The Plan

Last time we had Project 505 on the dyno was the June 2010 issue of Mopar Muscle when we modified our Indy EZ heads for Jesel rocker arms. During that round of dyno testing we saw a peak of 805 horsepower, but we also encountered some valvetrain oiling issues. For this round of testing we set out to solve the oiling issue as well as try a new cam profile and different rocker arms. This time, we're running the Max-Wedge Super Victor intake with a BLP-modified Dominator carburetor. Finally, one thing that we have wanted to try for a long time is a dry-sump oiling setup. We couldn't find much in the way of store bought parts, so we got busy and fabricated a low-buck way to turn Project 505 into a dry-sump lubed engine.

<STRONG>1</STRONG> The Mopar Performance P4876337 intake manifold surprised us by squeaking out a little more power than the Super Victor intake. We left the valley cover in place when running this intake, which gave us an odd looking double valley plate arrangement.

<STRONG>1</STRONG> The Mopar Performance P4876337 intake manifold surprised us by squeaking out a little more power than the Super Victor intake. We left the valley cover in place when running this intake, which gave us an odd looking double valley plate arrangement.

The Short-Block

Project 505 is based on a stock 440 block with a 4.250-inch stroke crankshaft from 440Source, a set of 6.800-inch long rods from SCAT, and forged pistons from Diamond Racing. The pistons have small 5cc domes that yield a compression ratio of 13.5:1 when combined with the 75cc chambers in the Indy EZ heads.

This engine has seen a lot of testing duty over the last couple of years so it is equipped with dyno friendly parts such as a Jesel beltdrive (for ease of cam timing), an electric water pump, 2-inch dyno headers, and a belt-driven distributor. We left all of these support pieces in place for this round of dyno testing but we did install cylinder head studs rather than re-use our existing head bolts. ARP makes several very high-quality cylinder head stud kits for the big-block Mopar engine so we gave them a call for one of their Indy kits. The Indy cylinder heads require a special kit because two studs on each bank need to be slightly longer than the other studs. For the exhaust side, we purchased some special head studs from ARP that were just 2.725 inches long. We needed the special studs to gain clearance for the header flanges because the exhaust ports on the EZ head are in a fairly low position. You would not need these shorter studs with raised exhaust ports.

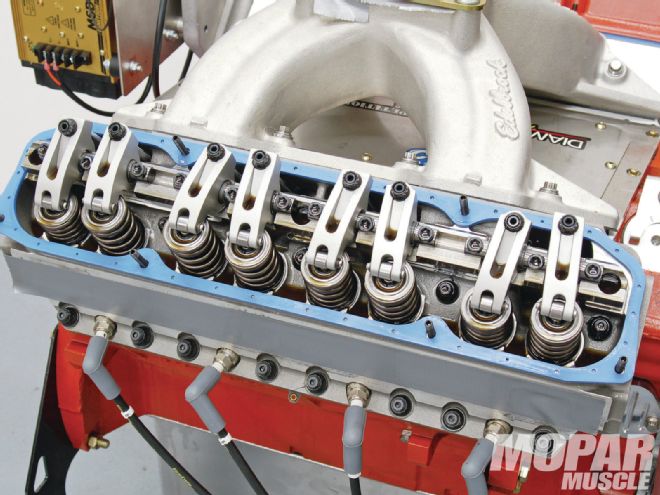

<STRONG>2</STRONG> Increasing the intake rocker arm ratio from 1.70 to 1.85 added 10 horsepower by itself. The Jesel paired rocker arm system is very stable and provides excellent valvetrain geometry at high valve lifts. Our thick-wall pushrods from Smith Bros had an overall length of 9.625 inches. Both ends are drilled so oil can be fed directly to the rocker arms.

<STRONG>2</STRONG> Increasing the intake rocker arm ratio from 1.70 to 1.85 added 10 horsepower by itself. The Jesel paired rocker arm system is very stable and provides excellent valvetrain geometry at high valve lifts. Our thick-wall pushrods from Smith Bros had an overall length of 9.625 inches. Both ends are drilled so oil can be fed directly to the rocker arms.

Camshaft and Valvetrain

The Chrysler big-block motor was originally produced with 1.50 ratio rocker arms, but engine builders have long been running higher-ratio rocker arms in an effort to make additional power. Following that trend, we converted these EZ heads over to 1.70 ratio Jesel rocker arms last year when we installed a roller cam.

One of the many advantages of the Jesel rocker arm system is that they have a complete selection of rocker arm ratios, ranging from 1.55 to 1.85. For this round of testing we consulted with Mike Jones at Jones Cam Designs and decided to go with a ratio of 1.85 on the intakes and 1.70 on the exhaust. Mike's advice on the subject is that higher ratio rocker arms can provide the valve motion that the engine needs without compromising the base circle on the camshaft.

<STRONG>3</STRONG> Since many Mopar cams are designed to work with only 1.50 ratio rocker arms, we worked with Mike Jones at Jones Cam Designs to pick a set of solid-roller camshaft lobes that would work best with our high ratio rocker arms. The camshaft that Mike designed for us was part number R80393-82401. This cam has a fairly mild lobe shape with only .393-inch lobe lift, and a duration of 266 degrees at .050. When combined with the 1.85 rocker arm ratio, this cam profile gave us .707 net-inch lift on the intake side. The exhaust lobes have 272 degrees of duration at .050-inch and lobe lift of .401-inch for a net valve lift of .661 inch.

<STRONG>3</STRONG> Since many Mopar cams are designed to work with only 1.50 ratio rocker arms, we worked with Mike Jones at Jones Cam Designs to pick a set of solid-roller camshaft lobes that would work best with our high ratio rocker arms. The camshaft that Mike designed for us was part number R80393-82401. This cam has a fairly mild lobe shape with only .393-inch lobe lift, and a duration of 266 degrees at .050. When combined with the 1.85 rocker arm ratio, this cam profile gave us .707 net-inch lift on the intake side. The exhaust lobes have 272 degrees of duration at .050-inch and lobe lift of .401-inch for a net valve lift of .661 inch.

The camshaft that Mike designed for us was part number R80393-82401. This cam has a fairly mild lobe shape with only .393-inch lobe lift and duration of 266 degrees at .050-inch lift. When combined with the 1.85 rocker arm ratio, this cam profile gave us .707 net-inch lift on the intake side. The exhaust lobes have 272 degrees of duration at .050-inch and lobe lift of .401-inch for a net valve lift of .661 inch.

We matched the camshaft with a set of 26097-16 valvesprings from Comp Cams as well as a set of their tool-steel valvespring retainers. These springs are made from an enhanced processed material, and are only 1.539-inches in diameter, which leaves plenty of room around the rocker arms. We set the springs up with 220 pounds of pressure on the seat and 560 pounds over the nose.

Our last trip to the dyno was cut short when we scorched some pushrod ends due to a lack of lubrication. We had been using spray bars in the valve covers to provide lubrication to the Jesel rocker arms, but that setup didn't work correctly and several pushrods were ruined. An excellent solution to this problem is to use pushrod oiling, but in order to do that you need roller lifters that provide oil to the pushrods. There are roller lifters available for big-block Mopar engines which are capable of pushrod oiling, but as we found out, several of the lifters on the market do not work in an unbushed production block. The lifter bores in a big-block Mopar intersect the main oil galley, so each lifter bore is exposed to full oil pressure and volume. Because of that, roller lifters for a big-block have to be designed correctly, or else too much oil will flow through the lifters. After a little research, we discovered that the guys at Indio Motor and Machine (IMM) had a new roller lifter, which is capable of pushrod oiling in an unbushed block. These lifters also have an internal oil passage that provides high pressure oil to the roller's wheel, and they are available with a .180-inch offset pushrod cup if one needs that feature.

<STRONG>4</STRONG> The valvesprings from Comp Cams were installed at a height of 1.950-inches. We also used lightweight tool-steel retainers from Comp, as well as a set of their 10-degree locks.

<STRONG>4</STRONG> The valvesprings from Comp Cams were installed at a height of 1.950-inches. We also used lightweight tool-steel retainers from Comp, as well as a set of their 10-degree locks.

To go along with the new lifters, we needed a new set of pushrods with oiling holes. A quick call to Smith Bros netted us a set of .120-inch thick-wall pushrods that have a 3/8-inch outer diameter, and are 9.625 inches long. The IMM lifters require a 5/32-inch radius ball-end, while our Jesel rocker arms require a 9/64-inch radius cup-end.

Intake and Heads

Edelbrock recently introduced two Super Victor intakes for the RB motor, part number 2891 for standard port heads, and part number 2893 for the larger Max Wedge sized ports. For this motor we needed the version with the larger runners since our Indy EZ heads have Max Wedge ports. The Super Victor intake is designed for the larger 4500 flange carburetors, which was perfect for us since we prefer to use our Holley UltraHP Dominator when testing Max Wedge heads. We installed the intake manifold right out of the box without performing any cleanup grinding or port matching. No doubt a little bit of port matching and plenum work on this intake would pick up some power, so that is an area for future attention.

<STRONG>5</STRONG> New solid roller lifters from IMM are capable of pushrod oiling in a stock block. These lifters feed high-pressure oil to the roller wheel, and they have an available offset cup that moves the intake pushrod for more clearance.

<STRONG>5</STRONG> New solid roller lifters from IMM are capable of pushrod oiling in a stock block. These lifters feed high-pressure oil to the roller wheel, and they have an available offset cup that moves the intake pushrod for more clearance.

Before this round of testing, we sent the cylinder heads back east to our buddy Dwayne Porter at Porter Racing Heads in South Burlington, Vermont. Dwayne gave our EZ's a quick tune-up and a flow check on his bench. The heads checked out fairly well on his bench where they measured 362 cfm of flow on the intakes at .700-inch lift. The exhaust flow on these EZ heads is held back a bit by the stock port location, so it only runs about 66-percent of the intake flow. Even given the less than optimal exhaust flow, the EZ heads are no slouch in the power department when matched with the correct camshaft design.

Carburetor

Our Holley Ultra HP Dominator has performed great for us since we first got it, but when we came across the fully tunable metering blocks that BLP is making for the Dominator we decided to give them a try. These 5120 series metering blocks have jets in each of the fuel circuits so the engine builder can quickly make adjustments to the fuel curve. In addition to the jets in the fuel circuits, the BLP metering blocks have been redesigned so that the idle circuit is divorced from the main circuit. The separation of the idle circuit from the main circuit provides the main circuit with additional fuel flow capacity for large engines that make a lot of power. While we didn't necessarily need the extra fuel flow for this engine, we wanted to get a baseline established with these new BLP metering blocks for future projects down the road.

<STRONG>6</STRONG> We used the Edelbrock intake with the Max Wedge ports because our Indy EZ heads had been ported to the larger runner size. Our Indy EZ heads have seen quite a few dyno tests over the years and they produce a consistent 100 horsepower improvement over the various standard port heads that we've run on this short-block. Since this intake also uses a 4500 carburetor flange, we used Holley's Ultra HP 1050 Dominator

<STRONG>6</STRONG> We used the Edelbrock intake with the Max Wedge ports because our Indy EZ heads had been ported to the larger runner size. Our Indy EZ heads have seen quite a few dyno tests over the years and they produce a consistent 100 horsepower improvement over the various standard port heads that we've run on this short-block. Since this intake also uses a 4500 carburetor flange, we used Holley's Ultra HP 1050 Dominator

The installation of the 5120 series metering blocks onto our Dominator wasn't a simple bolt on since these blocks are substantially thicker than a Holley metering block. The additional thickness meant we needed to bend up some custom levers for the accelerator pumps. We also needed to acquire longer fuel bowl screws from BLP as well as a selection of jets and air bleeds. The BLP jets and air bleeds have a more streamlined shape than their Holley equivalents and they are available in a wider selection of sizes.

<STRONG>7</STRONG> The metering blocks from BLP have jets in all of the fuel circuits, so making adjustments to the fuel curve is quick and easy. The 5120 series metering blocks wasn't a simple bolt on since these blocks are substantially thicker than a Holley metering block. The additional thickness meant we needed to make custom levers for the accelerator pumps. We also needed to acquire longer fuel bowl screws from BLP. The BLP metering blocks also required that we alter the air bleed sizes and locations. The outside air bleed now feeds the intermediate circuit, while the middle one feeds the idle circuit.

<STRONG>7</STRONG> The metering blocks from BLP have jets in all of the fuel circuits, so making adjustments to the fuel curve is quick and easy. The 5120 series metering blocks wasn't a simple bolt on since these blocks are substantially thicker than a Holley metering block. The additional thickness meant we needed to make custom levers for the accelerator pumps. We also needed to acquire longer fuel bowl screws from BLP. The BLP metering blocks also required that we alter the air bleed sizes and locations. The outside air bleed now feeds the intermediate circuit, while the middle one feeds the idle circuit.

Dry-Sump

Dry-sumps are very popular for circle track racing and are used in almost all of the professional-level drag racing classes, but they haven't caught on with the average Mopar bracket racer for a variety of reasons. One stumbling block we discovered in converting a big-block Mopar engine over to dry-sump is the lack of parts. We could not find vendors for either a block plate, or a dry-sump drive, so we had to design our own.

We decided to go as low buck as possible. A custom-built dry-sump pan wasn't in the budget so we decided to see how well our existing deep-sump dyno pan would work as a dry-sump pan. Our existing pan was already plumbed for a dual-line swivel pickup so that gave us two pickup points where the scavenge lines could be attached. The existing pickup in our pan was designed for wet-sump operation, but we didn't see any reason why it wouldn't work as a dry-sump pickup so we decided to give it a try.

<STRONG>8</STRONG> Since the BLP metering blocks are thicker than the standard Holley blocks, we also had to bend the lever arms for the accelerator pumps. We have gotten word, though, that Mike at BLP is looking into it.

<STRONG>8</STRONG> Since the BLP metering blocks are thicker than the standard Holley blocks, we also had to bend the lever arms for the accelerator pumps. We have gotten word, though, that Mike at BLP is looking into it.

Given that our existing pan only had two lines coming out of it, we were restricted to running a three-stage oil pump consisting of two scavenge sections and one pressure section. Since this was just a test, we borrowed an older three-stage dry-sump pump from a local circle track racer and fabricated a simple mount to hold it in place for the dyno session.

On the Dyno

The engine bolted right onto the dyno, and once the lines were hooked up, we were able to quickly prime the oil system by spinning the pump with a hand drill. Our first round of testing was with the Super Victor intake and 1.70 rocker arms on both the intake and exhaust. The engine sounded great during these pulls, and it made an average of 780 horsepower at 6,600 rpm throughout several pulls. After a quick swap to the 1.85 rocker arms, we made another handful of pulls and saw a consistent set of 790 horsepower at 6,600 rpm readings for a solid 10 horsepower gain. We carefully inspected the rocker arms and pushrods after the dyno tests, and everything was in great shape, which told us that our new pushrod oiling setup was working perfectly.

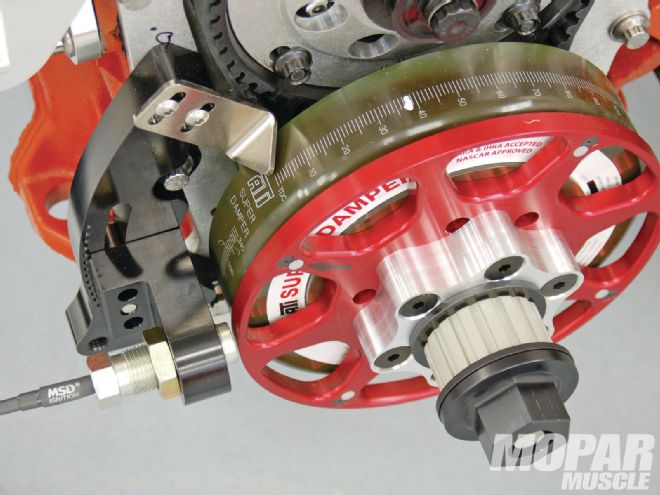

<STRONG>9</STRONG> We purchased a spline drive assembly for the dry-sump oil pump from Peterson Fluid Systems. The crank trigger assembly came from Mancini Racing.

<STRONG>9</STRONG> We purchased a spline drive assembly for the dry-sump oil pump from Peterson Fluid Systems. The crank trigger assembly came from Mancini Racing.

The jetting recommendation that BLP had provided us was very close right out of the box. We made some jetting adjustments to the intermediate circuit, but the main jets were fine. One nice feature of working with these BLP metering blocks is that you can quickly adjust the specific circuit that needs attention. The new ignition system from MSD worked perfectly during these dyno tests. With this much ignition capacity on hand, we can start to open up the plug gaps in a search for even more power gains.

Wrap-up

We were certainly happy to see almost 800 horsepower on the dyno, but quite frankly we were a little surprised that this combination made the power that it did. The last time we ran this engine we saw 805 horsepower, but in that series of tests we were running a bigger camshaft with 10 degrees more duration at .050 inch, and over .120-inch more lift. We did change ignition systems since that last test and we changed to the dry-sump setup, so maybe those changes picked up some power that was lost by going with the smaller camshaft? Originally we planned to continue the testing to see if we could better understand the changes that we had made, but the post test teardown revealed some cracks in the main webs. Not to worry, though; we have already ordered up a new block from the local Dodge dealer so we'll be back bigger and better before too long.

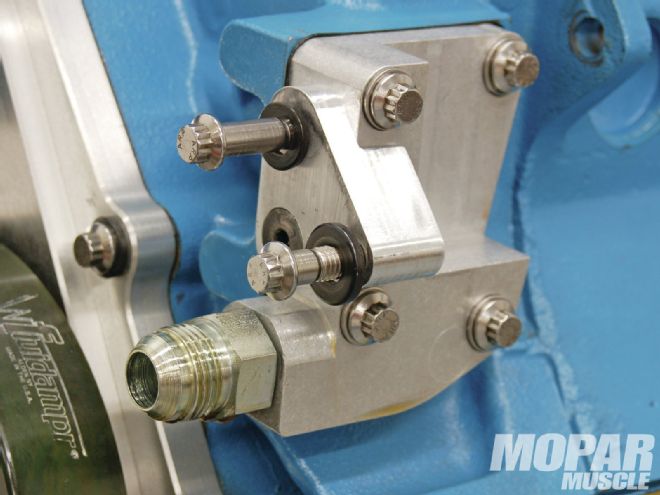

<STRONG>10</STRONG> We were not able to find a dry-sump block plate from any vendor so we designed and built our own. Mancini Racing now has these in stock.

<STRONG>10</STRONG> We were not able to find a dry-sump block plate from any vendor so we designed and built our own. Mancini Racing now has these in stock.

A New Oldie

Mopar Performance has re-released a single carburetor intake that fits the Max Wedge heads on an RB block. This M1 intake, part number P4876337, had been discontinued for awhile but it is now back in the catalog. The 337 intake has a unique cast-in valley floor, which allows it to be installed without using a traditional bathtub type intake gasket. The other interesting feature of the 337 manifold is that it is a very low-rise design so it might just fit under a stock hood.

We had been curious about the potential of this intake manifold for some time so we decided to run some tests while we had Project 505 on the dyno. The intake quickly bolted on with a pair of Max Wedge gaskets, but we needed to use a 4150 to 4500 carburetor base adapter since we wanted to stay with the same Dominator that we had been using for the other dyno pulls. We assumed this low-rise intake manifold would be down on power from the taller Super Victor, so when the dyno readout showed that we had lost 15 horsepower, we weren't overly surprised. But then the dyno operator decided to run the engine at a slightly higher engine speed to see what would happen, and we about fell off of our chair when the motor picked up significant power. We actually saw the best power numbers of the session with a 797 horsepower reading at 7,300 rpm. Evidently the shorter runners on the 337 intake wanted a little more engine speed before they hit their stride. We usually never turn this motor past 7,000 rpm since the peak power has always been down in the 6,500 range, but now we know that this particular combination works better at higher speeds.

<STRONG>11</STRONG> Our wet-sump oil pan was converted into a dry-sump pan by simply routing the existing pickup lines into a dry-sump pump. This low-buck arrangement worked just fine during dyno testing.

<STRONG>11</STRONG> Our wet-sump oil pan was converted into a dry-sump pan by simply routing the existing pickup lines into a dry-sump pump. This low-buck arrangement worked just fine during dyno testing.

Parts

PartPart NumberCost*

Mike Jones camshaftR80393-82401$365.00

Super Victor intake2893$376.00

Jesel Rocker ArmsCustom order$1,350.00

Comp Valvesprings26097-16$545.00

Comp Valve retainers1721-16$160.00

IMM liftersNA$500.00

Smith Bros. PushrodsNH312B-OB$240.00

BLP Metering blocks5120$265.00

3-stage Dry-sump pumploaner/Swap meet$300.00

*Prices we found. can you do better?