When last we left Project City Boy, Pete and Justin had just completed installing a full containment seat from Summit Racing. There is still plenty of work to be done to get the Mini Stock race ready, which includes fabrication such as building a cage for the fuel cell, which you can read all about on page 24 of this very same issue.

Even though Pete drained all the fluid from the motor before pulling it from the car, City Boy left our intrepid crew chief a little surprised once all the work was complete.

Even though Pete drained all the fluid from the motor before pulling it from the car, City Boy left our intrepid crew chief a little surprised once all the work was complete.

Prior to jumping into that part of the build, our City Boys spent an evening pulling the motor and stripping it down in preparation for a journey south to Lake Worth, Florida, and our good friends at Race Engineering. While owner Bob Koch and his crew stock a complete line of parts for V-8 engines, they are known as four-cylinder specialists, both import and domestic, which in our case is perfect for the Ford 2300 engine that came out of our Fox.

Race Engineering's specially designed products can get an obscene amount of horsepower out of four-cylinders. And while we have a rule book to adhere to, Bob Koch tells us that there is plenty of room to play. But before we can send the motor down south we first have to get it out of the car. Since we weren't using much of the top end and accessories on the motor, we didn't much care about salvaging these items but as you can tell from the pictures, getting the motor out of the car still proved to be a small adventure.

Once the motor was out of the car, we began the disassembly process and found the little 2300 to be in remarkably good condition. While it was completely stock, a brand-new oil pan made us think that someone had already been through it once. We would find more, there was nice cross hatching on the cylinder walls and even the head gaskets were in great shape.

Off to the East Coast

We removed everything except the rotating assembly and headed to the other side of the state. Race Engineering is on the Atlantic Coast of Florida near West Palm Beach, just slightly more than three hours from our Tampa home base. And even though we made the trek at the height of sailfish season, we (sadly) left our poles in the garage as we had work to do.

City Boy’s 2300 four-cylinder powerplant is gently hauled out from between the fenders of our ’93 Fox-body Mustang. Most of what you see on this motor will never actually make it into the race car. We’ll be stripping the bulk of it before taking it to Race Engineering in Lake Worth, Florida, for a complete rebuild.

City Boy’s 2300 four-cylinder powerplant is gently hauled out from between the fenders of our ’93 Fox-body Mustang. Most of what you see on this motor will never actually make it into the race car. We’ll be stripping the bulk of it before taking it to Race Engineering in Lake Worth, Florida, for a complete rebuild.

Our block happened to be a small-main E89 block, which would make Bob smile. You can find other blocks in four-cylinder Mustangs with larger mains, but the guys at Race Engineering prefer the E89 because the smaller mains translate into a reduced main bearing speed.

Based on a thorough reading of the rules and a conversation with the track tech, Bob chose specific parts that he wanted to use in this build. The goal is to be as light as possible and to reduce internal friction wherever possible, all staying within the rules of course.

Why do we want light? Light parts reduce internal rotating weight which in turn increases engine acceleration, very helpful coming off the corners. It also helps driving deeper into the turns as it assists in engine braking. Reduced friction also improves acceleration.

We ended up keeping very little of our original E89 block and some of the first things to go were the stock pistons. Since the track has a flat-top piston rule, we will install Race Engineering's ultralight pistons by CP Pistons. This unique design, which is proprietary to Race Engineering, is built on a strutted CP forging which yields a remarkably low weight.

The struts (reinforcement ribs) under the deck allow for a thinner deck (lower weight) while still providing additional strength. The pin towers are spaced closer together than in a conventional design, which allows Koch to use a shorter 2-inch wristpin and yields even more weight savings. Because we will be using a rod that's 0.640-inch longer than stock, piston weight is further reduced. Race Engineering has these pistons laterally gas ported to improve ring seal.

With the cylinder head removed we got a clearer picture of what the guys at Race Engineering were going to have to work with and it all looked good. If only every junkyard motor was this nice.

With the cylinder head removed we got a clearer picture of what the guys at Race Engineering were going to have to work with and it all looked good. If only every junkyard motor was this nice.

These Race Engineering/CP pistons weigh only 276 grams. We shed even more weight because the wristpin supplied with these pistons weighs in at just 74 grams, while normal aftermarket pins tip the scales at a minimum of 117 grams.

Fortunately for us, the rules don't restrict ring selection, so we used Race Engineering's new Super-Metric ring pack. These rings measure 1.0 (0.039-inch)x1.5x2.0 mm instead of the more common and wider 1/16 (0.062-inch) or 5/64 (0.078-inch) rings. Thinner rings increase seal thanks to their improved ability to conform to the cylinders. Believe it or not, thinner oil rings generally have better oil control as well. Thin rings induce less drag and reduce flutter at TDC and BDC, especially at higher rpm, another bonus.

Like the ring selection, rod length is not specified in the rules so we opted for a longer 5.840-inch ultralight rod. The track is a fast 3/8-mile and Justin promises to be aggressive behind the wheel, so we went with the longest rod Bob normally recommends on a track of this size. One thing to remember when going with such a long rod is that you want to keep the rpm up, so running something that long isn't recommended on shorter/tighter tracks. Generally speaking, short rods make torque and long rods build horsepower.

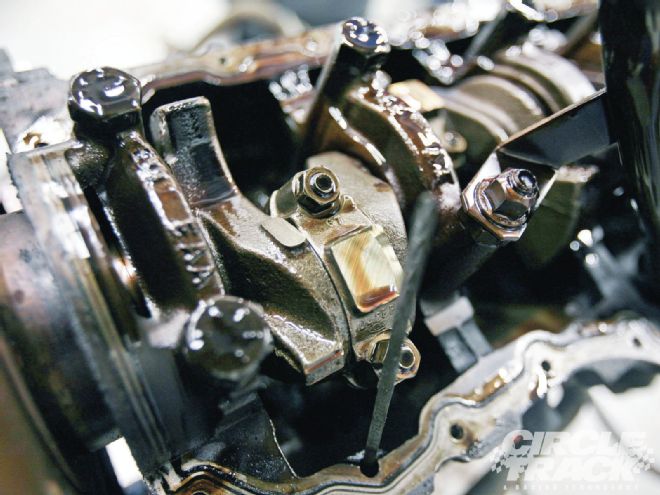

As we removed the timing cover, we found the timing belt to be in great shape. Of course, we wouldn’t be using it, so it really didn’t matter.

As we removed the timing cover, we found the timing belt to be in great shape. Of course, we wouldn’t be using it, so it really didn’t matter.

In the course of our rod discussion, Bob mentioned that he even offers a 5.930-inch rod that he likes to run on 4/10 and longer tracks, but since we're not running Bristol Motor Speedway with this car (yet) we stuck with the 5.840.

Race Engineering's H-beam rod weighs less than 500 grams. For comparison, stock 5.2-inch rods weigh around 630 grams.

Unfortunately, the rules don't permit any lightening of the crankshaft, so Bob and company left the counterweights and stroke alone. They did however prep and balance the crank, and as we mentioned earlier, we do have an advantage with this smaller main E89 motor. Those smaller mains mean decreased bearing speed for reduced friction. In addition, Bob turned the rod journals down to the standard 2-inch Chevy journal size which not only reduces friction, but also adds strength by allowing increased fillet sizes.

Block

Once the block and crank were delivered to Race Engineering, Bob and his crew got right to work getting everything prepped for all those wonderful new parts. First, the crank and stripped block are thermal cleaned and normalized (stress relieved for added strength ) at Lake Park Machine in Lake Park, Florida. The block was then pressure tested, jet washed and square decked. Cylinders were then bored and honed with a torque plate and main caps installed. This simulates the stress of an assembled block which means that the cylinders are round and straight when the head and crank are installed.

A closer examination of the cylinder revealed that the crosshatching on the walls was still there. Somebody sure babied this engine!

A closer examination of the cylinder revealed that the crosshatching on the walls was still there. Somebody sure babied this engine!

The mains are then align honed to ensure proper main bearing clearances. Bob says he typically shoots for 0.0027-inch on average, however, he can go a little tighter with no problems as all bearing clearances are measured with a dial bore gauge during assembly. Unlike some shops, Race Engineering never uses plastigauge. This is critical as many engine failures can be traced to improper bearing clearance.

Finally, the block is machined for a mechanical fuel pump. Our motor was originally fuel injected as most small-main blocks generally are, however, they still have a mounting flange for a mechanical pump. So all you need to do for the conversion is to machine the opening.

Crank

With most of the block work done, it was onto the crankshaft. As we said earlier, the rules prohibit us from playing around too much with the crank, but there was still plenty to get done to it. First off, the crankshaft is cleaned, then normalized (stress relieved) before going into the crank grinder. The second step is to turn the mains 0.010-inch to the low limit. Even if the crank is new (or perfect) Race Engineering always turns the mains 0.010-inch under to achieve proper racing clearance. That's because stock motors run less clearance than required for racing and it's not possible to turn a standard journal crank 0.001-inch or so and keep the journals round.

Even the oil remaining on the crank looked decent.

Even the oil remaining on the crank looked decent.

Step number three is to turn the rod journals to 2.000-inch Chevy small journal, which also generates larger fillets for added strength. However, care must be taken during assembly as V-8 bearings aren't chamfered on both edges and narrowed bearings only clear one side. So, V8 bearings must be checked and modified. Race Engineering stocks and installs bearings that have both edges chamfered. This whole process results in reduced bearing speed, proper clearance (vertical and horizontal), and a stronger part. Finally, the crankshaft is carefully balanced.

What's Next?

In the next installment we'll follow along as the guys at Race Engineering begin putting the internals of the engine together. What we'll have when we're finished is a race-prepped short-block assembly that's ready for final assembly and a session on the dyno. Stay tuned!