Using a Hughes cam with lobes designed for the large .904 Mopar lifter diameter, this street 440 cranked out a maximum performance of 544 hp and 557 lbs.-ft. of torque.

Using a Hughes cam with lobes designed for the large .904 Mopar lifter diameter, this street 440 cranked out a maximum performance of 544 hp and 557 lbs.-ft. of torque.

Pick up any camshaft and it's pretty simple to see what it does. It turns, the little bumps come around and move the lifters, which-through the pushrods and rockers-open the valves. The truth is, there is no part of an engine's design as complex as that simple-looking bump on a camshaft. The trend in current cam design is to accelerate the valve more quickly off the seat and open the valve at a higher velocity than older cam designs. This results in more lift for a given amount of duration, which, in turn, offers better low-end performance and torque production for a given level of top-end power output. The limiting factor in how much velocity can be designed into a flat-tappet cam is the diameter of the lifter.

For example, if your lifter's diameter is comparable to that of a 55-gallon drum, it's not hard to imagine a monster camshaft lobe which could lift it a foot or more off the ground. On the other hand, if the lifter is the diameter of a pencil eraser, a similarly matched cam under it would be able to move it only a fraction of an inch without it binding on the lifter edges. These are extremes, but it doesn't take a huge difference in lifter diameter to make a significant difference in the velocity designed into a cam lobe. Mopar engines had relatively large 0.904-inch-diameter lifters from the factory, while Chevy small-blocks came with puny 0.842-inch lifters. So who cares about the size of a Chevy lifter? We hate to say it, but cam grinders do. Typical aftermarket cam lobes are designed to work with a Chevy-sized minimum tappet diameter of 0.842 inch, since a lobe designed for the smallest lifter will work in any engine with a lifter that size or larger. These lobe designs are transferred to masters on cam grinding machines, and the lobe is duplicated onto cam blanks, be it a Ford, a Chevy, a Mopar or an International. Sure, these "Chevy" lobes work well and make horsepower, but the potential advantage of the larger Mopar lifter is left untapped.

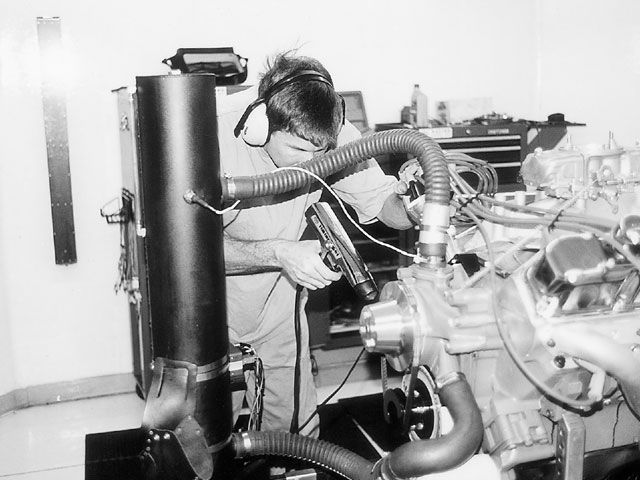

Steve Brule, the dyno operator at Westech, already had the 440 mounted to the Superflow 901 engine dyno by the time we arrived at opening time. Our objective was to run the Hughes "Mopar" grinds, designed with increased velocity to take advantage of Mopar's .904 lifters versus some typical aftermarket "Chevy" grinds we made to match the duration specs on the Hughes offerings. The baseline 223/230 duration at .050 inch, .465/.480-inch "Chevy" cam was already installed.

Steve Brule, the dyno operator at Westech, already had the 440 mounted to the Superflow 901 engine dyno by the time we arrived at opening time. Our objective was to run the Hughes "Mopar" grinds, designed with increased velocity to take advantage of Mopar's .904 lifters versus some typical aftermarket "Chevy" grinds we made to match the duration specs on the Hughes offerings. The baseline 223/230 duration at .050 inch, .465/.480-inch "Chevy" cam was already installed.

Luckily, there are a few cam grinders out there that have developed lobe profiles designed to take advantage of the higher velocity possible with Mopar's larger lifters. These 0.904-inch minimum tappet diameter lobes won't work with the smaller 0.842-inch Chevy lifters, or even Ford's 0.875-inch tappets, without the camshaft lobe catching the edge of the lifter. How much of a difference is there? That depends on how aggressively the lobe is designed, but a typical "Chevy" flat-tappet performance grind with 230-degree duration at .050 inch can deliver 0.480-inch lift at the valve with a 1.5:1 rocker. A lobe with the same 230-degree duration at .050 inch designed to take advantage of the higher velocity possible with a Mopar's 0.904-inch lifter will provide 0.515-inch valve lift. Hey, I'll take an extra .035-inch lift for the same duration any time!

It's true that just going up in duration, say to a 240-degree at .050-inch cam with a "Chevy" lobe, will bring that lift up to the 230-degree Mopar lobe's level. However, having to step up in duration has its price. Going up another size in cam will add to top-end power, but driveability and low-speed response will typically suffer. In theory, the timing of the valve events has more to do with the engine's idle quality and low rpm cylinder pressure than the max-lift figure. Put another way, duration and lobe separation specs will have the greatest effect on the idle quality and low-end power achieved with a selected cam. Therefore, if more lift can be built into a cam with otherwise the same specs, the potential is there to make more power, without giving up much, if anything, in terms of driveability and low-end output.

All of our tests at the stock 1.5:1 rocker ratio were conducted using the stock big-block Mopar stamped-steel rockers and a set of replacement tubular pushrods. With these moderate hydraulic cams, if running the stock ratio, the stock valvetrain is quite difficult to beat.

All of our tests at the stock 1.5:1 rocker ratio were conducted using the stock big-block Mopar stamped-steel rockers and a set of replacement tubular pushrods. With these moderate hydraulic cams, if running the stock ratio, the stock valvetrain is quite difficult to beat.

OK, so much for theory, but what about the real world? To determine if high-velocity Mopar OE lobes are a real advantage, we decided to gather up some cams and run a direct back-to-back dyno test. Hughes Engines markets a line of cams designed for the 0.904-inch lifter profile, so we ordered a couple of street hydraulics: their popular HL 2330 BL and HL 3038 BL cams (see the sidebar Cam Specs). For the sake of comparing otherwise identical typical "Chevy" profiles, we had a local cam company grind a pair of custom cams on the same duration and lobe separation specs as the Hughes cams. The custom grinds allowed us to match the valve event specs of the Hughes cams exactly. Since they are specifically designed to take advantage of the 0.904-inch lifter profile, the Hughes cams have a significant advantage in lift for the same duration. Would they pay off with more horsepower? The dyno would tell the tale.

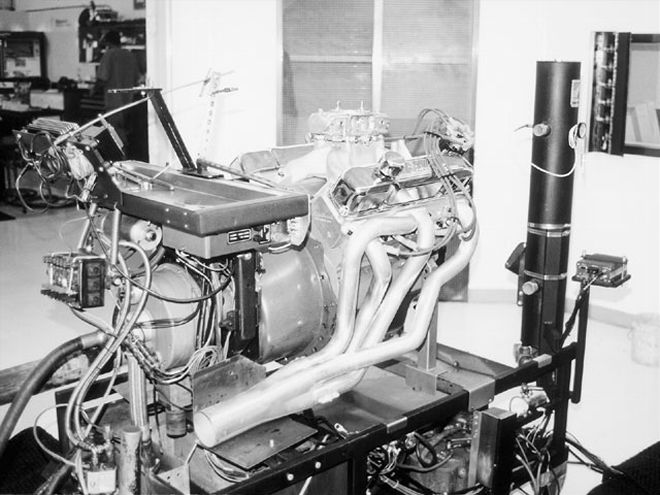

For our test mule, we lucked out, as Car Craft Editor Matt King had a fresh 440 sitting at our dyno shop. A basic .030-inch-over 440 with Speed-Pro "Six Pack" pistons, 10:1 compression, and a new set of out-of-the-box Edelbrock heads, Matt's engine is a typical, hot street 440. With only a few previous dyno pulls under its belt, it was just broken in. We added an M-1 single-plane intake, a Demon 950 annular booster drag race carb, stabbed in the baseline 224/230 "Chevy grind," and finished it off with a stock set of Mopar stamped steel rocker arms and replacement tubular pushrods. The package is pretty basic as far as the cam and valvetrain, fairly representative of a street performance setup with a "Chevy"-style lobe, with lift specs of .465 intake/.480 exhaust.

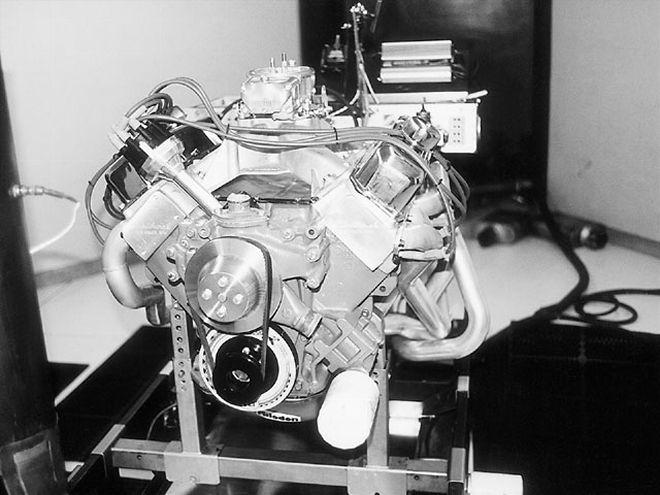

Up front, we were envious of the trick underdrive pulley arrangement, which was definitely nicer than the 1:1 junkyard steel pulleys we normally use. The damper is an ATI Rattler.

Up front, we were envious of the trick underdrive pulley arrangement, which was definitely nicer than the 1:1 junkyard steel pulleys we normally use. The damper is an ATI Rattler.

With the baseline combo in place, the 440 was loaded on the dyno. We would give each cam about 15 minutes break-in time, then go for the power pulls. After our first pull, one thing was clear: This Edelbrock-headed 440 cranked. We had 555 lbs.-ft. at 3,500 rpm, the bottom of our test range, and 510.2 hp at 5,200 rpm. The true torque peak was actually below our starting rpm, so it wasn't recorded; this thing was a tire-smoker. Though power peaked at a relatively low 5,200 rpm, it kept pulling to our 6,000 rpm upper limit with nary a drop-off in output. The idle quality with this cam was puppy-dog smooth, pulling 14.5-inch Hg of vacuum at an 850 rpm idle. Impressive.

Next, we made a quick swap to the identical Hughes 223/230 cam, which upped the lift at the valve to .504 inch on the intake and .515-inch exhaust, for a gain of .039/.035-inch, respectively. All the other cam specs remained the same. The higher lift was strictly a result of this being a Mopar .904 lifter grind rather than a "Chevy" grind. Did it pay off? Testing with the Hughes cam upped torque right from the bottom to 558.7 lbs.-ft. at 3,500 rpm with the torque peak below the bottom rpm of our test. The torque increase was even greater all the way to the top of the scale at 6,000 rpm. Peak horsepower was now 523.1 at 5,800 rpm, and though peak horsepower rpm was a good 600 rpm higher, the Hughes cam was making more horsepower than the baseline cam all the way from the bottom to the top. We were impressed with this 440's output before, but the cam change definitively proved an advantage. Idle quality and vacuum was unchanged from our baseline cam, so the bottom line was more output and more rpm with no apparent downside.

With the baseline 223/230 "Chevy" grind, the Brule-built 440 was impressive, belting a solid 510 hp and an amazing 555 lbs.-ft. of torque, running on plain 92-octane Unocal pump gas. Are you sure about that 10:1 compression, Mr Brule? The idle was silky smooth and the vacuum was 14.5 inches with 17 degrees initial advance. That mild "Chevy" grind worked better than we expected.

With the baseline 223/230 "Chevy" grind, the Brule-built 440 was impressive, belting a solid 510 hp and an amazing 555 lbs.-ft. of torque, running on plain 92-octane Unocal pump gas. Are you sure about that 10:1 compression, Mr Brule? The idle was silky smooth and the vacuum was 14.5 inches with 17 degrees initial advance. That mild "Chevy" grind worked better than we expected.

So far, theory and experimental data were right in line. For the next test, a bigger "Chevy" grind was installed; this time, a healthy 230/238 duration at .050 inch cam (with the resultant lift of .480-inch intake/.491-inch exhaust). Forty-five minutes later, we had the engine running. Stepping up in duration altered the sound of the engine considerably. It definitely had a tougher sound and more lope at idle than the smaller two cams. Idle vacuum was down to 10.5-inch Hg. Though this cam was significantly longer in duration than the baseline cams, it would have needed to be one size longer yet to match the lift of the shorter duration .904-inch lifter profile cam. Would the added duration pay off?

Running for the numbers with this cam, we found torque down slightly at 551 lbs.-ft. at 3,500 rpm, the lowest peak number of the day. Again, peak torque came in below the minimum rpm tested. Horsepower output actually dropped slightly as well, to 521.5 at 5,300 rpm. The change in peak power rpm was the most surprising result, dropping by some 500 rpm. We now had a longer duration, a more choppy, lopier "Chevy" grind, and didn't have as nice of a power curve as with the smaller Mopar grind. In all fairness, the outputs were quite close, but the cost in idle quality and vacuum were significant. Again, the theoretical benefit of the higher lift .904-inch lifter grind with its higher velocity was proven by the dyno numbers.

Next, we tore down this sweet-running 440 to swap in the 223/230 duration Hughes real Chrysler cam. It had the same duration and lobe separation as our baseline cam, but with a higher velocity and ,thus, more lift, upping the score to .504-inch intake, .515-inch exhaust. The higher velocity of the Hughes cam paid off with 558 lbs.-ft., and 523 hp. It was a sizable gain for a cam with exactly the same duration numbers, stronger over the entire rpm range, but the idle quality was every bit as good as with the previous cam.

Next, we tore down this sweet-running 440 to swap in the 223/230 duration Hughes real Chrysler cam. It had the same duration and lobe separation as our baseline cam, but with a higher velocity and ,thus, more lift, upping the score to .504-inch intake, .515-inch exhaust. The higher velocity of the Hughes cam paid off with 558 lbs.-ft., and 523 hp. It was a sizable gain for a cam with exactly the same duration numbers, stronger over the entire rpm range, but the idle quality was every bit as good as with the previous cam.

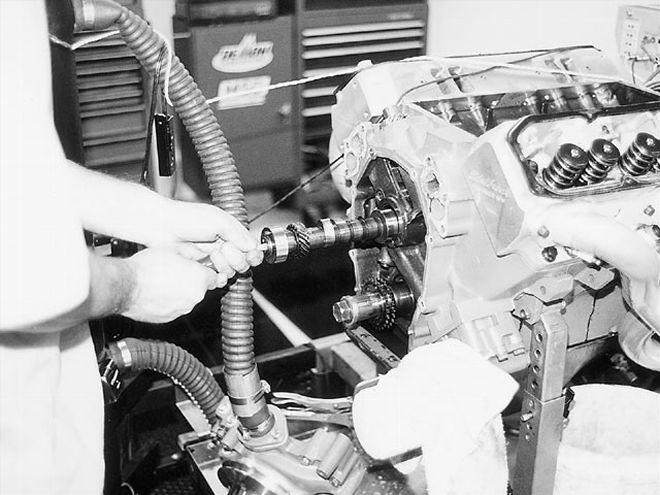

Our last cam was Hughes' 230/238 duration at .050-inch piece, the same duration specs as the generic "Chevy" grind we had just run. Again, the velocity advantage of this .904-inch lifter profile cam really brought up the lift numbers compared to the .842-inch lifter grind. Lift with this cam went to .515/.535 inch, for a lift increase of .035-inch intake, .044-inch exhaust. This time, we swapped the cam and had the engine back up and running in under 30 minutes, an unofficial record at this dyno shop. Fired up, the idle quality was quite similar to the 230/238 "Chevy" grind we had just run, with 10.5 inches of vacuum at idle, and a noticeable lope.

It wasn't long before we had our figures, and oddly, the highest recorded torque of the day was at 561.2 at 3,600 rpm. Power output was up as well, with the 440 now shoving the dyno to the tune of 528.3 hp at 5,500 rpm. It seemed strange that peak-power rpm was slightly lower than with the smaller Hughes cam, though the output was indeed higher with the bigger Hughes throughout the entire rpm range. We suspected that the valvesprings were approaching their limit of control with this high-lift cam.

For the Martini run, we decided to pull out the stock stamped-steel, nonadjustable 1.5:1 rockers and replace them with a set of Comp 1.6:1 aluminum roller rockers. The 1.6:1 rockers are another approach to increase the opening velocity at the valve. After all, the engine isn't concerned with what's going on anywhere else but the valves, so at first blush, it would seem that a rocker change would accomplish the same thing as an even faster velocity cam. There is, however, a subtle difference in the effect of a high ratio rocker versus a high velocity cam. The rocker ratio change will have a noticeable effect on overlap lift, increasing the overlap area, though overlap duration is unchanged. The increase in overlap area will often be evident in a change in idle quality. On the other hand, increasing the velocity at the cam doesn't affect the overlap area as significantly, meaning intensity gained here won't typically alter idle quality a noticeable amount, if at all.

We installed the Comp 1.6:1 rockers, set the preload on the Hughes anti-pump-up lifters to just under zero lash, and again the 440 was ready to run. Though we now suspected a slight high-rpm control problem was detracting from our top-end numbers (valvesprings), running these lifters at zero lash might help. Moreover, with the higher ratio rockers, the intensity and lift would be even greater, placing an even greater demand on the valvetrain. We had the engine fired shortly, and ran it down to idle speed. True to expectations, the 1.6:1 rockers cost about 1/2-inch Hg vacuum compared to the stockers.

Our next dyno pull netted us 544 hp at 5,600 rpm, and 557.3 lbs.-ft. at 4,400 rpm, the highest power output of the day. The engine responded favorably in horsepower production to the increase in lift. Torque, on the other hand, was down a bit and came in at a higher rpm. Again, with the higher ratio rockers, we still suspected some valvetrain instability at higher engine speeds. A stouter valve-spring would have likely resulted in more power upstairs; we estimated there was 550 hp here with a stiffer spring combo. Nevertheless, there was no doubt that more pop at the valve paid off with more twist of the crank without having to resort to the chop of a long duration stick. Overall, the advantage indeed went to Mopar OE engine design, and cams using the .904 lifter dimension fared better in this lobe-to-lobe challenge.

Dyno Results

Superflow 901

Dyno-Tested At Westech

TorqueRPMTest 1Test 2Test 3Test 4Test 53,600549.4554.5544.5561.2556.73,800548.7555.0547.7552.9549.54,000548.1555.4548.7553.9552.24,200546.4552.6549.0552.6554.34,400544.5553.0548.9553.0557.34,600542.2551.1549.3550.1556.54,800538.3545.5544.8545.5554.75,000532.1538.8535.3537.8550.65,200515.3526.6523.8526.7541.05,400494.9505.6506.7511.8522.35,600476.6487.9486.8494.9510.25,800461.2473.7467.2475.9465.26,000NRNRNRNR430.6

HorsepowerRPMTest 1Test 2Test 3Test 4Test 53,600376.6380.1373.2384.6381.63,800397.0401.5396.3400.0397.64,000417.4423.0417.9421.8420.64,200436.9441.9439.1441.9443.24,400456.2463.3459.8463.2466.94,600474.9482.7481.1481.8487.44,800492.0498.5497.9498.6507.05,000506.5512.9509.6512.0524.25,200510.2521.4518.6521.5535.75,400508.8519.8521.0526.3537.05,600508.2520.2519.1527.7544.05,800509.3523.1515.9525.6513.76,000NRNRNRNR491.9Test 1: 2330 Custom grind on typical "Chevy" lobe profile; 223/230 duration at .050-inch 1.5:1 ratio stock stamped-steel rockers; .465-in Int./.480-in Exh. lift.

Test 2: Hughes HE2330BL Mopar lifter profile cam; 223/230 duration at.050-in 1.5:1 ratio stock stamped-steel rockers; .504-in Int./.515-in Exh. lift.

Test 3: 3038 Custom grind on typical "Chevy" lobe profile; 223/230 duration at .050-in 1.5:1 ratio stock stamped-steel rockers; .465-in Int./.480-in Exh. lift.

Test 4: Hughes HE3038BL Mopar lifter profile cam; 230/238 duration at .050-in 1.5:1 ratio stock stamped-steel rockers; .515-in Int./.535-in Exh. lift.

Test 5: Same as above but with Comp Aluminum roller rockers 1.6:1 ratio; .549-in Int./.571-in Exh. lift.

Camshaft Specifications

CAMCUST 2330HE2330BLCUST 3038HE3038BLDuration at .050"Intake223°223°230°230°Exhaust230°230°238°238°Lobe Separation 110°110°110°110°Cam Lift (lobe)Intake.310".336".320".343"Exhaust.320".343".327".357"Valve Lift 1.5:1Intake.465".504".480".515"Exhaust.480".515".491".535"Valve Lift 1.6:1Intake.549"Exhaust.571"