In what the old timers called the "good old days," blown head gaskets used to be a real pain in the...well, you pick the body part. Poor machining practices that left the decks of both the heads and the block wavy, subpar bolts that weren't torqued accurately, and old-school head gaskets left a lot to be desired. And that's why all those additional practices popped up to help increase the chances of getting a long-lasting head gasket seal.

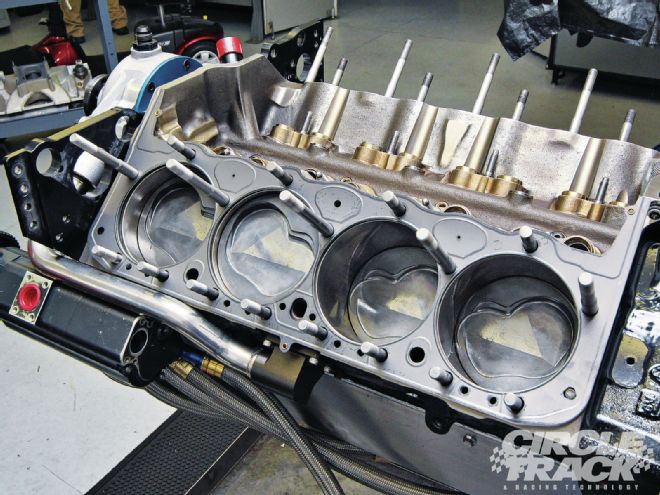

Modern MLS (Multi-Layer Steel) gaskets like this one from Cometic that’s going on an SB2 can provide superior sealing and are popular in every circle track racing class, but they can be worthless if the engine builder doesn’t use the correct installation procedures.

Modern MLS (Multi-Layer Steel) gaskets like this one from Cometic that’s going on an SB2 can provide superior sealing and are popular in every circle track racing class, but they can be worthless if the engine builder doesn’t use the correct installation procedures.

Of course, if you're racing a 1,000-plus-hp dragster with forced induction or nitrous, then things like spraying your gaskets with a copper sealant or O-ringing the block may still be necessary. But for modern circle track racing engines, all that should be required are the right gaskets, good machining of the block and heads, some quality head bolts and—probably most important—proper installation practices.

Get Flat

Of course, it really doesn't matter what head gasket you use or how you install your heads if they haven't been machined properly. Both the deck of the block and the cylinder heads must be flat and on a plane that's parallel to the centerline of the crankshaft. This means that whether you have a new block and heads or are performing a rebuild, they should at least be checked by a quality machinist—especially if the engine has overheated or you have already suffered a head gasket failure.

This Cometic MLS gasket uses embossing to create a seal around both the cylinder and the water and oil passages. In the event that combustion pressure does force the head to lift a bit, the embossed bead can expand a bit to maintain the seal between the block and cylinder head when other gaskets will fail.

This Cometic MLS gasket uses embossing to create a seal around both the cylinder and the water and oil passages. In the event that combustion pressure does force the head to lift a bit, the embossed bead can expand a bit to maintain the seal between the block and cylinder head when other gaskets will fail.

Incidentally, MLS (Multi-Layer Steel) gaskets typically seal better against a block or cylinder heads that have a smoother surface finish than is normally used with a composite gasket. Make sure you let your machinist know which gasket style you're using.

Also, when performing a rebuild avoid using any power tools to clean the deck surfaces. This is especially critical if you're racing aluminum cylinder heads. It can be tempting to use a Scotch Brite pad on a small hand sander or even one of those scuffing discs because they make quick work of cleaning, but they can actually put undulations into the surface of the head that can lead to poor sealing. Instead, take your time and clean the decks by hand with a scraper.

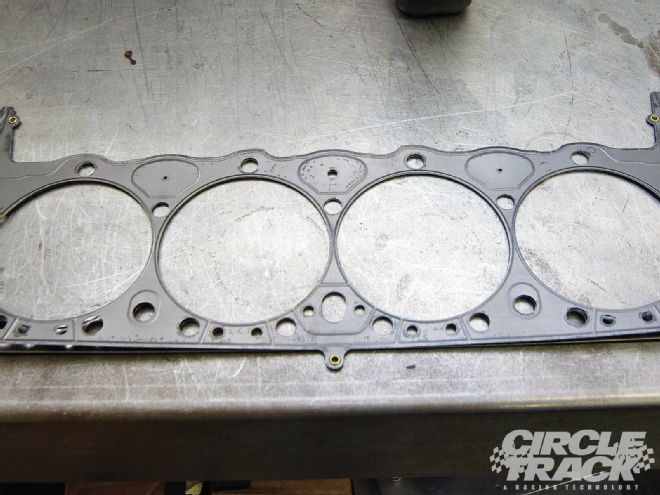

The inner layer on an MLS gasket not only provides a sealing surface for the embossing on the outer layer, but the stainless steel sheet also controls the gasket’s compressed thickness. Notice how the layers are loose except for a rivet holding them together (gold colored in the background). This makes assembling a gasket with different thicknesses relatively easy for the manufacturer and can be a good way for a smart engine builder to adjust compression ratio if he needs to.

The inner layer on an MLS gasket not only provides a sealing surface for the embossing on the outer layer, but the stainless steel sheet also controls the gasket’s compressed thickness. Notice how the layers are loose except for a rivet holding them together (gold colored in the background). This makes assembling a gasket with different thicknesses relatively easy for the manufacturer and can be a good way for a smart engine builder to adjust compression ratio if he needs to.

MLS—The New Standard

MLS head gaskets have been out for several years now, and they've gone from exotic components for only the most high-end race motors to standard equipment on just about everything from Street Stock engines to Cup motors. "MLS" stands for Multi-Layer Steel and refers to how these gaskets are constructed. Unlike a more traditional composite gasket which uses different materials pressed into one solid gasket, an MLS gasket is constructed of three or more pieces of steel that are only attached together at a few points, typically by rivets.

But the most interesting aspect of the MLS design isn't the number of layers of steel it uses, but what is done to the two layers on the outside of the gasket. A bead is rolled, or embossed, into the steel that goes around the cylinder bores as well as the water passages and even the oil drain back holes between the block and heads. When the cylinder heads are bolted to the block, the gasket is compressed but the sealing beads aren't crushed flat. It's these beads that provide the seal. And in the event combustion pressure causes the head to lift off the block slightly, the beads are able to spring back a bit so that the seal is maintained between the block and heads.

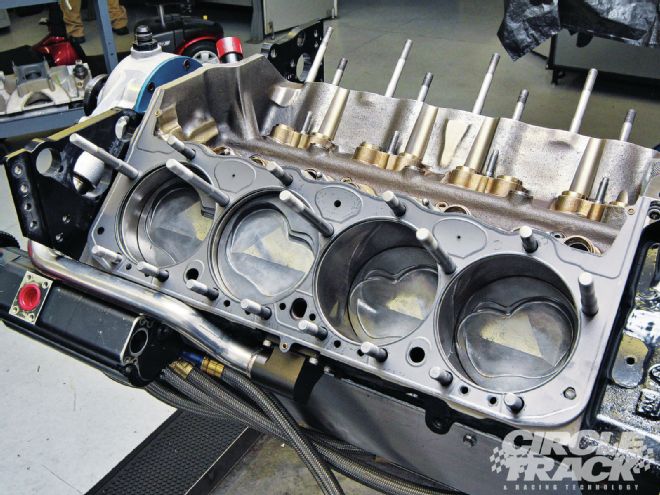

This is an SB2 Chevrolet engine that Keith Dorton of Automotive Specialists is building for an ARCA race team. Many of the components, including the block and heads were previously raced in the NASCAR Sprint Cup Series, but it uses the same head bolt pattern as a standard Chevy small-block. Here, Dorton is installing the head studs and torquing them to 20 ft-lb. When using head studs, the torque into the block isn’t critical but you do want to make sure that they don’t come loose. If they aren’t fully seated they can cause bore distortion when the head is tightened down.

This is an SB2 Chevrolet engine that Keith Dorton of Automotive Specialists is building for an ARCA race team. Many of the components, including the block and heads were previously raced in the NASCAR Sprint Cup Series, but it uses the same head bolt pattern as a standard Chevy small-block. Here, Dorton is installing the head studs and torquing them to 20 ft-lb. When using head studs, the torque into the block isn’t critical but you do want to make sure that they don’t come loose. If they aren’t fully seated they can cause bore distortion when the head is tightened down.

"There are actually many differences between our MLS gaskets and composite gaskets offered by other companies," explains Kevyn Kistner of Cometic Gasket, one of the leading manufacturers of MLS gaskets in the industry. "The most noticeable difference is the materials used in each design. Cometic's MLS gaskets utilize multiple layers of embossed 301 stainless spring steel which can withstand the constant abuse provided by today's high-performance and race engines. By utilizing this design we take advantage of an active seal that is capable of sealing even when a cylinder head starts to move around.

"Another added benefit is the gaskets are a uniform thickness allowing for a better clamp load distribution from the head into the block which in turn reduces overall bore distortion and improves piston ring seal. Composite gaskets focus the majority of the clamping load to the cylinder bore because of the fire rings that are typically used are thicker than the overall gasket."

Here, you can see the gasket before the head has been bolted down. The embossing on the two outside layers of steel is holding the head up. Once the head has been torqued down, the layers will compress but can spring back out if necessary to maintain gasket seal if the head moves.

Here, you can see the gasket before the head has been bolted down. The embossing on the two outside layers of steel is holding the head up. Once the head has been torqued down, the layers will compress but can spring back out if necessary to maintain gasket seal if the head moves.

Another useful feature of the MLS design is that it's easy to use the gasket as a method for dialing in the exact compression ratio you need. By making the inner piece (or pieces) of stainless steel thicker or thinner, you can control the compressed thickness of the gasket without affecting the quality of the seal.

"Cometic offers gasket thicknesses from 0.027-inch up to 0.140," Kistner says. "We design our MLS gaskets in a way that allows all thickness to seal equally. (But) the engine builder does need to keep in mind that intake manifold fitment and pushrod length need to be checked if the thickness of the head gasket has been changed drastically."

To achieve the proper bolt stretch the torque values need to be consistent. This means the bolt threads must be lubricated. Many engine builders use ARP’s Ultra-Torque lubricant and Dorton says it works well, but he says he’s used extreme pressure lube for years with no problems so he sticks with that. What you use as a lubricant isn’t as important as long as your bolt manufacturer provides a torque value to use with that specific lube. Because different lubricants have different lubricating properties, the torque value you use will be different depending on the lubricant. Don’t forget to lubricate both sides of the washer as well as the underside of the nut or bolt flange as well.

To achieve the proper bolt stretch the torque values need to be consistent. This means the bolt threads must be lubricated. Many engine builders use ARP’s Ultra-Torque lubricant and Dorton says it works well, but he says he’s used extreme pressure lube for years with no problems so he sticks with that. What you use as a lubricant isn’t as important as long as your bolt manufacturer provides a torque value to use with that specific lube. Because different lubricants have different lubricating properties, the torque value you use will be different depending on the lubricant. Don’t forget to lubricate both sides of the washer as well as the underside of the nut or bolt flange as well.

Better Bolts

"Head gaskets in general are extremely dependent on the head fasteners, torque values, and procedures," Kistner adds. "In fact, this is one of the main causes that leads to premature gasket failure. Cometic's MLS head gaskets will seal with stock bolts and stock torque values, however, if the cylinder pressure of the engine is enough to overcome the tensile strength of those bolts then the heads could lift the block enough to compromise the gasket. This is why so many engine builders prefer the use of aftermarket head studs made from stronger materials that have a higher resistance to stretching."

In other words, it doesn't matter if you're using premium gaskets in your engine build if the head bolts you've chosen aren't up to the job. Quality aftermarket fasteners are more expensive, but they will prove their worth, not only in improved sealing ability but also in the fact that they are reusable through multiple engine rebuilds while stock head bolts should be thrown out after every rebuild.

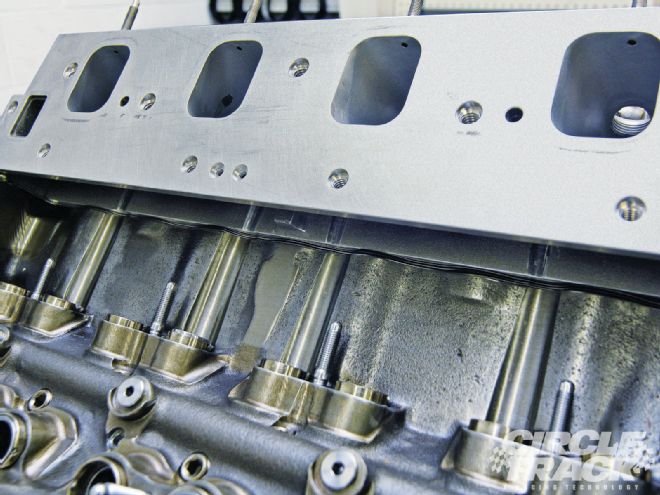

The SB2 cylinder head definitely adds a bit of complexity to installation. In addition to bolt holes that extend through the water jacket, others must be accessed through the intake ports. After they have been torqued properly, Dorton uses a machined threaded plug that seals off the intake port while maintaining the optimum port shape.

The SB2 cylinder head definitely adds a bit of complexity to installation. In addition to bolt holes that extend through the water jacket, others must be accessed through the intake ports. After they have been torqued properly, Dorton uses a machined threaded plug that seals off the intake port while maintaining the optimum port shape.

To give you a better idea of the best practices when it comes to installing a set of cylinder heads and getting optimum gasket seal, we visited the shops of Automotive Specialists where owner Keith Dorton was working on an ARCA SB2 race engine. We thought it would be interesting to show you an SB2 because, while you may never see these heads in Street Stock racing classes, it's becoming more accepted in other classes.

All the basic concepts are still the same no matter if you're working on the traditional Chevy small-block (the head bolt pattern is even the same) or a Ford Windsor. The complexity of the SB2 head just requires a few extra precautions. And a little extra time up front will result in better performance down the road.