Part I: The Installs

Although publishing a cooling system article as the weather starts to turn cold and blustery may seem inappropriate, it's the perfect time to reflect on the happenings of summer and plan to correct or avoid future cooling system problems in your Pontiac. By employing the latest technology, your Poncho will be prepared on the street and the track to handle anything that Mother Nature can dish up when the mercury rises. Besides, magazine publishing lead times being what they are means that in order to test in the superheated temp-eratures and oppressive humidity of August, the story will hit the newsstand in October or later.

Fortunately for the hobbyist, there are many quality choices out there to upgrade your cooling system, so we rounded up components from Meziere, Performance Rod & Custom (PRC), SPAL, and Butler Performance to outfit the '66 Tempest test car, owned by Floyd Hand of Dallas, Texas. As an entrant in the inaugural Lone Star Shootout back in '00, Floyd's A-body is a stellar performer that posts mid 11-second quarter-mile e.t.s, utilizing an iron-headed 455.

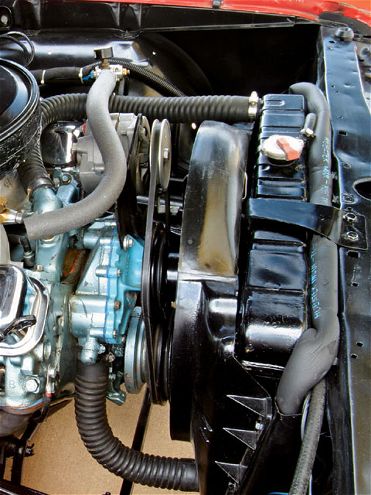

Currently, the '66 utilizes an OEM-style 4-core brass and copper radiator with a shroud from a GTO. Equipped with a stock-type iron water pump and 7-bladed factory clutch fan, the Pontiac doesn't "overheat," but it does routinely see over 200 degree coolant temps after being driven hard on the street or at the end of the quarter-mile.

Currently, the '66 utilizes an OEM-style 4-core brass and copper radiator with a shroud from a GTO. Equipped with a stock-type iron water pump and 7-bladed factory clutch fan, the Pontiac doesn't "overheat," but it does routinely see over 200 degree coolant temps after being driven hard on the street or at the end of the quarter-mile.

The Radiator

Floyd's cooling system was due for an upgrade, so the task of replacing the aging brass-and-copper reproduction radiator in his '66 was assigned to PRC. According to Shawn Kenney of PRC, "Our business has been built on constructing custom high-performance aluminum radiators and providing cooling system advice in order to make sure each component works well together.

"Though common Pontiac applications are available from PRC, each radiator is built to the owner's specs. We use 100 percent aluminum cores that have been furnace brazed and sourced from U.S. manufacturing facilities. No glues or epoxies are used in the cores, so common core failures due to inferior manufacturing are virtually eliminated. Based on customer feedback, the aluminum radiators we build are up to 20 percent more efficient than the copper/brass radiators they replaced." In this case, we wanted a drop-in replacement that didn't have provisions for an automatic transmission cooler. Had we opted for a transmission or oil cooler, or placement of the inlets and outlets in any position, PRC could have built it.

Electric Water Pump

To augment the radiator upgrade, an electric water pump from Meziere was sourced. Available in blue, black, red, or a polished finish from the manufacturer or Butler Performance, the pump is rated in excess of 2,500 hours of running time and includes all the necessary gaskets, seals and wiring for installation. David Butler states, "Meziere makes an excellent electric water pump for the classic Pontiac, and it is very popular with the street/strip enthusiast. In addition to reduced parasitic accessory drag by eliminating the engine-driven fan and mechanical water pump, the electric water pump and electric cooling fan combination allows racers to quickly cool down their cars between rounds at the dragstrip, leading to more consistent performance."

The two steel sleeve inserts to the timing cover can be pulled out by hand. If they are stuck, a gentle tap on the joining line between the sleeve and cover usually frees them. If that doesn't work, crank pulley, balancer, and timing cover removal will be necessary to work the sleeves out from the back side.

The two steel sleeve inserts to the timing cover can be pulled out by hand. If they are stuck, a gentle tap on the joining line between the sleeve and cover usually frees them. If that doesn't work, crank pulley, balancer, and timing cover removal will be necessary to work the sleeves out from the back side.

Electric Fan

Heath Langenfeld of SPAL related, "Since electric water pumps eliminate the factory belt-driven fan, not only is a highly efficient radiator required, but also a high-quality electric fan has to be employed to ensure adequate cooling for the engine, especially when the Pontiac is driven around town. Since the OEM car manufacturers have utilized electric fans and aluminum radiators for decades, enthusiasts can rest assured that the proper selection of components will ensure that even high-compression engines-notorious for running hot-can be accommodated."

We chose a SPAL 16-inch puller fan for our test car. As the supplier to many OEM automobile manufacturers, SPAL's puller fan incorporates a fully balanced and sealed motor that enables it to flow up to 2,360 cfm.

The fan comes with a SPAL thermostat switch, which is designed to send a signal to a relay once it reaches 185 degrees to enable the fan. After the engine cools down to 165 degrees, it signals the fan to turn off.

Alternator Relocation Kit

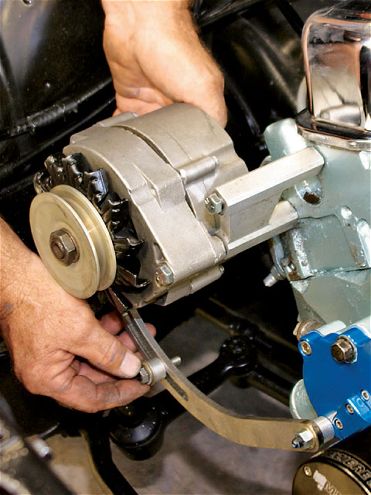

According to David Butler, "An alternator relocation kit is required for Pontiac owners converting to a Meziere electric water pump. The driver's side kit works on applications without power steering where the passenger side kit is for cars without air conditioning. Both kits relocate the alternator closer to the engine's pulley and virtually eliminate thrown belts at the track."

Now that you have been introduced to the parts and enlightened as to why we chose them, strap yourself in as we install the PRC aluminum radiator, SPAL 16-inch electric fan, Meziere electric water pump and a Butler Performance Alternator Relocation Kit. In Part II, the effectiveness of the new cooling system will be tested under the grueling Texas sun.

Radiator SpecificationsThe 1966 specifications are for commonly available OEM reproduction radiators. Though 4-core radiators are listed, many stock Pontiac applications used 3-core radiators. OEM-style 1964-1967 radiators used a downflow design that featured tanks located on the top and bottom of the radiator. The PRC radiator features a cross-flow design and has upper and lower fin covers. Radiator Specs '66 Standard '66 HD and A/C PRC Custom Construction Brass/Copper Brass/Copper Aluminum Type Flow Downflow Downflow Crossflow Core Rows/Width (4), 1/4-inch (4), 1/4-inch (2), 1-inch Core Depth 2 1/4-inches 2 1/4-inches 3-inch Core Width 15 1/4-inches 17 1/4-inches 20 1/4-inches Core Height 23 1/4-inches 23 1/4-inches 20 1/4-inches Overall Width 25 1/4-inches 25 1/4-inches 25 1/4-inches Overall Height 20 1/4-inches 20 1/4-inches 20 1/4-inches Weight 23-pounds 26-pounds 16-pounds Shawn Kenney, of PRC states, "Using distilled water in radiators is very important to ensure that the minerals in tap or bottled water don't react and facilitate corrosion via electrolysis. In addition, the popular acid-based cooling system additives are destructive to aluminum.

In essence, the acid smoothes out water jacket imperfections so that bubbles don't form as readily, but in the process it attacks the aluminum."

One of the aluminum spacers in the Alternator Relocation Kit is slipped over the stud and then the alternator slotted arm is mounted to the water pump. The other spacer, washer and 1/4-inch headed bolt are placed through the slotted arm and threaded into the alternator.

One of the aluminum spacers in the Alternator Relocation Kit is slipped over the stud and then the alternator slotted arm is mounted to the water pump. The other spacer, washer and 1/4-inch headed bolt are placed through the slotted arm and threaded into the alternator.

Recommended Tools

Standard socket set

Standard wrenches

Allen wrenches

Cut-off wheel or grinding wheel

Electrical Tester

Electrical service tools (wire cutters, crimp tool, soldering iron, solder)

Recommended Parts And Supplies

Thread sealer

Fel-Pro timing cover gasket set, part number TCS-13383 (optional)

1/4-inch convoluted tubing

Electrical tape

RTV gasket maker

Conclusion

While technology has advanced significantly over the past four decades since the '66-'67 Pontiac A-bodies prowled the streets, one thing is very consistent: A cooling system that operates at peak efficiency often makes the difference between an enjoyable cruise on the town and/or success at the dragstrip, versus a frustrating day dealing with a hot-running car or, even worse, being stranded on the side of the road. HPP believes in real-world testing and the best way to do it with a cooling system is to perform it in the heat of the summer. In Part II, we will test the effectiveness of the new cooling system in August heat in Texas and explore common cooling system foibles and solutions.