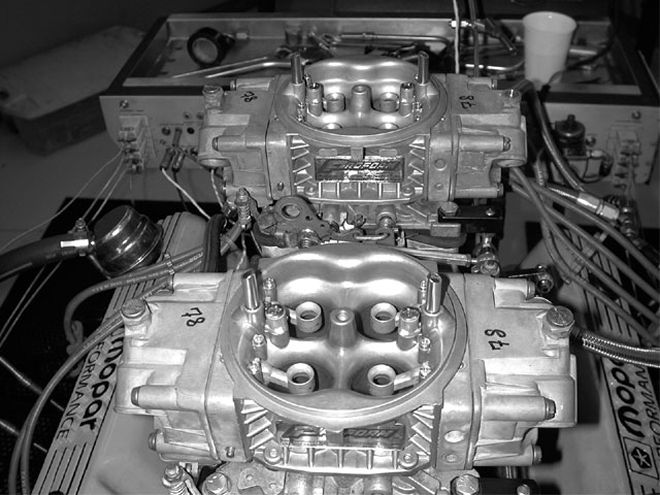

Topping off the Mopar Performance "T-ram" are a set of ProForm carb bodies mated to the remains of some scrapped 650 double pumper cores.

Topping off the Mopar Performance "T-ram" are a set of ProForm carb bodies mated to the remains of some scrapped 650 double pumper cores.

Bench racing and jaw-boning had set us up with a lofty goal for our buddy Marko "The Rooster" and his 340 small-block. What started out as idle talk about building a 500-horse 340 while road tripping from L.A. to the 'Nats last year ended up as a plan to shoot for a big 600 number from Chrysler's performance small-block. While that would be enough to make his street/strip 'Cuda scoot, coaxing that much power from that many cubes is usually the realm of exotic, high-dollar parts. Conversely, we had a less-than-exotic stock 340 core, a set of good W-2s, a die grinder, and a plan. Making big power from small cubes takes airflow, rpm, cam, and squeeze; everything else is just there to help keep it together. With a tight budget for the power goals in mind, we had to limit the major expenditures to where it did the most good, and use what we could of the original 340.

We outlined the build of the basic long block in last month's issue ("Giant Slayer," May '02). A quick recap here-the basic combo started with a stock block, bored +.040-inch, and stiffened up with a partial fill of Moroso Block Filler. Nestled inside the factory main caps is the reground stock forged crank, clamped with Milodon studs. Eagle's budget I-beam rods got the nod for dollar value, while we shelled out for top-of-the-line Arias forged domed racing pistons and C&A Duramoly rings, because we didn't want to skimp in those areas. Up top went our own ported W-2s ("Porting The Magnificent W-2," Nov. '01), with Mopar's 2.02-inch/1.60-inch valves. A heavily discounted new MP tunnel-ram intake was carved to match the heads, and the basic combo was set.

While a fat roller cam would have been the ticket to high rpm power, a thin pocketbook meant "The Rooster" would have to scratch around for a flat-tappet to do the job. A custom-ground Competition Cams solid lifter cam-using one of Comp's extremely quick MM-series high-lift Mopar lobes on the intake and their XX series on the exhaust-seemed like it would do the trick. The MM-series solids aren't cataloged-it's a call-and-ask deal. We had ours ground with the 263 at .050-inch MM series on the intake, their 268 at .050-inch XX-series lobes on the exhaust, on a 108-degree lobe spread. A set of custom Smith Brothers pushrods working Crane's Gold 1.6:1 ratio rockers were ordered to open the valves. The bottom-end was buttoned up with a Milodon pump and sump, and that's where we left off.

Finishing It Off

With the basic package put together, it was simply a matter of dressing it out and running it to see how the power numbers stacked up against the mark. Carbs were a primary concern, since "The Rooster" was budget-bustin'. We found that ProForm carb bodies were available from Jeg's at a discounted price. A pair of these would offer bargain fuel mixing, since we knew of a well-used set of Holley 650 double-pumper cores we could score for parts. The ProForm bodies have a radiused-entry high-flow design, downleg boosters, and are rated at 750 cfm each. More importantly, they come with replaceable screw-in air bleeds, since air bleed tuning is a given when dialing in carbs for a high-rpm dual-quad tunnel-ram application. We went to Enderle for the linkage kit. Enderle builds a trick billet and spherical rod-end linkage setup specifically for the W-2. Though their broad range of kits are resold under many labels, they are surprisingly economical when dealing direct.

W-2 headers and dual-purpose duty could never be mentioned in the same breath until now. Now tti makes 1 7/8-inch W-2 underchassis headers with the features we've come to expect from tti-like fit.

W-2 headers and dual-purpose duty could never be mentioned in the same breath until now. Now tti makes 1 7/8-inch W-2 underchassis headers with the features we've come to expect from tti-like fit.

Header choices are limited when going with W-2s. Until recently, brutal-fitting drag-race headers or fenderwell headers were about all that were available. We had a four-speed A-Body, which is tight even with convention heads and small tubes. Recently, our buddies at tti stepped up with the tooling to create tight fitting 1 7/8-inch headers for the W-2 heads. We already had plenty of experience with these guys, and the previous 340 combo had used a set of tti 1 5/8-inch/1 3/4-inch step headers, so we didn't have to guess about quality. This was a place where we decided it would be money well spent, plus save the usual hassles of poor fitting and limited clearance typical of race headers.

Stashed in "The Rooster coop" from the original 340 combo were an MSD distributor and a set of premium Taylor wires. We poached those proven components to handle the ignition, as well as the MP valve covers, and a set of MP underdrive accessory pulleys. A used stock 318 damper was bolted to the front of the crank; it's not SFI approved, but we had one, so the price was right. To vent the crankcase, a Milodon EVAC breather system was employed. Installation was simply a matter of welding the bungs into the headers, pushing the breather into the valve covers, and running hose between the two.

Crunch Time

Since we were assembling the engine at the Westech facility, which is our regular dyno shop, it wasn't far from the workshop to the dyno cell. We had figured about 1.3 lb-ft per cubic inch would be the maximum realistic torque output for a normally aspirated two-valve engine of this type-and it had to be good to hit those levels. With 345 cubic inches at hand, this translates to slightly under 450 lb-ft. To make power in the 600 horse range, it had to carry that torque well up into the 5,500-plus rpm zone and hold on to make peak power above 7,000. For the sake of reliability, the combo was designed to reach that goal with the minimal amount of cam duration and rpm required. Were we dreaming? We'd soon find out.

With the extremely aggressive flat tappet cam and resultant high lift, the break-in procedure required lessening the valvespring load considerably while running-in the cam. We assembled the engine with only the outer set of our dual valvespring assembly for the initial run-in. This allowed the cam and lifters to establish a wear pattern, which effectively increased the surface area of contact between the cam and lifter, helping it live under high loads later. Too much load on a flat tappet on initial fire-up is a quick way to wipe a new cam, and high loads are part of the territory here. The timing was dialed up to 15 degrees initial on the crank, the fuel pumps lit up, followed by the starter, then ignition, and the 340 fired instantly. There's nothing like the crackle of compression and cam through open exhaust. Once we made the initial running checks of timing, we let it go through the automated low rpm break-in load cycle on Westech's SuperFlow dyno.

With their radiused and chokeless entry, we suspect the ProForm bodies flow in excess of their rated 750 cfm. Regardless, even at their rated numbers, we had 1,500 cfm on our diminutive 345-cube small-block.

With their radiused and chokeless entry, we suspect the ProForm bodies flow in excess of their rated 750 cfm. Regardless, even at their rated numbers, we had 1,500 cfm on our diminutive 345-cube small-block.

After an hour of run-in, we lifted the valve covers for the installation of the inner half of the spring set; it was now showtime. We had the carbs baseline-jetted to #78s all around, fired it up again, and set the timing at a conservative 32 degrees total. After warming up, we shut it down and relashed the valves hot. Fired up once again, the 340 was loaded for a static pull at 4,000 rpm so we could get a read on fuel mixture. It looked safe for a go, and the dyno was set for a short pull from 4,500-6,000 rpm. We had 433 lb-ft at 5,500, with 471 hp at 6,000 and climbing quickly. Our initial dyno plot showed peak torque rpm was where it needed to be to make some big numbers up top, but the air/fuel ratio was much too lean. We swapped #78s for some #82 jets and ran another abbreviated pull. This time, peak torque moved up to 440 lb-ft at the same rpm, while peak power was up to 501 hp by the end of the run at 6,000 rpm. The air/fuel and BSFC numbers still looked too lean, so we upped the jetting again, to #84s at all eight corners. A third test over the same range showed the power dipped by five horses to 496 at 6,000 and a loss of 2 lb-ft, but the A/F ratio looked safer, so we decided to stay with the #84 jetting for now.

We moved the dyno control up to 6,500 rpm and let it run with no changes. The engine had legs, as the power curve reached 542 up and rising at 6,500 rpm. The dyno's rpm control was increased again, this time to 7,100 rpm, and we showed 574 horses at 7,000. That's rockin' for a 340, and we still had our baseline timing set at a short 32 degrees. We upped it to 35 and ran another pull, only to lose about 9 hp. Back to 32 degrees we went, and the power came back in line, showing 448 lb-ft at 5,500 rpm and 575 ponies.

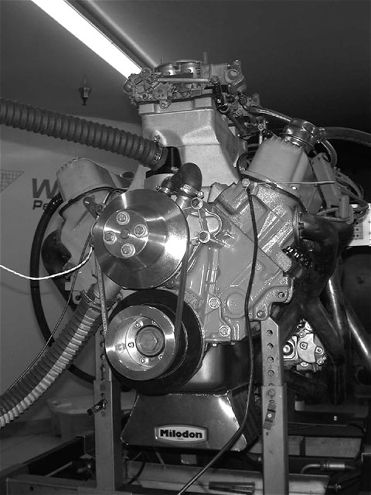

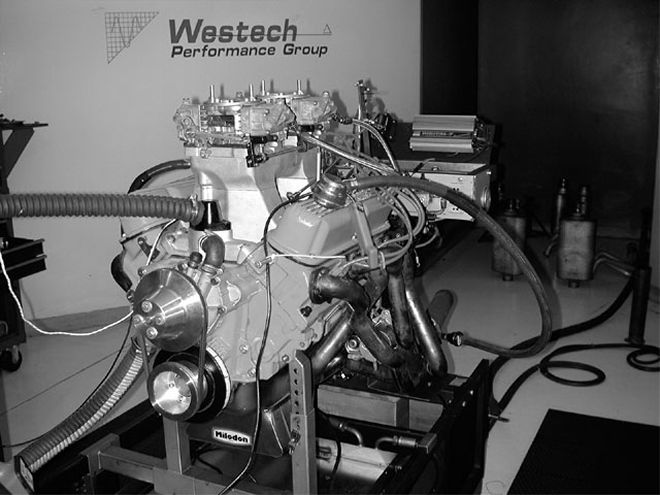

Our formidable looking mill was soon ready to run, but not before a long break-in period without the inner valvesprings; this was essential to ensure the longevity of the radical Comp flat tappet camshaft. Fired up and running, this thing sounded fierce. Notice the crankcase scavenging evac system running from the valvecovers to the headers.

Our formidable looking mill was soon ready to run, but not before a long break-in period without the inner valvesprings; this was essential to ensure the longevity of the radical Comp flat tappet camshaft. Fired up and running, this thing sounded fierce. Notice the crankcase scavenging evac system running from the valvecovers to the headers.

At 575, we could have gone home happy, but the fuel curve clearly needed some work. While the A/F ratio showed borderline lean at around peak torque, it swung dramatically fat at the 7,000 rpm mark; it's very typical for the mixture to start pulling fat at high rpm with dual quad carbs and a tunnel-ram. However, the dramatic surge in fuel flow we were recording was unusual. We saw the A/F ratios spike downward to single digits at the top of the rpm range. To try and cut down on how hard the boosters pulled fuel at high rpm, we opened the high-speed air bleeds .001-inch, and it helped, adding three horses at our 7,100 rpm limit, to 578 hp, while dropping the total fuel at 7,100 by 30 lbs/hr (from 310 lbs/hr to 280 lbs/hr). According to our data, it was still going fat up top, but with the BSFC number now .541, we were in the ballpark.

We opened the carbs again to take some jet out of them, going down a step to #83s. Our top numbers were coming in right at the top of the test range, so it was time to spin the control dial up to 7,500 rpm and see if there was anything left. We let it rip, only to be frustrated with the numbers. With the lower jetting, we were on the lean side going up to 7,000 rpm, seeing BSFC numbers in the high .4s at 7,000, then wham! The fuel surged, and our BSFC jumped into the .6s, pulling a recorded 60 lbs/hr (24 percent) more fuel only 100 rpm later at 7,100 and up-just as we were getting into the rpm range where we expected the engine to make peak power. We had almost the same peak power as before, showing 579 hp at 7,100 rpm; all that fuel hitting above 7,000 rpm washed away any chance of the engine making use of the extra rpm.

The clock was ticking on our dyno time, leaving us with only one more chance to tune the mixture curve up top. We pulled the high-speed air bleeds once again, opening them another thou, and pulled the jets down a notch to #82s. One thou in bleed orifice and one size in jet isn't a drastic change, but we weren't going to gamble with wild moves. That martini run netted us a great 592 hp at 7,100 rpm, and 460.1 lb-ft at 6,000 rpm. While the calibration changes were a step in the right direction, the dyno numbers clearly showed our fuel surge problem wasn't really solved. Dialing-up a high rpm tunnel-ram application eats testing time, and it was, unfortunately, time to pack it up.

Were we happy? That 1.33 lb-ft/ci coming in at 6,000 rpm is rarely seen, probably numbers only an engine builder can appreciate. While within a fistful of 600 horses and clearing over 1.7 ponies per cube, this 340 small-block was big on power; we had only the heartache of going home without having the calibration nailed. But, then again, that's racing.

RPMFt/LbHPBSFC LBS/HR{{{4000}}}400.3{{{300}}}.9.3924500421.6361.2.385{{{5000}}}459.0437.0.3735200459.3454.7.3815400458.0470.9.3795600454.9485.0.3925800449.9496.8.396{{{6000}}}460.1525.7.4156200454.0535.9.4356400452.0550.9.4386600457.7575.2.4366800446.8578.5.4427000439.2585.4.4577100437.7591.7.5507200431.6591.6.5867400414.4583.9.5527500407.1581.4.536What's BSFC? Fuel,Power, and Efficiency

Brake specific fuel consumption (BSFC) is a measure of pounds of fuel per hp per hour. Simply put, it measures how efficiently the engine is converting the fuel's chemical energy into output at the crank. All dynos measure engine power output, so with the addition of sensitive fuel flow meters, the amount of fuel used in pounds per hour for each horsepower of output can be calculated. Sophisticated modern computerized dynos, such as the Superflow 901 at Westech, collect fuel flow data and then calculate the BSFC at each point over the rpm range of the test.

The lower the BSFC, the more power is being made with a given amount of fuel. Conversely, high BSFC can mean the engine is not making efficient use of the fuel, which can indicate too much fuel, or, on the other side of the equation, poor power production. An engine is typically most efficient in the vicinity of peak torque rpm, and it is here that the volumetric efficiency is also at its peak.

What BSFC numbers are ideal? There's no hard rule here, since the engine combination plays an important role. High compression, for instance, makes the engine much more mechanically efficient at making power, so the BSFC typically will be a lower value for a compression motor than for a low-compression pump-gas burner. Airflow, cylinder head material, and combustion chamber efficiency are other factors that influence BSFC. That said, an experienced dyno operator will have a feel for the numbers expected for conventional engine combos. In a high compression, high powered, high rpm, iron-headed engine like ours, Steve Brule, Westech's dyno operator, likes to see BSFC numbers in the low .4s around peak torque and high 4s to .500 at peak power rpm. We were just about on the money at peak torque, too lean below, too rich above, and way too rich over 7,100 rpm.