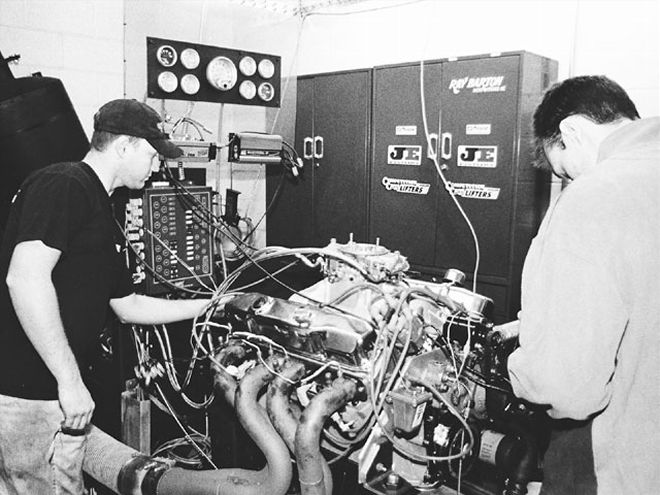

Last month, the engine machining, blueprinting, balancing, and assembly was completed. Here, Clay Fetter (left) and Dave Barton ready our street brute for dyno duties. For baseline dyno pulls, our wedge was equipped with a RBRE .638-inch-lift solid flat-tappet cam and 2 1⁄4-inch dragster-type headers with 4-inch collectors. These dyno headers feature exhaust gas temperature (EGT) probes on each primary tube to monitor exhaust temperature at each cylinder, which is useful in tuning the motor. The baseline began with the 950 Holley HP, and then we switched to the 1,000 Race Demon. The deep-breathing 493 enjoyed the bigger carb, exhaling 5 more horsepower.

Last month, the engine machining, blueprinting, balancing, and assembly was completed. Here, Clay Fetter (left) and Dave Barton ready our street brute for dyno duties. For baseline dyno pulls, our wedge was equipped with a RBRE .638-inch-lift solid flat-tappet cam and 2 1⁄4-inch dragster-type headers with 4-inch collectors. These dyno headers feature exhaust gas temperature (EGT) probes on each primary tube to monitor exhaust temperature at each cylinder, which is useful in tuning the motor. The baseline began with the 950 Holley HP, and then we switched to the 1,000 Race Demon. The deep-breathing 493 enjoyed the bigger carb, exhaling 5 more horsepower.

In the first installment, we put the finishing touches on our Barton RB wedge. We featured some of the balancing, blueprinting, and machining procedures a motor needs. Barton builds all types of motors for all kinds of customers, be it a restoration, a street/strip, a small-block, a big-block, or a Hemi.

Many, but not all, motors completed at Barton's go for dyno testing. Ray gave us the OK to prepare our motor for the dyno, so we installed the distributor, ignition wires, plugs, carburetor, and the oil and filter. Next, the wedge was loaded onto the dyno stand and wheeled into the dyno room for hookup to the water brake.

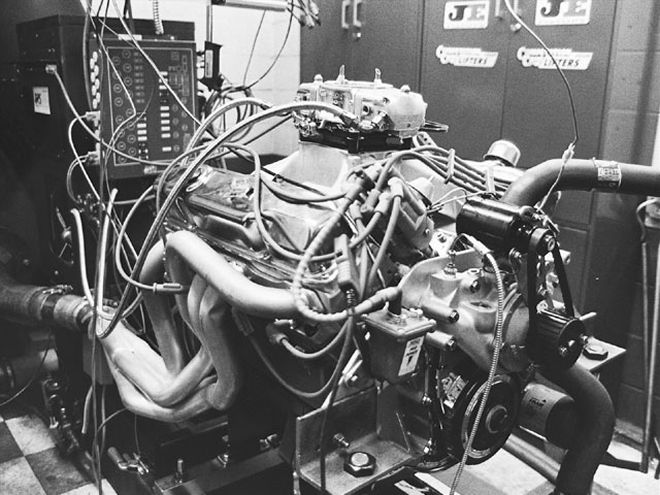

Before dyno testing our motor, Ray mentioned his new DTS dyno is dead-on accurate, but the horsepower readings would be 5 percent lower. For example, a 600hp motor on his new dyno would have shown 630 hp on his old dyno. Here's a brief summary of our RBRE 493: mildly ported Edelbrock heads, 10.8:1 compression, 638-lift solid cam, MP M1 single-plane intake, and Holley 950 HP carburetor.

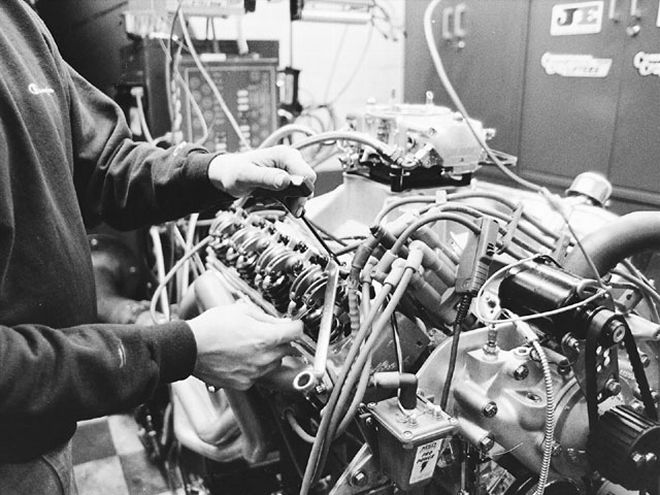

Precautionary measures were taken before the motor was rung out on the dyno. Our motor was warmed up and run at 2,000 to 2,500 rpm for 30 minutes. This ensures proper cam and lifter break-in. Dave Barton handled dyno duties for the day. After cam break-in, we removed each valvespring and returned the inner springs to their home. The valve lash was set, and we were almost ready to rock!

First, Dave made a 5,000 to 5,500-rpm pull and then three 6,000-rpm pulls before letting it rip. Initial testing showed our combo made its most power at 39 degrees total timing. We were comfortable the air/fuel mixture and oil pressure was on, so Dave cranked it up to 7,000 rpm. The dyno's readout told us 615 hp at 6,400 rpm and 596 lb-ft of torque at 3,900 rpm. That's big-time power for any street-driven machine. We made another baseline pull, and our stroker put out identical numbers. With a solid baseline, we were now ready to try a few bolt-ons.

The smaller tti headers with 1 7⁄8 tubes and 3-inch collectors improved the peak torque by 32 lb-ft. Ironically, torque with the 2 1⁄4-inch tubes peaked at 3,900 rpm, while the 1 7⁄8-inch tubes peaked at 4,700 rpm. Still, at 3,900 and 4,700 rpm, the smaller pipes boasted 17 and 51 more lb-ft of torque, respectively. The 3,500 to 6,000-rpm average horsepower and torque gains were 29 hp and 31 lb-ft.

The smaller tti headers with 1 7⁄8 tubes and 3-inch collectors improved the peak torque by 32 lb-ft. Ironically, torque with the 2 1⁄4-inch tubes peaked at 3,900 rpm, while the 1 7⁄8-inch tubes peaked at 4,700 rpm. Still, at 3,900 and 4,700 rpm, the smaller pipes boasted 17 and 51 more lb-ft of torque, respectively. The 3,500 to 6,000-rpm average horsepower and torque gains were 29 hp and 31 lb-ft.

A good friend offered his brand-new, still-in-the-box 1,000-cfm Race Demon carb. Off came the 950 Holley HP, and on went the 1,000 Demon. Two consecutive pulls showed us 5 more horsepower and 2 lb-ft of torque at the same rpm. Our deep-breathing 493 enjoyed a bigger carb. So far, we were on the road to more power. Since they've worked well in drag testing, we tried a Wilson Manifolds carb spacer next. This 1-inch, four-hole, tapered spacer was worth a tenth on both a 360 Challenger and 440 R/T. Once in place, we were astounded when peak horsepower jumped up to 633 at 6,400 rpm, for an increase of 13 hp. This spacer was designed for the single-plane intake, but it worked well on the dual-plane RPM in those previous strip tests.

We felt the dyno headers, with their 2 1⁄4 into 4-inch collectors, were too large for the intended power band of our street motor, which is 3,500 to 6,000 rpm. We had a hunch the smaller tti headers, with 1 7⁄8 tubes into 3-inch collectors, would be more beneficial. The headers are about 12 inches longer and broaden the power range. Since the '60s, 1 7⁄8-inch tubes have been the ideal size headers for a street/strip 440. Would they be the right size headers for our 600-plus-horsepower 493ci motor? On the first dyno pull, the tti street tubes proved to be worth 32 more lb-ft of torque at peak rpm. At 4,700 rpm, they showed us 51 more lb-ft of torque. The smaller tubes lost only 2 hp-631 at 5,900 rpm-but peak horsepower was 500 rpm less. The 3,500-6,000-rpm average horsepower and torque went up 29 and 31 respectively, more than we expected and great for better street driving.

Mike Barton degreed-in the roller cam for us. A camshaft can't perform properly unless it's been degreed according to the cam card. Naturally, we could have advanced or retarded the cam to move the power curve around, but we didn't in order to have a fair comparison. The same RBRE 3-bolt steel billet timing set was used for both cams. Mike also observed the gross lift to check the cam lift and rocker geometry, which were right on.

Mike Barton degreed-in the roller cam for us. A camshaft can't perform properly unless it's been degreed according to the cam card. Naturally, we could have advanced or retarded the cam to move the power curve around, but we didn't in order to have a fair comparison. The same RBRE 3-bolt steel billet timing set was used for both cams. Mike also observed the gross lift to check the cam lift and rocker geometry, which were right on.

Rolling With It

At the beginning of this buildup, your hardheaded author wanted a particular solid street-roller cam for this motor. Ray suggested we try one of his solid flat-tappet cams that would make the power we wanted for less money than a roller cam. The RBRE .638-lift cam proved its worth, making more power than we anticipated. "Hey Ray, can we still try that roller?" we asked. Ray responded, "Why not?" Remember, upgrading to a roller cam will add $700 to $900 to the price of the motor.

Our cam choice was the Comp Cams Magnum solid street roller with .575-inch lift and .262-degree duration at .050, and a 110-lobe separation. The Comp street-roller cams have gradual and gentle ramps that are easy on the valvetrain. The next day, we easily performed the cam swap. The same RBRE three-bolt billet timing set and Comp Cams 929 double valvesprings were used. The taller Comp roller lifters necessitated the use of pushrods that were .200 inch shorter. Roller cams also require the use of a cam button to prevent cam walk. Also, a bronze gear was needed on the intermediate shaft. After Mike Barton degreed the cam and I lashed the valves, we readied the stroker for its next dyno session.

For a fair comparison, the same configuration of 1 7⁄8-inch headers, carb spacer, and carb, was used. The powerplant was warmed up for 25 minutes, and then the valve lash was reset. After a few preliminary pulls, the wedge was making its most power again at 39-degrees timing. On the best baseline blast, we observed 608 hp at 5,500 rpm (down 23 hp) and 660 lb-ft of torque at 4,100 rpm (up 21 lb-ft). The 3,500-6,000-rpm average horsepower was down by only 1 hp, but torque was up by 3 lb-ft. This is an acceptable trade-off in power for our heavy street driver. We'll call this "flat tappet versus roller cam fight an even brawl."

Once the flat-tappet cam was broken in, the inner springs were put back in their places-inside the outer spring. Valve lash was reset on both cams after initial cam break-in and warm-up (25 minutes). Going to the roller, we lost 23 peak horsepower, but gained 21 lb-ft of torque. Peak horsepower came in at 400 rpm less, and peak torque came in at 600 rpm less-good for street drivability in our 4,000-plus-pound B-Body.

Once the flat-tappet cam was broken in, the inner springs were put back in their places-inside the outer spring. Valve lash was reset on both cams after initial cam break-in and warm-up (25 minutes). Going to the roller, we lost 23 peak horsepower, but gained 21 lb-ft of torque. Peak horsepower came in at 400 rpm less, and peak torque came in at 600 rpm less-good for street drivability in our 4,000-plus-pound B-Body.

A little disappointed because the roller had less peak horsepower, we decided to see if a few tuning changes could get it back. First, we took a shot at leaning out the jetting. The 1000 Demon's stock 85/93 jets were replaced with a set of 83/91s. The jet swap picked up the peak ponies by 5 hp. Peak power was now up to 613 hp at 5,500 rpm. Average power was up a tad at 2 hp and 2 lb-ft of torque. Could we get peak power back to 631 hp with only an hour left in the day?

More Tuned Tubes

Most header manufacturers say the 1 7⁄8-inch header is sufficient for up to 575 hp. Hovering over 600 hp, we ordered a set of 2-inch tti's with 3 1⁄2-inch collectors. Would the 2-inch be too big like the 2 1⁄4-inch dyno tubes used at the beginning of dyno testing? We put the hammer down and soon realized 8 more peak horsepower. This moved peak horsepower up 200 rpm higher, topping out at 621 hp at 5,700 rpm. A plug check revealed the fuel mixture was right on. More tuning would be on the agenda after we dropped our Barton Bruiser in the R/T.

Driving Impression

Engine replacement was simple enough. We just pulled out the old 440, dropped in the new 493, bolted it in, and went! We did change the oil, and after 300 miles, we'll switch over to Mobil 1 15w50 synthetic. RBRE built us a powerhouse that has the same 1,200-rpm idle quality as the old 440. Yet, this monster has better street drivability, pulling faster through the gears, and it has more top-end power. How does smoking 'em at a 50-mph roll sound? We were anxious to drive to E-Town to strip-test our new Barton Brute, but it was January and what were we to do?

We needed a vacuum source to operate the power brakes and PCV valve. Neither the Race Demon nor the M1 intake had a provision for vacuum. RBRE drilled and tapped a vacuum port in the M1. The 493 has 11 inches of vacuum at its 1,200-rpm idle, just enough for our power brakes. We used the original valve covers as a reminder of our factory stock-appearing days-instead of using a racy-looking crankcase evacuation system, which could have given even more power.

We needed a vacuum source to operate the power brakes and PCV valve. Neither the Race Demon nor the M1 intake had a provision for vacuum. RBRE drilled and tapped a vacuum port in the M1. The 493 has 11 inches of vacuum at its 1,200-rpm idle, just enough for our power brakes. We used the original valve covers as a reminder of our factory stock-appearing days-instead of using a racy-looking crankcase evacuation system, which could have given even more power.

Wheeling The Rollers

A conversation at Pocono Raceway with Ed Hamberger's-Hamberger is the legendary Mopar small-block racer of the '70s, founder of Hamberger's oil pans and Street Legal Performance (SLP)-son Dave, led to the mention of a new chassis dyno at the SLP facility in Toms River, New Jersey. This new chassis dyno is the latest, most accurate dual Eddy-current-type that can withstand torque levels of up to 1,000 hp. SLP is welcoming owners of different makes of musclecars to make an appointment for dyno testing. All vehicles will see some horsepower losses through the drivetrain between the flywheel and tires. Automatic cars will typically see a 70-120hp loss and stick cars about 50-75hp.

We made an appointment with Brian Reese (chief engineer at SLP) for our dyno session. On the half-hour ride to SLP, the R/T easily wasted an M3 Beemer. Upon arrival of the R/T, a freshly modified Z06 Corvette pulled out to let the '60s Mopar muscle machine onto the rollers.

Our RBRE motor would remain in the same state of tune as it was on Barton's dyno. We expected horsepower losses from the belt-driven accessories, air cleaner, and exhaust system. We also considered drivetrain losses through the heavy 727, although it is rollerized. The R/T also sports a lightweight 4-inch aluminum driveshaft. Chassis dynos measure power in direct 1:1 drive ratio. Would 500 hp make it to the rear tires of the R/T?

With E-Town closed for the winter, we drove to nearby SLP Performance Parts for additional dyno testing. Before testing, a bung for an O2 sensor was installed. The O2 sensor monitored the air/fuel mixture ratio while idling, cruising, and WOT on the dyno. Also observed on each dyno pass were the mph, engine rpm, air inlet temperature, manifold vacuum, and water temperature. SLP's new chassis dyno is accurate (it estimated flywheel horsepower within 2 hp of Barton's new engine dyno) and can withstand extremely high torque levels of up to 1,000 hp. Some of the older-style dynos can't hold a high-powered car without tire slippage. We were able to coax 7 more horsepower and 12 lb-ft of torque through simple squirter swapping. We are anxious to see how 621-flywheel horsepower and 524 rear-wheel horsepower will relate to e.t.'s in our 4,000-pound B-Body. Maybe high 10s or low 11s. What's your guess?

With E-Town closed for the winter, we drove to nearby SLP Performance Parts for additional dyno testing. Before testing, a bung for an O2 sensor was installed. The O2 sensor monitored the air/fuel mixture ratio while idling, cruising, and WOT on the dyno. Also observed on each dyno pass were the mph, engine rpm, air inlet temperature, manifold vacuum, and water temperature. SLP's new chassis dyno is accurate (it estimated flywheel horsepower within 2 hp of Barton's new engine dyno) and can withstand extremely high torque levels of up to 1,000 hp. Some of the older-style dynos can't hold a high-powered car without tire slippage. We were able to coax 7 more horsepower and 12 lb-ft of torque through simple squirter swapping. We are anxious to see how 621-flywheel horsepower and 524 rear-wheel horsepower will relate to e.t.'s in our 4,000-pound B-Body. Maybe high 10s or low 11s. What's your guess?

With the R/T safely strapped down, the moment of truth came when Brian put the pedal down. The numbers read 515 hp at 5,431 rpm. Brian announced the R/T was the new dyno king on their two-month-old dyno! With that, more SLP employees came to see the car's power. Another spin of the rollers showed us 517 hp at 5,420 rpm.

Before the dyno testing began, SLP installed an O2 sensor to monitor the idle, cruise rpm, and WOT air/fuel mixture. The Superflow computer showed us we had an ideal 12.6 to 12.7 A/F mixture at WOT and 14.7 at idle and steady cruising speeds. With the proper A/F mixture, our jetting was on target, and the jets could stay in the box. At the strip, bigger-than-stock squirters always meant lower e.t.'s. We reached into our squirter box and grabbed a 37 and a 35 to replace the stock 31s. The larger squirters proved themselves worthy on the chassis dyno, picking it up to 520 hp at 5,462 rpm.

With the old 440 and the 950 Holley, a pair of 40 squirters worked for us at the track. We thought, shouldn't a pair of 42s be beneficial with more cubes (493) and the larger 1,000 Demon? Once again, it was proven bigger squirters equate to more power. Now the rear wheels were running to 524 hp at 5,476 rpm. The torque was up 12 lb-ft from the baseline made with the 31 squirters. With that, we called it a day.

Dyno tuning performed on Barton's engine dyno and SLP's chassis dyno enabled us to gain 38 hp and 84 lb-ft of torque at peak. The average 3,500-6,000-rpm improvement on Barton's dyno was 44 hp and 50 lb-ft of torque. On SLP's dyno, we picked up 14 hp and 19 lb-ft of torque using a 5,000-6,000-rpm average. We can't wait to get our dyno-tuned Barton engine to the track. We'll keep you posted-we're hoping for high 10s.

Conclusion

Working with Ray Barton and the gang, we could have built a motor with over 1,000 hp. But, that's not what we were looking for. We can't express how happy we are to have a real pump-gas (94 octane) street motor. The old 440 needed a half-race and half-pump-gas mixture to survive. Ray and his crew have put many R&D hours into these B&B "Krate" motors. So far, we've enjoyed over 300 miles with our Barton Bruiser. This motor delivers much more drivability and knockout power than the old 440, which was a strong runner.

Legend

Baseline: Balanced and blueprinted RBRE 493 engine with ported Edelbrock heads, .638-inch lift cam, M1 intake, 950 Holley, and 2 1⁄4-inch race-type headers.

Carb: Replace 950 Holley with 1,000 Race Demon carburetor.

Spacer: Add 1-inch, 4-hole, tapered Wilson Manifolds spacer. Change to 1 7⁄8 tti headers with primary tubes 10 inches longer.

Roller: Swap RBRE .638-inch-lift solid flat-tappet cam for Comp Cams .575-inch- lift solid street-roller cam.

Jets: Change from stock 85/93 jets to 83/91s.

Two tubes: Switch from 1 7⁄8-inch to 2-inch tti headers. Both have the same length primary tubes.

Chassis Dyno ResultsSuperflow SF840SAE-Corrected Rear-Wheel Horsepower And TorqueTested At SLP Performance Parts Engineering CenterBase 31 Squirters37/35 Squirters42/42 SquirtersMax hp @ rpm517 @ 5,420520 @ 5,462524 @ 5,476 Max torque @ rpm500 @ 5,368503 @ 5,362512 @ 5,316 Avg hp @ 5,000-6,000479487493 Avg torque @ 5,000-6,000452460471