Getting the fuel to the carburetor is a simple task if done right. But there are things that can go wrong, and they will show up on the track in the car's performance.

Getting the fuel to the carburetor is a simple task if done right. But there are things that can go wrong, and they will show up on the track in the car's performance.

Fuel lines, filters, pumps, and regulating devices exist for a specific task-to deliver gasoline or alcohol from the fuel cell to the carburetor, and, in a bypassing system, return it to the fuel cell. Pressures and volumes vary depending upon the kind of fuel used (gasoline or alcohol) and the type of fuel system employed. With routine maintenance, a good fuel system will pay dividends. However, many cars are fitted with systems that fall below the necessary standards.

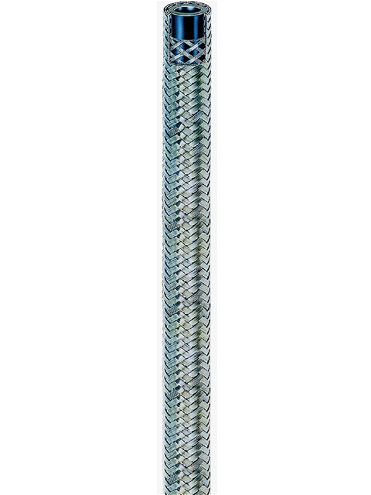

BG Fuel Systems has encountered some common concerns when handling customers' tech questions. The company put together a list of the most common mistakes in competition fuel systems and a guide for correcting them:1 Incorrect fuel lines Do not use 11/44 to 31/48-inch outside diameter lines on a racing fuel system between the fuel cell and the pump. Racers often joke about their first race cars and how the fuel line was so small it functioned as the main jet. Make sure the fuel is supplied through lines that are the correct size for the application. Remember, the fuel line's size is determined by the system, not the vehicle. Push-Lok, stainless steel braided hoses, and aluminum tubing are the most common fuel lines used on race cars.

Use adequate lines when bringing the fuel from the tank to the pump. If you starve the pump, you're going nowhere fast.

Use adequate lines when bringing the fuel from the tank to the pump. If you starve the pump, you're going nowhere fast.

2 Right-angle hose-end fittings from the pump to carburetor Avoid forged 90-degree elbow fuel fittings as much as possible. Although they are inexpensive and readily available, they're restrictive and frequently cause fuel flow troubles. Hose ends with angles of 90 degrees and 45 degrees should also be avoided if possible. Should it become necessary to use one, use radiused hose ends (90-degree bends) which have much better rates of flow. They're manufactured from aluminum, equipped with swivel ends for a positive seal, and are easy to install.

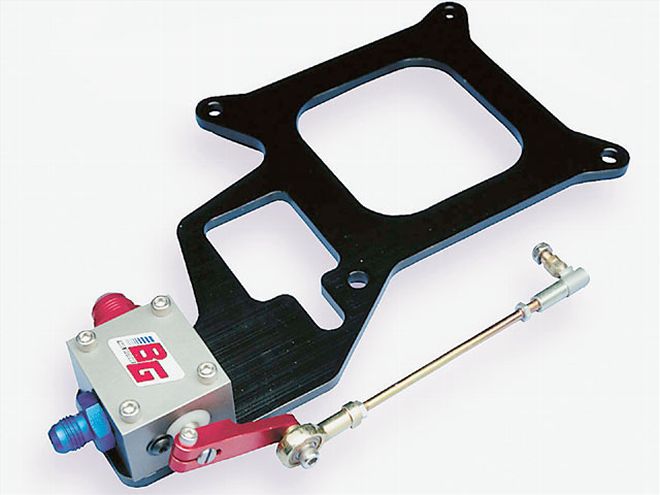

3 Fuel pumps unsuitable for alcohol An alcohol fuel system differs from the gasoline system in several crucial ways. Fuel pressures in a gasoline system are typically maintained between 7 and 9 psi throughout the rev range. Alcohol carburetors require low pressures of around 4-6 psi at idle and 9-11 psi at fully open throttle. This is necessary to prevent the carburetor from flooding at idle and under light engine load, yet maintain the extra volume necessary for maximum acceleration. Engines producing around 500 hp can be fueled with a 15-psi mechanical pump in conjunction with a throttle bypass valve. However, for engines over 500 hp, a belt-driven system with a diaphragm valve or poppet bypass should be considered. For overall reliability and performance, a belt-driven system is usually the better choice. When using a diaphragm bypass, BG Fuel Systems recommends it be installed close to the carburetor for faster response.

One of the most effective ways of regulating the fuel pressure of a 15-psi mechanical pump is the throttle bypass system.

One of the most effective ways of regulating the fuel pressure of a 15-psi mechanical pump is the throttle bypass system.

4 Incompatibility between bypass and pump Throttle bypasses were designed to operate with block-mounted pumps and, similarly, diaphragm bypasses with belt-driven pumps. Never use a throttle bypass with a belt-driven pump. They must function in pairs and are not to be mismatched.

5 Unsuitable fuel filter Fuel filters with conventional paper elements must not be used with alcohol. Alcohol absorbs water, so the paper and the bonding materials deteriorate quickly. As a consequence, particles can enter the float bowls or get stuck in the needles-and-seats and main jets. Furthermore, it's equally important on alcohol applications to avoid filters with inadequate flow rates and inlet and outlet sizes that are too restrictive.

6 Neglecting routine maintenance on an alcohol system Although alcohol fuel additives can help prevent corrosion and provide lubrication for pumps and other components, alcohol can severely corrode metal objects, especially aluminum, if allowed to remain in contact too long. There is no substitute for a strict maintenance program. It will prolong the life of the carburetor and fuel system and also keep it trouble-free.

The right fuel pump for the job makes a world of difference. Pressures in the alcohol system are different from the gasoline system. Make your components match the task.

The right fuel pump for the job makes a world of difference. Pressures in the alcohol system are different from the gasoline system. Make your components match the task.

Alcohol will naturally absorb water from the air. This not only dilutes the fuel, but also adds to the corrosive effects of alcohol. After every race, the alcohol should be drained from the race car and stored in air-tight containers. A vented fuel cell is not considered an appropriate storage container.

The fuel system and carburetor should also be thoroughly drained and flushed of any residual alcohol. Some racers will add gasoline to the empty fuel cell and run the engine until they are certain the carburetor is filled with gasoline.

Other methods include removing the carburetor and flushing it with a cleaning solvent or lubricating aerosol sprays. Removing inlet and outlet fittings from the pumps, bypasses, etc. and lubricating the internals is also an acceptable practice. Whatever the method, maintenance on an alcohol system is crucial. If you ignore it, the system will fail.

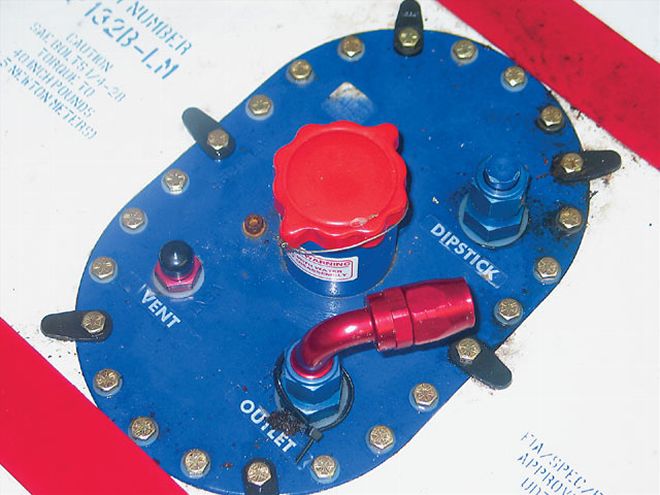

Proper fuel cell venting is important. This ATL cell is clearly marked for getting the best fuel delivery. The venting will be an important consideration when the system is put into place.

Proper fuel cell venting is important. This ATL cell is clearly marked for getting the best fuel delivery. The venting will be an important consideration when the system is put into place.

7 Failing to use a high-flow air cleaner Race engines rely on receiving air as well as fuel, but are frequently starved by the use of thin, small-diameter air filters that are detrimental to their performance. If possible, use a filter that is 14 inches in diameter and 4 inches tall. If clearance is at a premium, get one with a recessed pan, which allows for deeper filter elements. Also, get a good-quality air filter. If you're constantly cleaning dirt from the surface of your race car, your air cleaner is struggling to filter the dirt and debris from your engine.

8 Deterioration of foam-filled fuel cells Modern military-spec foam-filled fuel cells are compatible with conventional fuels, racing fuels, and alcohol. However, alcohol can cause the foam to deteriorate and it must be renewed once a year. To check the condition of the foam, simply remove the cap and pinch it between finger and thumb. If pieces come away, the foam must be replaced.

9 Lack of proper linkage travel and return springs Make sure that the butterflies of the carburetor are fully open at wide-open throttle. Use a minimum of two good-quality return springs, preferably of stainless steel, and employ them, if possible, in two different places on the linkage. Ensure that the linkage and the return springs operate without interference throughout the full range of throttle travel.

This billet aluminum construction inline fuel filter has a stainless steel element for alcohol or gasoline. If there is a paper element in your fuel filter, it will not work for alcohol applications.

This billet aluminum construction inline fuel filter has a stainless steel element for alcohol or gasoline. If there is a paper element in your fuel filter, it will not work for alcohol applications.

10 Failure to use an adjustable pedal stop It's amazing to consider the large numbers of race cars that have no form of throttle-pedal stop, and it's inexcusable that so many are permitted to compete. Excessive loadings on the linkage, carburetor shafts, and butterflies can cause the mechanisms to distort and jam, and the consequences are usually grim. To avoid the inevitable, use an adjustable pedal stop. At the fully-open throttle position, synchronize the stop on the carburetor with the stop on the pedal.

11 Lacking the proper size of carburetor for the application Having the proper venturi sizes for a given application ensures that the carburetor generates sufficient air speed. Air speed creates the necessary depression (low pressure) to draw fuel through the metering systems and booster venturis into the air stream to be atomized. The Race Demon, which is equipped with removable venturi sleeves and boosters, overcomes most of the sizing problems.

12 Inadequate fuel cell venting If the fuel cell vent is too small, the fuel system can malfunction. In extreme cases, inadequate ventilation can cause permanent damage to the system. As the fuel pump draws fuel from the cell, it needs to be replaced by air. If the vent on the cell is too small, the pump will try to draw the fuel from the cell faster than the air replaces it. This can create a vacuum in the cell, distort its shape, and starve the pump and engine of the fuel it requires.

Having two throttle return springs is the best way to go. Be sure the springs are mounted properly, and check them frequently.

Having two throttle return springs is the best way to go. Be sure the springs are mounted properly, and check them frequently.

13 Filtering of fuel cell vents Just as an undersized vent will adversely affect your fuel system, not having a filter on the vent will cause dirt and debris to enter it. As air replaces the fuel, the vent hose will attract anything that's in the air, including dirt, sand, or debris. These particles will eventually destroy a fuel system as well as an engine.

14 Fuel filter location To protect the fuel pump and carburetor, use a good filter between the tank and fuel pump, and filtered fittings at the carburetor.

15 Inspections Steel braided fittings and aluminum fittings have a life cycle. Over a period of time, the rubber bore will deteriorate, causing the line to either collapse and starve the engine of fuel, or disintegrate and possibly block the passage. Radiator hoses and fan belts are routinely replaced. The same thinking holds true for fuel system components. From a safety and performance standpoint, regularly check the lines and fittings. Try to detect soft or weak spots by feeling the outside of the lines, and visually inspect the internals each season. Keep the connections tight.

The air quality makes a huge difference in the fuel system's production. A well-made and well-maintained air filter of adequate size will improve performance.

You can overcome sizing problems with a removable sleeve model when picking a carburetor. This two-barrel Demon has one sleeve installed for illustration purposes. Several sleeve sizes are available.

This is the schematic of a system that uses a throttle bypass.

This fuel system uses a belt-driven fuel pump with diaphragm bypass.