All the parts are here for the makings of an ideal bottom end, with Federal Mogul's excellent H116CP hypereutectic pistons filling the 360's bores. Too bad the decks weren't zeroed to let the pistons make the most of the closed-chamber heads.

All the parts are here for the makings of an ideal bottom end, with Federal Mogul's excellent H116CP hypereutectic pistons filling the 360's bores. Too bad the decks weren't zeroed to let the pistons make the most of the closed-chamber heads.

It's a common misconception, bigger has to be better, right? when it comes to the selection of engine parts, nothing can be farther from the truth. Take, for example, the camshaft. A typical hydraulic cam can cost somewhere in the ballpark of 150 bucks. Now, if you feel you have to have the biggest one available, and you find out after you put the engine together that it doesn't work with your combination, what's it going to cost to tear the engine down and replace it with what the manufacturer suggested in the first place? How about the intake choice? How often have you heard someone say they have a single plane intake on their stock 360? Sure, that single plane may look racier on your engine. But how often is the combo your running going to see any rpm above 6,000, where a single plane is optimized. Again, the choices you make before you build are crucial to an optimized engine combo. A buddy of ours had a strong running 360 swapped into his nicely done '68 Barracuda. The engine ran fine on pump gas while delivering good pulling power up to the 6,000 rpm range. It also had enough of a lope with the Mopar Performance "508" cam to get noticed at cruise nights. After several years of running this combo, he was looking to remove the 360 primarily for detailing and decided to step up the basic combo just a little while the engine was out.

The best parts money can buy won't necessarily make for an optimally performing motor. The aggressive XE295 HL is a stout beast of a cam, but to take advantage of the specs you'd better look to prepare your combination to rpm big time. The (PN 26915) beehive springs will rev like crazy in an LS1, but with the heavy Mopar valvetrain worked by a super aggressive hydraulic camshaft, the application is just wrong.

The best parts money can buy won't necessarily make for an optimally performing motor. The aggressive XE295 HL is a stout beast of a cam, but to take advantage of the specs you'd better look to prepare your combination to rpm big time. The (PN 26915) beehive springs will rev like crazy in an LS1, but with the heavy Mopar valvetrain worked by a super aggressive hydraulic camshaft, the application is just wrong.

The Baseline Combo

The 360 was about as typical a combination as you'll ever see in a street small-block. Starting at the bottom end, the block was bored .020-over and fitted with a set of federal Mogul flattop pistons at a negative .020-inch deck. This put the compression ratio at 9.8:1. The stock rods and crank were retained, but reconditioned. Providing the engine's character was an MP .508 cam with a rated duration of 292 degrees, and reportedly having a duration at .050-inch of 248-degrees. Ground on a 108-degree lobe separation angle, the "508" small-block cam is known for its radical lopey idle-just the sound of power the builder was after. The valvetrain combo included a set of Comp Cams Pro Magnum steel-bodied, roller-tipped rockers. Topping the short-block was a pair of common 587-casting production heads, which had received basic reconditioning, and an increase in intake valve size to 2.02-inch. The heads were pocket ported, but never flow tested. Providing the induction, a Mopar Performance M-1 intake worked in conjunction with a 750 Speed Demon carb.

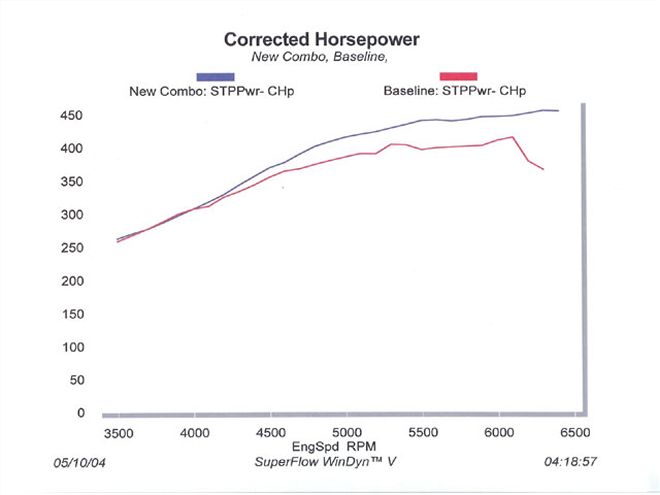

With the engine out of the car, we had the opportunity to baseline this combo on the dyno. The engine was taken to Westech Performance Group for initial testing, using the same pair of 1 5/8-inch tube headers as run in the car, but flowing through the dyno's set of Flowmaster 3-inch mufflers. With some basic tuning, the 360 delivered very good output considering the basic combination, netting 416.5 lb-ft of torque and 416 hp. With that, the satisfied owner took his engine home for a teardown and detailing, and began to formulate the upgrade plans.

Parts Department

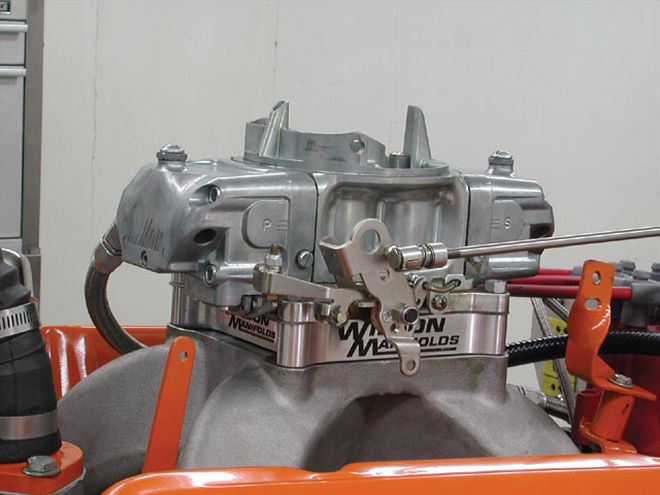

The first change our pal had in mind was making a move to a more modern camshaft profile. he had heard good things about the Comp XE HL series of hydraulics, which are some very fast-acting and aggressive .904-inch lifter profiles. There are basically three XE HL camshafts available for the Mopar small block, ranging in duration from 275 to 285 to 295-degrees. Mistake one occured when our friend chose to go with the XE 295 HL, the biggest of the series, with a whopping 251/257 duration at .050-inch lift and .564-inch lift. The engine can't have less lope than it started with, right? This cam is rated to 6,800 rpm, well past the intended rpm range of this 360, but the decision was made to over-cam the engine for the wild sound and big lope. To control the cam action, a set of Comp's latest beehive springs (PN 26915) designed for the LS1 were picked. That was mistake number two. The Comp Cams LS1Beehive springs are an excellent spring when used as intended, but with only 105 pounds on the seat and 280 pounds over the nose, these springs would have to work miracles to control the intense action of the XE HL profile. A good choice was made when our friend decided to use a set of mildly ported Edelbrock heads, a nice upgrade from the production iron 587's.

Buttoning It Up

The engine was cleaned and detailed as planned, and the new cam installed, along with a new double roller timing chain and Mopar's timing chain tensioner kit. With the aluminum heads in place, the engine certainly did look like a much more serious piece than the older version of the engine. It was put up on the dyno to determine if the added punch would match its looks. Back to Westech, and the engine was once again fitted with the 1 5/8-inch headers and the identical induction system used in the previous baseline testing. No additional parts were brought to the party, so the entire day was devoted to tuning. In the end, the engine showed 439.8 lb-ft of torque and 456 hp-a gain of 23 lb-ft of torque and 40 hp.

Critical Analysis

While the power gains were nothing to scoff at, and 450-plus horsepower from a 360 small-block is pretty stout output, we had to believe there was more in the combo. These power levels could likely have been achieved with the smallest of the HL series cams-the 275-with better power production through the midrange. With the relatively small header and moderate compression ratio, the camshaft was much bigger than optimal. Frankly, in the correct combination, to make use of a cam that large, the engine speed at peak power should have been closer to 6,800-7,000 rpm instead of 6,300. Conspiring to hold the rpm range down was the spring choice. The 26915 spring is designed for a very specific application known for an exceptionally light valvetrain with very low inertia. In this application, the cam/spring combo was simply not appropriate to maintain control of the radical action of the HL cam and relatively heavy valvetrain. The (PN 26120) beehive-spring is designed for big-block Chevy applications, but easily adaptable to the small Mopar, and likely would have fared better. This theory was borne out when the engine was later installed back into the car, and valve float became more readily apparent, particularly under the faster engine acceleration rates experienced through first gear.

The detail that raised our hackles more than any other-there was no effort to machine the block for a zero deck height. With the closed chamber Edelbrock heads, a zero deck would have provided the advantage of an optimal .040-inch quench clearance. As it was, the pistons remained .020-inch in the hole, opening the quench number up to .060-inch, far from ideal and a definite disadvantage in detonation tolerance and engine output. There may well have been another 10-15 lb-ft tossed out because of the .020-inch of extra clearance. The increase of a couple of tenths of a point in compression ratio resulting from decking the block would also have been welcome with the aluminum heads.

Too much cam, too little compression, not enough spring, too little header, dead quench, and way short on rpm can cripple a combo. Power was up, but considering the effort and parts list, these cats missed the mark by a mile. Details and planning make the difference.

Too much cam, too little compression, not enough spring, too little header, dead quench, and way short on rpm can cripple a combo. Power was up, but considering the effort and parts list, these cats missed the mark by a mile. Details and planning make the difference.

Considering The Combo

The Overall Picture

There's just no way to break component selection down on a part-by-part basis without having a good handle on the overall picture. Before buying anything, the goals of the build-up have to be clearly in mind. Will it be a mild, pump-gas cruiser built to rack the miles up while delivering a satisfying punch? A low-buck time bomb built for max power at a minimum outlay (for as long as it holds together)? A cost-is-no-object dragstrip crusher? A big-inch, moderate-rpm torque churner? A gas-sipping econo mill? The possibilities are limited only by your imagination, but the plan has to be locked down to make the right decisions in parts selection.

Defining the goals sets the constraints of the build, and the parts selected that will work best within these constraints. Before moving on, you should have a handle on the engines displacement, a rough idea of the budget, the upper-and-lower working rpm limits, the fuel requirements, and the targeted power output.

The big single plane is tossing torque out the window at the rpm range involved here. If the cam was working to its rpm potential, it probably would have been a good choice. Since the combo was off, so was power.

The big single plane is tossing torque out the window at the rpm range involved here. If the cam was working to its rpm potential, it probably would have been a good choice. Since the combo was off, so was power.

Ratio Rationale

The compression ratio should be dialed in to the optimal level for the buildup, but this isn't always the case. If budget is one of the key constraints, sometimes the compression ratio is already pretty much set by the pistons and heads at hand. Ideally, the ratio choice should be set by the fuel requirements of the completed engine. Compression ratio is a key component in both power and efficiency, so it pays to spend the time to get it right.

Compression ratio is directly related to cylinder pressure, and typically more pressure will result in more power. While the ratio is a big part of making pressure, it is actually only half the picture. The other half is the camshaft, since the compressing doesn't begin until the valves are shut. The cam and compression are closely related, and really should be considered together when working out a combination. The rule of thumb is simple: the bigger the cam, the more ratio that can and should be used. There are numerous other factors that also affect the amount of ratio and, ultimately, cylinder pressure the engine will tolerate. These fall into two basic categories: thermal management and combustion efficiency. Basically, these are the details that separate a well scienced-out engine from a regular bolt-together job.

This graph illustrates the change in horsepower output with the reworked 360. We didn't write this article to badmouth anyone. On the contrary, the parts used were excellent pieces, but this will show what happens when the build is not a well-thought-out execution, and manufacturer's recommendations are not followed. So keep in mind, a lot more power potential was hidden within this engine, if the owner would have only asked a couple questions of the manufacturer.

This graph illustrates the change in horsepower output with the reworked 360. We didn't write this article to badmouth anyone. On the contrary, the parts used were excellent pieces, but this will show what happens when the build is not a well-thought-out execution, and manufacturer's recommendations are not followed. So keep in mind, a lot more power potential was hidden within this engine, if the owner would have only asked a couple questions of the manufacturer.

Combustion efficiency includes chamber design, squish/quench, swirl/tumble, ring placement, and plug location. There's no way for the average Joe to evaluate this stuff, but he can pick a head with good quench, a compact chamber, and a deep plug location. Thermal management is easier to picture and has a significant affect on how much ratio you can run. Compressing a gas creates heat, so more ratio means more heat and pressure in the chamber. If we could subtract some of the heat in the gas, some more pressure can be added in. Simple, huh? Steps here include blocking the exhaust heat crossover, adding a cold air induction, and, finally, employing thermal barrier coatings. Coatings are most effective on the valves, particularly the exhaust; other areas to consider are the manifold, chambers, piston tops, and even the ports themselves. A good gauge of the balance of compression ratio and cam timing is in the cranking compression of the assembled engine. A good, strong, street/strip, pump-gas engine will typically have a cranking compression of 180 psi; a highly scienced-out engine may approach 200 psi while still swilling pump brew.

Which do you think will make more power?

Hyd Flat TappetSolid Flat TappetHyd RollerSolid RollerCostLeastModerateHighHighEase Of InstallSimplestModerateModerateModerate AggressivenessModerateModerateHighHighestPower BandNarrowestGoodBroadBroadestRPM CapacityModerateHighModerateHighestLongevityHighGoodHighModerate Camshaft Considerations <strong>Camshaft Considerations</strong><br>The camshaft is the heart of the engine, and will affect virtually every aspect of how the engine will run. The cam alone will not make huge power if the other players are not in place, and some of the key teammates to the camshaft are the cylinder heads, induction, exhaust, and the compression ratio. The first decision has to revolve around what type of camshaft will be used. Here's a little chart to break down the characteristics of each.

<strong>Camshaft Considerations</strong><br>The camshaft is the heart of the engine, and will affect virtually every aspect of how the engine will run. The cam alone will not make huge power if the other players are not in place, and some of the key teammates to the camshaft are the cylinder heads, induction, exhaust, and the compression ratio. The first decision has to revolve around what type of camshaft will be used. Here's a little chart to break down the characteristics of each.

The next question has to do with the specs of the cam, which is dictated by the actual grind put on the camshaft. There's four key factors here: lift, duration, lobe separation, and the final aspect the actual lobe design, given by the series of camshaft. Herein lies the toughest decision in building the engine-which cam series to use and what specs. Making the correct selection takes experience and an understanding of how the various specs affect the engine's running characteristics and powerband, and interacts with one another. In most cases, the best chance of success is to talk to an expert, be it an engine builder with plenty of experience with your type of engine, or consult with the cam manufactures directly. Comp Cams offers free tech advice on their CamHelp line (800/999-0853). A wrong decision here can seriously set back the combination.

A camshaft requires the rest of the valvetrain to be up to the task to get the most from its designed performance. First on the list is the appropriate valvesprings, correctly installed. Hydraulics can be particularly problematic if the goal is very high rpm, since the slightest false motion will begin to upset the delicate balance of the hydraulic mechanism. Most manufactures recommend specific springs or load levels for a given lobe, and these recommendations are typically a safe bet for most applications. If you decide to stray away from the recommended springs, you'd better have a good reason for making the change, and be prepared for some testing and trial and error before hitting on the ideal combo. Always pay strict attention to the installed height, coil bind clearance, and open and closed load, as installed.

Induction Investigation

The induction system has a very important role in providing for the air and fuel mixture, and delivering it to the cylinder heads. At the top is the carburetor. Here, the primary consideration is the size, typically in CFM of airflow. Various manufactures have published charts in their catalogues making sizing selection a relatively simple matter. Carb size, to a certain point, can be edged up from these base recommendations for a small increase in top-end power, but the danger is in losing sharp throttle response, or potentially having the engine fall over at lower rpm. Here a little judgment is called for. If the car is a deeply geared drag machine with a loose converter, far more carb size can be tolerated before any negative effects become apparent. The fact is the engine never really sees loading at an rpm range low enough to bring the loss of drivability into evidence. Two plane manifolds with true divided plenums can also tolerate more carb size, owing to the 180-degree division of the intake pulses entering each half of the plenum, a factor which increases booster signal. The design of the carb also plays a role. Modern, highly streamlined carbs, such as the Demons or HP-series Holley's have much higher airflow than earlier carbs of similar orifice size, achieving higher flow through efficiency rather than by an increase in venturi and bore size alone. For instance, the Holley 950 HP carries the same critical dimensions as an old 750, but flows 200 more cfm of air. Chances are if it didn't bog or lay down with the 750, the new 950 HP will boost top-end power without giving anything up to the old 750 down low.

Manifold choice is also vital. The two things to consider here are the layout and the airflow capacity. The airflow of the manifold needs to be sufficient to sustain the peak flow potential of the cylinder heads for the combination to work most efficiently. The layout of the manifold is equally important. Here the basic choices are single plane or two plane. Two-plane manifolds will produce more torque lower in the rpm range primarily due to the 180-degree pulse separation inherent in the layout, with a secondary effect favoring the low-end stemming from the longer runner length and reduced plenum volume. A two-plane manifold virtually always favors engines built for power under 5,500 rpm. Up to engine speeds of 6,500 with street-type cylinder heads, the latest crop of high-performance two planes (such as the Edelbrock Performer RPM AirGap) will generally provide top-end output on par with a single plane, while retaining the two plane's inherent low-end torque advantage. The advantage of the two plane is typically 20-25 lb-ft at the low-to-mid range in comparison to a single plane. Higher engine speeds or race-type cylinder heads will require the airflow capacity of a single plane for optimal high-rpm output. Carefully consider the intended rpm range and airflow requirements when selecting an intake manifold.