In Major League Baseball, the idea of stepping up to the plate is a big commitment. Once you enter the batter’s box, you’re at the mercy of the pitcher with thousands of fans’ eyes fixed on you. A lot can go wrong, but when all goes right, the payoff is incredible.

When we installed the new Zex Perimeter Plate Nitrous system, the analogy went a little deeper than first considered. Everyone in the office was curious to see what could be done with it. Some were banking on modest gains; others had hopes for a tremendous power increase.

In our first installment, we plumbed the Zex LS Series Perimeter Plate Nitrous System on a ’99 Trans Am with a T56. The car already had a handful of bolt-ons and a diminutive-by-today’s-standards T1 cam (221/221-degrees duration with 0.558/0.558-inch lift on a 112-degree LSA). We then wired the Zex system, and upgraded the fuel pump to a Racetronix in-tank, 255-lph pump and hotwire kit. We were ready to hit the dyno.

As we stepped up to the plate, all eyes were on us to make a good number. Unfortunately, things weren’t going according to plan. With the T/A strapped to the Dynojet, we soon learned from the wideband A/F meter that the engine was running a 15:1 air/fuel ratio—very lean, even for naturally aspirated. We immediately corrected it to 13:1, made a pull, and achieved the horsepower number we were looking for. However, something was still off. We knew we needed a tuner to dial-in the car correctly, but with deadlines looming, we pushed on.

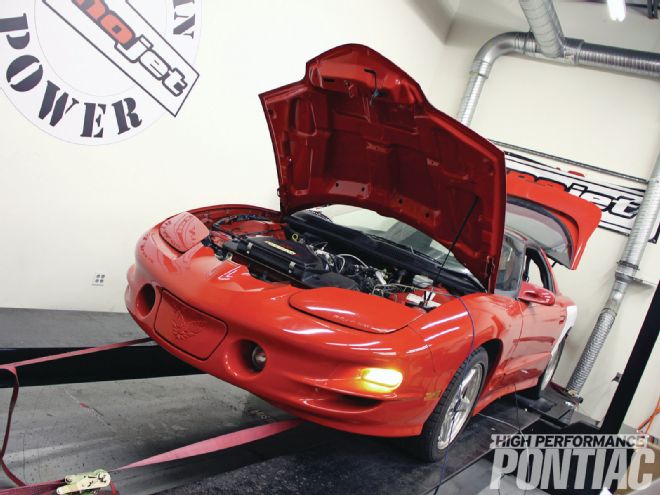

The chassis dyno is an indispensible tool for tuning. We strapped this ’99 Trans Am to our in-house Dynojet and plugged the wideband into the rear O2 sensor for the most accurate air/fuel ratio readings.

The chassis dyno is an indispensible tool for tuning. We strapped this ’99 Trans Am to our in-house Dynojet and plugged the wideband into the rear O2 sensor for the most accurate air/fuel ratio readings.

Unfortunately, the perfect storm had amassed in the FAST 90mm intake manifold. A fuel puddle had accumulated in the back of the manifold, which is common and clears out quickly and harmlessly in a properly running engine. A telltale sign that it’s there is the motor idling high for a few seconds. In our case, however, the ignition system was not up to 100-percent, and we later found out that our spark plug wires were backing off the plugs. The wires were just worn and not “clicking” into place correctly.

When you combine the circumstances of a weak ignition system, fuel in the intake, and the fact that we didn’t run the engine long enough prior to the next pull to evacuate the excess fuel in the intake, it resulted in a nitrous backfire into the intake manifold, which broke it.

Bruised, but not beaten, we dusted ourselves off and went back to the drawing board—Nitrous Safety 101. We determined where we went wrong and made corrections. First, we replaced the plug wires. Second, we converted the car to run an LS2 intake—we didn’t have a spare FAST intake lying around. Third, we installed a replacement MAF—ours was no longer reading. Finally, we performed a compression check and confirmed the engine to be in great shape.

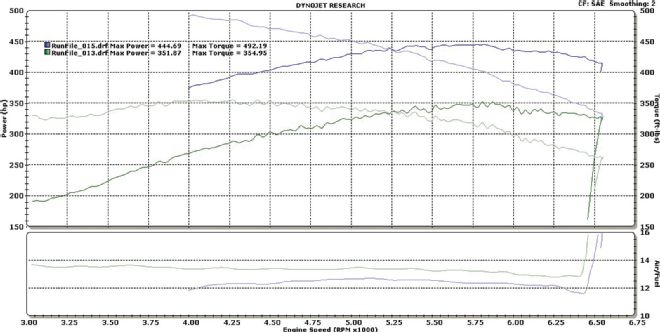

Our baseline pull at 26-degrees timing with no nitrous netted 346 rwhp and 361 lb-ft of torque, but we needed to add fuel before spraying anything. Greg richened the air/fuel from 13.80 to 13.21, ideal for a normally aspirated setup, and the engine produced 351 rwhp and 354 lb-ft of torque.

Our baseline pull at 26-degrees timing with no nitrous netted 346 rwhp and 361 lb-ft of torque, but we needed to add fuel before spraying anything. Greg richened the air/fuel from 13.80 to 13.21, ideal for a normally aspirated setup, and the engine produced 351 rwhp and 354 lb-ft of torque.

Thankfully, Greg Lovell from AntiVenom in Seffner, Florida, was able to come to our Tech Center and help us start from scratch with the T/A’s tuning using HP Tuners VCM Suite. He reduced timing and adjusted our fuel curve until he had a safe tune that still made power. Greg answered a few questions about nitrous systems and tuning to help give you a better idea of where to begin with your Pontiac.

HPP: What do you think everyone should do before installing nitrous on a higher mileage car?

GL: You should do a compression test and make sure there is good even pressure in all cylinders. This means the rings are fine and the engine’s top end is healthy. Make sure the intake is sealed correctly and the ignition system is working properly because it could create a whole list of problems if it’s not. Finally, and most importantly, make sure your fuel system is up to snuff. Delivering the proper amount of fuel is paramount with any engine modification, and keeping up with the fuel demands to compensate for 100 or more horsepower of nitrous is a must.

HPP: Reducing timing is always a big factor when we discuss nitrous tuning. Can you explain why?

GL: You have to think about what nitrous is doing. It’s two parts nitrogen and one part oxygen. Those extra oxygen molecules are concentrated and cause increased cylinder pressure once the spark fires. Reducing the timing helps compensate for the increased cylinder pressure and prevents detonation. This is also why you run a colder-range plug, such as the NGK TR6 plugs used in this car.

HPP: What did you reduce our timing setting to?

GL: The Trans Am started with 30 degrees of timing, and I dropped it down to 26 degrees to help combat detonation. On our pulls I never saw any knock, and that’s a good sign. The engine has a knock sensor that would catch any predetonation and should pull timing on its own. What you don’t want to do is rely on the knock sensor to pull the timing because you don’t want to count on a part that can fail.

HPP: It’s also a rule that you should never spray under 3,000 rpm. Could you tell us why?

GL: Well, first off, there is no point in spraying that low. Your engine won’t benefit from it, so why do it on the dyno? At the lower engine speeds, you’re at a greater risk for damage with nitrous and potential backfires. It’s just a good practice to observe this rule on the dyno, street, or the track.

In the real world, nitrous and forced induction achieve the same goal of putting more oxygen and fuel into each cylinder. When all the proper precautions are taken, nitrous is a effective way to deliver power to your Pontiac, be it a late-model or a classic. As you have seen, you should never overlook anything. There are a lot of simple steps that should be taken before spraying a car, but when done correctly, it should hold the power for a long time.

We hit the T/A with a 100-shot and made 444 rwhp and 492 lb-ft of torque. Best of all, the air/fuel ratio maintained itself below 12.6:1 and fattened up on the top end. This made for an ideal dyno pull, and a safe tune to get out on the street or track and spray it! Using HP Tuners VCM Suite, Greg was able to nail down a near perfect air/fuel ratio and eliminated the risk of detonation and engine knock. Our gains were excellent, with an increase of about 93 hp and 138 lb-ft of torque to the rear wheels. This Zex nitrous system should provide more terrific gains since we can grow into a larger shot in the future.

We hit the T/A with a 100-shot and made 444 rwhp and 492 lb-ft of torque. Best of all, the air/fuel ratio maintained itself below 12.6:1 and fattened up on the top end. This made for an ideal dyno pull, and a safe tune to get out on the street or track and spray it! Using HP Tuners VCM Suite, Greg was able to nail down a near perfect air/fuel ratio and eliminated the risk of detonation and engine knock. Our gains were excellent, with an increase of about 93 hp and 138 lb-ft of torque to the rear wheels. This Zex nitrous system should provide more terrific gains since we can grow into a larger shot in the future.

Special thanks to Jeremy Formato at Fasterproms in Lutz, Florida, who allowed us to borrow an LS2 intake and fuel rails to complete our testing.