With the machine work completed in Part I, the day arrived when HPP was scheduled to travel to RaceKrafters Automotive Machine in Lancaster, Pennsylvania, for the assembly of customer Jason Korb's Pontiac 350. I've put together countless engines, but the excitement of working with Craig Wise on a "real" Pontiac 350 and not a "corporate" version got me to the shop an hour earlier than scheduled. What better way to start a day than bolting together a finely-machined Poncho mill?

Though our subject engine was treated to top-level machine procedures with no corners cut, we want to establish that this wasn't intended to be a high-dollar, big-horsepower project, but instead a cost-effective, reliable, streetable and powerful engine for a classic First-Gen Firebird. Other than a few components, such as the camshaft (which is very mild), oil pan, intake manifold, carburetor, and distributor, everything else is pure Pontiac. The project is representative of what a large number of hobbyists want in a powerplant. The total cost of the buildup was $4,842 and dyno testing added another $400.

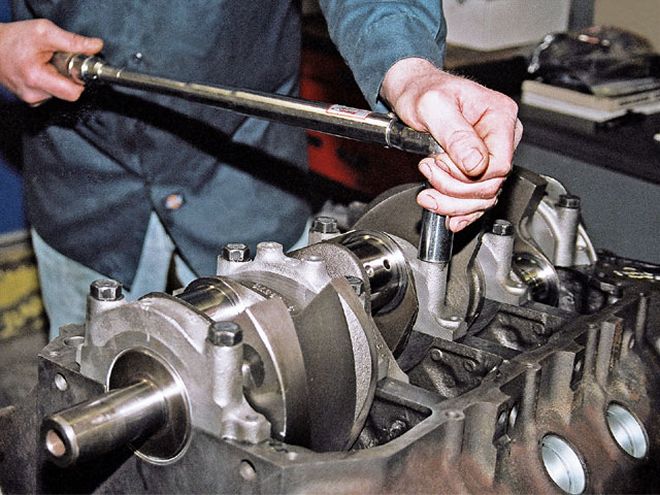

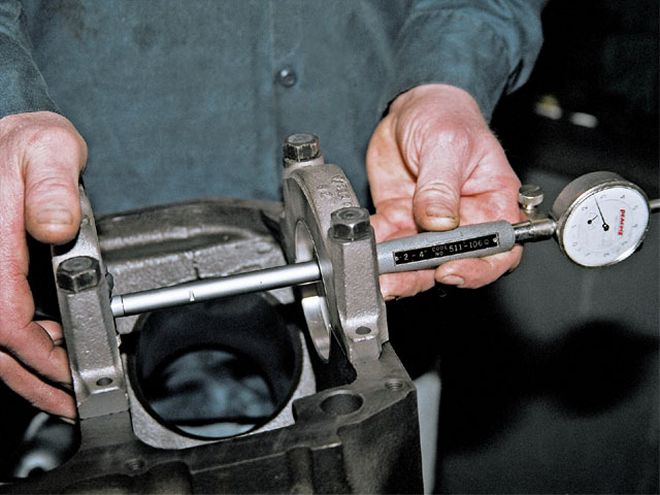

Following good mechanical procedure, all clearances were confirmed one last time before final assembly began. The rod-bearing clearances were checked using a dial bore gauge for extreme accuracy and were set to 0.0022 to 0.0025-inch.

Following good mechanical procedure, all clearances were confirmed one last time before final assembly began. The rod-bearing clearances were checked using a dial bore gauge for extreme accuracy and were set to 0.0022 to 0.0025-inch.

The goal was to maximize the efficiency of the Pontiac YJ-code 350 and to provide a strong running engine that offers excellent manners, fuel mileage and reliability-all traits that this mill was known for when it was built back in the '60s. But that doesn't mean a high level of attention to detail isn't required.

Many times, hobbyists and engine builders alike falsely believe that a "stock" rebuild doesn't require the effort and close-tolerance machining that a race engine does, which couldn't be farther from the truth. The assembly procedure was executed with the same standards employed for a drag engine.

Keep this in mind when building a street engine. Shortcuts and assumptions that all the dimensions are fine will most likely result in a poor-performing, short-lived engine.

In this installment, we'll build the 350 up to the intake manifold, since the valve covers hadn't arrived when HPP was at RaceKrafters. The distributor, valve covers and carburetor will all be installed just prior to the engine dyno session that'll be covered in the next issue of HPP.

Cylinder Head Flow After Porting

Due to a computer issue at RaceKrafters, baseline numbers aren't available. However, for comparison sake, a typical D-port head with larger 2.11/1.77 valves than the No. 17 head used here usually flow between 205 and 210-cfm on the intake at 28 inches of depression at 0.450 lift.

The main-bearing clearances were also confirmed (0.0025 to 0.0027-inch) and were done with the caps torqued to spec.

Lift (inch)

The main-bearing clearances were also confirmed (0.0025 to 0.0027-inch) and were done with the caps torqued to spec.

Lift (inch) Installing the Durabond cam bearings was the first step in the assembly procedure after the two-bolt main 0.030-over 350 block was washed one last time.

ENGINE BUILDUP WORKSHEET

Installing the Durabond cam bearings was the first step in the assembly procedure after the two-bolt main 0.030-over 350 block was washed one last time.

ENGINE BUILDUP WORKSHEET New, high-quality Pioneer brass freeze plugs and steel oil gallery plugs were installed. These parts don't seem important because they don't make horsepower, but a leak can very easily require the engine to be pulled out of the car and possibly disassembled.

Oiling System

New, high-quality Pioneer brass freeze plugs and steel oil gallery plugs were installed. These parts don't seem important because they don't make horsepower, but a leak can very easily require the engine to be pulled out of the car and possibly disassembled.

Oiling System The stock Pontiac rods, attached to the Sterling cast +0.030 pistons were each placed in a rod vise so the caps could be unbolted safely. For this combination, cast pistons are strong enough and offer advantages. The cast piston is less expensive than the forged, uses a tighter wall clearance so the engine is quieter, and the engine uses less oil. The cast piston is also closer to the weight of the original so there is less cost in balancing. Finally, the cast piston is press-fit to the rod. A forged piston requires the stock rods to be bushed for floating pins, which also adds cost.

Cam

The stock Pontiac rods, attached to the Sterling cast +0.030 pistons were each placed in a rod vise so the caps could be unbolted safely. For this combination, cast pistons are strong enough and offer advantages. The cast piston is less expensive than the forged, uses a tighter wall clearance so the engine is quieter, and the engine uses less oil. The cast piston is also closer to the weight of the original so there is less cost in balancing. Finally, the cast piston is press-fit to the rod. A forged piston requires the stock rods to be bushed for floating pins, which also adds cost.

Cam