Back in the turbulent '60s, a young Bob Dylan proclaimed, "The times they are a-changin'." Roughly a half century later, automotive engineering has continued to deliver on that theme. Among this constant evolution is plastic (more accurately, polytetrafluoroethylene or PTFE) fuel lines and odd-looking steel fuel-line quick-disconnect (QD) fittings. The PTFE lines are designed to create a vapor barrier and should last nearly forever, and with that, the connectors have indeed become true quick-disconnect fittings. But they only live up to their name if you know the secret to creating separation. For the most part, reassembly is a snap—literally, as these fittings click together by hand. Disassembly takes only slightly more effort and a simple plastic tool. Just like anything else in the world, if you know the trick to making this all work, the steps are easy. We'll fill that knowledge gap and make you the neighborhood expert. We will be dealing with the GM LS engine QDs here, but Ford connectors operate in a similar fashion, although they require a different tool. Some Chrysler QDs are also similar to the GM connectors. What makes this whole process attractive is that the necessary tools are very affordable.

We'll start with a quick how-to and then follow up with the latest on aftermarket adapter fittings that allow you to connect AN lines to the GM fittings. There are lots of options when it comes to adapting these fuel-line fittings, so there's bound to be several fittings that will meet your needs.

Pressure Play

Car builders tend to take fuel and fuel-delivery systems for granted. But it's worth mentioning that GM factory fuel systems operate at a nominal pressure of 50-plus psi. Even with a stock fuel pump at 58 psi, a small leak can instantly turn into a nasty conflagration. We mention this only to reinforce the importance of using quality products and installing them with an attention to detail. When assembled properly, a quality LS engine fuel system will last a long time. Any other approach is merely asking for trouble.

Parts List

For both safety and emissions reasons, all new-car manufacturers have eliminated rubber fuel line from their cars, moving to quick-disconnect (QD) fittings.

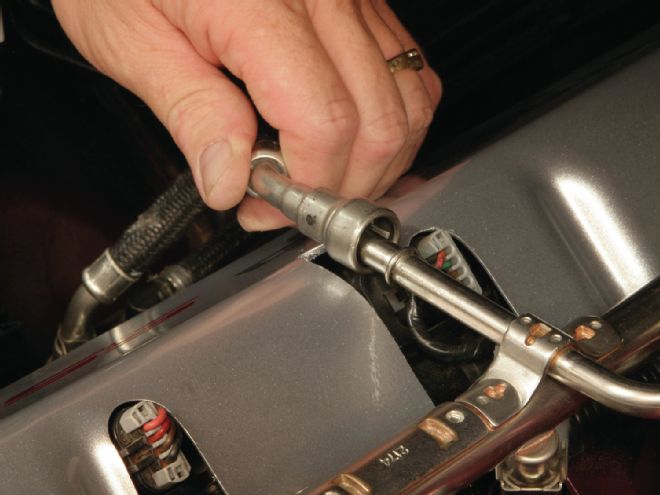

The first step to removing a factory fuel line is to bleed off any residual line pressure in the system. On this LS engine, this is as simple as removing the small knurled cap from the fuel-line tap and using a small awl or punch to depress the Schrader valve and bleed off any fuel pressure. Use a rag or paper towel to collect the fuel.

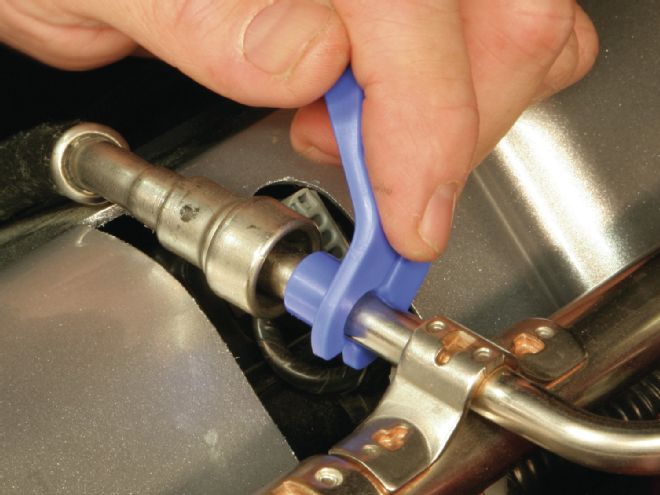

Newer GM cars are now equipped with this redundant clip that must be removed first. Simply pull up on the clip tab, and it will release from the fuel line. This clip is used to ensure that when the fuel line is reattached, it is fully engaged in the fitting.

To disassemble the GM QD fuel fittings, you will need a collection of these small plastic release tools. This is a Lisle angled QD fuel-line kit (PN 39400). Your local tool outlet probably carries this, but we found it on eBay for roughly $13. You can also buy the individual release tools for as little at $4.

Most LS engines use a 3⁄8-inch high-pressure line, which uses the blue plastic Lisle tool. Slip the tool over the fuel line and push the tapered portion of the tool into the fitting. Smaller fuel-return lines are usually 5⁄16 inch.

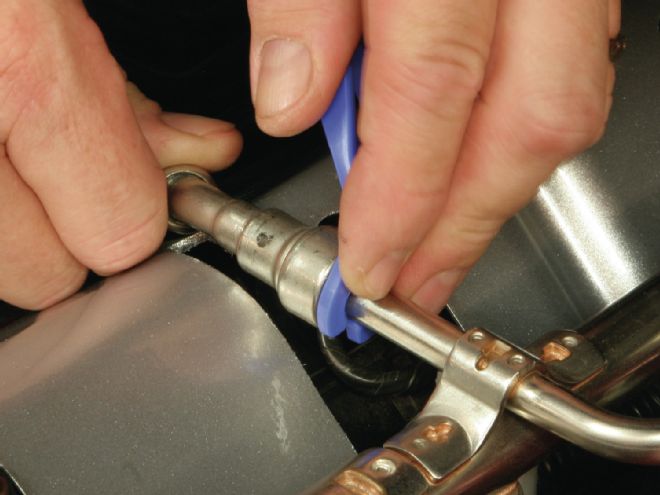

Once the tool is pushed completely into the fitting, it should release. You might have to wiggle the tool slightly, but the tapered portion of the tool should release the fitting.

The QD fitting will now release. It's that simple. Reconnecting the line is even easier, as it merely snaps back together and the clip is reinstalled.

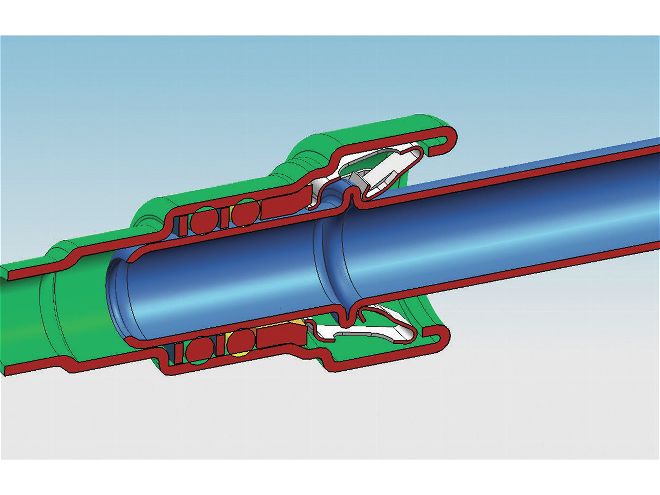

Our pals at Tech AFX sent us this slick cutaway drawing of the factory QD fitting. You can see the double O-ring seal that ensures the leak-free connection. You can also see how the simple tool enters and releases the clip that holds this whole rascal together.

Russell makes an adapter to connect the GM 3⁄8-inch male to AN -6, as can be seen here used on a GM fuel filter (PN 640850). This version uses a plastic clip that we strongly recommend against using. We've seen these come apart under vibration and pressure with disastrous consequences. Russell now makes an aluminum adapter that appears to be far better.

This is the revised Russell adapter with the aluminum adapter ring (PN 640850). This fitting appears to create a far more accurate connection and is available in black or blue. Russell also has several other GM and Ford QD adapters that can help with just about any fuel-line issue.

Classic Tube offers a very nice hydraulic flaring tool that makes the 5⁄16 and 3⁄8 GM QD flares on steel or aluminum tubing, which allow you to fabricate your own hard lines. This tool is not cheap, but it makes all the basic 45-degree tubing flare fittings, including metric bubble fittings. It can also make AN flare fittings, but you have to purchase a separate die (PN 7205).

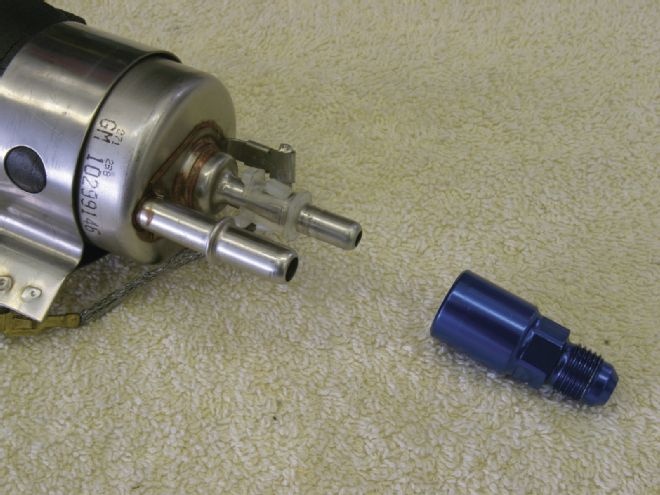

Aeromotive also offers adapter fittings. This is one of its more popular adapters that accept a GM 3⁄8-inch male fuel-line fitting and convert it to a female -08 AN O-ring boss (ORB). If you are not familiar with the ORB designation, the female end of the fitting uses straight threads (not tapered pipe threads) that match a male AN fitting. The seal is accomplished using an O-ring.

Instead of adapters, TechAFX has created 24-inch lengths of factory-style, non-conductive PTFE -6 hose with a GM QD connector on one end. The hose end is open and requires using a TechAFX AN fitting. The QD fittings come in straight or 90-degree versions in either 3⁄8- or 5⁄16-inch sizes.

This would be an example of a -10 ORB fitting that adapts into a fuel pump. If you're in a pinch and are short on fittings, you can use a male AN to adapt to a female ORB fitting using an O-ring as shown (arrow). ORB fittings often do not come with O-rings. Earl's sells packages of Viton O-rings for just that reason. For fuel applications, it's best to use Viton rather than neoprene O-rings, as Viton is far more robust.