If we were all die-hard gearheads, we'd all run solid cams. A solid coupling between each cam lobe and pushrod makes the valves move directly in response to the lobe profile. That means the lobes can be ramped more aggressively for better efficiency and more total power. Hydraulic lifters require compromised, slower lobe profiles to prevent them from pumping up under severe high-rpm flogging (see Hydraulic Lifter Test, Sept. '02, for more on the subject).

Even so, the relatively heavy hydraulic valvetrain probably won't do a good job controlling the cam's signals above 6,500 rpm. For the price of a lash adjustment every few thousand miles, a solid-lifter camshaft is just plain better in our book, whether it's the flat-tappet version or the way-more brutal and costly solid-roller variety. So it's quite the bummer that maintenance and emissions issues keep the OEMs from stuffing solid cams into today's high-performance mills. But we digress.

If you've upgraded to a solid cam, chances are you prudently set the lash to the manufacturer's spec listed on the cam card. The Crane solid-roller bumpstick in our Chevy 406 (see "Mean Mouse: Chevy 406" for the engine build) called for 0.020 inch of clearance (on a hot engine) on both the intake and exhaust valves. The hot spec is the most critical measurement because the engine components can fluctuate in size as engine temperature increases, so it's appropriate to fix the specification at operating temperature. But while we gearheads agree on that, everyone's got an opinion on the right amount of lash to run.

Changing the valve-lash clearance effectively alters the cam's profile. For example, a cam with a listed 0.500-inch valve lift lashed at 0.020 inch hot, actually only opens the valve a total of 0.480 inch (the first 20 thousandths of movement are used to take up the slack). Tighten the lash to 0.010 inch and voila, the valve opens 0.490 inch. Conversely, loosening the lash to 0.030 inch cuts actual valve motion to 0.470 inch. Duration also increases slightly as the lash is tightened; less clearance means the valve opens earlier and closes later as the lifter gets a longer ride on the lobe.

But should we care? Fact is, experimenting with valve lash can affect horsepower, and where and how the power gains are seen give you a clue as to whether your engine is over-cammed, under-cammed, or spot-on. Our 406 is a recent solid-roller convert making just a tick under 600 hp, and we were curious to see how the dyno curves would shift with lash changes.

Proof in the Numbers

For our initial test, dyno op Steve Brul of Westech Performance Group lashed the valves to the recommended 0.020-inch spec using the exhaust opening/intake closing (EO/IC) method (see sidebar). We ran the motor for a few minutes until it warmed up, and then we made a few pulls to baseline the motor with Crane's lash spec. We were greeted with nearly 593 peak horsepower at 6,400 rpm, and a relatively smooth torque curve that climbed all the way to 550 lb-ft at 4,900 rpm. The engine easily revved to 7,000 rpm without a hint of a struggle.

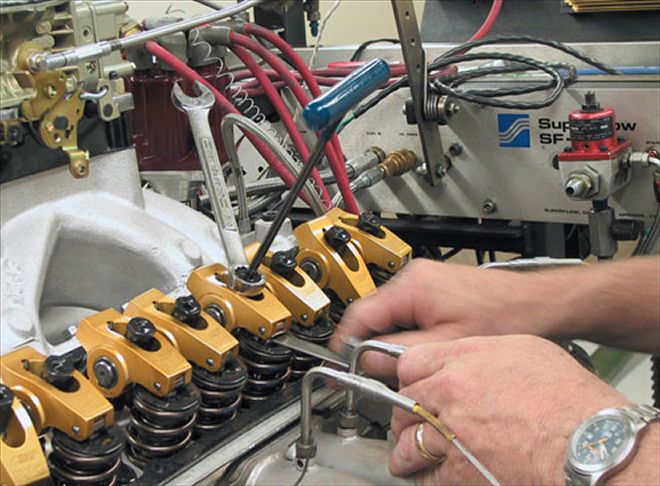

Once the motor cooled down enough for safe disassembly (about five minutes), we pulled off the rocker covers and Brul relashed the valves to achieve 0.030 inch of clearance. A few pulls told us we'd lost about 9 peak horsepower but gained a bit of low-end torque, exactly the result you'd expect if we'd installed a slightly smaller-duration and lower-lift camshaft. Now we had to validate the opposite claim - that tighter lash effectively increases the size of the camshaft - so Brul lashed the valves to a tight 0.010 inch of clearance.

The dyno results from this lash setting looked similar to what you'd expect from installing a slightly bigger cam. Horsepower and torque were both down significantly at the lower end of the rpm range, but peak horsepower remained about the same. We concluded that our cam was nearly ideal for this engine; it didn't make any more power with the "bigger" cam profile imposed by the tighter valve lash, and it lost power from the "smaller" cam profile effected by the looser valve lash.

Lashing the Right Way

Setting valve lash accurately requires that each lifter be on the base circle of the camshaft to ensure it's fully closed when you adjust the rocker arm. You've probably heard of "shortcut" methods for ensuring that the lobe you want to adjust is centered on the base circle, but the most foolproof method, hands down, is to remember "EO/IC" which stands for exhaust opening/intake closing. Pull off the valve covers and pick a cylinder to start with. Crank over the engine (preferably with a remote starter button and the spark plugs removed), keeping your eye on the exhaust valve. When the exhaust valve just starts to open, stop cranking and adjust the lash on that cylinder's intake valve. Then, crank over the engine again, keeping your eye on the intake valve of the same cylinder. After it's fully open, and the rocker tip is at the bottom of its travel, crank it over slowly until the valve is about 2/3 closed. Stop and adjust the exhaust valve on that cylinder. Repeat on each of the remaining cylinders - the order is up to you.

So how do you get accurate, repeatable lash adjustments on every rocker? Some guys adjust the rockers until the feeler gauge has slight drag when slid between the tip of the rocker and the valve stem; others prefer the gauge to fit tighter. We've found that proper valve setting should pass the "go/no-go" test - that is, for a correct 0.020 inch of lash, a 0.020-inch feeler gauge will slide through, but a 0.021-inch gauge will not.