It's a recurring theme from which we just can't seem to escape. We discovered an iron 5.3L truck engine on Craigslist for $300, handed the owner three bones, tossed the greasy long-block in the back of our trusty GMC pickup truck, and headed for the barn. The plan was to slip a cam in it and see what would happen when we bolted on a ProCharger P1SC self-contained centrifugal supercharger. Self-contained means you don't have to punch an oil return hole in the pan to make this blower work. It also means we had little self-control when it came to bolting that blower to the unsuspecting little 5.3L truck motor. The opportunity was more than we could resist.

Bolting on the supercharger was one of the simplest parts of this buildup. Making 644 hp on good gas was even easier.

Bolting on the supercharger was one of the simplest parts of this buildup. Making 644 hp on good gas was even easier.

You may recall we've done this before-twice. The first time ("Make 600 HP on Pump Gas," Dec. '07), we pounced on a junkyard Ford 5.0L motor. With a set of RHS heads, a Comp hydraulic roller, an Edelbrock intake, and a blow-through Holley, the ProCharger huffed and puffed to 605 hp at 6,200 rpm. We were so jazzed by the P1SC's performance that we tried again with a 350ci small-block Chevy ("A Boat Anchor into a 611HP Screamer," Feb. '09) that made 611 hp at 6,000 rpm. We decided to pull off the hat trick with a 'tweener 5.3L (325ci) LS engine. That's when our good idea turned a little sideways. After The Supercharger Store sent us the kit, we discovered the cheapie iron block 5.3L motor was missing a couple of essential mount bosses for the accessory drive. By the time we realized this, we had no time to make a new mounting bracket (see the "When in Doubt, Adapt"). So we punted and used an aluminum block 5.3L motor instead. The mount is actually for the power steering pump (or idler if the pump is not used). The supercharger uses a completely separate eight-rib drivebelt. ProCharger has promised a kit to accommodate the iron block soon after you read this. Our test is still valid since there's no difference between an iron and an aluminum 5.3L. In spite of all this drama, we did make 644 hp . That made the sacrifices a little easier to take, don't you think?

This is what our truck escapee looked like sitting in the back of our parts-chaser pickup after we rescued it from abandonment. We started pulling parts off it immediately, using our new Ingersoll Rand 3/8-inch impact gun.

This is what our truck escapee looked like sitting in the back of our parts-chaser pickup after we rescued it from abandonment. We started pulling parts off it immediately, using our new Ingersoll Rand 3/8-inch impact gun.

CAM SPECS

DURATION ADVERTISED

DURATION AT 0.050

LIFT

LOBE SEPARATION

Comp Cams, intake

269

219

0.607

112

269LrHR12, exhaust

277

227

0.614

The ProCharger LSx Serpentine System

We obtained our ProCharger system through our pals at The Supercharger Store, and the kit includes a system that relocates the alternator and power steering pump to create enough room for the supercharger. The beauty of this design is that it does not rely on the narrow, six-rib, stock serpentine belt package. ProCharger instead adds a separate blower pulley to the crank-necessitating a swap to an ATI harmonic balancer-that spins an eight-rib belt wholly for the supercharger. This does add length to the overall engine package, but ProCharger says the company has already fit these blower packages in early Chevelles.

This is how the engine was configured on the dyno with the supercharger system completely installed and ready to run. The ProCharger kit includes a blow-off valve that opens a bypass valve when the throttle is closed while under boost. This vents the pressure out of the hat and prevents damage to the compressor wheel.

This is how the engine was configured on the dyno with the supercharger system completely installed and ready to run. The ProCharger kit includes a blow-off valve that opens a bypass valve when the throttle is closed while under boost. This vents the pressure out of the hat and prevents damage to the compressor wheel.

Water Injection

The big issue with making boost is that it also adds heat. The one-two punch of heat and added cylinder pressure makes it very difficult for pump gas to control detonation. One solution is to inject a measured amount of water into the inlet system when the engine is under boost. The secret is called latent heat of vaporization. The simple side of this concept is that during the conversion of a liquid to a gas, heat is absorbed, which lowers the inlet air temperature. This is the same concept your body utilizes to regulate excess heat by using sweat to pull heat away from your skin. In your engine, the injected water cools the air and makes it denser (a greater amount of oxygen in a given space). The water doesn't put out the flame, as is the common misconception. Instead, the small amount of injected water reduces the peak cylinder pressures that contribute to detonation.

The Supercharger Store Stage 1 water injection kit employs a 5-gallon cell for the water to give you plenty of capacity along with a high-pressure pump and nozzle system. The kit is designed to inject water only after the engine sees 4 psi of boost.

The Supercharger Store Stage 1 water injection kit employs a 5-gallon cell for the water to give you plenty of capacity along with a high-pressure pump and nozzle system. The kit is designed to inject water only after the engine sees 4 psi of boost.

The two keys to water injection are to use as little as necessary and to inject the water in very fine droplets to allow them to more easily vaporize. This is exactly the design for The Supercharger Store's water injection system. While is not inexpensive, that is mainly due to the high-pressure pump and engineered injector nozzle that are required to help vaporize the water. For blow-through centrifugal superchargers, The Supercharger Store mounts the nozzle upstream of the supercharger inlet to take maximum advantage of the water's inherent cooling abilities. We didn't get a chance to try the water injection on our engine, but we can tell you that it does work. Bob and Terry Woods at the Supercharger Store currently have a ProCharger D1SC blower on a 318ci Mopar engine that has made 663 hp at 6,000 rpm with 91-octane pump gas and water injection at 16 psi and 30 degrees of total timing. The package is in a '73 Plymouth Scamp that runs 12.55 at 118 mph and gets 16 mpg on the highway. Before you replicate this tuneup, be aware that the Supercharger Store is at 4,200 feet. If you're closer to sea level, plan on using less timing and boost.

Testing, Evaluations, and Conclusions

We knew from previous experience with this P1SC supercharger that we could see a 50 percent power increase. We also hoped we could pull 400 hp out of the stock 5.3L motor, which we also achieved. After determining that belt slip was causing our boost drop-off at higher engine speeds, we tightened the snot out of the drivebelt. The first pull after that generated well over 600 hp. Yeehaw! In fact, we had to install a larger 4.15 pulley on the supercharger to keep the boost level below 15 psi to protect the factory cast pistons. We added four jet sizes to both the primary and secondary to ensure a safe air/fuel ratio and used MSD's software to program the ignition curve to no more than 22 degrees of ignition timing. Westech's Steve Brulé also pulled out 2 degrees of timing between 4,000 and 5,500 rpm, where maximum torque occurs, to again keep us out of detonation. With that tune-up, the engine pulled out 644 hp at 6,500 along with a best torque of 546 lb-ft at 5,900 rpm.

Centrifugal superchargers generally don't add dramatic torque at lower engine speeds, as was evident with this engine as well. Because our engine is only 325 ci, it doesn't make a ton of torque at lower engine speeds. In our case, it took until 4,700 rpm to make more than 500 lb-ft of torque, but considering we're talking about a 325ci engine with stock heads, a torque output of 1.68 lb-ft per cubic inch isn't bad. Our cast-piston short-block limited the safe boost to 12 psi and total ignition timing to a mere 22 degrees to ensure the engine would not experience detonation. The combination of detonation/preignition with cast pistons is a recipe for disaster, so we were conservative even with 100-octane Rockett unleaded fuel. We ran out of time to try a pump gas combination, but 18 degrees of timing with around 8 to 9 psi of boost would probably be safe and still make 590 hp. We'd suggest adding water injection to this combination just to be safe (see sidebar).

One essential key to making reliable horsepower with any type of power-adder is a colder-heat-range, nonprojected-nose spark plug. We used these Autolite AR474 race plugs to avoid preignition problems. These plugs use a very short ground strap with a short heat path to the head to avoid the glow plug problems with projected nose plugs that can cause preignition problems. A nonprojected-nose spark plug is essential for super- or turbocharged engines.

One essential key to making reliable horsepower with any type of power-adder is a colder-heat-range, nonprojected-nose spark plug. We used these Autolite AR474 race plugs to avoid preignition problems. These plugs use a very short ground strap with a short heat path to the head to avoid the glow plug problems with projected nose plugs that can cause preignition problems. A nonprojected-nose spark plug is essential for super- or turbocharged engines.

Test 1|

This was the normally aspirated baseline using a nearly stock long-block. The only real changes were the Comp hydraulic roller camshaft and matching valve-springs. We also added a Victor Jr. single-plane intake manifold, a Holley 750 carburetor, and a set of 13/4 to 17/8 stepped headers.

Test 2

This was the test for all the horsepower marbles. Using 100-octane unleaded race gas, the only addition was to hook up the ProCharger P1SC supercharger and a Quick Fuel blow-through 650-cfm carburetor. As you can see from the numbers, this was a huge improvement in power.

We used an MSD LS6 box to control ignition timing. It uses the factory cam and crank sensors to control the stock GM ignition coils. We used the MSD plug-in Curve 1 for the normally aspirated tests but set up our own custom curve for the blower tests by pulling out 2 degrees of timing around peak torque where cylinder pressure is the greatest.

We used an MSD LS6 box to control ignition timing. It uses the factory cam and crank sensors to control the stock GM ignition coils. We used the MSD plug-in Curve 1 for the normally aspirated tests but set up our own custom curve for the blower tests by pulling out 2 degrees of timing around peak torque where cylinder pressure is the greatest.

TEST 1

TEST 2

DIFFERENCE

RPM

TQ

HP

TQ

HP

Boost (PSI)

TQ

HP

3,500

359

239

428

285

4.2

69

46

3,700

348

245

428

301

4.8

80

56

3,900

356

264

441

327

5.5

85

63

4,100

359

280

465

363

5.9

106

83

4,300

360

295

482

395

6.3

122

100

4,500

362

310

493

423

6.9

131

113

4,700

363

325

504

451

7.4

141

126

4,900

370

345

515

480

7.9

145

135

5,100

376

365

528

512

8.4

152

147

5,300

379

382

530

535

8.9

151

153

5,500

377

395

538

563

9.5

161

168

5,700

374

405

545

591

9.9

171

186

5,900

366

412

546

614

10.7

180

202

6,100

356

414

541

629

11.1

185

215

6,300

344

412

531

637

11.5

187

225

6,500

-

520

644

11.9

-

-

Peak

379

414

546

644

11.9

187

225

Average

363.7

339.8

503.2

485.2

8.2

139.5

145.4

Averages were taken from the entire dyno pull

every 100 rpm, while our chart shows only the odd rpm points.

When in Doubt, Adapt

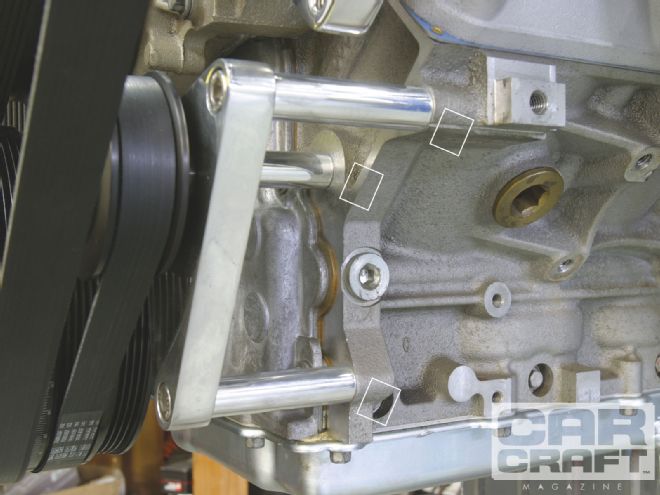

After converting over to our aluminum block 5.3L motor to do the testing, we spoke with the ProCharger people and they told us they are working on a kit that will adapt the power steering mount to an iron LS block that is missing that one essential bolt boss. We came up with what might be a workable solution. In the accompanying photo, arrow 1 points to the one threaded boss that is common between the iron and aluminum blocks. Arrow 2 points to a threaded boss on the aluminum block that is on the iron block but must be drilled and tapped. Arrow 3 points to the boss on the aluminum engines that is missing on the iron block. If we made a 1/2-inch-thick aluminum plate that bolted to an iron block using bolt bosses 1 and 2, we could drill and tap the plate for boss 3 and merely shorten the aluminum spacers by 1/2 inch and mount the adapter to the iron block. That would allow us to use a cheap, iron 5.3L motor with the Procharger blower.

This shows the location of the existing bolt bosses on an aluminum-block LS engine. By using an adapter plate, it's possible to make this existing system work with any iron-block engine, even a 6.0L engine. Hmmm...

This shows the location of the existing bolt bosses on an aluminum-block LS engine. By using an adapter plate, it's possible to make this existing system work with any iron-block engine, even a 6.0L engine. Hmmm...

PARTS LIST DESCRIPTION PN SOURCE PRICE Used 5.3L iron-block long-block N/A Craigslist $300.00 Quick Fuel blow-through 650 SS-650-BAN Quick Fuel 693.00 Fel-Pro head gasket 9292PT Rock Auto 14.71 (2) Posi-Lock three-jaw puller 104 Sears/Craftsman 79.95* ProCharger LS P1SC kit 1LS100-P1SC Supercharger Store 3,696.00 Water-injection system Stage 1 Supercharger Store 790.00* Comp 269Lr hydraulic roller 54-456-11 Summit Racing 396.95 Comp LS-X timing set 7106 Summit Racing 126.95 Comp beehive valvesprings 26918-16 Summit Racing 187.95 Comp hydraulic roller lifters 875-16 Summit Racing 219.95* Comp Hi-Tech pushrods 7955-16 Summit Racing 134.95 ATI balancer 918853 Summit Racing 477.42 ATI crank pin kit, LS1 918993 Summit Racing 117.60* Edelbrock Victor Jr. intake 29087 Summit Racing 269.75 Fel-Pro intake gasket 13123 Summit Racing 25.88 MSD 6LS ignition controller 6010 Summit Racing 309.95 MSD LS1 plug wires, black 32823 Summit Racing 65.95 ARP head bolt set 134-3609 Summit Racing 152.95 ARP intake bolt set 430-2001 Summit Racing 47.95* ARP crank bolt 234-2503 Summit Racing 28.95* Autolite race plugs (8) AR474 Summit Racing 21.52 Grand total $6,888.64 *Options not included in the Grand Total