E-mail: [email protected] * Mail: HOT ROD PIT STOP, 6420 Wilshire Blvd., Los Angeles, CA 90048 * Fax: 323/782-2223 * Message Board: HOTROD.com

Working on your car shouldn't be a "wrenching" experience. If you've got a problem, an engine buildup in mind, or even a theory question, this is the place to get it answered. Send your questions here to Pit Stop and I'll answer as many as I can in the pages of HOT ROD. When e-mailing, please include Pit Stop in the subject line. You must also include your real first and last name (not screen name), and hometown or military unit, base, or ship in the message. Don't forget that I'd also like to see any of your digital photos of the cars or problems that you're working on, and if they're at least 300 dpi at 4x4 inches or larger, we might print them in the magazine if I select your letter as one to be answered in print.-Marlan Davis

Fluid Line sizing

I am building a 362ci Olds engine with an Engle 20-22 cam and street-ported cast heads with 2.000-inch intake and 1.625-inch exhaust valves. The compression ratio will be between 9.0:1 and 10:1. I want to run an Offy dual-quad manifold with 500-cfm Edelbrock carbs. The engine will go into an '87 Olds 442 and be primarily street driven.

I would like to run a mechanical fuel pump. I came across two choices: a Holley PN 12-836 or a Mr. Gasket PN 7709. Both are rated at 80 gph and 7.5 to 8 psi shutoff. Is 80 gph enough volume for dual quads? The stock fuel-line diameter is 51/416 inch. Should I run a 31/48-inch line back to the tank? Is a regulator necessary?Bob SlifkaDowners Grove, IL

An engine's fuel requirement is based on its power output as expressed by the brake specific fuel consumption (BSFC) number, a measure of how many pounds of fuel the engine needs to make 1 hp for 1 hour (hp/hr). In other words, if the engine makes 400 hp and its BSFC number is 0.50, then it theoretically requires 400 x 0.50 or 200 pounds of fuel per hour of operation. Usually BSFC is measured on an engine dyno. If you don't know BSFC, 0.50 is a good number to use for a typical carbureted engine. But it pays to have a safety margin of at least 50 percent, so for a fudge factor multiply the engine's peak horsepower by 0.75.

This gives you the amount of fuel in lb/hr, but most flowcharts, filters, and fuel pumps are rated in gallons per hour (gph) or gallons per minute (gpm). The actual weight of gasoline varies by temperature, density, and the particular molecular composition of the gas you're using, but a good rule of thumb is that one gallon of gas weighs about 6.2 pounds. So, if we had a 400hp engine, how much flow capability in gph do we need, assuming a 50 percent safety margin? See the above equation.

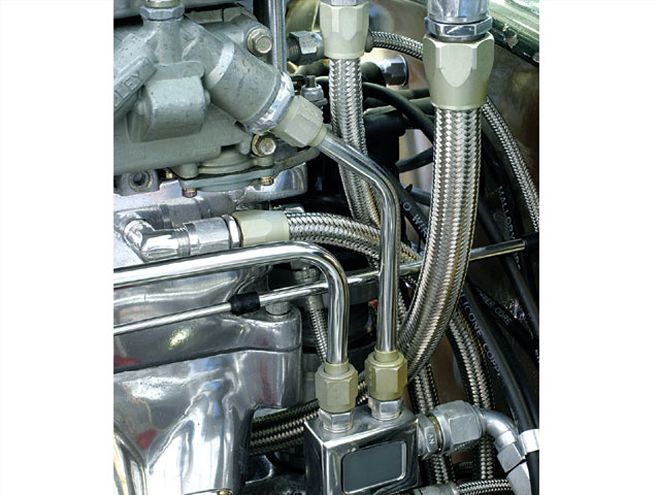

The next step is to choose a fuel pump, fuel line, and filter capable of meeting this criterion. Reputable aftermarket companies publish the ratings of their filters and pumps, but what about the plumbing? The flow/velocity chart on page 140, developed by Weatherhead, shows required fluid-line id (inside diameter) for typical fuel and oil systems. Use the low-pressure fuel-system line with carburetors; for fuel injection, the high-pressure line is acceptable. The chart is calibrated in gpm rather than gph. There are 60 minutes in one hour, so merely divide gph by 60 to determine gpm (0.810 for the above example). The chart indicates an id of just over 0.370 inch is needed for a 0.810 gpm low-pressure fuel system. If the horizontal flow line and the vertical velocity line intersect between two diagonal lines, normally the larger inside diameter would be selected since it would mean less velocity.

Note that rubber hose is rated by id, but tubing is rated by its outer diameter (od). For example, 31/48 tubing has a 31/48 -inch od, which is why 31/48 -id rubber hose fits over 31/48 -od tubing. To find the actual tubing id, subtract double its wall thickness from the od. Typically 0.0350-inch-wall tubing is used for common steel fuel-line, so if you want to end up with a 0.3700-inch id, in theory 71/416-inch-od tubing is about right (0.4375 - [0.0350 x 2] = 0.3675). But that size is uncommon, so we'd move up to the next larger size (11/42 inch).

Assuming the referenced fuel pumps are adequate for the engine's power level, neither needs a regulator.

Las Lowdown

What's the deal with different lobe-separation-angle numbers on identical-lift camshafts? And would a '95 Ford Lightning cam work on a carbureted 302? The engine would be going into either a '65 Falcon wagon or '73 Maverick. I'm looking for excellent torque and good horsepower for highway passing. What are the cam specs for the '93-'95 Lightning anyway?David James HillyerWoodville, TX

Lobe separation, also called "lobe displacement angle" (LDA), is obtained by dividing the sum of the intake-lobe centerline and the exhaust-lobe centerline by two; it is ground into the cam and can't be changed during installation. Don't confuse it with lobe centerline, which is the angle in crank degrees between the max-lift points of the intake and exhaust lobes; the centerline can be altered during cam installation. Cam timing is considered advanced when the installed intake-lobe centerline is a lower number than the LDA.

A typical LDA for a street/strip carbureted-application camshaft is 110 degrees. Wider LDA is a higher number (say, 114 degrees for an EFI cam) or a lower number for a narrower LDA (like 106 degrees).

Considering otherwise-identical cams, the cam with a narrower LDA has more overlap. It will have more midrange torque and the engine should rev faster. The cam with a wide LDA usually has a broader powerband and more peak power at the price of somewhat lazier initial response. A street cam with a wide LDA has higher vacuum and a smoother idle. The wide-LDA cam also has more piston-to-valve clearance at TDC than an otherwise-identical narrow-LDA cam. Because they have less overlap, a wide-LDA cam is usually cleaner from an emissions standpoint.

One other factor is connecting-rod length versus crankshaft stroke (R/S ratio). Higher R/S ratios increase piston dwell time near TDC. This makes the engine act like it has increased overlap. Higher R/S ratios also increase the intake-charge signal by accelerating the piston more quickly after it moves away from TDC. On otherwise-identical-displacement engines, the one having longer rods, a higher R/S ratio, and a longer stroke generally needs a wider LDA cam to get power to peak at the same rpm point.

On the street, LDA should be tailored to the induction system in use. Typical carbureted, dual-plane manifold apps work best with 110-112 LDAs, while fuel-injected combos want slightly wider 112-114-degree LDAs. Fuel injection doesn't require the signal during overlap that carburetors need to provide correct fuel atomization, and most computer controllers require the additional idle vacuum that results from decreased overlap. Bracket racers with high-stall converters, high compression ratios, single-plane intakes, and large carbs usually want 106-110-degree LDAs.

A supercharger cam needs to carefully tailor the intake-centerline location as well as the exhaust opening and closing points. It would take a whole book to describe all the variables, and research is still ongoing. In general, superchargers want wide, 112-116-degree LDAs and minimal overlap. Superchargers generate a large amount of exhaust volume compared to inlet volume, so they need dual-pattern cams that have as much as 14-20 degrees more exhaust duration at 0.050-inch tappet lift and as much as 0.020-inch more valve lift.

As for the '93-'95 Ford Lightning cam, this is a hydraulic flat-tappet cam, PN D3OZ-6250-A. It's ground 1 degree retarded with a 114.5-degree LDA, and the exhaust side is way larger than the intake side (see spec chart). Not bad for a blower cam, right? But as the "D3" in Ford's part number nomenclature indicates, the cam was originally introduced back in 1973-for a 351W Torino smog motor. It was also used on carbureted '82-'84 302-H.O. Mustangs. Not that it'll run bad in a classic, free-flowing musclecar engine, but there are just so many better choices out there these days. For your application, I'd take a close look at a Comp Cams XE262H. It works good between 1,300 and 5,600 rpm. You can keep the stock torque converter, but at least 3.23:1 rear gears are recommended.

If you use the Ford Lightning cam, remember to rewire the distributor to the 351W/late-302-H.O. firing order of 1-3-7-2-6-5-4-8, not the early 289/302 1-5-4-2-6-3-7-8 firing order.

Nitrous And Rev Limiters

I have had conversations with friends regarding whether hitting a rev limiter while on the bottle would do any damage. I never came to any definite answer. I've never heard of anyone doing this, but since a motor revs much higher and faster when on the juice, this is something that someone is bound to run into sooner or later. Could you shed a little light on this for me?Kris AllisonNewberg, OR

This is another one of those "it depends" questions-in this case, it can depend on what type of rev-limiting system is used, as well as the design of the nitrous system itself.

Looking first at a conventional aftermarket rev limiter that controls engine rpm by cutting off ignition spark, there is indeed a lag caused by nitrous-induced engine acceleration. The seemingly simple workaround is adjusting the rev limiter's activation threshold lower than normal. Although this prevents possible overspeed-induced damage, under some conditions there is still a possibility the engine could backfire or experience self-ignition from nitrous and fuel present in the intake and continuing to flow into the engine. The ultimate fail-safe solution is an MSD rpm-activated window switch that activates and deactivates a given electrical circuit as a function of rpm. It can be used to control many different circuits, including a nitrous system's nitrous and fuel solenoids. The window switch works with stock inductive ignitions or an MSD ignition and can handle up to 1.5 amps, so you'll need to add a relay in the system.

The beauty of the window switch is that it also can delay nitrous engagement at low rpm, not just deactivate it up high. Activating nitrous at too low an rpm (generally, below 2,500 rpm) can cause puddling from insufficient air velocity; excessively stress the bottom-end from the shock of suddenly adding 100 lb-ft or more of torque, increase detonation tendencies from the sudden fuel-system strain, and of course blow away the tires.

Instead of interrupting ignition spark, most late-model OEM electronically managed fuel-injected applications limit engine rpm by cutting off the fuel supply (injector-pulse-width goes to zero). By itself this can be deadly when used with a conventional wet nitrous system, which introduces both nitrous and fuel into the intake manifold. On a wet system, added nitrous-enrichment fuel is supplied independently of ECU control and not through the stock fuel injectors. When the stock ECU acts to limit rpm by cutting out the main fuel supply, some fuel is still supplied by the wet system's independent delivery system; with nitrous also continuing to flow, this results in a lean condition and catastrophic detonation.

According to the experts at ZEX, the solution is a dry nitrous system, which supplies added nitrous-enrichment fuel by increasing fuel delivery through the existing injectors, usually through turning up the fuel pressure. Because all fuel must pass through the ECU-controlled injectors, activation of the rev-limiting function eliminates all fuel-flow into the engine. With 100 percent fuel removal, combustion cannot occur no matter how much nitrous still flows into the engine. Without combustion, there's no detonation. With no fuel puddling in the intake, there's less chance of backfire. It's one case where no fuel at all is better than too little fuel.

The very latest engines (including Ford Modular motors and GM Gen III engines except '97 Corvette) have a returnless fuel system with no pressure regulator in the engine compartment. Those dry systems that depend on raising the fuel pressure for fuel enrichment won't work; however, other dry systems use injector pulse-width modulation for fuel enrichment, which would be acceptable up to the limits of the injector's duty-cycle. These late engines could also default back to a wet system if the window switch is also used. In the case of GM and similar late engines where each ignition coil has its own self-contained driver, this requires MSD's newest digital window switch to pick up the ECU's tach output signal.

Driveshaft Hits Floorpan

I recently purchased a '66 GTO from a musclecar dealer. The problem I have is with the driveshaft not having enough clearance from the floorboard. When I have passengers riding in the back, the front U-joints where the shaft couples with the tranny hit the floorboard on heavy deceleration or when any bumps in the road are hit. I have installed air shocks, which seem to help a little, but only when they are full and just one person rides in the back. Should I change all four springs? Someone even suggested that the body could be shimmed up, though I never have heard of this. Please help.Egils BurgisIndianapolis, IN

There have been reports that this problem sometimes occurred even on brand-new A-bodies of that era-things just weren't as scienced out back in the so-called good old days. Anyhow, suspension springs act on the frame, and the body bolts to the frame, so installing springs to raise the car raises everything. Shimming the body could throw off the alignment of parts that connect to both the body and chassis/drivetrain parts, like the steering column. It's better to attack the problem head on rather than crutch it.

Start by replacing the engine and trans mounts; they may be old and sagging or broken. Next up, many of these cars have been jacked up in the wrong place, which can tweak the frame and crossmember area-or the car may have just been hit. So you need to at least eyeball the frame and see if it's been dinged, although having it dimensionally checked at a frame shop is preferred.

I'd also look at the body bushings. As they age they get soft and compress more. Replace them and the car will feel like it's brand-new. Original Parts Group is one source for new body bushings.

Finally, on the GTO the trans crossmember mounts on rubber insulators on top of the frame. You could try eliminating the insulators and bolting it solid to the frame to gain about 11/42 inch more clearance. This may misalign the pinion angle, which should be rechecked and corrected as necessary.

As a last resort, there's always the Neanderthal approach: Carefully clearance the floorpan in the area of interference with a large wood block on a floor jack (ugh).

Blown Hemi Buildup

I plan on building a 1,000-plus-horsepower, pump-gas, blown, injected Hemi. Here is a list of components I am considering:

*7.5:1 pistons*12-71 blower with pulley ratio for 20 psi boost*Blower Drive Service 16-nozzle electronic fuel injection with bugcatcher scoop*Billet crank*Dry-sump oil system

Please tell me what you think. I would also like your opinion on whether or not to use an aluminum block and connecting rods. I only plan on driving it 1,000-2,000 miles a year. Also, some suggestions on cams would be helpful.John LubisichFresno, CA

Pump gas is the limiting factor here. It requires holding max boost down to 12 psi or less. You can still reach the power goal by substituting cubic inches for raw boost: Build a 528 (4.5-inch bore x 4.15-inch stroke). Mopar Performance offers a cast-iron siamesed-bore Hemi block that comes rough-bored at 4.498 inches (PN P5007623), though they are currently out of production and difficult to obtain. Even so, I'd stay away from aluminum blocks, which sometimes have porosity problems and will often leak in a street application. Besides, a Hemi aluminum block could cost almost as much as the rest of the engine.

I also prefer steel rods on the street. Aluminum rods have a finite fatigue life and huffing 1,000 hp for a couple thousand miles a year on aluminum rods could get dicey.

It's hard to zero in on the cam without knowing about the vehicle the engine is going in, what you're looking at in terms of the trans and rearend ratio, and how much real street driving this combo will actually see. Assuming about a 3,500-pound car, an automatic trans with a 3,000-stall converter, at least 4.10:1 rear gears, and a goal of reasonable valvespring pressures and valvetrain component life, we asked Comp Cams and Crane Cams for their recommendations (see the accompanying table). Generically, for a street-driven car I would not recommend exceeding 0.675-inch lift or 275 degrees duration (at 0.050). With the Hemi combustion chamber, hold lobe separation (intake/exhaust lobe displacement angle) between 112-116 degrees to avoid excessive blow-through.

If it's subjected to extended street idling, beware of Hemi mechanical-roller-lifter oiling problems. Most Hemi solid-roller lifters are intended for full-race use and lack sufficient trunion lubrication for sustained low-rpm operation. A solution is special lifters with pressurized oiling to this critical area that are available from Jesel (but they're pricey).

Everything else about the projected combo-including your plans for a 7.5:1 compression ratio, 16-nozzle fuel-injection, and dry-sump oil system-should work OK

Olds V-8 Balance

I have a '71 Olds 455 engine. Is it externally or internally balanced?Jimi CoffeyVerona, NY

As manufactured, the Olds is externally balanced, with weights on both the harmonic damper and flywheel or flexplate

Where Do I Get

...books on building molds to make fiberglass or carbon-fiber parts? I want to build lightweight front fenders for my '71 Chevelle SS.Fargo RaySomerset, PA

Check out Fiberglass and Composite Materials by Forbes Aird (HP Books PN HPB1239, ISBN 1557882398), published by The Penguin Group USA Inc. (New York, NY; 800/223-0510 or 212/366-2385; www.penguinputnam.com) and Competition Car Composites: A Practical Guide by Simon McBeath (ISBN 1859606245), published by Motorbooks International (Osceola, WI; 800/826-6600 or 715/294-3345; www.motorbooks.com).

...the parts to swap the original flathead V-8 engine and three-speed/overdrive in my '50 Ford car with a new Ford V-8 engine and automatic transmission?James WilliamsRacine, WV

Speedway Motors Inc. (Lincoln, NE; 402/323-3200; www.speedwaymotors.com) can fix you up with small-block Ford engine mounts (PN 1353764), frame adapters (PN 1353294), and cushions (PN 7209314), as well as a variety of universal trans crossmembers with various center-drops.

...in touch with companies that specialize in dropping a big-block Chevy/TH400 combo into an '84 El Camino?Tony PetersonPeoria, AZ

The big-block installs using Chevy small-block engine mounts and brackets, but clearance mods for the heater-core box may be needed. Headers are available from Hooker Headers (A Division of Holley; Bowling Green, KY; 270/781-9741 [tech] or 800/HOLLEY-1 ext. 8530 [nearest dealer]; www.ilovemyhookerheaders.com) and Hedman Hustler Hedders (Alpharetta, GA; 770/664-8880; www.hedman.com). G-Force Performance (Remsenburg, NY; 631/325-7947; www.crossmembers.com) has double-hump transmission crossmembers.