Up until now, my personal experience with Ford’s venerable L-head V-8 has been, oh, let’s just say anything but venerable. My first one, a bone-stock 8BA that powered my chopped ’49 Shoebox, was like me—hot headed … literally. After the culprit (head gasket) decided to make a break for it, I’d about had it with Flatheads (I was young and didn’t like messing around with old engines at the time—especially anything with a Blue Oval). But that wouldn’t be my last Flathead experience.

Fast forward roughly 10 years and once again I found myself with another Shoebox—a '51 Club Coupe to be exact. And just like before, "stock" Flathead powered (lack of oil bath air cleaner notwithstanding). At first, the only problematic issue was a badly slipping clutch—but seeing as I lived but a block from CW Moss at the time (and back then, good ol’ Bill McGrath had his used parts section there!), that problem was quickly cured with a new disc and a reconditioned pressure plate. Unfortunately, that wouldn’t be the last of my Flathead troubles—among other things, excessive blow-by and, just like before, excessive overheating ultimately dictated the lil’ 239 go bye-bye, making way for a 302/T-5 combo. That, it seemed, would be my last Flatty foray.

From that point on, my focus engine-wise went Inline—sixes, that is, Stovebolts to be precise. And oddly enough, the first- and second-gen Chevy straight-six is no less quirky, finicky, and hot-tempered than the Flatheads, yet that didn’t discourage me nearly as much as it had in the past. So, as time went on, my horizons re-widened, and when it came time to decide on an engine for my '33 Tudor, while the old circa-’64 283 small-block in the corner of my garage seemed to be the easiest choice, it also posed the challenge and temptations to revisit the old Flathead again. But this time, I wasn’t going it alone, nor was I jumping in without first doing my research, just as I’d done with all my recent, well-running 235s—the right combination of parts (most importantly, the proper block to start with), setup, and tuning … with a few tricks thrown in for very good measure.

1. Flathead heaven—or boat-anchor hell?! For H&H Flatheads, their “stash” is what keeps business thriving by offering customers blocks from each and every era Henry Ford originally produced them.

1. Flathead heaven—or boat-anchor hell?! For H&H Flatheads, their “stash” is what keeps business thriving by offering customers blocks from each and every era Henry Ford originally produced them.

As with the Inliners, there’s more than one way to skin a Flatty, and even more opinions, philosophies, etc., regarding the skinning—er, building and tuning—of said Flatties. To say one particular model and one particular technique is right/best is to say all Flatheads are created equal to begin with … no and no. But I had to start somewhere, and that somewhere led me to La Crescenta, California, where, midway up the Angeles Crest Mountains, H&H Flatheads is located discretely behind a corner service station.

H&H has been in the Flathead business for decades now, and its current proprietor, Mike Herman, has not only learned the ropes from his father, Max Sr., he was able to slide more than a few tricks up his sleeve, thanks to developing a close relationship with one of hot rodding’s leading Flathead performance experts, the late Barney Navarro. Rather than simply asking Mike to build me a decent little 8BA for my ’33, I sat down and picked his brain to get his opinions, insight, and whatnot regarding all things Flathead—all the good things, that is.

1. Let’s start from the beginning. Why Flatheads? What drew your family to them in the first place—but maybe more importantly, what kept you at it all these years rather than going out and getting a "real" job?

It all just seemed to fall into place like it was planned. When I finished college I was working for my brother, Max Jr., helping him with the Model A engines, but that wasn’t going to work. So it came to a point where I either needed to find a job or start something here. My dad threw out the idea to start building Flatheads, and Rod & Custom liked the idea so they came up here and followed my first Flathead build—it just kept going from there. Since the shop was already set up for the old engines and my dad had the knowledge to pass down to me, H&H Flatheads has been growing every year. I continue to build these Flatheads because they are the best-looking engines ever produced and it brings me great pride to know that I am restoring and preserving history and keeping these old cars on the road. Plus, who wants a real job?!

12. And lest we forget Ford’s "lil" L-head, the V8-60. Produced only from 1937-40 only, it was commonly used in Midget racing. With a mere 136ci displacement, it put out 60 hp in stock form, hence the “60” designation.

12. And lest we forget Ford’s "lil" L-head, the V8-60. Produced only from 1937-40 only, it was commonly used in Midget racing. With a mere 136ci displacement, it put out 60 hp in stock form, hence the “60” designation.

2. What have you learned over the years (that you’re willing to share) that has allowed you to improve on Flathead performance and maybe even set your engines apart from others? Are there any tricks you’ve developed for keeping Flatheads from running hot, anything like that?

Even in the last few years there have been new products that have made it much easier for the Flathead to be more reliable. We acid dip all of our cores before we even start to machine anything. This helps remove the flaky rust and even core sand that is still in the pan rail from Ford. It is a crucial part of the cooling. We also pressure-seal every block with a cast-iron resin that we heat to 180 degrees and pump through the water jackets at 20 pounds of pressure. It will show if there are any leaks and also coat all the water jackets. This is a must; we have been doing it for over 40 years with thousands of engines. In every engine I install hard seats for the unleaded gas and stainless valves. I use Isky springs, hollow body adjustable lifters, and only the best parts. Now, there are new water pumps with sealed bearings and improved impellers, new radiators available for everything, all of which make it really easy to keep the Flathead running cool.

13. A lot of people like to brag about running a 4-inch Merc crank. The way to distinguish a 3 3/4-inch Ford from the larger Merc (and possibly dispel someone’s bragging rights!) is by the size of the oil plug—on the 8BA crank it’s the size of a pencil; the more desirable Mercury crank oil plug is the size of a finger (to be safe, though, always measure—the standard crank size is 2.138/2.139 on the rod journals and 2.498/2.499 on the mains).

13. A lot of people like to brag about running a 4-inch Merc crank. The way to distinguish a 3 3/4-inch Ford from the larger Merc (and possibly dispel someone’s bragging rights!) is by the size of the oil plug—on the 8BA crank it’s the size of a pencil; the more desirable Mercury crank oil plug is the size of a finger (to be safe, though, always measure—the standard crank size is 2.138/2.139 on the rod journals and 2.498/2.499 on the mains).

3. For the people who may think a Flathead’s just an old V-8, explain what it is that makes a Flathead what it is, and why, unlike a small-block Chevy where you can simply go to Pep Boys and buy a complete rebuild kit (and then some), it takes more effort and more financial investment to end up with what seems like less?

Flatheads are in a class of their own. It was the first production V-8 Henry Ford ever made and was produced from 1932-53. It has a siamese center exhaust port, which gives it that unique sound. All the valves are in the block, which is why the heads are so thin. There are no pushrods or rocker arms. This is the engine that built hot rodding and a lot of America. It was used in forklifts, welders, wind mills, pumps, etc. This was an engine that just kept running. It was the first engine that speed equipment was readily available for (following the four-bangers, which had their share of hop-up parts, but not nearly as easy for just anyone to get), and style was introduced to speed. It is easy to drop a 350 Chevy in any fiberglass kit car, but it takes dedication and a goal to preserve history and put a Flathead in a car. Hot rodding is about being an individual and making your car your own. Flatheads are a just a way of life—something your grandfather drove, which also makes it a generation bridge. There is so much history behind the Flathead and people always tell me about the car their family drove every day back in the ’40s and it just brings people back to a good place in time.

14. A lot of people like to brag about running a 4-inch Merc crank. The way to distinguish a 3 3/4-inch Ford from the larger Merc (and possibly dispel someone’s bragging rights!) is by the size of the oil plug—on the 8BA crank it’s the size of a pencil; the more desirable Mercury crank oil plug is the size of a finger (to be safe, though, always measure—the standard crank size is 2.138/2.139 on the rod journals and 2.498/2.499 on the mains).

14. A lot of people like to brag about running a 4-inch Merc crank. The way to distinguish a 3 3/4-inch Ford from the larger Merc (and possibly dispel someone’s bragging rights!) is by the size of the oil plug—on the 8BA crank it’s the size of a pencil; the more desirable Mercury crank oil plug is the size of a finger (to be safe, though, always measure—the standard crank size is 2.138/2.139 on the rod journals and 2.498/2.499 on the mains).

4. How’d you first develop your relationship with Barney Navarro? Of all the Flathead "gurus", he remained one of the best right up until his death. How much of his "insight" did he instill in you? Obviously it was enough to believe in the Navarro name to the extent of acquiring all his molds and whatnot, but I’m sure his wisdom went far beyond the particulars of his cylinder heads and intakes.

I first met Barney Navarro at his shop on Chevy Chase Drive in Glendale. I needed some parts to build an engine and I took the time to go down there and learn why Navarro heads and intakes were the best on the market. As my company grew, I had to visit him more and more, each time spending an hour talking to him about engines, flow, and why he did the different things he did. He was incredibly sharp and knew every date and why he did what he did all the way back to when he started machining intakes for Weiand. He was incredibly proud of every part he produced and it was always the highest quality. He was the type of guy who, when you asked him a question, always knew the answer. He taught me why his heads have a horseshoe-shaped chamber for better flow and his intakes have reverse 180 ports for equal distribution (he also changed the ports of his intake to act as an extension of the ports on the block). Barney never did something just because someone told him to—he had to figure it out for himself. He was also involved in boat racing, Indy racing, concrete cutting, and even built a heart and lung pump that was used at Kaiser Hospital for many years. He was a true thinker and pioneer of the industry. It was an honor to call him a friend of mine.

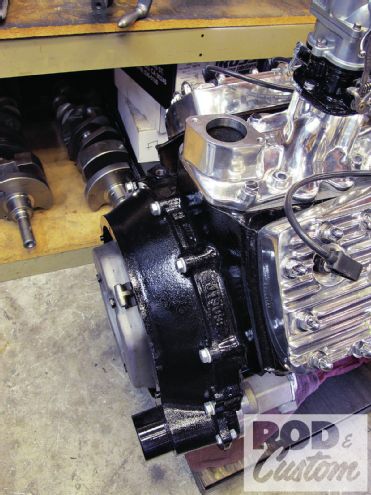

21. While H&H now manufactures its own aluminum starter plates, like most of the previously mentioned OE components, they have a fairly decent supply of original ’49-53 stamped-steel and cast-iron bellhousings.

21. While H&H now manufactures its own aluminum starter plates, like most of the previously mentioned OE components, they have a fairly decent supply of original ’49-53 stamped-steel and cast-iron bellhousings.

5. How did you transition the parts production from when/how Barney did it to the way H&H does it now?

The transition from Barney Navarro making the parts to me making them was almost seamless. Barney has used the same fourth-generation family business foundry, AFCO in Los Angeles since 1946, so I didn’t change a thing. When I bought the company I didn’t have to move anything since I still used his foundry and tooling. It has been a great process reintroducing all the intakes and heads that Barney hadn’t made for years. He felt there wasn’t a market for them anymore. So as I started making the intakes that were out of production. I would bring them to show him—it brought him great happiness and pride that his name would be carried on.

22. Just like Henry Ford made ’em—a bone-stock 100hp 59A. It runs like a sewing machine (the working test stand will prove that) and has been converted over to 12 V with a PowerGen alternator.

22. Just like Henry Ford made ’em—a bone-stock 100hp 59A. It runs like a sewing machine (the working test stand will prove that) and has been converted over to 12 V with a PowerGen alternator.

6. Finally, where do you see yourself in the next 10 years as far as Flatheads are concerned? You’d mentioned expanding to Y-blocks and other OHV engines—realizing the economy’s somewhat coming back around, where do you foresee the vintage engine world going?

In 10 years I see myself building as many Flatheads as possible. This engine has passed the test of time and with the younger generations getting into the history of hot rodding, there is little chance this part of American heritage will disappear. I am also expanding, building other vintage engines like Y-blocks, Lincoln V-12s, early Hemis, Nailheads, and Cadillac engines. I love the challenge building something different, something that allows me to help the hobby grow at the same time.

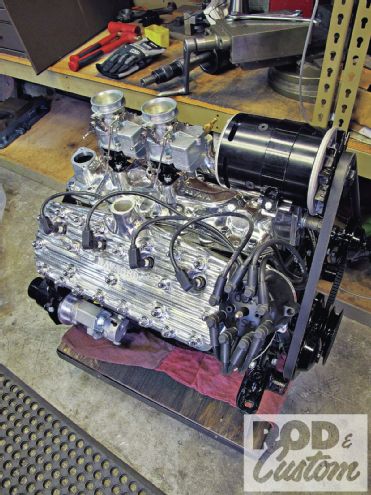

23. Here’s just a sampling of H&H’s range of performance Flatheads. This is a full polished 2x2 Navarro-equipped 8BA engine with early 58A heads (it’s real easy to plug to holes on the deck of the block and bolt them on) built for Old Crow Speed Shop.

23. Here’s just a sampling of H&H’s range of performance Flatheads. This is a full polished 2x2 Navarro-equipped 8BA engine with early 58A heads (it’s real easy to plug to holes on the deck of the block and bolt them on) built for Old Crow Speed Shop.

This is the crown jewel of H&H’s gamut: a fully polished, 250hp Navarro stroker motor complete with H&H’s own S.Co.T. blower topped by a pair of Genuine 97s.

This is the crown jewel of H&H’s gamut: a fully polished, 250hp Navarro stroker motor complete with H&H’s own S.Co.T. blower topped by a pair of Genuine 97s.