It's easy to get carried away with horsepower plans. The "more is better” approach to horsepower and torque is as hard to ignore as the promise of stylish new shoes to a Hollywood starlet. But we're reading Lindsay Lohan's new book 10 Steps to Avoiding Temptation and practicing on our Blue Collar 454. So far, we've refrained from throwing expensive alloy heads and other big-ticket items at our cast-iron creation, but the lure is incredibly tempting—how does Lindsay do it? Back in the Oct. '12 issue, John McGann stuffed a budget set of Sealed Power 12.5:1 compression pistons in the iron Rat that, along with a simple Comp mechanical flat-tappet camshaft and the Blue Collar 454 (close friends call him BC), stumped out a reasonable 550 hp on E85. The more we looked at those numbers, the more the devil angel said we could do better. We yanked the heads and took them to Jim Grubbs Motorsports for a personal massage session, along with a bigger E85 carburetor, and uncovered a large pile of torque and nearly 40 more horsepower. We're not near done yet, although the jungle drums speak of a tunnel-ram and nitrous that we can neither confirm nor deny. In the entertainment business, that's called a hook, and we not-so-subtly planted it. Stay tuned, as we have major plans for BC—assuming we fall off the Lohan wagon.

Cylinder Head Testing

For mild street and budget bracket big block Chevy 454, the factory iron 049 heads are outstanding; if they were cast in aluminum, they would be ideal. After BC did so well with bigger valves, we thought more attention to the valve job might add a little power. We took the heads to Jim Grubbs Motorsports (JGM) and established a flow-bench baseline. Big block Chevy 454 heads feature what are referred to as good and bad intake ports. The good intake ports direct the inlet charge toward the center of the cylinder, while the other four unfortunately point into the cylinder wall. This directly affects airflow. We included all our modification efforts on all ports, but we did all of our testing on the same good port on the flow bench.

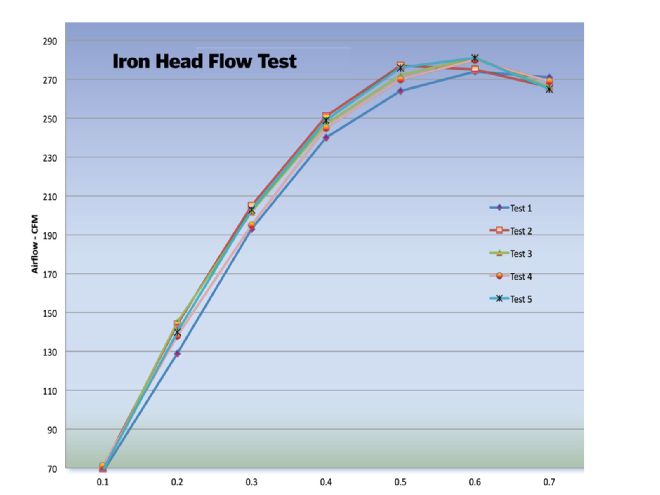

The late John Lingenfelter once told me that as little as a 1-degree change in valve angle will affect airflow. While we'd love to do the definitive test on valve and seat angles, the electrical load for all that flow-bench testing would probably cause a three-state brownout, so we settled instead for a test of varying back-cut angles. A back cut is a shallow angle cut on the inboard or back side of the standard 45-degree valve-seat angle. Over the years, we've relied on the standard 30-degree back cut, but this time we augmented our testing with 28-, 32-, and 35-degree angles. As our results reveal, these angles redistributed the flow gains but didn't improve upon the classic 30-degree effort. Note that the 30-degree cut helps the flow at valve lifts below 0.600 inch, while above this lift, flow measurably decreases. Since our Blue Collar 454 Comp Cams flat-tappet XS290S camshaft achieves a net lift of only 0.582 inch, we planned to emphasize flow improvements in the valve-lift range between 0.200 and 0.500 inch. We also added a set of Manley Racemaster stainless valves from Summit Racing to which we also added 30-degree back cuts. This was mainly to take advantage of the smaller, 11⁄32-inch stem diameter to shave some valvetrain weight. These valves are not too expensive, but you could opt for 3⁄8-inch stem Street Flo valves that are even more affordable. The flow numbers in the accompanying chart are intake cfm using JGM's SuperFlow 600 flow bench at a 28-inch test depression using a 4.310-inch bore adapter. The numbers in parenthesis are the improvements against the test 1 baseline.

It's important to point out why we chose to emphasize the mid-lift flow improvements. We can start with the fact that the valve will be at the mid-lift position twice in its lift curve as opposed to only once for peak valve lift. But equally as important is that when the intake valve is on the closing side of the induction cycle, the piston is rising and pressure is increasing in the cylinder. A valve job with strong flow velocity (higher cfm flow equates to greater velocity) at lower lift will be able to overcome the pressure in the cylinder and do a better job of filling the cylinder, which will improve power across the engine's entire powerband, but especially at lower engine speeds, where the longer-duration cam is a detriment to torque. In our experience, higher peak valve-lift flow numbers generally only improve peak horsepower but not the overall curve. A head with a stronger average flow curve will tend to make more power across the entire rpm band. This is exactly what we saw with the modifications to the stock Rat head.

A simple intake-valve tweak, a new intake, and a Pro Systems E85 carburetor produced a very rewarding 589 hp and 550 lb-ft of torque. Even better, we vastly improved the torque right where the torque converter would flash. ➔Is that a Weiand tunnel ram on the bench with a pair of Pro Systems E85 carbs? Hmm…

A simple intake-valve tweak, a new intake, and a Pro Systems E85 carburetor produced a very rewarding 589 hp and 550 lb-ft of torque. Even better, we vastly improved the torque right where the torque converter would flash. ➔Is that a Weiand tunnel ram on the bench with a pair of Pro Systems E85 carbs? Hmm…

The graph reveals that the 30-degree back cut (test 2) offers the best flow curve under 0.500-inch valve lift. Changes that improve the mid-lift flow numbers often result in excellent torque gains.

The graph reveals that the 30-degree back cut (test 2) offers the best flow curve under 0.500-inch valve lift. Changes that improve the mid-lift flow numbers often result in excellent torque gains.

Cam Specs

Comp Cams SX290S Advertised Duration Duration at 0.050 Lift in inches (net lift minus lash) Lobe Separation Angle Intake 290 252 0.598 (0.582) 110 Exhaust 298 260 0.598 (0.582) ---Intake Flow

Valve Lift Test 1 Test 2 Test 3 Test 4 Test 5 0.100 68 70 (+2) 69 (+1) 71 (+3) 69 (+1) 0.200 129 144 (+15) 145 (+16) 138 (+9) 140 (+11) 0.300 193 205 (+12) 202 (+9) 195 (+2) 203 (+10) 0.400 240 251 (+11) 247 (+7) 245 (+5) 249 (+9) 0.500 264 277 (+13) 272 (+8) 270 (+6) 276 (+12) 0.600 274 275 (+1) 281 (+7) 280 (+6) 281 (+7) 0.700 271 266 (-5) 266 (-5) 269 (-2) 265 (-6) Avg. 205.6 212.5 211.7 209.9 211.8Flow Test Results

Test 1: Stock 049 iron heads with 2.18-inch intake—on "good” port

Test 2: Mild pocket blend, new Manley valves, five-angle valve job, 30-degree back cut

Test 3: Same as above with 32-degree back cut

Test 4: Same as test 2 with 35-degree back cut

Test 5: Same as test 2 with 28-degree back cut

We used the same Comp springs but changed to Comp’s Ultra Tech rockers with the stock 1.7:1 ratio. We set the lash at 0.016 inch for both the intake and exhaust.

We used the same Comp springs but changed to Comp’s Ultra Tech rockers with the stock 1.7:1 ratio. We set the lash at 0.016 inch for both the intake and exhaust.

Power Testing

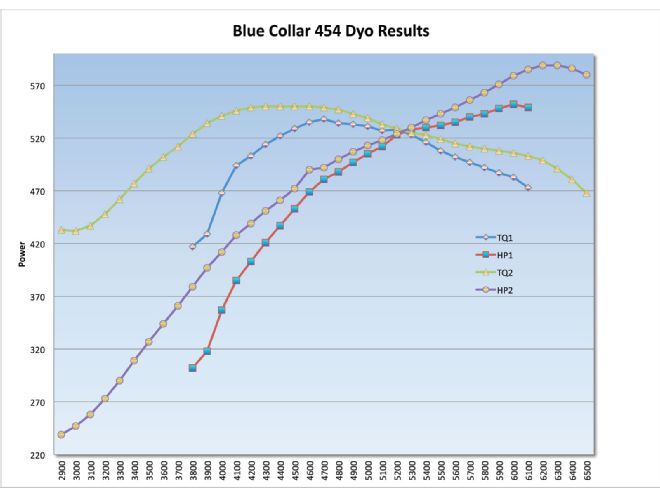

Dyno testing is a lot like bracket night. You only have one shot to get it right. With the previous dyno test performed with JMS as our baseline, the pressure was on to see if all our head work would pay off. Yes, we used a different intake manifold—the Summit single plane—and a larger 950-cfm Pro Systems Holley E85 carburetor (the previous carb was a 750 cfm from Quick Fuel), so this isn't a true evaluation of the head work alone. Despite the differences, we forged ahead. We didn't need to tune the Pro Systems carburetor at all, and after a quick timing session, we learned that 37 degrees was what the Rat liked best. This resulted in a peak horsepower gain of nearly 40 hp. Torque also improved at the peak by 12 lb-ft—from 538 to 550 lb-ft. But the real story is the torque gains down low. Looking at the power numbers, our larger carburetor might have helped with a better fuel curve at the lower speeds and certainly our improved flow numbers helped, but we gained more than 100 lb-ft at 3,900 and 52 lb-ft at 4,100 rpm! This is all fantastic news and reveals what can be done with only simple head work, a good carburetor, and good tuning.

We used a different carburetor for this series of tests, adding a Pro Systems 950-cfm, 4150-style carburetor. We literally set the idle mixture and speed and never touched it again. The jetting and fuel curve were nearly spot on.

We used a different carburetor for this series of tests, adding a Pro Systems 950-cfm, 4150-style carburetor. We literally set the idle mixture and speed and never touched it again. The jetting and fuel curve were nearly spot on.

Of course, there's always more to be done. The iron-head flow numbers indicate that more valve lift would be helpful. Using what we learned on the flow bench, with a 0.700 inch lift (or more) mechanical roller cam, we'd change the back cut on the valve from the 30-degree to the 28-degree angle in search of a more stable flow curve through the higher valve-lift portion of the curve. We probably wouldn't change the duration, so with an Extreme Energy mechanical roller, we could expect to push the lift up to 0.660 on both the intake and exhaust. This change would also demand better valvesprings and roller lifters, which will add roughly $600 to the cost of the engine, but this might be worth another 20 hp and push BC up into the 600hp area. But let's not skip over the fact that we simulated this Rat using Quarter, Pro in a 3,500-pound Chevelle with 3.55 gears and a 3,000-rpm-stall speed converter, and the simulation reported 11-teens at 121 mph. Not bad for an iron-head big-block that looks like a 396. Blue collar, indeed!

Test Day

Test 1 is the Blue Collar 454 as reported in the Oct. '12 issue using a swap-meet Dominator intake and an adapter for the Quick Fuel E85 750-cfm, 4150-style carburetor.

With our 12.5:1 compression, we decided early that E85 is a far more efficient fuel to use than dedicated race gas. But we also wanted to try some of Rockett’s new race E85 fuel, and with this convenient 55-gallon drum, the decision was made easy. Rockett’s race E85 has an even higher octane rating of 112 versus typical pump fuel of around 105. Plus, the motor-octane rating is significantly higher.

With our 12.5:1 compression, we decided early that E85 is a far more efficient fuel to use than dedicated race gas. But we also wanted to try some of Rockett’s new race E85 fuel, and with this convenient 55-gallon drum, the decision was made easy. Rockett’s race E85 has an even higher octane rating of 112 versus typical pump fuel of around 105. Plus, the motor-octane rating is significantly higher.

Test 2 used the modified iron oval-port heads, new Manley valves and JGM valve job, a Summit single-plane intake, and the Pro Systems E85 950-cfm 4150 carburetor. All tests were run on Rockett Brand E85 fuel.

Power Numbers

RPM TQ1 HP1 TQ2 HP2 TQ gain 3,100 --- --- 437 258 --- 3,300 --- --- 462 290 --- 3,500 --- --- 491 327 --- 3,700 375 264 512 361 +137 3,900 429 318 534 397 +105 4,100 494 385 546 428 +52 4,300 514 421 550 451 +36 4,500 529 453 550 472 +21 4,700 538 481 549 492 +9 4,900 533 497 543 507 +10 5,100 527 512 533 518 +6 5,300 523 528 525 530 +2 5,500 508 532 519 543 +11 5,700 497 540 512 556 +16 5,900 487 548 508 571 +21 6,100 473 550 503 585 +30 6,300 --- --- 491 589 --- 6,500 --- --- 468 580 --- Peak 538 552 550 589 ---

Parts List

Description PN Source Price Manley Racemaster Rat intake valve 11872-8 Summit Racing 119.95 Manley Racemaster Rat exhaust valve 11881-8 Summit Racing 119.95 Summit Stage 4 intake manifold 226052 Summit Racing 199.95 Pro Systems 950 E85 carb N/A Pro Systems 790.00 (check) Comp XS 290 solid cam 11-679-5 Summit Racing 191.69 Comp spring spacers 4779-8 Summit Racing 24.95 Comp 1.7:1 rocker arms 1021-16 Summit Racing 314.95 Autolite race plugs AR-25 Summit Racing 5.95 (x8) Fel-Pro head gasket 1037 Summit Racing 46.95 Fel-Pro intake gasket 1281-3 Summit Racing 21.95 MSD Pro Billet 8361 Summit Racing 212.95 MSD plug wire 35379 Summit Racing 85.95 Comp oil, 10w-30 1594 Summit Racing 39.75 ARP headbolt set 135-3601 Summit Racing 77.15 Machine Work New guides N/A JGM 188.00 Competition valve job/clean/surface N/A JGM 324.00 All our dyno tests were performed using a pair of 21⁄8- to 23⁄8-inch stepped headers with no mufflers on Westech’s engine dyno. End

All our dyno tests were performed using a pair of 21⁄8- to 23⁄8-inch stepped headers with no mufflers on Westech’s engine dyno. End