offers a 540/555/565 stroker rotator package that includes 4340 steel 4.250-inch crank, SRP pistons, 6.385-inch, H-beam 4340 steel rods, Total Seal rings and Federal-Mogul bearings all for less than $2,000. Bolt that spinning combo into a Dart block and for less than $4,500 you have the basis of a killer big-block. Of course, Ohio Crank isn't the only game in town. Companies like Scat, Eagle, Callies, and Crower offer packages that range widely in price, depending upon quality. We found a Scat rotator assembly with a 4340 steel crank, H-beam rods, pistons, rings, and bearings for $2,030 through Summit Racing. Like these, there are dozens of combinations too numerous to list. Variables include important stuff like metallurgy where 4340 is stronger than 5140, which is, in turn, stronger and more ductile than cast iron. Small things like rolled fillet edges for the rod journals drastically increase strength, even for a cast crank. One way to compare cranks would be to evaluate weight. A lighter rotating weight requires less horsepower to accelerate. This won't show up on an engine dyno but will reveal itself on the dragstrip or an acceleration-rate-chassis dyno, where power is extrapolated by how quickly the engine accelerates the drum. Of course, a big stroke needs counterweight to offset piston and rod mass. This is why buying a complete rotating assembly is a very good idea since the company has already done the bob-weight research.

A good steel 4340 stroker crank, such as this one from Ohio Crankshaft, is a key component for a durable Rat package.

A good steel 4340 stroker crank, such as this one from Ohio Crankshaft, is a key component for a durable Rat package.

Tall Deck: 10.20

Cylinder Heads

The only reason to build a stroker big-block Chevy is to make power. The best way to get maximum benefit from all this displacement is with a great set of heads. Here is where the best money is spent in terms of dollars per horsepower. High-flowing big-block heads are not cheap, so don't be misled by the siren song of budget Chinese heads. The good stuff all comes from domestic-based companies like AFR, Brodix, Dart, Edelbrock, and TFS. There are also dozens of good race heads out there, but we'll keep our discussion centered on mainstream heads. For a 540- or 572-inch Rat, we're going to focus on rectangle-port heads with an intake-port volume of between 325 and 355cc. Cam specs will determine the peak torque and horsepower points based on intake lobe duration, but let's apply Westech's Steve Brulé's formula for power that uses 1.25 torque per cubic inch (lb-ft/ci) formula for a 10.5:1 compression, pump-gas Rat. Applying this formula (1.25 x ci = peak torque) to a 540 creates 675 lb-ft of torque. Using 90 percent of that number for torque at peak horsepower at 6,500 rpm (675 x 0.90 = 607 lb-ft) delivers 751 hp (607 x 6,500 / 5252 = 751). That's amazing power for a single four-barrel pump-gas motor.

We've listed just a few of the more impressive cylinder heads on the market today so you can get an idea of what's out there. Peak flow numbers are typically in the near-400-cfm-plus range. Our chart lists the flow at 0.600-inch lift because that's a reasonable valve lift number for a street-driven camshaft. Often these heads will flow 400-plus cfm at 0.700- or even 0.800-inch lift. For best peak horsepower, don't forget to inspect the exhaust flow numbers. One way to evaluate an exhaust port is to divide the exhaust flow cfm at a given valve lift by the intake cfm; the result will be expressed as a percentage. A rule of thumb is a good exhaust port will come in at 70 percent or above. But don't condemn a head that fails to reach this 70 percent level, but it will require more exhaust duration (more time) to evacuate the cylinder at high rpm. Also keep in mind that all big rectangle-port big-block Chevy head manufacturers will raise the exhaust port between 0.250- and 0.600-inch above the stock big-block port location. This radically improves exhaust port flow but makes it difficult to fit an off-the-shelf header. This is especially problematic when using large 21⁄8- to 21⁄4-inch primary pipe diameter headers. It's best to consider that when building a 500-plus-ci big-block those custom headers should be part of the budget.

If there is a critical component in the rotating assembly besides the forged piston, it has to be the connecting rod. If you plan to spin a long-stroke engine beyond 6,500 rpm, invest in the best connecting rods you can afford. Higher engine speeds place enormous loads on the rod when changing direction, especially at bottom dead center (BDC).

If there is a critical component in the rotating assembly besides the forged piston, it has to be the connecting rod. If you plan to spin a long-stroke engine beyond 6,500 rpm, invest in the best connecting rods you can afford. Higher engine speeds place enormous loads on the rod when changing direction, especially at bottom dead center (BDC).

Big-Block Head Chart

*The cylinder-head flow numbers were taken from manufacturer published data. There are multiple variables among these numbers from different flow benches, bore diameters, and other inconsistencies that directly affect these flow numbers, so all these numbers should be used merely as trend indicators and not as hard facts. If there are enough interested readers, we could be persuaded to do a more complete rectangle-port head test in a future issue.

Induction

We won't spend a lot of time here, except that with large-displacement engines, the sheer size will make massive torque even when you build an engine where peak horsepower has the emphasis. We built a 496 a few years ago (“707 HP for $6,720,” Mar. '07) that included a cast crank, stock rods, a Comp mechanical roller 254/260-degree cam, 305cc AFR rectangle-port heads, an Edelbrock Victor, Jr, and an 850-cfm carburetor. Even with a relative big mechanical roller, this “small” Rat made 514 lb-ft at 3,000 rpm and peak torque came in at 5,400 with 603 lb-ft. So for our next 496, we've upped our game, and from our Rat-friendly friends we hear that a Dominator carburetor is worth some power. The research indicates that while 1,050 cfm seems like overkill, the wider spacing of the throttle bores improves mixture distribution and that, with the larger venturis, inlet air speed is reduced. This can be an advantage because high mixture velocities have to make that 90-degree turn from vertical to horizontal flow to enter the intake ports. Since fuel is heavier than air, the air makes the turn and fuel slams into the bottom of the intake manifold. This is why taller manifolds also help. With a Dominator carb, the slower air speed at high rpm has a better chance to make the turn. Of course, this also means that low-speed throttle response may be a little sluggish. That's the compromise with any street engine. For street use, this will also require some specific tuning to lean the idle and low-speed circuits in the carburetor to prevent running the engine excessively rich at part-throttle boulevard engine speeds.

This 1,050-cfm Ultra Dominator is easily identified as a three-circuit carburetor by its additional intermediate bleed (arrow 2) located in between the low-speed (arrow 1) and the high-speed bleed (arrow 3).

This 1,050-cfm Ultra Dominator is easily identified as a three-circuit carburetor by its additional intermediate bleed (arrow 2) located in between the low-speed (arrow 1) and the high-speed bleed (arrow 3).

Three-circuit Dominators have received a bad reputation as street carburetors, but the reality is that this added low-speed circuit could be leaned out just as easily as the idle circuit in order to produce acceptable part-throttle operation. This is where a wideband oxygen (WBO2) sensor can be used as an excellent tuning aid.

You know that big-inch Rats have become popular with the number of manifolds available. We chose this Edelbrock Victor 454-O oval-port single-plane that mounts this Holley 1,050-cfm Ultra Dominator. You can adapt a Dominator to a 4150 intake, but expect that smaller carb opening to minimize the advantage of the larger carb.

You know that big-inch Rats have become popular with the number of manifolds available. We chose this Edelbrock Victor 454-O oval-port single-plane that mounts this Holley 1,050-cfm Ultra Dominator. You can adapt a Dominator to a 4150 intake, but expect that smaller carb opening to minimize the advantage of the larger carb.

Short-Block Kits

Here's where the fun really begins. It is time-consuming and challenging to build your own short-block, unless you have all the proper tools for measuring, creating custom clearances, and assembling an engine. But you don't have to because there are multiple companies out there that make the difficult part easy by offering outstanding deals on assembled short-blocks. ATK has been assembling performance engines for years, and we ran across an attractive 540ci internally balanced package using a standard-deck Dart Big M block, a forged 4340 steel crank, a forged piston, and H-beam rods all for a Summit Racing price of $4,799. Given that the block goes for $2,250, this means you're getting an assembled and balanced short-block for an excellent price. This still requires the usual cam, valvetrain, heads, oiling system, and all the rest, but an assembled short-block is an excellent way to begin your big-block journey.

Along those same lines, Ohio Crankshaft offers the choice of a 509/540/555/565ci Rat using a Merlin block with a 4.250-inch steel crank, 6.385-inch H-beam rods, and forged pistons assembled for $4,395, or you can step up to a 572- or 588ci Rat still at the standard 9.8-inch deck height assembled for $4,995. Scott Shafiroff Racing is right there in the hunt with a 540ci assembled short-block that starts with a Dart Big M block, an Eagle 4340 crank and H-beam rods, JE/SRP forged pistons, and Clevite bearings all assembled for $4,595. Or if displacement envy is your thing, but with a standard deck motor, Shafiroff builds a 582ci Big Dawg motor with similar parts to the 572 for $4,845. At 1.25 lb-ft/ci, we're talking about a Rat that will twist nearly 730 lb-ft of torque. Think diesel-locomotive-level torque and then go from there.

There are many other examples, but by now you get the picture. Torque is what shoves you back in the seat in the middle of Second gear when wimpy motors have fallen off the torque curve. If we haven't got you thinking in terms of expansive valve covers and driveshaft-twisting torque, check your pulse.

572ci Big-Block Chevy

To put some real numbers to all this conjecture, Steve Brulé at Westech built a thumpin' street big-block a couple of years ago and put it on the dyno. As you can see from the numbers, this beast never fell below 600 lb-ft of torque and twisted more than 820 hp at a mild 6,400 rpm. What might really tweak the naysayers is that this was with a hydraulic roller cam. A quick rundown of the specs below includes a Dart Big M block, an Eagle crank and rods, Mahle 10.5:1 compression pistons, a Comp Cams hydraulic roller cam (271/274 duration with 0.680/0.647-inch lift and 112-degree LSA). The heads were a pair of Dart 355cc Pro-1 CNC heads with a Dart Dominator intake and a Holley 1150-cfm two-circuit Dominator carb. Brulé even used off-the-shelf roller rockers instead of an expensive shaft rocker system. This motor makes excellent torque down low and would be simple to maintain with the hydraulic rollers. This beast makes 600 lb-ft of torque at 3,200 rpm.

Chevrolet Performance offers a forged crank 502ci long-block with 9.6:1 compression and a mild hydraulic roller cam in a 4.47-inch-bore-times-4.00-stroke configuration that would be great with more cam and good heads. This package has the potential to make 600-plus lb-ft of torque. You can buy this warrantied short-block right now for $4,980 from Scoggin-Dickey (PN 125658782).

Chevrolet Performance offers a forged crank 502ci long-block with 9.6:1 compression and a mild hydraulic roller cam in a 4.47-inch-bore-times-4.00-stroke configuration that would be great with more cam and good heads. This package has the potential to make 600-plus lb-ft of torque. You can buy this warrantied short-block right now for $4,980 from Scoggin-Dickey (PN 125658782).

572ci Power

Westech’s Steve Brulé assembled this 572 completely from off-the-shelf pieces. We plugged this 572’s torque curve into a theoretical 3,700-pound Chevelle with a TH400 trans, 4.10 gears, and 28x12.50-inch sticky drag radials, and the simulation responded with 9.80s at 139 mph. Torque is a wonderful thing! End

Westech’s Steve Brulé assembled this 572 completely from off-the-shelf pieces. We plugged this 572’s torque curve into a theoretical 3,700-pound Chevelle with a TH400 trans, 4.10 gears, and 28x12.50-inch sticky drag radials, and the simulation responded with 9.80s at 139 mph. Torque is a wonderful thing! End