The Gen III Hemi was unveiled to the world in 2003 in Dodge's Ram pickup trucks, and we didn't yet know what to make of the clean-sheet-of-paper engine design. Well, we now know that this is one bad dude. It's mean enough that the stock heads are capable of making a true 700 hp on 91-octane pump gas, as Tony Bischoff's 417-cube engine recently did at the 2010 AMSOIL Engine Masters Challenge. It's tough enough that even the stock head and main bolts were used to capture the 621 lb-ft of torque the mill was twisting out.

In a recent conversation with Bischoff, PHR learned a little history as to what lead the NMCA record holder to choose the late-model Hemi as his platform for the EMC: "Two things really. One, we do a lot of short-blocks and cylinder heads for HHP [High Horse Performance] and they've been pushing me to do it. Two, per the rules, with the hydraulic roller cam rule and .650 lift, and the powerband of 2,500-6,500, I honestly thought it was the best engine for the job. Small bores and big strokes work really good when you're talking about a low powerband and broad rpm range."

Nothing says sexy like a set of dual-plug Hemi heads!

Nothing says sexy like a set of dual-plug Hemi heads!

Bischoff started his small-bore/big-stroke combination with a stock cast-iron 5.7 block that was treated to a half-fill of Hard Block to stabilize any potential cylinder movement due to the engine making twice its original horsepower. "We've done a lot of the 426s that guys put superchargers and turbos and nitrous on, and at least from the mains' standpoint and even the cylinders, even though they're pretty thin, they actually hold up really well." Similar to the Hemis of yesteryear, the Gen III takes advantage of cross-bolted mains and a full-skirted block to house and stabilize the crankshaft.

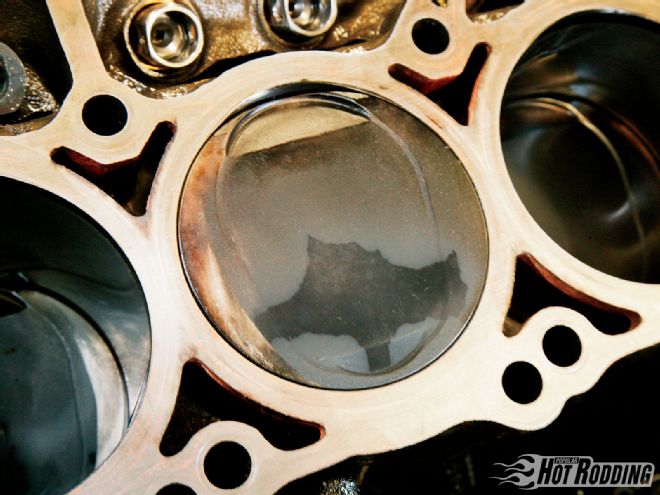

The cylinders were bored and torque-plate honed to match a set of Ross pistons designed specifically for Bischoff. "They have a real neat inboard pin boss forging that they use that actually runs real well. The only problem with the motor combination that we had, and that we had to kind of compromise on, was that because we had such a large stroke and only a 6.125-inch rod, it ends up with a compression height of under 1 inch. To run a camshaft that is in at 102 degrees, because of the Hemi design, the valve ends up almost in the ring land. We had a ring land that was only 20-thousandths thick between the ring land and the valve pocket. The farthest we could advance the cam was 102 degrees to make it fit together, and we actually had to sink the valve into the head .070 inch to make that fit together. That was kind of a challenge." On the other end of the difficulty scale, the Bischoff Engine Service team used an off-the-shelf Sealed Power ring pack for the pistons. "It's designed to be put in your everyday street car."

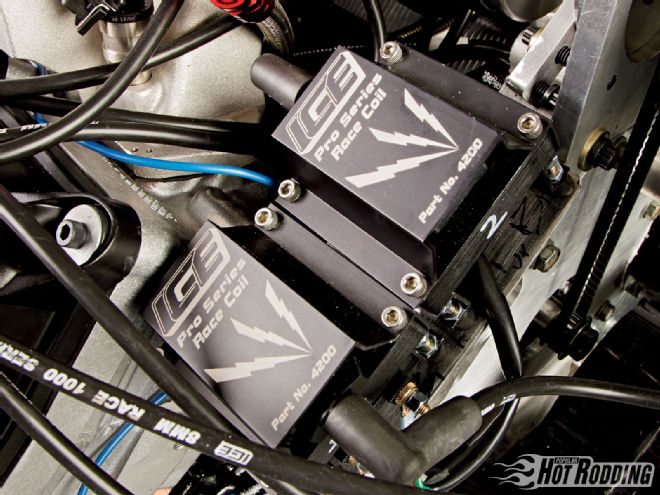

The BES Hemi's dual plugs are fed by a set of dual high-output 10-amp coils. Bischoff said that in testing, running the dual-coil setup was definitely worth power.

The BES Hemi's dual plugs are fed by a set of dual high-output 10-amp coils. Bischoff said that in testing, running the dual-coil setup was definitely worth power.

The crankshaft used was a K1 piece with a 4.25-inch stroke that is commonly used in "440" Gen III combinations. It was matched with a set of K1 H-beam rods and Mahle/Clevite bearings to finish off the rotating assembly.

Innovators West provided the harmonic balancer for the engine using a trick-looking CNC-machined aluminum housing and a unique inner structure. The damper houses spring-loaded inertia rings that work in conjunction with friction clutches. Fluid inside the damper acts as a lubricant for the clutches and does double duty dissipating heat.

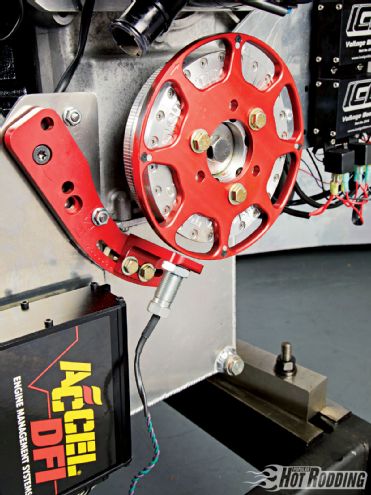

A Chevy-style crank trigger bolts right up to the late-model Hemi, thanks to the fact that the Innovators West Damper is set up for a Chevy front bolt pattern to accommodate blower pulleys more readily.

A Chevy-style crank trigger bolts right up to the late-model Hemi, thanks to the fact that the Innovators West Damper is set up for a Chevy front bolt pattern to accommodate blower pulleys more readily.

On the rear end of the crank, an SFI-approved flywheel connects the shaft to the dyno; however, for enthusiasts interested in seeing an engine like this in an actual hot rod, Chrysler conveniently designed the bellhousing with the same bolt pattern and size as the old-school small-block LA engines. So with a crankshaft adapter and a kick-down cable like the ones available from Buchillon Performance, it is entirely feasible to hook one of these up to an early style tranny that might be residing in your "muscle generation" car.

Chrysler engineers spent enough time designing the oiling system for the Gen III that Bischoff felt the OEM oil pump was more than adequate for the combination. Aside from detailing the oil passages and lowering the pressure in the pump, it was basically stock. With low-tension rings and a hydraulic roller cam, the short-block is certainly ahead of its low-brow flat-tappet predecessors, but where the engine really starts to make power is on the north side of the deck.

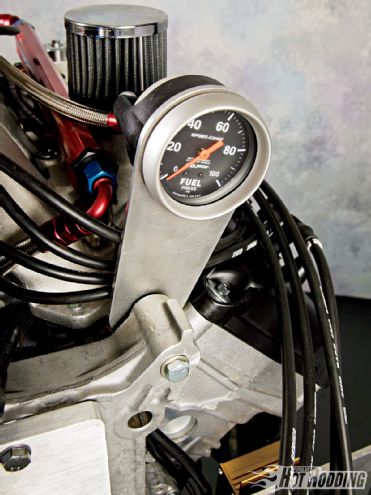

Though data logging is verboten during the money runs of the AMSOIL Engine Masters Challenge, the team was able to make sure the engine didn't lean out unexpectedly by installing a simple Auto Meter mechanical fuel pressure gauge.

Though data logging is verboten during the money runs of the AMSOIL Engine Masters Challenge, the team was able to make sure the engine didn't lean out unexpectedly by installing a simple Auto Meter mechanical fuel pressure gauge.

BES is definitely a player when it comes to CNC-ported Hemi heads, and they've spent a good deal of time figuring out how to get the most out of the stock castings. "We used some late-model 5.7 heads on it and we tried some, for lack of a better term, tricks. We didn't pay so much attention to the flow bench. We kind of went more for cross-sectional area. They didn't flow very well. As a matter of fact, our 6.1 heads that we do every day for HHP with the stock size valve actually out-flow them. But obviously these performed pretty well." New intake seats were installed to handle the massive new intake valves, and the bowls were worked to match the combo. Even downplaying the flow numbers, Bischoff alluded to the power potential for the heads by letting slip that they flow right about 360 cfm. "With a mild port job on the 6.1 heads and a 2.08 valve, they'll do that, so that's what really makes the Hemi work really well without opening the valve a mile."

Another key factor in choosing the engine was the availability of the skyscraper Drag Pak single-plane intake manifold from Mopar Performance. Dale Aldo of Mopar Performance says they are completely committed to the Gen III engines and have been stepping up with a slew of parts for them including that tall single-plane, two shorter single-plane intakes (carb and EFI), and even a trick dual-quad intake. Aldo also mentioned that they have just received their first batch of aluminum 6.1 blocks, so keep an eye open for those to be available soon.

Simple math determined the injector size. Desired HP × Brake Specific Fuel Consumption (typically .500 to .550 for pump gas) / number of cylinders = pounds of fuel used per hour. This is then usually divided by a normally recommended maximum duty cycle of 80 percent, or 0.8 to get the injector you need. In Bischoff's case it, was 700 × .45 (very efficient) / 8 = 39 lb/hr, and we see that at that rate he was at 86 percent duty cycle.

Simple math determined the injector size. Desired HP × Brake Specific Fuel Consumption (typically .500 to .550 for pump gas) / number of cylinders = pounds of fuel used per hour. This is then usually divided by a normally recommended maximum duty cycle of 80 percent, or 0.8 to get the injector you need. In Bischoff's case it, was 700 × .45 (very efficient) / 8 = 39 lb/hr, and we see that at that rate he was at 86 percent duty cycle.

One of the neato factors with Hemis has always been the rocker arm setup, and the Gen III is no different there. With a net-form casting, the rockers waste no material and their only downside is a lack of adjustability. Regarding stock Hemi rockers, Bischoff says: "They're kind of light, but they work very well. We've never seen a failure out of them with the street car stuff that we've done. For this application, we wanted to do well in the contest and we thought for sure we needed the adjustability of the Jesel valvetrain. We weren't going to do the Chrysler engine until they opened the rule up where we were allowed to have a modified lifter. Because the Chrysler Hemi's oil backward-they oil from the rocker down to the lifter-you can't put a Jesel rocker on unless you oil from the lifter up to the rocker arm." Apparently, this was done as part of the Multi Displacement System feature that shuts off certain cylinders when under low load to save fuel. Bischoff modified the stock lifters by drilling a small hole in the side, allowing oil to travel up the hollow Manley pushrods to the rockers.

Operating the modified lifters is a custom COMP camshaft that was ground with an eye on increasing cylinder pressure and closing the intake valve quickly-to fool the engine into thinking it has more compression than it really has. "Typically on stock and street high-performance stuff, these things run the cams really retarded. They run them at about 120 degrees lobe separation. Unfortunately, for the contest, the tightest lobe separation cam core we could get was 108. We would have liked to get a cam even tighter than that, so we only tried one cam. I suspect there could be more score there. To make a cam like we wanted, we would have had to buy a core out of round stock, and it's about a six-week wait period and about a thousand dollars." BES said they have tried different cams in their street engines but they tend to be milder since the factory ECU doesn't care for anything too radical. Fortunately in this case the team had an ACCEL DFI system, and team member Richard Kolb was there to tune it.

With a fairly compact combustion chamber, the pistons didn't require much of a dish to hit 11.3:1 compression, even with the mighty 4.25-inch stroker crank.

With a fairly compact combustion chamber, the pistons didn't require much of a dish to hit 11.3:1 compression, even with the mighty 4.25-inch stroker crank.

BES has run the DFI system in the past and has been extremely pleased and comfortable with it. The operation of DFI begins with a crank position signal provided by an MSD flying-magnet crank trigger. The signal is received by a VR (variable reluctance) pickup, but DFI also has the option of using a Hall effect sensor as a trigger. Baseline tables generated by inputting the basic engine design (including cubic inches, ignition system type, batch or sequentially fired injectors, rpm range) are then used to get the engine up and running. Wideband oxygen sensors then allowed Kolb to monitor the engine's performance and adjust the tables for maximum performance in real time. Rockett Brand 91-octane unleaded gas was then sent through 46 lb/hr injectors to get burned in the chambers.

The job of burning the gas fell to a custom dual ignition system built with ICE Ignition components and put together by BES team member Brad Nagel. Since the Hemi is designed for dual spark plugs and the crew wanted to use the high-output 10-amp ICE system, they constructed a system using two distributor bodies mounted on a common shaft and driven by a belt coming off the camshaft. Innovative? You bet. Tricky to build? Definitely. But BES is known for thinking outside the box.

Team members John Lahone, Tony Bischoff, Richard Kolb, and Brad Nagle stand proudly with their creation minutes after being crowned the Engine Masters!

Team members John Lahone, Tony Bischoff, Richard Kolb, and Brad Nagle stand proudly with their creation minutes after being crowned the Engine Masters!

It is that outside-the-box thinking that has lead BES engines to absolutely dominate the NMCA ranks and being a multitime winner of the Engine Masters Challenge. Bischoff and his team have proven once again that when thrown into any kind of race, they have mo' skill and mo' knowledge, and their engines definitely make mo' power.

BY THE NUMBERS BISCHOFF ENGINE SERVICE 417CI GEN III HEMI Bore: 3.950-inch Stroke: 4.250-inch Displacement: 417 actual cubic inches Compression ratio: 11.3:1 Camshaft: COMP hydraulic roller Cam duration: 235/241 degrees at .050-inch tappet rise Valve lift: .650-/.650-inch Rocker ratio: Jesel 1.7 ratio Lobe separation: 108 degrees Installed centerline: 102 degrees Top ring: 1.2mm Speed-Pro Second ring: 1.2mm Speed-Pro Oil ring: 3mm Speed-Pro Piston: Ross dished Block: OEM 5.7 Crankshaft: K1 forged Rods: K1 forged 6.125-inch Cylinder head: OEM 5.7 Hemi, ported Intake valve diameter: 2.19-inch Exhaust valve diameter: 1.60-inch Intake manifold: Mopar Performance single-plane EFI: ACCEL DFI 7 Header: Schoenfield Ignition: dual ICE 10 amp Damper: Innovators West

ON THE DYNO BES 417CI GEN III HEMI BEST QUALIFYING PULL RPM TQ HP 2,500 476 226 2,600 493 244 2,700 509 262 2,800 518 276 2,900 526 290 3,000 528 301 3,100 524 310 3,200 518 316 3,300 515 323 3,400 513 332 3,500 510 340 3,600 513 352 3,700 523 368 3,800 534 387 3,900 544 404 4,000 553 422 4,100 564 441 4,200 574 459 4,300 580 475 4,400 585 489 4,500 588 504 4,600 592 518 4,700 596 534 4,800 603 551 4,900 608 568 5,000 615 585 5,100 618 600 5,200 621 615 5,300 621 626 5,400 620 638 5,500 619 648 5,600 616 656 5,700 611 663 5,800 607 670 5,900 602 677 6,000 598 683 6,100 593 689 6,200 588 694 6,300 581 696 6,400 573 698 6,500 565 700