Last month we kicked off the first of a two-part story about getting the underhood details right on several Mopar big-blocks. The days of a thorough cleaning being good enough are long gone. Car shows have become so fiercely competitive that the smallest item can separate a class winner from the runners-up.

To find out what’s right—and wrong—under Mopar hoods, we turned to Frank Badalson, who has made a career out of researching the build details of vintage Mopars. With his background in law and legal matters, he has a sharp eye for what’s right and a good nose for bull stories.

Leaning on Frank’s expertise, we are examining a trio of ’70s meticulously detailed by him: a 440 Six Barrel, a 440 four-barrel, and a 426 Hemi. Also in the mix for comparison’s sake is a very original, unrestored ’68 440 four-barrel in a GTX. Last month we covered the engine—mounts, block, heads, and so forth. Here we get into carburetors, ignition, and other engine accessories.

Often missing altogether, this plug wire grommet and bracket for the No. 8 cylinder hardly gets noticed, being at the back corner of the engine. But it’s there to keep the plug wire from flopping around and rubbing against things it shouldn’t, like the very hot exhaust manifold. This is the right way for it to look: bracket, bolt, and stud painted with the engine, and the grommet, which was supplied already on the wire, unpainted. The No. 8 plug wire boot is angled differently than the other seven, says Frank. “The No. 8 spark plug wire boot is a specially angled boot. All other boots are 90-degree style.”

The Nos. 6 and 8 spark plug wires have heat shields since they are so close to the exhaust manifold on two sides. The two exhaust manifold bolts near the exhaust manifold collector are original-style sleeve nuts. Because this 440 Six Barrel engine was built before May 1970, it has the correct, early-style valve cover on the right side. Later production right-side valve covers were notched at the front. Original valve cover gaskets are cork, and their exposed areas are painted. The breather grommet (out of view with the breather canister in place) is also painted engine color. The correct oil filler cap is stamped “F-E.” The counterweight for the heat riser is visible, as are the unpainted exhaust pipe bolts. As on the Hemi (below), these plug wires have orange paint spots from contact with the wet engine.

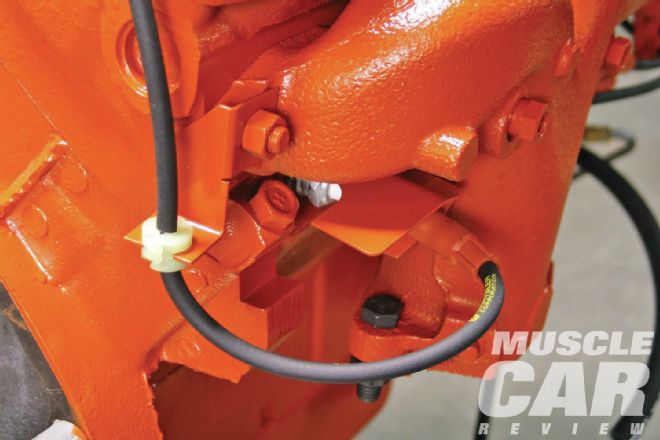

At the rear of the left cylinder head is the positive battery cable support bracket. This is a Hemi-only item. The end is dipped in rubber, bolts to the cylinder head, and is painted on the engine. They’re usually a little longer on a ’70, but Frank says that this one is known to be original to the car and that early production cars often have nonstandard parts as leftover stocks from the previous model are used up. Paint coverage is frequently spotty. Note the unpainted cork gasket and valve cover nuts.

If you really want to go all out with originality, search out a set of original Champion spark plugs. They were produced by the millions, so they’re out there if you do some looking at swap meets, online, and with specialty vendors. J-11Y spark plugs were the OE plug on 440 four-barrel and 440 Six Pack engines.

When plug wires were installed on the engine, the paint was still wet. Original, unrestored cars have orange paint marks on their plug wires where they rubbed against the wet engine paint. The paint tracks could and did also get on the valve covers. “Restorers are very reluctant to do this,” says Frank about recreating any kind of mess on expensive, freshly restored parts, especially rare N.O.S. plug wires. “There is haze, there are strings of paint on the valve covers, it’s all over. But this is authentic. Anybody who’s seen and studied untouched Hemis will know that this is very common. Hemis were assembled at the Marysville Marine plant in Marysville, Michigan. The engine was painted and fully trimmed and shipped as a complete unit. Tape and paper were used to tape off the valve covers, however sloppy the masking might have been, and the engine was painted. There is haze from where the tape didn’t completely seal. You’ll see this on most original cars. Then they took the masking paper off and dropped the distributor in with the plug wires already on it. Those wires hit that freshly painted engine and that’s where all this comes from.” Look close and you’ll see “H 3Q-69” on the plug wires. It’s a date code that decodes as the third quarter of 1969. The nylon grommets are originals, but they have been reproduced.

Champion N-10Ys were factory issue for the 426 Hemi. Gas fouling wasn’t uncommon for street-driven Hemis. It is important that you do not use the metal ring gasket supplied with Champion spark plugs on a Hemi. It will damage the spark plug tube and cause oil leaks. The aluminum spark plug tubes seal in place of the gasket. This is per the Chrysler Service Manual. Do use the metal ring on 440s.

Prior to the ’69 model year, 440s were painted turquoise like this survivor ’68 440 Super Commando. Look closely and you’ll see remnants of turquoise paint on the plug wire loom at the front of the engine. The looms were on the engine when it was painted, but the paint didn’t stick very well to the loom. After it flaked off, the black was all that was visible, and many restorers assumed that the looms were unpainted. But careful examination of originals like this shows that their original finish was engine color. Loom style and placement usually changed year to year.

The rear of a typical 440 four-barrel and 440 Six Pack alternator has a red-orange color code, as commonly seen on a ’70 37-amp alternator. The casting is unfinished aluminum. Wires are routed through a vinyl- covered, three-finger holder. The center finger is pushed closed to secure the wires. Down low is the output terminal, which handles the alternator’s output and has a protective black plastic collar. The flat section of the case, near the output terminal, is an ID pad and has a part number and date code stamped into it. This unit’s part number is 3438172, correct for ’70 non-air performance cars with the standard alternator. Starting with the ’70 models, the last two digits, 72 in this case, will be on the build sheet. Other alternators may function, but for highest originality, the part number and date code should match the car. At the very center is an OE shaft bearing. The other disc-shaped objects are diodes, which have visible date codes printed on them. Hemis did not use this alternator.

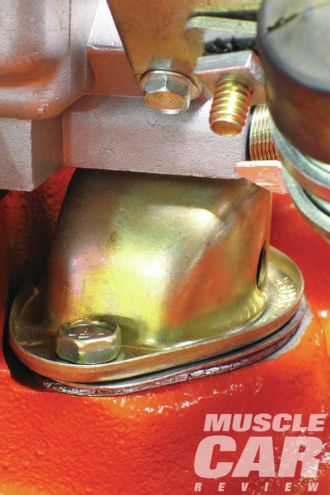

Lots of important details here at the back of the 440 carb. Bolts holding the 440’s Carter AVS (Air Valve Secondary) carb to the intake are manufactured by Highland and have a logo stamped on top. Finish is black phosphate plating. Between the carb and intake is the correct black gasket, 5⁄16 inch thick and comprised of two laminated layers. Frank says that 90 percent of the time, he sees a standard—and incorrect—brown or tan gasket from a carb rebuild kit. The thick gasket provides necessary clearance between the carb and choke. It is no longer available at auto parts stores but is available from Frank Badalson. The open-ended 5⁄16-inch vacuum hose at the base of the carburetor connects to the bottom of the dual-snorkel breather once installed. The hex-head manifold plug is painted orange with the engine. On cars with power brakes and/or an Air Grabber hood, a silver cad-plated nipple is fitted to this port as a source for manifold vacuum.

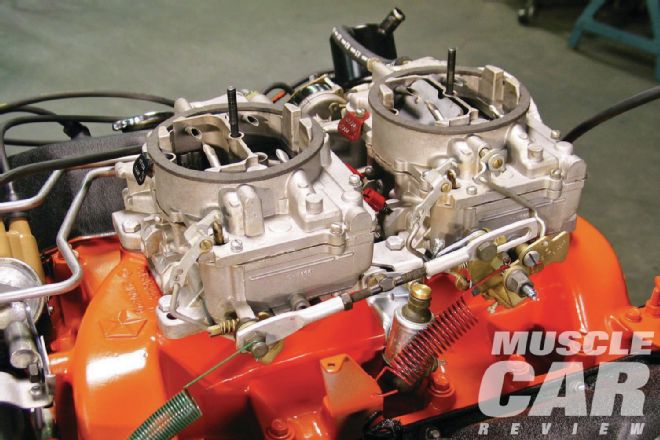

Detailed to perfection, this trio of Holley 2300s is the highest evolution of the triple deuce, a traditional hot rodder’s favorite. Only the center carb has a choke, a bowl vent, and a metering block. Carb bases are bare aluminum; return spring is orange. A black S-clip holds the OE ribbed vacuum hose to the rear carb fuel line.

These original Carter Hemi carburetors are concours correct. There’s more detail here than we have room for, but we can hit some highlights. The rear is the primary carb. Only the rear carb has a choke and the red idle-limiter caps. Return springs are different colors. Each carb has a breather gasket and its own ID tag. Mounting bolts are silver cad-plated and have a manufacturer’s logo that leads Frank to nickname them “dog bone bolts.” “They’re kind of rare,” says Frank, “used pretty much only on ’70 and ’71 Hemis and ’71 440 Six Pack cars.” Stamped into the right front corner of the front carb’s base (inset) is the date code J9 (J means September, 9 means 1969) and the Carter carb model number 4742S. The rear carb should be 4745S for a ’70 Hemi with manual transmission.

With the choke mechanism mounted in the intake manifold, it is often, but wrongly, assumed to be painted engine color along with the rest of the engine. Franks says, “We see that a lot out in the field, and it is incorrect. It is very important to note that this choke is not painted engine color. That choke should be its own natural zinc dichromate color, not painted on the engine.”

This is how the throttle return spring bracket is supposed to be configured on the ’70 440 Six Pack. Actual bracket types vary by engine, but the negative battery cable always goes between the intake manifold and the bracket on a 440 four-barrel and 440 Six Pack. It was installed like this before the engine was painted to ensure a good electrical connection—not a connection obstructed by paint. Frequently the cable terminal is incorrectly fastened on top of the bracket.

Emissions devices were already being used in 1970. This 440 distributor used an electrical solenoid within the vacuum-advance canister to retard ignition timing under certain conditions. This is unique to the ’70 440 four-barrel. The plug wires (these are reproduction) and the distributor itself all have date codes. Plug wires show “1Q 70” for first quarter of 1970, while the distributor’s original ID tag is date-coded 379, which stands for the 37th week of 1969. The tan distributor cap is an N.O.S. cap (PN 2444507) used on single-point distributors. It is completely different from the 2585000 cap used on dual-points. On ’70 models, both 440 four-barrel/automatics and 440 four-barrel/four-speeds used the single-point distributor.

The ’69½-’70 440 Six Pack distributor is much different from the four-barrel distributor. All ’69½-’70 440 Six Packs used dual-point distributors with black housings, a tan distributor cap (PN 2585000), and no retard solenoid. The coil wire boot is red. By the ’71 model year, 440 Six Packs did have the retard solenoid.