It’s an accepted part of hot rodding lore that headers help make more power and torque on any engine versus the typical stock cast manifold, but do you know why? It’s all about flow, right? Well, yes and no. It’s more about optimizing how the exhaust exits the engine’s combustion chamber, but there is much more to it than just using the largest pipe possible. Before you throw down some hard-earned hundies for a set of tubes for your car, it pays to have a basic understanding of what you’re getting in return and why.

Why Are Headers Better?

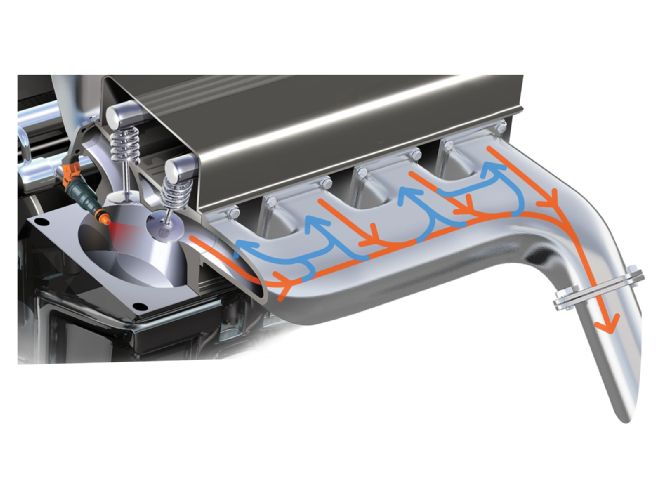

If an internal combustion engine is just an explosion-powered air pump, then how the air exits the engine is just as important as how it gets ingested. As the piston travels through the exhaust stroke, the burned gases are expelled past the open exhaust valve and into the exhaust manifold. By nature, manifolds have very short runners that dump into a common plenum (or "log"), which causes the gases from each cylinder to build up pressure in the manifold. That backpressure can not only prevent all of the exhaust from being emptied from the chamber, the proximity of the log to the chambers can allow exhaust from one cylinder to flow back into another cylinder during cam overlap. If all the exhaust gases are not removed from the cylinder, the intake charge will be diluted, meaning less power will be made. On top of that, backpressure also requires power to be expended to force the gases out of the cylinder, so there is a loss there as well.

Aside from the restriction created by their very short runners and log, OE exhaust manifolds also allow exhaust to crossflow from one cylinder to another, contaminating the intake and costing power. The loss is often overlooked by OEMs as it aids exhaust gas recirculation (EGR) for a reduction in emissions.

Aside from the restriction created by their very short runners and log, OE exhaust manifolds also allow exhaust to crossflow from one cylinder to another, contaminating the intake and costing power. The loss is often overlooked by OEMs as it aids exhaust gas recirculation (EGR) for a reduction in emissions.

Four Common Header Types

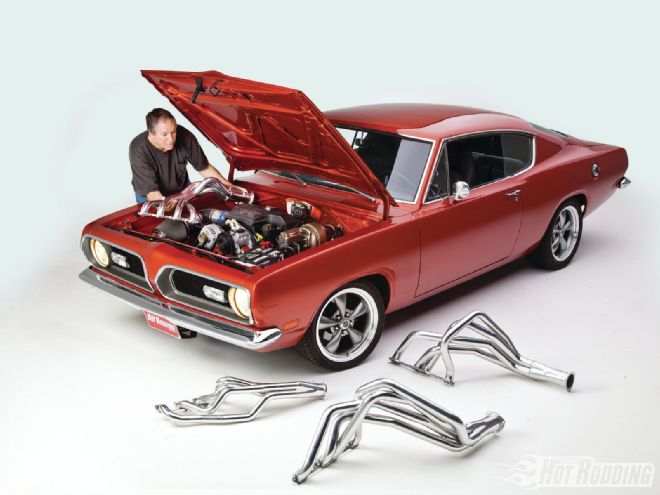

4-into-1 Long-Tube: This is the classic long-tube header that everyone is most familiar with, and comprises the vast majority of the aftermarket offerings for street and race application. The benefit of long-tube headers is the significant decrease in backpressure on the cylinder due to the separation of exhaust gases into their own individual pipes. Their length also prevents the crossflow of exhaust from one cylinder to another. These are also the most versatile headers since they can be tuned in different ways via primary diameter, length, secondary (collector) diameter, and shape to account for different horsepower and operating ranges. They’re the go-to design for most hot street and race cars.

Tri-Y Long-Tube: Tri-Y headers came to popularity when they were used by Shelby for the GT350 Mustangs. The tri-Y design combines a short primary that is paired with another cylinder that is synchronized in the firing order into a 2-into-1 collector that steps to a larger diameter secondary tube. The two secondary tubes are then merged into a final 2-into-1 collector creating an overall length similar to a 4-into-1 design. The traditional design works well to build more torque from idle to 4,500-5,000 rpm, so they are very effective for street use, however, autocrossers and road racers also love them for their midrange torque and increased throttle response as well. NASCAR teams use a derivative design, called a 4-into-2-into-1 (4:2:1), which uses much longer primary and secondary tubes for higher-rpm effectiveness.

Tri-Y headers, like these from Doug’s are traditionally designed for a midrange torque increase by merging complementary exhaust pulses. If custom built for a particular engine combo, they can be tailored for an extreme power increase.

Tri-Y headers, like these from Doug’s are traditionally designed for a midrange torque increase by merging complementary exhaust pulses. If custom built for a particular engine combo, they can be tailored for an extreme power increase.

Shorty & Block Hugger: Shorty headers primarily came into existence because of emissions systems that require catalytic converters and oxygen sensors located in a specific range close to the exhaust ports. Shorties are better than most manifolds since they offer short runners that do not combine into a single log, which helps separate exhaust gases and prevents crossflow into another cylinder. Nevertheless, the tubes are too short to maximize potential gains and they lack a collector of any significant length, which also hurts overall gains. Some performance-oriented cars actually come from the factory with a shorty-style header, Mustangs for example. These factory headers work pretty well considering the confines and are often only bested by shorty headers that have runners dyno tuned for increases on specific engine combinations—and by long-tubes, of course.

Mid-Length: Brought out as an alternative to shorties without the ground clearance issues of full lengths, mid-length headers keep the tubes and collector up above the chassis but allow for longer primary lengths. Not much length is sacrificed in the primary tubes, but the collectors are very short, which does affect their tunability. Mid-length headers will almost always make more usable power on the street than shorties, although not quite as much as long-tubes or tri-Y designs.

Mid-length headers, like these from Hooker, maintain stock ground clearance while still giving longer primary lengths.

Mid-length headers, like these from Hooker, maintain stock ground clearance while still giving longer primary lengths.

Tube Diameter

To decide on the right primary tube diameter, there are numerous formulas used in the design of race headers, but for a street car, Don Lindfors of PerTronix (makers of Doug’s, Patriot, and JBA headers) says the following is a great rule of thumb: 200-325 hp look for 1.50-inch diameter primaries, 275-425 hp use 1.625 inches, 400-500 hp use 1.75 to 1.875 inches, and 500 hp and up look for 2 inches or bigger. If you’d like to get more specific, keeping in mind that smaller diameters set a lower limit on peak torque, a 300hp motor could use 1.5- or 1.75-inch primary depending on whether you want the torque at a lower rpm, or to allow it to keep moving higher at a higher rpm. Just a .25-inch increase in primary diameter will push the torque peak up by about 700-800 rpm.

We know many hot rodders like hard numbers, so if you’d like to get as specific as possible and try to size your primary tubes to work effectively within a specific rpm range, try these formulas out:

Flowmaster’s retrofit-style 4-2-1 Scavenger Series “C” Collectors are inspired by the high-end Trans-Am and NASCAR–type tri-Y design, and use large D-shaped junctions to help pull the exhaust pulses from the opposing connected cylinders.

Flowmaster’s retrofit-style 4-2-1 Scavenger Series “C” Collectors are inspired by the high-end Trans-Am and NASCAR–type tri-Y design, and use large D-shaped junctions to help pull the exhaust pulses from the opposing connected cylinders.

Primary Pipe Area (PPA) = (peak torque RPM ÷ 88,200) × 1 cylinder ci

To find the PPA, we use A=πr²

For a few common header sizes, this is:

1⅝ = 2.07

1¾ = 2.19

1⅞ = 2.53

For example, for a 350ci engine with a peak torque goal of 5,000 rpm:

PPA = (5,000 ÷ 88,200) × 43.75 ci

PPA = 2.48

By separating the ports from one another in a true header, exhaust velocity is maintained or increased to help extract the exhaust from the cylinder, while also preventing the exhaust from one cylinder from diluting the incoming intake charge in another cylinder. This also helps optimize pressure wave timing. Rule of thumb is that you want to use the smallest diameter that will not hinder high-rpm flow. To a modest extent, a smaller diameter helps keep exhaust velocities high and that is where the largest improvements will be seen in terms of torque, which is what you want on the street. Bigger can be better when it comes to headers, but not at the expense of fitment.

By separating the ports from one another in a true header, exhaust velocity is maintained or increased to help extract the exhaust from the cylinder, while also preventing the exhaust from one cylinder from diluting the incoming intake charge in another cylinder. This also helps optimize pressure wave timing. Rule of thumb is that you want to use the smallest diameter that will not hinder high-rpm flow. To a modest extent, a smaller diameter helps keep exhaust velocities high and that is where the largest improvements will be seen in terms of torque, which is what you want on the street. Bigger can be better when it comes to headers, but not at the expense of fitment.

To see what the theoretical peak torque rpm of a certain set of headers is for your particular engine, just rearrange the formula:

Peak torque rpm = (PPA × 88,200) ÷ 1 cylinder ci

1⅝ (2.07) = 4,175

1¾ (2.19) = 4,415

1⅞ (2.53) = 5,100

So theoretically, our fairly high-winding 350 with a peak torque of 5,000 rpm should run a set of 1⅞-inch headers. But if your street-oriented 350 makes peak torque at a more typical 4,000 rpm, a set of 1⅝-inch headers would make more sense.

Primary Tube Length

How long should your primary tubes be? In most cases, this one is going to be mostly dictated by your chassis constraints and emissions considerations on a street car, and what is available in the aftermarket for it. In general, the ideal overall length of the primary header pipe is governed almost exclusively by the target engine’s rpm range. Typically, a lower engine rpm range likes a longer primary pipe, while a high-rpm engine prefers a shorter primary. Also, the longer the primary tube, the greater the emphasis on torque production below the peak-torque rpm of the header. Making the primaries shorter will slide the emphasis above the peak-torque rpm. So, with slightly different length primary tubes you can actually tune the engine’s powerband, and increase torque at a slight cost of peak horsepower.

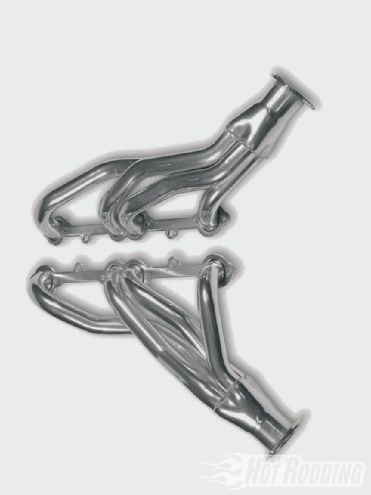

These long-tube small-block Chevy headers from Flowmaster are a traditional design, but feature a merged collector for additional power.

These long-tube small-block Chevy headers from Flowmaster are a traditional design, but feature a merged collector for additional power.

More esoterically speaking, primary-tube length also works to control the timing of the exhaust pressure wave that is travelling near the speed of sound. Some of that pressure will exit the collector through the exhaust pipes, but the remaining pressure wave will reflect back up the primary tubes with a negative pressure. This effect is called scavenging. Lindfors explains: "The idea is to time this negative pressure wave to coincide with the cam overlap so the low pressure helps draw the incoming intake charge into the cylinder for more complete filling of the cylinder while at the same time pushing out any residual spent exhaust gases. The timing of these events is mostly controlled by the length of the primary pipes in the header design."

Much like length, there are several different formulas to calculate a theoretical ideal length for a header primary tube.

One example is:

Primary Tube Length = [(850 × Exhaust Duration) ÷ RPM] − 3

Exhaust Duration = 180 + the number of degrees before bottom dead center (BDC) that the exhaust valve opens

Shorty headers, like this Hedman system for fourth-gen F-bodies, are designed as a well-crafted compromise among optimum power, fitment, and emission compliance.

Shorty headers, like this Hedman system for fourth-gen F-bodies, are designed as a well-crafted compromise among optimum power, fitment, and emission compliance.

RPM = the engine speed we are trying to tune the primary length for

For example: the exhaust valve opens at 60 degrees BDC, so the exhaust duration is 60 + 180, or 240

Using the same 350ci engine running in the 5,000-rpm range from before:

Primary Tube Length = 850 × 240 = 204,000, then 204,000 ÷ 5000 = 40.8, then 40.8 − 3 = 37.8 inches

So a good starting point for the length of the primary tube (as measured from the back of the exhaust valve to the collector (not the exhaust port) should be around 37.8 inches.

The top illustration shows the turbulence inherent in straight-cut primaries dumping into a canister-style collector. While this design will still make good power, there is additional power to be found by merging the primaries in some way (accomplished with a spike in the lower illustration) and smoothing the flow into the collector.

The top illustration shows the turbulence inherent in straight-cut primaries dumping into a canister-style collector. While this design will still make good power, there is additional power to be found by merging the primaries in some way (accomplished with a spike in the lower illustration) and smoothing the flow into the collector.

But it’s really not just that simple in the world of racing. To get the full picture of exactly what length (and diameter, for that matter) that a custom set of headers for a particular car should be, Chris Vandergriff of Hedman’s Husler race header division says he needs to consider every aspect of the combination from camshaft specs, to cylinder heads, to fuel type, power adder, and, of course, rpm range. For example, nitrous cars tend to want more volume than naturally aspirated cars. Formulas can take you so far, but much of what top custom race header builders create is based on experience and testing on the track.

There is also somewhat of a debate over equal versus unequal tube length, since in theory equal-length tubes are preferred. "The thing to keep in mind about equal length is that you can’t just measure the length of each tube and compare. Since bends are necessary in the tubes and airflow is laminar in nature, bends cause a disturbance that change the flow rate. The radius of the bend will also change the effective length of the tube. In reality, there can be some benefit to slightly different length tubes on a street car header," Lindfors explained. That type of esoteric data is exactly what Vandergriff is referring to.

The Collector

While it seems like little more than a means to bring the four individual primary pipes into one tube that can attach to the rest of the exhaust system, the collector has a great deal of potential to positively affect the output of the engine. The obvious alterations are diameter and length, and those do make a difference, but there is actually so much more going on inside a collector due to the simple fact that essentially four single-cylinder engines are dumping exhaust into one tube. The key is handling both the exhaust waves and pressure waves that converge there.

Much like the primary tube diameter, the collector diameter is critical to power production. Ideally, the diameter needs to be large enough to support the amount of exhaust that will be entering it. Due to broad application considerations, most street car headers have a larger collector than they need, but that can be mitigated by how the collector handles the exhaust and pressure waves. The exhaust waves are somewhat self-explanatory; each cylinder sends a slug of exhaust down the primary tubes into the collector at around 350 feet/second. Standard headers will exit with a simple cutoff of the primary tubes into a canister-style collector. This design works and will make good horsepower in a relatively narrow rpm range, and is usually sized to maximize peak horsepower. One drawback, though, is that it tends to create a swirling of exhaust gases that will slow down their flow, making the collector diameter even more critical.

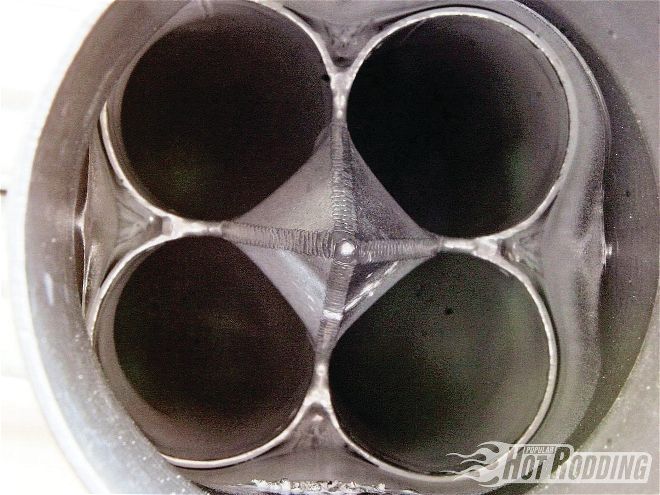

A spike is a common choice to smooth flow as it transitions into the collector from the primary pipes. This version features four flat sides, while some, like those from Cone Engineering, feature concave sides that match the primary tube’s walls.

A spike is a common choice to smooth flow as it transitions into the collector from the primary pipes. This version features four flat sides, while some, like those from Cone Engineering, feature concave sides that match the primary tube’s walls.

To counter that, several different designs have been created that work to more subtly merge the primaries into the collector and manage the pulses. The designs differ from cones to slash-cut pipes, or even multi-stage 4-2-1 collectors, but the goal is the same: control exhaust flow and maintain speed while not negatively affecting the exhaust pressure wave. These higher-end collectors are typically only found on more expensive headers since the labor involved to craft them is much higher. Nevertheless, companies such as Burns Stainless and Cone Engineering have kits that can be added to a header to improve the collector flow. If you want to get even more aggressive, Flowmaster and Stainless Headers have 4-2-1 merge collectors that can work remarkable well for broadening a power curve. Alternatively, many racers have found great success and power rewards simply by adjusting the length of their collectors. This one is definitely a "try it and see" approach best left to racers looking for the last bit of power under the curve.

What Do I Need For My Car?

All that theory is fun to know, allowing you to enter the decision process educated, but we know that most of you will likely stick to what is available off-the-shelf rather than have custom tubes bent. The good news is pretty much all standard combos are covered with a header that will work well on mild to super aggressive street cars. Could you be giving up some slight power under the curve somewhere versus an optimized custom header? Probably. Will you notice? Probably not.

With that in mind, the first consideration you’ll butt up against is physical fitment of the header. There’s more to consider than you probably realize, so Lee Robinson of Hedman Hedders helped us create a very practical list of things you need to know about your project before you even pick up the phone or start looking for headers. Check PopularHotRodding.com for our web-exclusive rundown on all the little stuff you may not have thought about!