This here's what we call last-minute filler. At least we're good at it, and have had plenty of practice lately. Most recently, the engine for our long-lost '77 Nova project finally came back from the machine shop, but with egg-shaped big ends on the rods and ring gaps way too tight for the nitrous we plan to throw at it. It happens to you, it happens to us. So, while this story was supposed to show you how we built that Disco 350, we instead used the time we could have spent fixing it to bring you this story: a shootout of iron and aluminum heads that are identical except for the material they're made from.

Coming next, a Freiburger versus Brule cholesterol shootout.

Coming next, a Freiburger versus Brule cholesterol shootout.

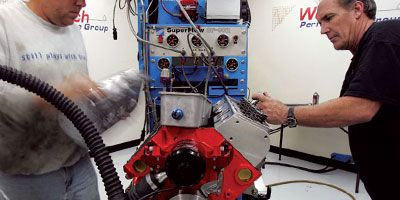

Why? Because we question stuff. You know-bench racing stuff like, "you can get away with more compression ratio with aluminum heads because they dissipate more heat," and "iron heads make more power because they keep the heat in the chambers." We've heard those things a million times, and we've written it a bunch too. But has anyone really tested these claims, or is it just theory? To find out, we put some Dart heads through the ringer. One set was the Iron Eagle Platinum Series (PN 10511122P) with 215cc intake runners, and the other was the aluminum Pro 1s (PN 11511122). Both had 64cc chambers, angled plugs, 2.05/1.60 valves of the same design, and 1.437-inch-diameter valvesprings. We tested these as complete assemblies supplied by Dart. Aside from the material they are made of, the heads seem to differ only in the spark-plug type: the iron heads use short-reach, tapered-seat plugs, and the aluminums take long-reach, gasket-seat style. Externally they appear to be the same casting, and to verify that they are functionally identical, we cc'd the chambers (around 63.8 cc each) and intake runners (almost 217 cc on both). We also threw both heads on Westech Performance Group's Superflow flowbench. There were some variances of a few cfm here and there, but nothing we'd call relevant overall.

By now you've figured out that we're talking about a small-block Chevy again. The engine was a 388-incher (4.06x3.75 bore and stroke) with a China crank and 5.7-inch rods and Keith Black forged-flattop pistons with two valve reliefs that we've hand-enlarged to a dish volume of 6.5 cc. The pistons are set 0.005 inch below the deck. Add that up with the 63.8cc head chambers and the 0.041x4.166-inch Fel-Pro head gaskets, and the static compression ratio is 10.88:1. You'd presume that was too much compression for iron heads on pump gas. The cam is a Comp Cams 306S (PN 12-445-4), a mechanical-flat-tappet grind with 260/260 duration at 0.050 tappet lift, 0.555/0.55-inch lift with our Comp Pro Magnum roller rockers, and a lobe displacement angle of 110 degrees.

Our test procedure involved changing no hard parts except the two styles of Dart heads. With both the iron and the aluminum, we ran sweeps to find the best total ignition timing, thinking perhaps the differing heat-retention characteristics would require different timing settings. We ran each set of heads with 91-octane pump gas then backed up our findings with a load of Rockett Brand 118-octane fuel just to ensure that there was no possibility of detonation that we did not discern audibly or through checking spark plugs. Also, we tested each set of heads with a beginning coolant temp first at 110 degrees, and second at 185 degrees, thinking that perhaps the differences in the heat characteristics of each head material would be revealed by wildly disparate coolant temps; would one material lose more power at higher temps than the other? Finally, we executed a steady-state test at 190 degrees of coolant temp with the dyno holding the engine at peak torque for 10 seconds and capturing data 10 times per second to see if heat buildup in the head would cause power to fall at a different rate with the varied metal of the heads. We beat the engine pretty hard.

Can you guess what we learned? Zilcho. As in zero difference anywhere in the power or detonation characteristics of the iron versus aluminum heads. Even the optimum total ignition timing was the same at 36 degrees. Regardless of coolant temp, rate of acceleration, steady state, or through a sweep, the dyno curves for the two styles of heads were identical. If anything, we could squint and guess and mumble that maybe aluminum heads were better by 2-3 hp. But the one thing we could never say is that the iron heads retained more heat and made more power than the aluminum. Maybe it's different on some engines with a drastically different water-jacket design, but we'll stand up and say that the old bench-racing line just ain't true.

We're not going to be quite so cocky about debunking the claim that you can run higher compression on pump gas with aluminum than with iron. Our test does not definitively prove that. It may not have even tested it. We can say with complete confidence that we did not encounter detonation at any point during our testing, even at 10.88:1 compression. That could be because the cam was pretty big, with an intake-closing point 79 degrees ABDC. With cranking compression in the 185s, it was not taxing the detonation point even with 91 octane. Also, the Engine Masters thing has pretty well demonstrated that a dyno seems to have far more detonation tolerance than do actual driving conditions in a car. So, ultimately, we don't think we pushed that limit enough to make a positive finding.

Still, that's one bench-race axiom that's still up for grabs and another one chucked out the door. Not bad for page filler.

Head Flow Test DataAll testing was done on a 4.030-inch bore fixture and at 28 inches of pressure drop. A flow tube with 1 3/4-inch diameter was used on the exhaust side. IronAluminumLIFTINEXINEX0.050312531230.{{{100}}}655464{{{57}}}0.{{{200}}}1211091271050.3001651381741380.4002131682131690.5002421852421820.{{{600}}}258192250189 The PowerThese charts reveal the STP-corrected power curves for the 388. Both curves are with the aluminum heads, but the curves for the iron heads are identical, give or take a number here and there. These two columns reveal the difference in power when the dyno pull is made starting with a coolant temp of 110 degrees versus 185 degrees. Heat kills power. 110 DEG. F185 DEG. FRPMLB-FTHPLB-FTHP3,0004102343932253,1004132443932323,200414252394{{{240}}}3,3004152613962493,4004162693972573,5004182793982663,6004222894012753,700427301{{{405}}}2853,8004313124072953,{{{900}}}435{{{323}}}4113054,0004383344163174,1004453474223304,2004513614303444,3004583754363574,4004653894423704,5004714034483844,6004754164533974,7004784284564084,8004804394584194,9004814494604295,0004814584614395,1004804664604465,2004764724574535,3004724764544585,4004684814504635,5004644864474685,6004604904424715,7004554934374745,8004504974324775,9004444994274806,0004385004214816,1004325024154836,2004255014084826,3004164994014816,4004105003944806,500402497387479