Last month, we left our brave iron big-block Chevy 454 snortin' to the tune of 589 hp using little more than a tuned-up set of factory iron oval-port heads, 12.5:1 compression, a mild flat-tappet mechanical cam, a single-plane intake, and a 950-cfm E85 carburetor. Until now, this has been a real budget effort; remember, this Chevy 454 motor spins a stock cast crank, stock rods, and a stock oil pan. Of course, all it takes is one bench-racing session to spice things up a bit. That's when Editor Glad declared our Blue Collar Chevy 454 needed a tunnel-ram and nitrous. The call went out across the land until we found a cast-aluminum Weiand tunnel-ram and matched it with a set of Holley carburetors. Holley has promised an E85 carburetor that should hit your favorite speed emporium sometime soon, but once again, we were too far out in front of demand, so we were directed to Patrick James at Pro Systems, who was happy to oblige us with the 950-cfm carburetor we used last month in the single four-barrel attempt, plus two more 750-cfm fuel mixers for our nitrous attempt. While this represents a significant investment, we helped the budget by adding a twin-plate NOS Cheater system using only two solenoids for the whole system. This limits total power to a max of 250 hp, but that was more than we needed. Our goal was to make 800 hp. It seemed simple enough, and we're happy to report that we did achieve our goal. We also learned that this is might be the upper limit for a two-bolt main 454 with a stock cast crank, as it didn't survive the test unscathed. Our Blue Collar Chevy 454 is not dead, but he is certainly going to have to go on injured reserve for the near future. But look for Blue Collar to return, maybe with some better parts.

The Tunnel Ram

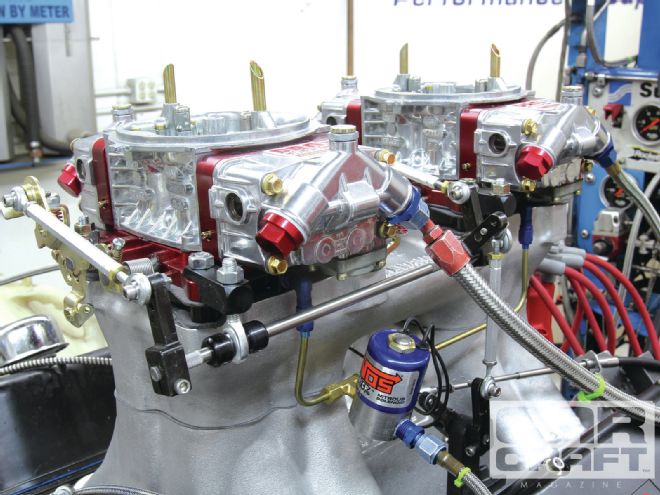

Rat motors just look nasty with a tunnel ram sitting up top. The already massive engine bulks up, and those two big carbs make it all come together. But we're not in this just for the fashion show. It takes some serious horsepower to make those twin carbs become meaningful. Because a sheetmetal tunnel ram intake was just plain out of the question and perhaps more than a little misplaced on iron oval-port heads, we looked into affordable castings. Weiand had just what we were looking for-an oval-port tunnel ram for just a smidge over $350-and with a call to Summit, we were in business. Pro Systems was already on board with the E85 carburetors, offering a pair of 750 fuel mixers fully tuned for that ethanol-based fuel. This is the point at which the budget took a significant hit, as this pair was every bit of $1,390. If you like the idea but just can't swing that much coin for a pair of carbs, there are several companies, including Pro Systems, that can convert your existing carbs or sell you the pieces to do it yourself. The conversion is relatively easy, especially if the carburetor has replaceable air bleeds. With the carbs in hand, we next decided on the basic, twin-plate Cheater nitrous system. We went this route rather than going with a dedicated fogger system mainly to keep the cost down. The 2x4 NOS Cheater system was only $600 (minus the bottle). It was at this point that we realized we would also need a 2x4 sideways linkage kit (thanks, Holley) and a fuel-line kit to connect all four inlets together. After much searching, we decided to let a pro build a fuel-line kit for us. We called Derek Stankowich at DMP Fasteners in Chatsworth, California, who built a fuel-line kit using stainless-steel lines and Earl's fittings that we supplied. The system ties both carburetors into a common inlet, which makes connecting it to a fuel-pressure regulator very easy. With the tunnel-ram system assembled and ready to go, we were one step shy of dyno-ready.

During our planning session, we realized that while we were running the engine on E85, the factory NOS nitrous tuning charts are based on using gasoline. Rather than getting bogged down with finding or creating an E85 tuning chart, we decided to go the safe route and use race gas for our 200hp nitrous adventure. While safe, this demanded building a separate fuel-delivery system for the nitrous. We assembled a somewhat clumsy-looking system from parts we had on hand, including a monster Holley electric fuel pump, -8 Earl's lines and fittings, a return-style regulator, and a Zex nitrous fuel-pressure test kit.

Because the pump was oversized for the task, we had to bypass a large volume of fuel to the tank to set the fuel pressure using a -8 fuel line. The best method is to set nitrous fuel pressure while flowing fuel through the same-size jet as the one used in the fuel side of the system. The Zex tool places a pressure gauge in a T fitting but was designed for a single jet. Since our system used two 0.065-inch-diameter jets, we needed to compensate for the second jet. We employed a little high school math by increasing the area of the single jet to equal the area of two smaller jets. Flow is related to a combination of pressure and area. With pressure constant, we calculated the area of a single 0.065 jet (0.003318 square inches), then doubled it because we have two jets in the system, for a total flow area of 0.006636 square inches. We then determined that a 0.092-inch diameter is very close, at 0.006647 square inches. Our closest drill diameter (332 inch) was 0.09375 inch, so we drilled a spare jet to that diameter and set the dynamic fuel pressure at 6 psi. Now we were ready for the dyno. Later, we discovered our fuel pump was very sensitive to battery voltage and that our fuel pressure may have changed during dyno testing.

There's something special about a tunnel-ram. Push a little magic gas in the mix, and all kinds of fun things happen to horsepower.

There's something special about a tunnel-ram. Push a little magic gas in the mix, and all kinds of fun things happen to horsepower.

Dyno Day

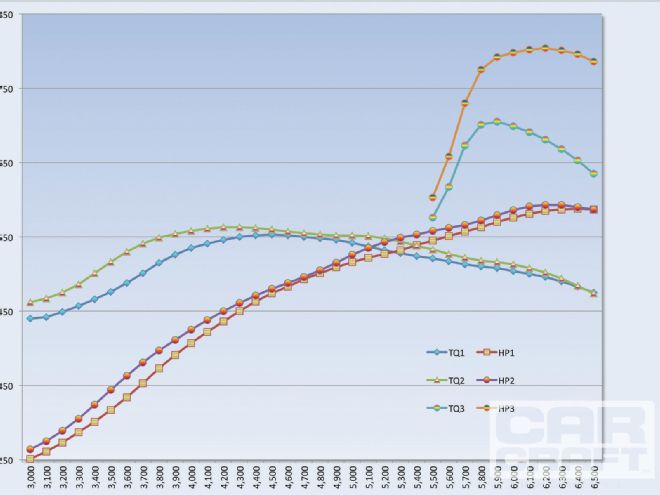

We re-baselined our 454 to come up with the initial numbers in the Power Numbers chart. The Rat did not quite achieve the same power numbers until we added a Wilson 1-inch-tapered pacer under the carburetor. We did not spend much time with this package, as we wanted to get right to the tunnel-ram. It would have been nice to put a nitrous plate under the single four-barrel package, but time constraints stood in the way. We bolted on the tunnel-ram, using a new Fel-Pro intake gasket, and soon we were making noise. As you can see from the graph, the tunnel-ram was worth a significant bump in torque, with as much as a 20-lb-ft improvement below 4,400 rpm, due to the 2x4 manifold's longer intake runners. With that pleasant benefit in our pocket, we switched on the nitrous fuel pump, opened the nitrous bottle, and were poised to squeeze the button and bask in the glory of a quick 800hp hero pull.

We again used Rockett’s race E85 fuel for the more consistent ethanol percentage and for its stronger 112-octane level. We also used Rocket 114-octane race gasoline for the nitrous fuel, although we probably could have used the 111-octane race gas instead.

We again used Rockett’s race E85 fuel for the more consistent ethanol percentage and for its stronger 112-octane level. We also used Rocket 114-octane race gasoline for the nitrous fuel, although we probably could have used the 111-octane race gas instead.

That's not what happened.

Instead of a nice, fat boost in power, we gained barely 120 hp, and our wideband air-fuel (A/F) ratio meter reported the engine was dead-rich, with an A/F of 9:1 and the ignition timing retarded 10 degrees back to 26 degrees total. After working through multiple testing sessions that involved squeezing our dyno Rat several more times, we finally arrived at a tune where the engine achieved our 804hp number. NOS' recommendation for all Cheater nitrous plate jetting is to match the fuel-jet size with the nitrous jet using 6-psi fuel pressure and a bottle pressure of 950-1,000 psi. In order to make maximum power with a safe A/F of 12.5:1, we had to substantially reduce the size of the fuel jet. In our testing, we started with both nitrous and fuel jets at 65. We gradually reduced the fuel-jet size, but we did not adjust the fuel pressure nor record that pressure at the time. Later, we duplicated our test and measured 7.0 psi, which is 1.5-2 psi higher than the NOS recommendation. After several tuning runs, we finally arrived at the combination of a 65 nitrous jet with a 40 fuel jet and the timing retarded 8 degrees to 28 degrees total. The Autolite race plugs all looked very good, and there was no evidence of any detonation. We were also using Rockett 110-octane race gasoline on the fuel-enrichment side to be doubly safe, and bottle pressure remained within spec at 950 psi.

While this looks cluttered, it worked great. This is our Rube Goldberg fuel-delivery system created out of parts we had in the shop the night before we did the dyno testing. The big Holley pump produces a lot of volume, which required us to build returns back to the fuel jug from both the pump and the pressure regulator.

While this looks cluttered, it worked great. This is our Rube Goldberg fuel-delivery system created out of parts we had in the shop the night before we did the dyno testing. The big Holley pump produces a lot of volume, which required us to build returns back to the fuel jug from both the pump and the pressure regulator.

We wanted to do some additional tuning runs by substituting E85 as the fuel enrichment for the nitrous, but that was when the Rat decided to lay down, killing the No. 2 main bearing. This likely happened because of the 800 hp, but not specifically because of nitrous. We spoke with a couple of Holley engineers, and they told us they intentionally set the budget Cheater kits on the rich side out of concern that some enthusiasts using the kit may likely have less than 5 psi of fuel pressure. Low-dynamic fuel pressure (with the nitrous engaged) requires a larger jet to supply a safe volume of fuel. We had exactly the opposite situation with an excess of fuel pressure. Our higher fuel pressure and rich A/F ratio built into the system would account for the major difference in the jet size our combination demanded to make the power. The bottom line here is that if you are going to add 200 hp worth of nitrous with an NOS Cheater system, you must accurately set the dynamic fuel pressure at 6 psi, and then evaluate the combination based on your engine's particular requirements and perhaps reduce either the fuel pressure or fuel-jet sizes to create a proper tune.

The main point is that we did make 804 hp from a relatively simple 454 with iron oval-port heads and E85. We have almost as much invested in the induction system as we do in the entire engine, but consider that we have barely $6,000 total invested in this engine. True, we knocked out a main bearing, so it could be that 750 hp would be a safe peak power number that you could run on a regular basis. If we bolted this beast into our Orange Peel '66 Chevelle mule, it's safe to predict that it could push the big orange beast well into the low 10s. Yahoo!

Holley doesn’t make a dual-carb feed line for a tunnel-ram, so Derek Stankowich, owner of DMP Fasteners, offered to build a dedicated stainless-steel fuel-line kit for our eight-barrel tunnel-ram. He used Earl’s fittings that we supplied to create a system that connects to one overall fuel line, making the fuel-feed connection really simple.

Holley doesn’t make a dual-carb feed line for a tunnel-ram, so Derek Stankowich, owner of DMP Fasteners, offered to build a dedicated stainless-steel fuel-line kit for our eight-barrel tunnel-ram. He used Earl’s fittings that we supplied to create a system that connects to one overall fuel line, making the fuel-feed connection really simple.

We used a ZEX tool to set the pressure while flowing fuel through a 0.092-diameter jet that equals the two jets used in the twin plates. We set the fuel pressure at 6 psi, reducing it from the 6.4 psi shown here.

We used a ZEX tool to set the pressure while flowing fuel through a 0.092-diameter jet that equals the two jets used in the twin plates. We set the fuel pressure at 6 psi, reducing it from the 6.4 psi shown here.

Cam Specs Cam : SX290S Adv. Duration Duration at 0.050 Lift in Inches (Net Lift Minus Lash) Lobe-Separation Angle Intake 290 252 0.598 (0.582) 110 Exhaust 298 260 0.598 (0.582)

Power Numbers

Test 1 was a re-baseline of the Feb. '13 test, with a single four-barrel and a Wilson 1-inch tall tapered spacer.

Test 2 is the same as the first run but with the Weiand tunnel-ram and two 750-cfm Pro Systems carburetors.

Test 3 is with the addition of the 200hp nitrous shot.

Test 1 Test 2 Test 3 RPM TQ1 HP1 TQ2 HP2 TQ3 HP3 3,100 442 261 467 275 --- --- 3,300 457 287 486 305 --- --- 3,500 476 317 516 344 --- --- 3,700 501 353 541 381 --- --- 3,900 526 391 554 411 --- --- 4,100 541 422 561 438 --- --- 4,300 550 450 563 461 --- --- 4,500 553 474 560 480 --- --- 4,700 550 493 555 496 --- --- 4,900 546 509 552 515 --- --- 5,100 537 522 551 535 --- --- 5,300 528 532 544 549 --- --- 5,500 521 545 533 558 576 603 5,700 513 557 522 566 673 730 5,900 508 570 516 579 705 792 6,100 500 581 508 591 691 802 6,300 490 587 494 593 668 801 6,500 475 587 475 587 635 786 Peak 553 588 563 593 705 804 Average 511.5 464.0 527.5 476.8 --- ---

Parts List Description PN Source Price Manley Rat intake valve 11800-8 Summit Racing $189.95 Manley Rat exhaust valve 11881-8 Summit Racing 119.95 Summit Stage 4 intake 226052 Summit Racing 199.95 NOS dual Cheater kit 02010-NBNOS Summit Racing 605.95 Weiand 2x4 linkage kit 4022 Summit Racing 139.95 Weiand tunnel-ram 1981 Summit Racing 355.95 Pro Systems 750 E85 carb Call Pro Systems 692.00 ea. Pro Systems 950 E85 carb Call Pro Systems 720.00 Custom stainless fuel lines Custom DMP Call (440.00 est.) Wilson 1-inch spacer 004110 Summit Racing 127.95 Comp XS 290 solid cam 11-679-5 Summit Racing 191.69 Comp spring spacers 4779-8 Summit Racing 24.95 Comp 1.7:1 rocker arms 1820-16 Summit Racing 399.95 Comp intake pushrod 7743-1 (x 8) Summit Racing 79.60 Comp exhaust pushrod 7756-1 (x 8) Summit Racing 87.60 Comp oil, 10w30 1594 Summit Racing 39.75 Autolite race plugs AR-3910X Carshopinc.com 6.95 (8) Fel-Pro head gasket 1037 Summit Racing 46.95 Fel-Pro intake gasket 1281-3 Summit Racing 21.95 MSD Pro Billet 8361 Summit Racing 212.95 MSD plug wire 35379 Summit Racing 85.95 ARP head-bolt set 135-3601 Summit Racing 77.15