It all started with a friendly conversation with Dick Anderson. He had come out to our office for lunch to discuss the details on a few story ideas we had thrown at him. After lunch, we were in the shop chatting about some track testing that was coming up and Dick said he would love to get his car on a chassis dyno. I smiled. He told me he has always run larger headers than the engine builder recommends. The wheels in my head started turning. He explained that he does this to kill a little torque off the corner so the car is a little easier to drive, but it still makes power down the straights. I smelled a great story. He told me it’s something he has always done, but he didn’t know if it actually did what he thinks. I quietly pointed to the dyno sitting on the other side of the shop. Dick looked at me said, “Is that a dyno?” I said yes and asked when he wanted to see if his header choice actually worked. Boom! That’s how these things come together.

In case you aren’t familiar with Dick Anderson (which you have no excuse for), he’s a legend in short track racing in the South. If there’s a big race down here, chances are, Dick has won it. Either as a driver or a car owner, when he shows up at the track, he’s in contention to win.

His newest car is a Dick Anderson Elite Super Late Model chassis with an AR Bodies Mustang Muscle Car body on it. The car is powered by a Ford Racing Performance Parts S374W sealed crate engine and was debuted in the Circle Track booth at the 2012 PRI Show. It has been on track a couple of times since, and has shown a great amount of potential. Since it’s last outing, Dick has changed a few things geometrically with the front suspension, and the car is ready to go back out. (We will be bringing you a few different tests in the next few issues)

Now that you know Dick and his Mustang, let’s get back to the story. We wanted to see if what Dick has been doing for years is actually beneficial -- after all, engine builders recommend header sizes for a reason, right? We made a call to Bill Hufstetler at Schoenfeld headers, and he sent an extra set of headers to test. The headers that Dick has already run on the car are a Tri-Y configuration with stepped primary tubes, measuring 13/4-2 inches. The smaller set of Tri-Y headers measure 15/8-17/8 inches. Along with the headers, Schoenfeld sent us collectors for both size headers and an X-style crossover pipe to complete the test.

The test started like any other chassis dyno session. We rolled the car onto the lift, backed it onto the roller, and strapped it down. Being that we had engine dyno numbers on the engine (541 hp at 7,100 rpm) we were excited to see how efficient (or inefficient) the drivetrain was, and where we could improve. After warming the car up and making three quick runs as a baseline, the Mustang laid down 500 rear wheel horsepower (rwhp). That’s roughly a 7.5-percent loss of power through the drivetrain. (We didn’t believe it at first either, but the math doesn’t lie!)

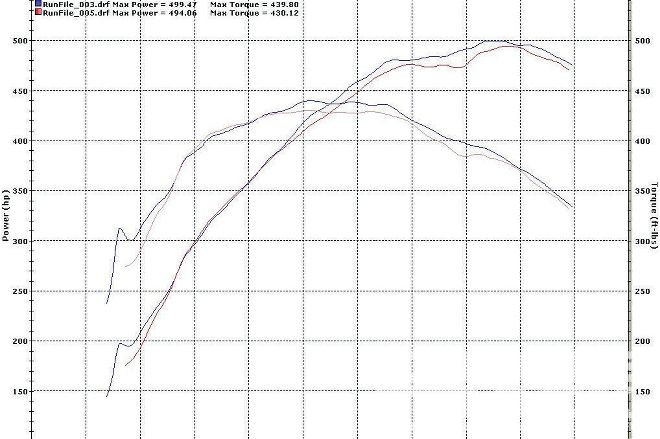

On the larger tube headers, the Tri-Y configuration made more horsepower and more torque than the collector. Through the middle of the curve, horsepower is up as much as 18, and torque is up as much as 13. The difference at the peak was 5 horsepower and 9 lb-ft of torque.

On the larger tube headers, the Tri-Y configuration made more horsepower and more torque than the collector. Through the middle of the curve, horsepower is up as much as 18, and torque is up as much as 13. The difference at the peak was 5 horsepower and 9 lb-ft of torque.

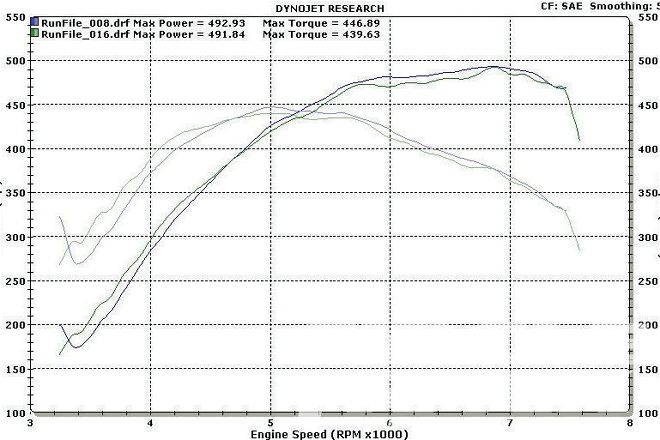

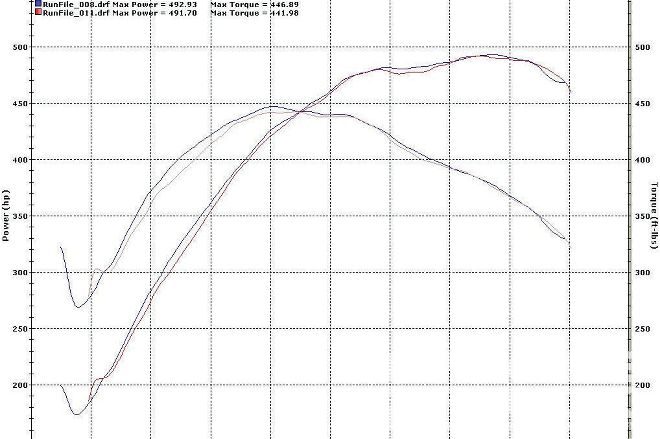

The smaller tube headers test yielded similar results as the larger headers. The Tri-Y headers made 492 rwhp and 446 lb-ft or torque compared to 491 rwhp and 439 lb-ft of torque from the collector headers. Through the middle, the Tri-Ys made as much as 11 more horsepower and 10 more lb-ft or torque.

The smaller tube headers test yielded similar results as the larger headers. The Tri-Y headers made 492 rwhp and 446 lb-ft or torque compared to 491 rwhp and 439 lb-ft of torque from the collector headers. Through the middle, the Tri-Ys made as much as 11 more horsepower and 10 more lb-ft or torque.

Over the next day and a half we test four different header configurations, two mid-pipes, and a couple of different carburetors (check an upcoming issue for the carb test), all in the pursuit of what will work best on track.

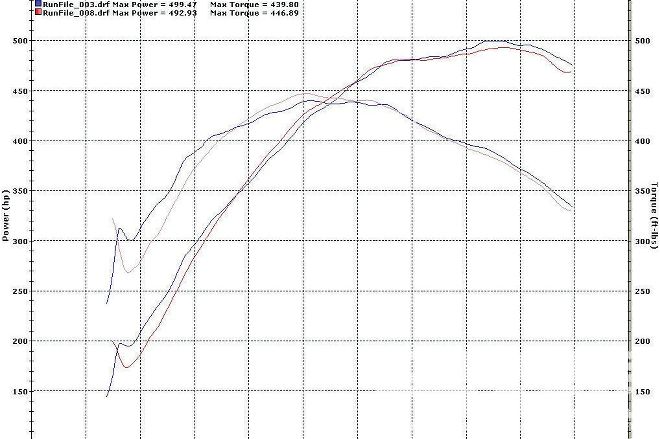

When the Tri-Y headers are put head to head, Dick’s thoughts on the larger tube headers are confirmed. The 13/4- to 2-inch headers made more top-end power and torque, but made a little less between 5,000 and 6,000 rpm. The larger headers made as much as 9 hp more up top, and made 8 lb-ft less at 5,000 rpm.

When the Tri-Y headers are put head to head, Dick’s thoughts on the larger tube headers are confirmed. The 13/4- to 2-inch headers made more top-end power and torque, but made a little less between 5,000 and 6,000 rpm. The larger headers made as much as 9 hp more up top, and made 8 lb-ft less at 5,000 rpm.

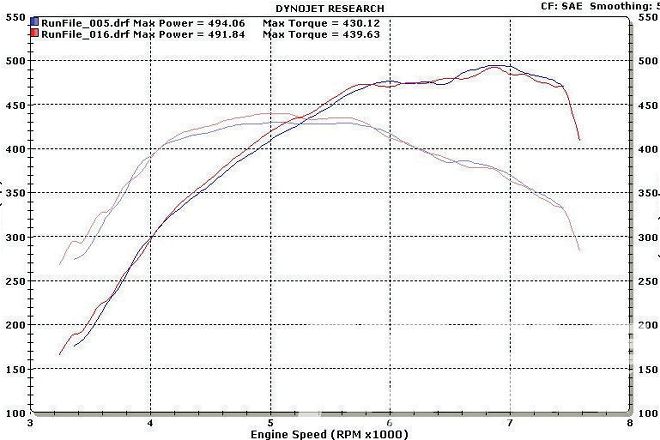

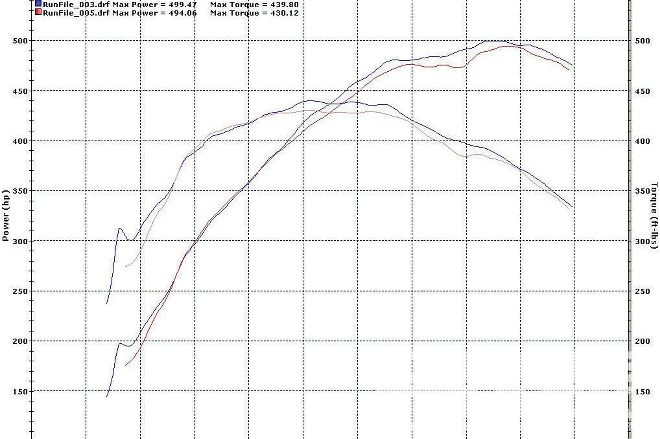

When you put the collector headers against each other you see less of a difference. They might attributable to a change in the weather, as a small storm blew through during this portion of the test. The larger headers made 494 rwhp and 430 lb-ft of torque, while the smaller headers made 491 rwhp and 439 lb-ft of torque. The smaller headers made more horsepower and torque below 5,800 rpm, with as much as a 10hp difference. Both headers were equal until about 6,500, when the larger header pulled ahead, making as much as 8 hp and 7 lb-ft more.

When you put the collector headers against each other you see less of a difference. They might attributable to a change in the weather, as a small storm blew through during this portion of the test. The larger headers made 494 rwhp and 430 lb-ft of torque, while the smaller headers made 491 rwhp and 439 lb-ft of torque. The smaller headers made more horsepower and torque below 5,800 rpm, with as much as a 10hp difference. Both headers were equal until about 6,500, when the larger header pulled ahead, making as much as 8 hp and 7 lb-ft more.

The tests gave us some interesting information. Unfortunately a storm rolled through Tampa halfway during the test and the change in air was visible in the horsepower numbers and the air/fuel numbers. Though we try to keep the environment controlled in our air-conditioned shop, the outside air still have a small effect on the inside air.

The Y-style mid-pipe (blue lines on the graph) made significantly more horsepower and torque in the lower rpm section of the graph. Above 5,500 rpm, the curves are very similar, although the X-style mid-pipe made as much as 5 more horsepower at some sections.

The Y-style mid-pipe (blue lines on the graph) made significantly more horsepower and torque in the lower rpm section of the graph. Above 5,500 rpm, the curves are very similar, although the X-style mid-pipe made as much as 5 more horsepower at some sections.

When the weekend was done everyone was happy. We know exactly where the car is in terms of horsepower and torque, we know we have the right header and exhaust system on the car, and we have a baseline for some carb testing to come. Now it’s time to get on track and win some races!