An intake manifold routes a combustible cocktail of atomized fuel and air from the carburetor to the engine, and its design can have a significant effect on operational characteristics. Certain examples accentuate low-end throttle response and street manners, while others may sacrifice some to improve top-end charge. The best manifold for a street driven combination is one that yields the best compromise of the two.

For Pontiacs, there are a great number of original and aftermarket intake manifolds to choose from. If you asked five different Pontiac engine builders to suggest a four-barrel manifold for a high-performance street engine, you’ll likely receive five different answers. The suggestions would likely include a mix of single-plane and dual-plane options, and while any would perform suitably, engine displacement, the rpm range it operates in, and the vehicle it’s installed in will dictate which manifold is best, and then you have to consider if your carburetor of choice will work with it.

Pontiac’s original four-barrel manifold is an excellent performer. We regularly use one and a modified Quadrajet on the 467ci in our ’76 Trans Am. At times we also use a modified Edelbrock Torker II and a Holley 950 HP carburetor. Going by seat-of-the-pants performance, the Trans Am certainly feels faster with the Torker II and Holley combo, but we haven’t ever measured engine output to prove it—until now. Follow along as we share the results.

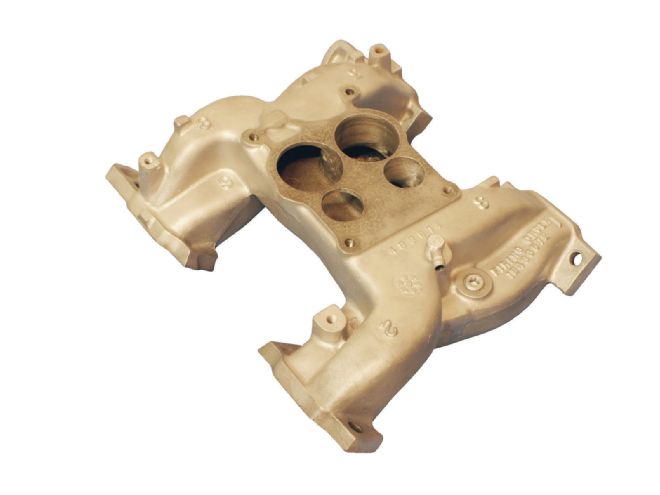

Pontiac’s cast-iron four-barrel intake manifold is a solid performer. Essentially a cast-aluminum version of the popular ’68-’72 iron unit, we often use this ’71 455 H.O. manifold (PN 483674) on the 467ci in our ’76 Trans Am. The coolant crossover was removed to facilitate easily swapping.

Pontiac’s cast-iron four-barrel intake manifold is a solid performer. Essentially a cast-aluminum version of the popular ’68-’72 iron unit, we often use this ’71 455 H.O. manifold (PN 483674) on the 467ci in our ’76 Trans Am. The coolant crossover was removed to facilitate easily swapping.

Intake Manifold Basics

An intake manifold is a design compromise. It provides maximum cylinder fill in a general rpm range. Certain variables can shift the power range of a particular manifold in either direction, and total engine displacement may be the greatest factor. Larger engines tend to pull power downward, so a particular manifold that may produce greatest average power from 3,000 to 6,000 rpm on a 400, may work best between 2,500 and 5,500 on a 455.

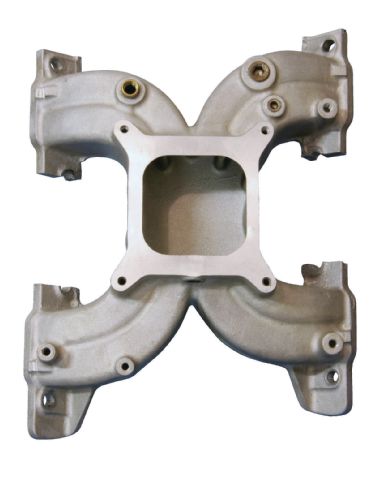

Edelbrock’s Torker II (PN 5056) is a low-rise, single-plane manifold aimed at improving high-rpm performance on vehicles with low hood lines. We found a simple way to make it work with our Trans Am’s Shaker assembly, and frequently use one.

Edelbrock’s Torker II (PN 5056) is a low-rise, single-plane manifold aimed at improving high-rpm performance on vehicles with low hood lines. We found a simple way to make it work with our Trans Am’s Shaker assembly, and frequently use one.

There are two distinct types of four-barrel intake manifolds—single-plane and dual-plane. Dual-plane manifolds feature two separate plenums with four separate intake runners connected to each plenum. It allows half of the engine to draw from one half of the carburetor, improving nozzle signal, charge velocity, and ultimately, throttle response and low-speed street manners, but tends to limit engine output at very high rpm.

To maximize the similarities of the two test manifolds, our Torker II was modified to replicate the Pontiac manifold. The coolant crossover was separated and the exhaust crossover was removed entirely.

To maximize the similarities of the two test manifolds, our Torker II was modified to replicate the Pontiac manifold. The coolant crossover was separated and the exhaust crossover was removed entirely.

Single-plane manifolds contain a large central plenum connected to all eight runners. The larger plenum gives the engine a greater area to draw from, feeding off of the entire carburetor. That can improve high-rpm performance, but tends to reduce nozzle signal and charge velocity at low speed, compromising throttle response and low-end performance.

Carburetor Classics

The Rochester Quadrajet was first used by Pontiac on its V-8 in ’67 as a single-unit replacement for Tri-Power. Featuring small primary barrels for excellent economy and low-speed street manners, and larger secondary barrels for strong full throttle performance, it remains a popular choice with Pontiac hobbyists as it looks stock and can perform very well when properly modified. Its “spread-bore” design seemingly lends itself to a dual-plane manifold, further accentuating low-end performance, but its rather small float bowl requires a fuel system that can deliver an adequate amount of fuel at all times.

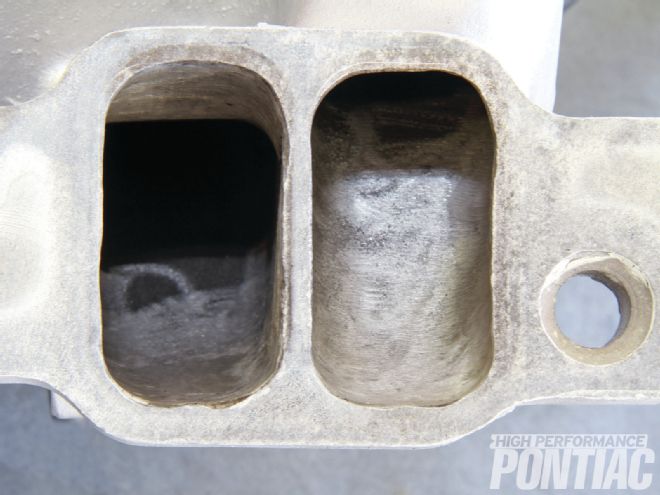

The intake runners of both manifolds were enlarged to full gasket size. It increases airflow and improves the transition into the cylinder-head intake ports.

The intake runners of both manifolds were enlarged to full gasket size. It increases airflow and improves the transition into the cylinder-head intake ports.

Holley’s 4150-series four-barrel carburetor is the most popular choice with those serious about performance. With large float bowls on each end, two separate accelerator pump circuits, and four evenly sized bores, it’s able to supply an engine with a uniform amount of fuel at full throttle. Its “square-bore” design may be best suited for a single-plane manifold, and the HP-series Holley may be the best presently offered, but its primary fuel metering isn’t as precise as a Quadrajet, which can negatively affect economy at low speed.

Pontiac Options

Pontiac’s cast-iron four-barrel manifold introduced in ’67 is a dual-plane design. By simply enlarging the runners to maintain full gasket size, it performs exceptionally well up to about 5,500 rpm on 455- to 468-inch engines. It, and the ’69-’72 Ram Air IV and 455 H.O. aluminum castings, are popular since they are compatible with all Pontiac hood lines and accept all original equipment—very important factors if you own a Second-Gen Trans Am and wish to retain the stock Shaker assembly.

Most aftermarket high-performance intake manifolds are designed to improve high-rpm horsepower. When compared to a stock Pontiac unit, the tradeoff is generally a bit less throttle response and low-end torque. Since most modern high-performance Pontiacs use deep rear-axle gears and/or high-stall torque converters, engines are rarely heavily loaded at very low rpm. That often allows hobbyists to reap the benefits of a high-performance manifold without as much negative effect.

Several dual-plane manifolds with similar but larger runner and/or plenum volume have been available on the aftermarket since the early ’70s. That includes examples from Edelbrock, Professional Products, and Weiand. While they contain spread-bore and square-bore carburetor-bolt patterns to accept a Quadrajet or Holley, respectively, not all are compatible with the Trans Am’s Shaker, however.

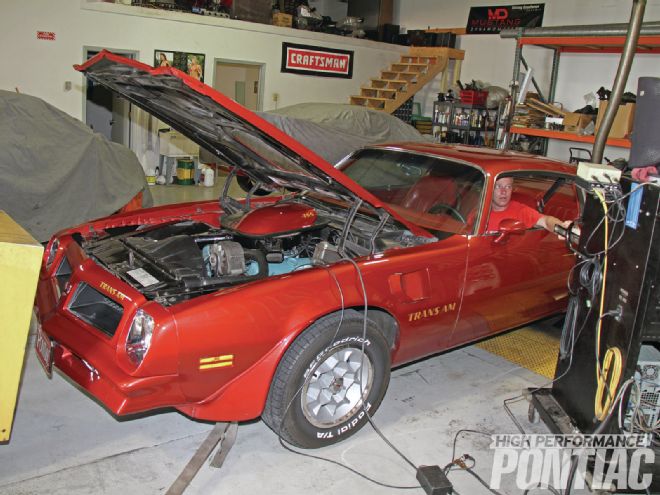

On our last dyno session at C&S Dyno Shop, the 467 peaked at 355 rwhp and 417 rwtq with the Pontiac dual-plane and Quadrajet. We returned a couple of weeks later to measure the effects of a Torker II and Holley on performance.

On our last dyno session at C&S Dyno Shop, the 467 peaked at 355 rwhp and 417 rwtq with the Pontiac dual-plane and Quadrajet. We returned a couple of weeks later to measure the effects of a Torker II and Holley on performance.

Single-plane Pontiac manifolds have been on the aftermarket nearly as long. The race-oriented units, such as the Doug Nash or Edelbrock Victor, are equipped with a square-bore bolt pattern and are typically regarded as race-only units. Other examples, such as the Holley Street Dominator and Edelbrock Torker, which feature a relatively small plenum, short runners, and near-stock carburetor positioning, were designed so hobbyists wouldn’t have hood clearance issues and could reuse their Pontiac’s original Quadrajet while achieving decent performance results on the street.

While Holley and Edelbrock no longer produce the Street Dominator and Torker for Pontiacs, used examples can be found fairly easily and affordably on hobby-related websites. Additionally, Pacific Performance Racing in San Pedro, California, introduced its Tomahawk manifold a few years ago, which is essentially a modern interpretation of the original Street Dominator with some flow enhancements. It’s a popular option with Second-Gen Trans Am owners for its low-rise design, good top-end performance potential, and Shaker compatibility.

Edelbrock presently offers two of the most popular high-performance manifolds on the aftermarket. The dual-plane Performer RPM provides excellent throttle response and low-speed street manners, and its generously sized plenum allows for strong top-end performance. While it’s ideal for a heavy street car, the additional plenum area is achieved by increasing the carburetor flange height by approximately 1.25 inches over stock, and that makes it difficult to install on a Second-Gen Trans Am without significantly modifying the Shaker.

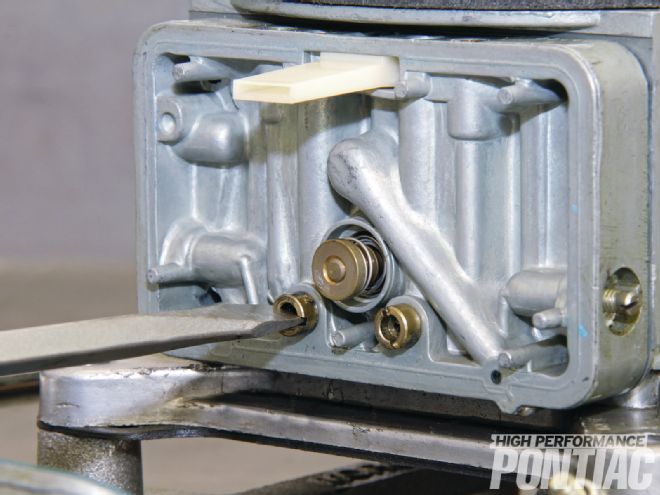

A jet change on a Holley requires removing the float bowl to access the metering block. We found that just one change was required to maximize the performance from our 467.

A jet change on a Holley requires removing the float bowl to access the metering block. We found that just one change was required to maximize the performance from our 467.

Edelbrock released its redesigned Torker II in 1988. Replacing the original Torker, the carburetor was raised nearly 0.5 inch, and the reshaped runners feature a smooth contour that connects to a moderately-sized plenum. On a larger engine, the Torker II is capable of dual-plane-type throttle response and street manners at low speed, yet produces strong peak horsepower numbers to nearly 6,000 rpm. Unlike the original Torker, however, a Holley-type carburetor is required.

The Test Pontiac

If you’ve read through the past several issues of HPP, you may have noticed the recent changes we made to the 467 in our ’76 Trans Am. In an attempt to improve its street manners, we replaced the large hydraulic flat-tappet camshaft with a smaller-spec grind. This resulted in significantly improved driveability but slightly reduced peak horsepower. Most recently we installed a hydraulic-roller camshaft, and that restored the lost horsepower and increased torque while further improving driveability.

With the tuning complete and the Shaker installed, the Torker II and Holley increased peak horsepower to 370 at 5,400 at the rear tires, but reduced peak torque to 394 lb-ft at 3,900. The result is typical for a single-plane manifold.

With the tuning complete and the Shaker installed, the Torker II and Holley increased peak horsepower to 370 at 5,400 at the rear tires, but reduced peak torque to 394 lb-ft at 3,900. The result is typical for a single-plane manifold.

Just before the series of camshaft swaps, we installed the Pontiac dual-plane and Quadrajet in an attempt to improve low-speed tractability. Now with the hydraulic roller camshaft installed, our Trans Am was so tractable that we felt the Torker II and Holley carburetor might improve performance without noticeably affecting street manners. We dug the pair out of hibernation and installed them on the 467, primed the carburetor, cycled the throttle until fuel discharged from the primary accelerator pump discharge nozzles, hit the ignition key, and the powerplant immediately roared to life.

The Road Test

After the engine reached its normal operating temperature, we trimmed the Holley’s idle mixture screws, readjusted the idle speed, and backed the Trans Am out of the garage. On the road and at normal speeds, it was very difficult to tell if the 467 was operating any differently than before. Throttle response remained crisp and responsive. Though engaging the clutch required slightly more finesse, the Trans Am still accelerated very smoothly and effortlessly from a stop.

Once underway, stomping on the accelerator proved the 467 was just as happy with the aftermarket induction system. When compared to the modified originals, the engine felt stronger from 3,500 rpm upward, and it pulled very hard just beyond 5,500.

But was it really producing more peak horsepower and torque? And how did the aftermarket components affect average power from 2,500 to the horsepower peak? The only way to determine that was with a chassis dyno session at C&S Dyno Shop in Omaha, Nebraska.

On a Second-Gen Trans Am, combining an aftermarket intake manifold with the stock Shaker can be challenging. A couple of companies offer kits to install Edelbrock’s Performer RPM, but they require some modifications and don’t necessarily look stock. We found a low-buck way to retain the original Shaker, make it look completely stock, and retain the correct Shaker height.

On a Second-Gen Trans Am, combining an aftermarket intake manifold with the stock Shaker can be challenging. A couple of companies offer kits to install Edelbrock’s Performer RPM, but they require some modifications and don’t necessarily look stock. We found a low-buck way to retain the original Shaker, make it look completely stock, and retain the correct Shaker height.

The Dyno Test

Our Trans Am is no stranger to the roller drum of the Mustang-brand chassis dyno at C&S Dyno Shop. Over the course of the past several months, we’ve made a countless number of full-throttle pulls, finely tuning the 467 in an attempt to extract the maximum possible amount of peak rear wheel horsepower and torque from the combination. With the Pontiac intake and Quadrajet installed, it peaked at 355 rwhp at 5,300 rpm, and 417 rwtq at 3,700 rpm. Average power between 2,500 and 5,300 was 294 rwhp and 389 rwtq.

With the Trans Am firmly secured and C&S Dyno Shop owner Tom VanVugt in the driver’s seat, the first full-throttle pull resulted in 363 hp and 385 torque at the rear tires. Reviewing the pull and comparing notes, we found it to be slightly more horsepower than we made before, but noticeably less torque. That’s the general trend we expected to see based on our experience with single-plane manifolds in other combinations. The Holley’s air/fuel ratio showed slightly rich, however, and we felt there was a bit more in it.

Using a spare Pontiac dual snorkel air cleaner, we removed its original drop area and installed a 14-inch aftermarket base with a drop of 1.25 inches (K&N PN 85-3549). We were then able to install a 14x2-inch filter, the stock filter lid, and the Shaker scoop. Best of all, our particular engine looked stock and showed no performance loss with the modified assembly in place!

Using a spare Pontiac dual snorkel air cleaner, we removed its original drop area and installed a 14-inch aftermarket base with a drop of 1.25 inches (K&N PN 85-3549). We were then able to install a 14x2-inch filter, the stock filter lid, and the Shaker scoop. Best of all, our particular engine looked stock and showed no performance loss with the modified assembly in place!

A follow-up pull revealed nearly identical numbers, so with a baseline firmly established, the next several pulls were spent whittling away at the air/fuel ratio by changing the Holley’s jets and adjusting total timing. At the end of our dyno session, the 467 peaked at 370 rwhp at 5,400 rpm, and 394 rwtq at 3,900. The average rear-wheel power numbers from 2,500 rpm to the horsepower peak were 292 and 373, respectively.

After reviewing the results of this dyno session, comparing peak and average numbers to our previous bests, we weren’t surprised to find that the Torker II influences horsepower and torque similarly to any other comparable single-plane. The combo improved horsepower by 15 but reduced torque 23, and that’s exactly how it feels on the street. It continues pulling where the Pontiac dual-plane flattens out.

We were, however, a bit surprised to find that the Torker II and Holley didn’t improve average horsepower. It historically shows a 10-15hp increase and a similar amount of torque at most every rpm with the addition of a carburetor spacer measuring at least 1 inch. That certainly would have yielded positive results in our test, but it wasn’t possible to fit one under our Trans Am’s Shaker assembly with either intake manifold, and it wouldn’t be representative of our Pontiac’s actual performance on the road. The same situation existed with testing the Edelbrock Performer RPM.

Conclusion

Even though the Torker II and Holley made our Trans Am feel much more powerful and its 467 showed a 15-rwhp increase, not every combination can benefit from the addition of a single-plane manifold. That doesn’t remotely suggest that the Torker II—or any other similar dual-plane, for that matter—is a bad choice.

The dyno chart clearly shows that the Torker II and Holley combo improves top-end performance, just as it’s designed to do. It also shows just how capable the stock Pontiac induction system is for midrange performance.

The dyno chart clearly shows that the Torker II and Holley combo improves top-end performance, just as it’s designed to do. It also shows just how capable the stock Pontiac induction system is for midrange performance.

Our particular combination is geared toward producing strong low-end torque, and the cylinder heads flow exceptionally well at low and mid-lift, peaking at 240 cfm. By design, a dual-plane intake and Quadrajet may be best suited for it, and the purpose of our test was to determine exactly that. It’s very likely that a single-plane would show significant gains if using cylinder heads with substantially more airflow.

We did learn that a properly designed single-plane intake manifold is quite capable of delivering good street manners while providing exceptional top-end performance, and it should make an excellent choice for lighter-weight cars and/or engines with additional airflow. But it also shows just how capable the original Pontiac induction system can be. And for those hobbyists trying to decide what manifold may work best for their Second-Gen Trans Am and want to retain the stock Shaker assembly, chances are an original Pontiac dual-plane and Quadrajet is up to the task!

Vehicle Specs

Year/Model: ’76 Firebird Trans Am

Weight With Driver: Approx 3,950 lbs

Fuel: 91-octane premium

Engine: ’74 code-YY 455

Cubic Inches Before/After: 455/467

Engine Built By: Willard Auto Machine

Induction System

Air Cleaner: Original dual-snorkel fitted with genericdrop base center

Carburetor: Holley 950HP, No. 80496

Primary Jets: No. 74

Secondary Jets: No. 85

Power Valve: 4.5-inches front, rear blocked

Intake Manifold: Edelbrock Torker II, No. 5056

Fuel System

Pump: Carter High Volume, No. M6907

Heads

Casting: ’71 No. 1971 455 H.O. round-port

Head Porting: Prepped by Nunzi’s Automotive

Flow Numbers at 28 inches:

0.100 inch 84/57

0.200 inch 168/105

0.300 inch 214/135

0.400 inch 230/153

0.500 inch 236/165

0.550 inch 241/168

Bottom End

Pistons: TRW forged-aluminum L2359F

Rings: Sealed Power replacement

Rods: Crower forged-steel, 6.625-inch

Compression Ratio: Approximately 9.2:1

Crankshaft: Original nodular-iron, offset-ground to 4.25-in stroke

Rotating Assembly Balanced: Yes

Camshaft

Brand: Custom hydraulic roller by Comp Cams

Duration at 0.050: 236/248-deg

Duration Advertised: 288/300-deg

Lift with Specified Rocker Arms: 0.520/0.560-in

Lobe Separation Angle: 113-deg

Intake Centerline: 110-deg

Rocker Arms: Comp Cams Ultra-Gold cast-alloy roller, 1.5:1 ratio

Ignition

Distributor: Pontiac HEI

Coil: Stock ACDelco

Wires: Taylor 8mm

Spark Plugs: ACDelco R45S

Total Timing: 36-deg

RPM Total Timing Is Reached: 3,200

Exhaust

Headers: Custom Tri-Y style with 1.75-inch primary tubes, 2.25-inch secondary tubes, and 3-inch collectors

Exhaust Pipes: 3-inch lead, 2.5-inch over-axle, 2.5-inch tail

Muffler: Custom Crossflow-type from Waldron Exhaust

Crossover: 3-inch Dr. Gas X-type

Drivetrain

Transmission: Tremec TKO-600

Clutch: Centerforce Dual-Friction

Rear Axle: Original 8.5-in GM 10-bolt

Rear Gear Ratio: 3.73:1

Dyno Chart

Intake

Carb

Jet(s)

Pri rod

Sec rod

Timing

RWHP

RPM

Pontiac dual-plane

Quadrajet

73

42

BF

36

355

5,300

Edelbrock Torker II

Holley 950HP

74/85

n/a

n/a

36

370

5,400

Difference

+15

Dyno Chart (cont.)

Intake

Carb

RWTQ

RPM

Avg hp from 2,500 rpm to hp peak

Avg tq from 2,500 rpm to hp peak

Average A/F Ratio

Pontiac dual-plane

Quadrajet

417

3,700

294

389

12.9

Edelbrock Torker II

Holley 950HP

394

3,900

292

373

12.8

Difference

-23

-2

-16